Automobile backrest folding mechanism

A technology for car seats and backrests, which is applied to movable seats and other directions, can solve the problems of no positioning reference, poor consistency, and deformation of connecting plates, and achieve the effects of simplifying the manufacturing and assembly process, avoiding inaccurate positioning, and avoiding welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

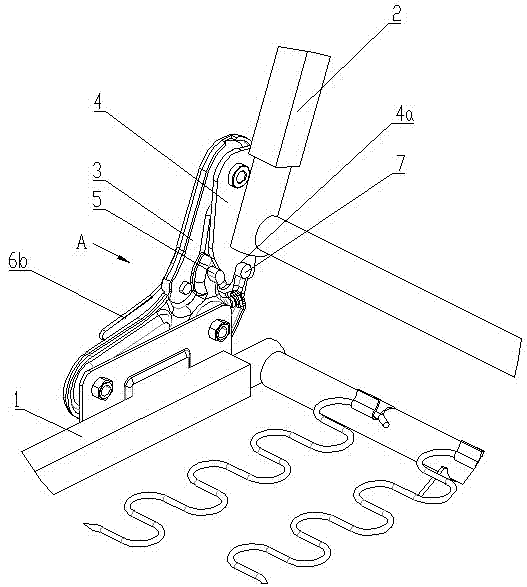

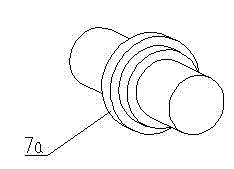

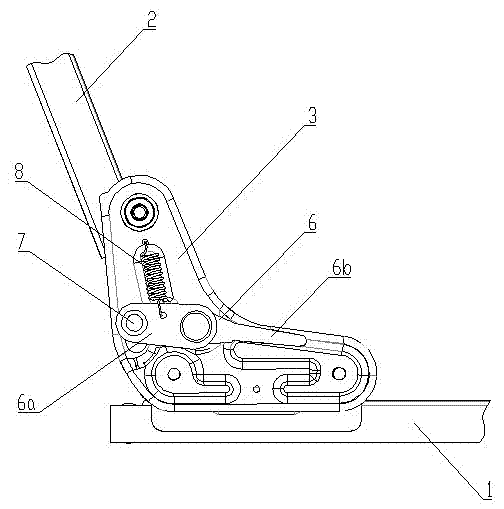

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings, as shown in the figure: the folding mechanism of the automobile seat back of the present embodiment includes a connecting plate 3 fixedly connected with the cushion frame 1 by bolts, welded on the back frame 2 and connected with the seat frame 1. The locking plate 4 that is rotatably matched to the connecting plate 3, the limit pin 5 that is arranged on the connecting plate 3 to limit the angle of the backrest, and the locking assembly that is used to lock or unlock the locking plate 4, the locking The assembly includes a rotating arm 6 that is rotatably matched with the connecting plate 3 to form a lever structure, a locking pin 7 that is vertically arranged at the resistance end 6a of the rotating arm 6, and a mechanism that acts on the resistance end 6a of the rotating arm 6 to make the locking pin 7 in the locking position. Return spring 8, one end of the return spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com