Frame of large pellicle and grasping method of frame

A frame and film technology, which is applied to the frame of large-scale film components and the control field of the frame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

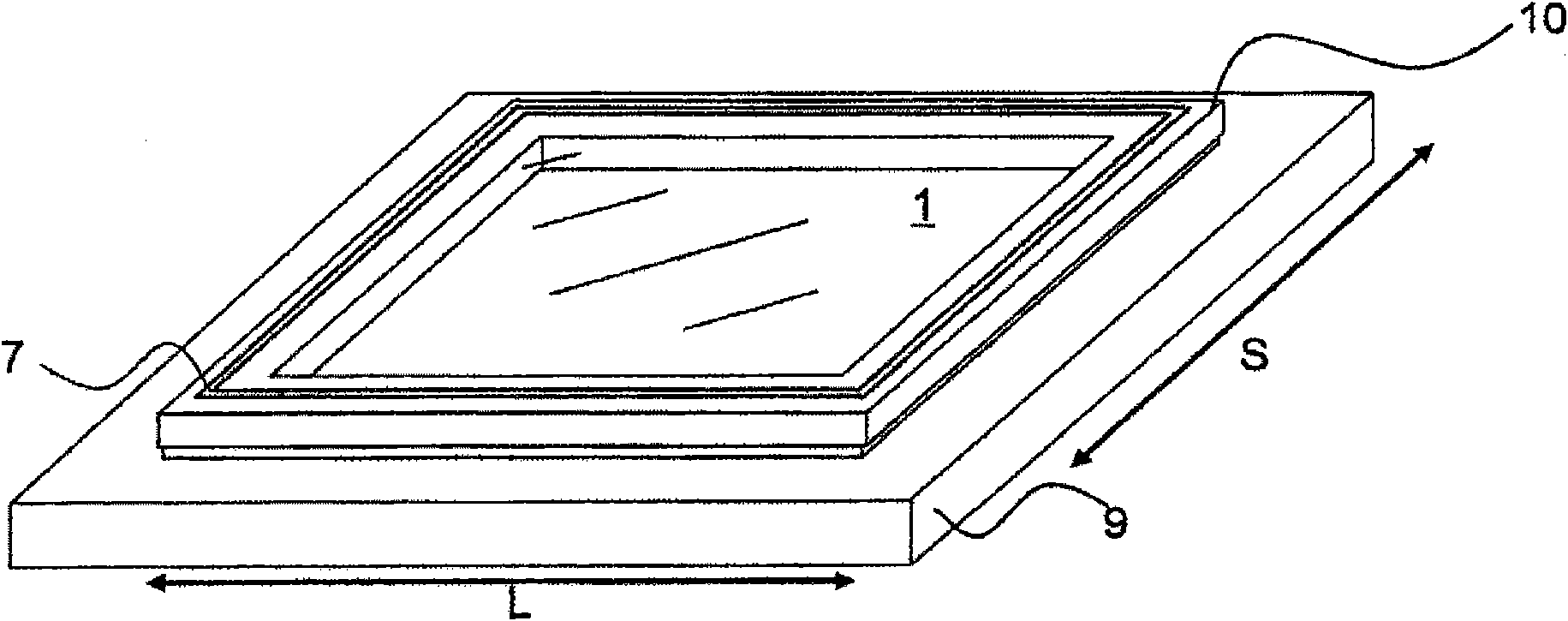

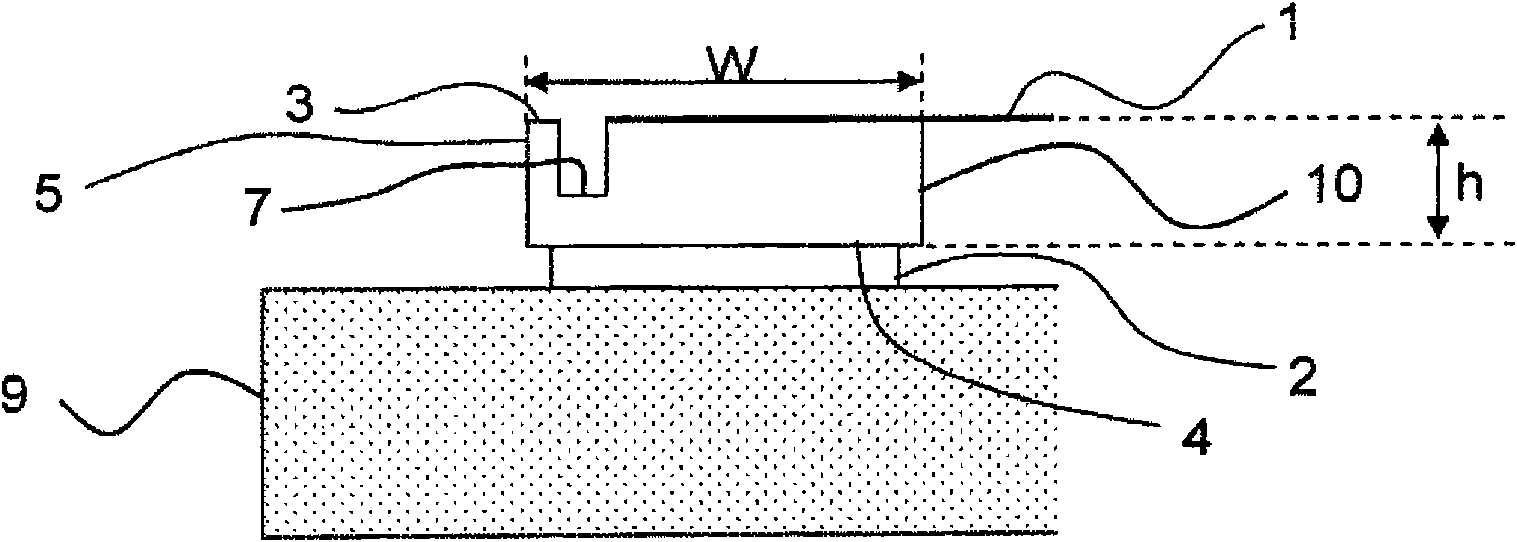

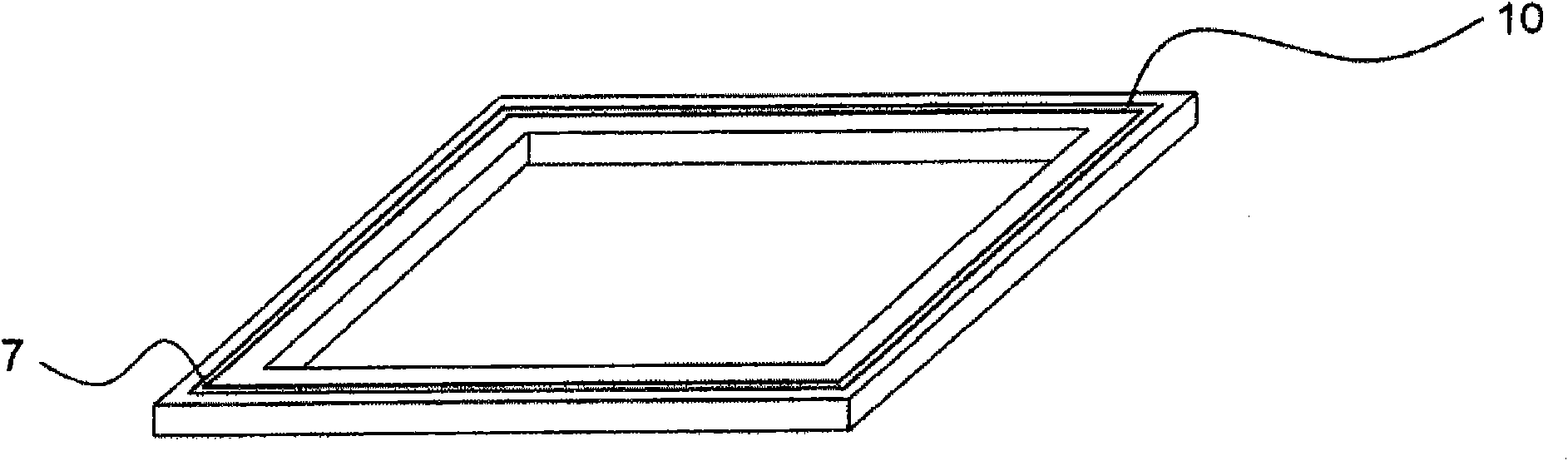

[0251] A quadrangular aluminum alloy frame body having a long side length of 1600 mm, a short side length of 1400 mm, a width of 14 mm, and a height of 6 mm was prepared. At the position where the height of the outer surface of each side is 3mm, centering on 3 points 250mm from the center of each side and the two ends of each side, 3 points are formed on each side of all 4 sides of the frame by cutting. A groove in which the circumferential length of the opening is 200 mm, the height of the opening is 1.5 mm, and the depth of the groove is 3 mm.

[0252] On the lower edge surface of the frame, a polyethylene foam substrate (thickness: 1 mm) coated with an acrylic adhesive was attached as an adhesive material layer. Next, the same frame-shaped protective film as the above-mentioned frame body, that is, a protective film made of polyethylene terephthalate resin coated with a silicon-based mold release agent on the surface, is laminated on the adhesive material layer. The protec...

Embodiment 2

[0255] Except that the length of the long side was 1800 mm, the length of the short side was 1600 mm, and the width was 16 mm, a frame body similar to that of the above-mentioned Example 1 was prepared, and it was fixed to the pallet in the same manner as in Example 1.

Embodiment 3

[0257] Except that the length of the long side was 2000 mm, the length of the short side was 1800 mm, and the width was 18 mm, a frame body similar to that of the above-mentioned Example 1 was prepared, and it was fixed to the pallet in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com