Turning and milling all-in-one machine

An all-in-one machine, turning and milling technology, applied in the directions of metal processing mechanical parts, clamping, support, etc., can solve the problems of slow processing speed, low positioning accuracy, unfavorable high-speed and high-precision processing, etc., to achieve fast processing speed and ensure processing accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

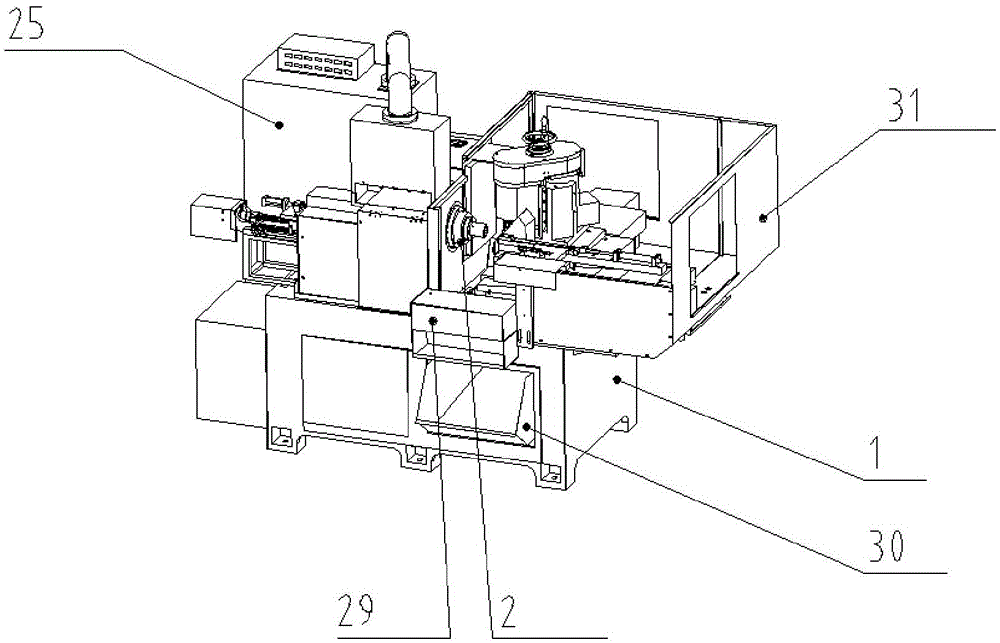

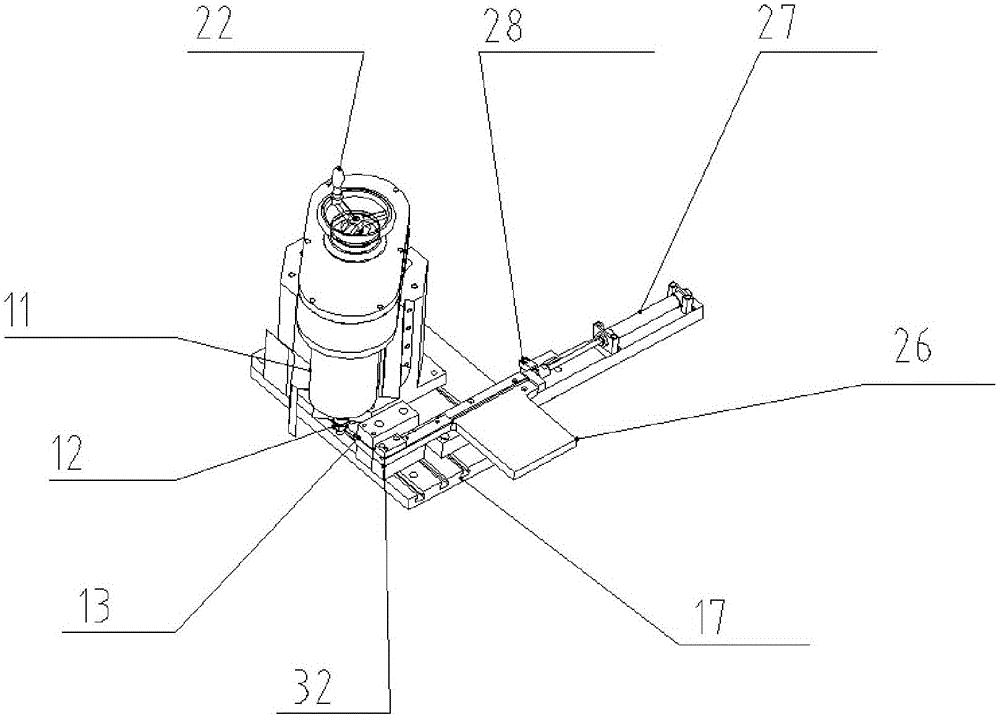

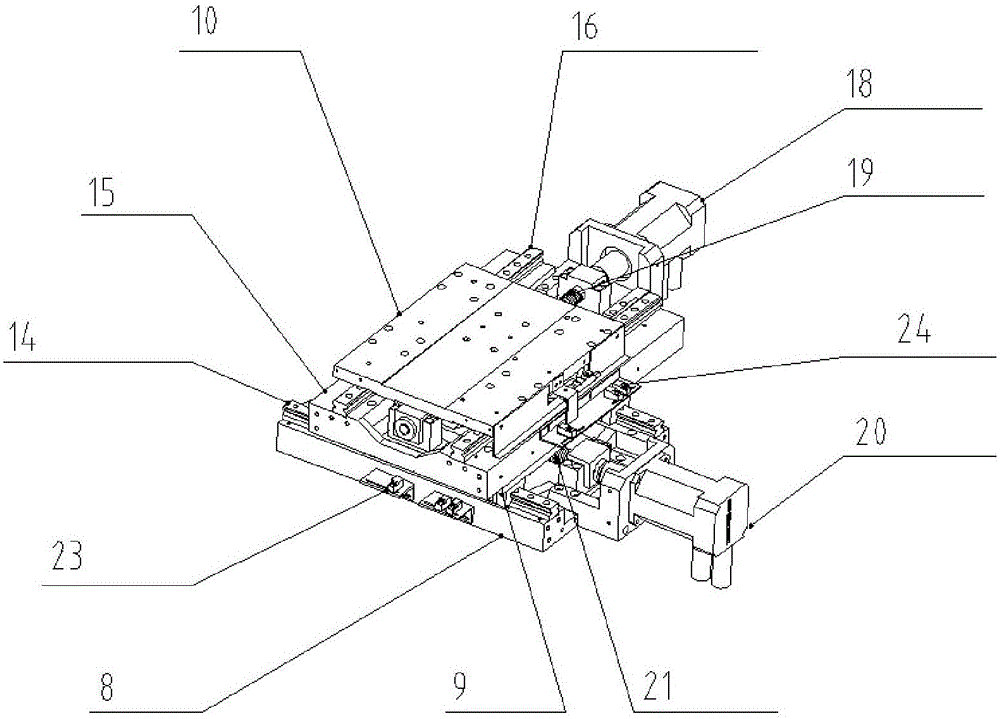

[0027] Example: an integrated turning and milling machine, comprising a bed 1, a main shaft 2, a clamping device, a horizontal feed mechanism, a longitudinal lifting mechanism, a milling device 12, a turning device 13, an automatic feeding mechanism and a rotary drive device 3, set X , Y, and Z are three mutually perpendicular directions, of which the Z direction is the vertical direction:

[0028] The main shaft 2 can be rotatably mounted on the bed 1 around the Y axis, and the rotary drive device 3 drives the main shaft 2 to rotate;

[0029] The clamping device is fixedly installed in one end of the main shaft 2. The clamping device includes a chuck 4, a chuck sleeve 5, a driving oil cylinder 6 and an elastic member 7. The inner side of the chuck 4 forms a clamping hole for the workpiece to pass through. 4. The outer side wall forms a conical structure, and the chuck sleeve 5 is axially slidably sleeved on the outer side of the chuck 4. The side wall of the chuck 4 can be co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com