Patents

Literature

91results about How to "Simple manufacturing and assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

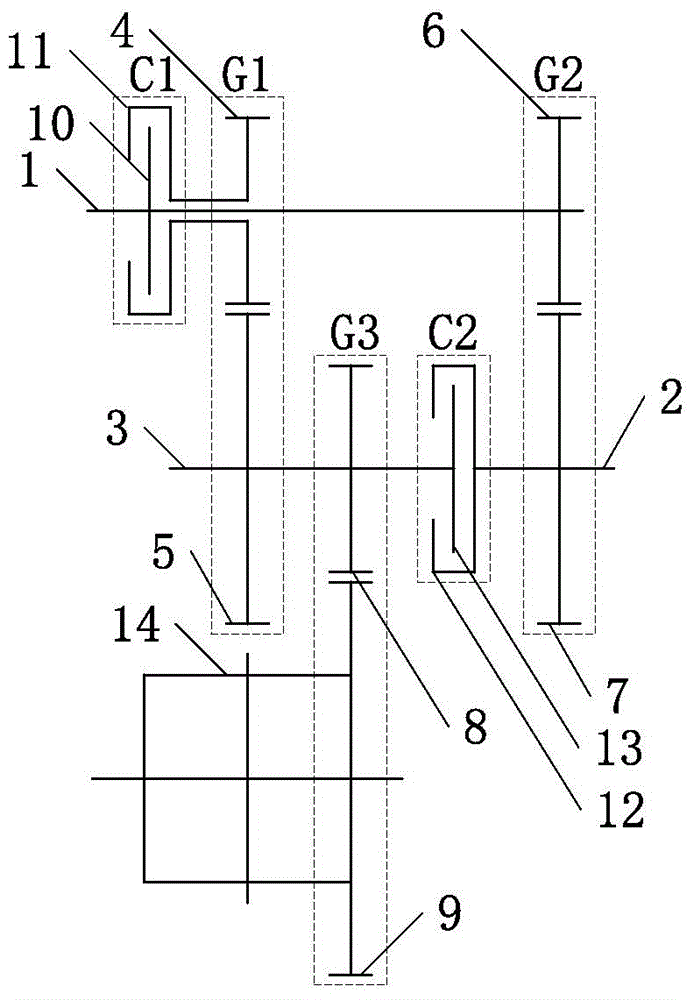

Automatic two-gear transformer for pure electric automobile

InactiveCN104595450ACompact structureLight in massElectric propulsion mountingToothed gearingsElectricityAutomatic transmission

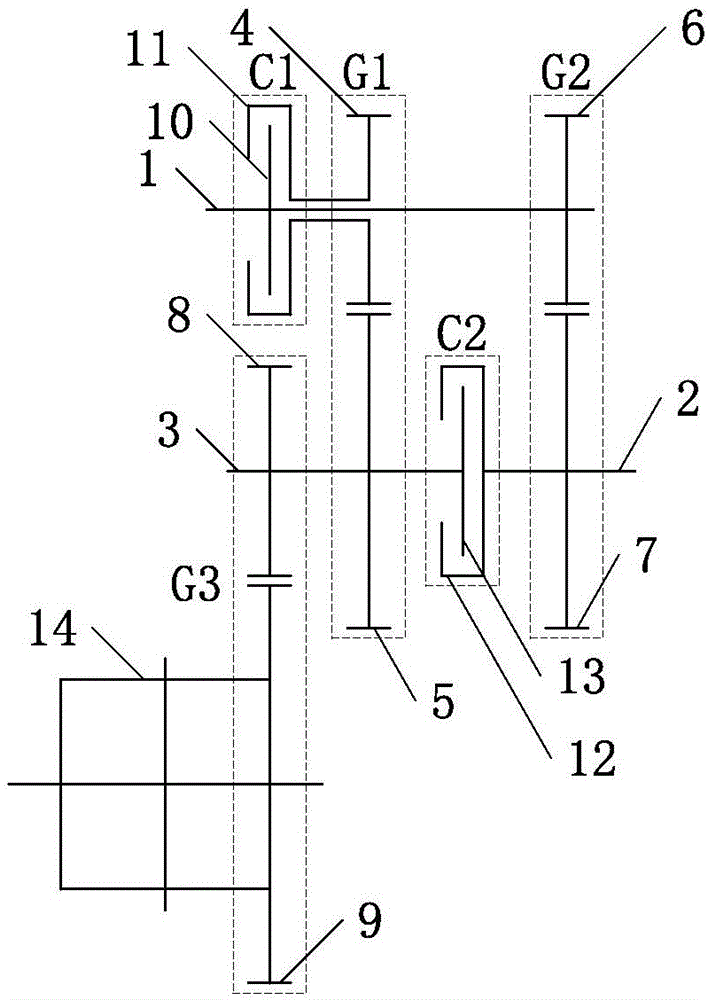

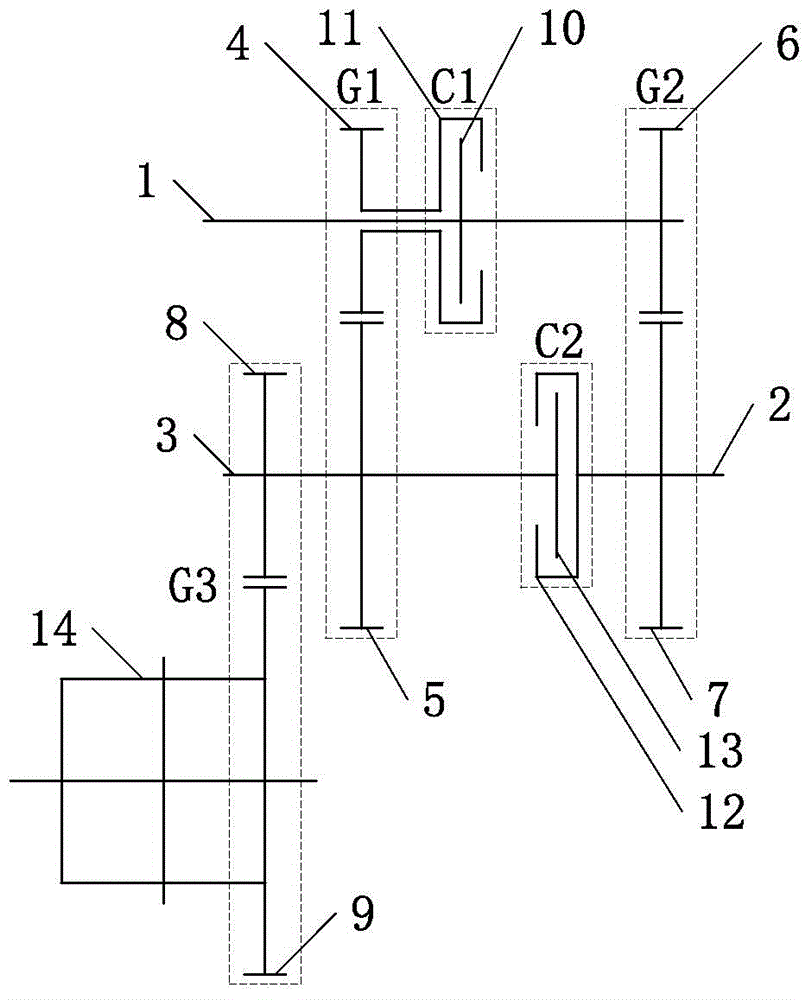

An automatic two-gear transformer for a pure electric automobile comprises an input shaft, a first middle shaft, a second middle shaft, a third middle shaft, a first cylindrical gear pair, a second cylindrical gear pair, a third cylindrical gear pair, a first torque transmission device, a second torque transmission device and a differential assembly; rotation center lines of the input shaft, the third middle shaft and the differential assembly are mutually parallel. According to the automatic two-gear transformer for the pure electric automobile, automatic two-gear speed change is adopted, the transmission ratio range is expanded, the performance requirement on a drive motor can be reduced greatly, an efficient and light drive motor is allowed to be used, and the total size, the total mass and the total cost of an electric drive system of the pure electric automobile are further reduced.

Owner:BEIHANG UNIV

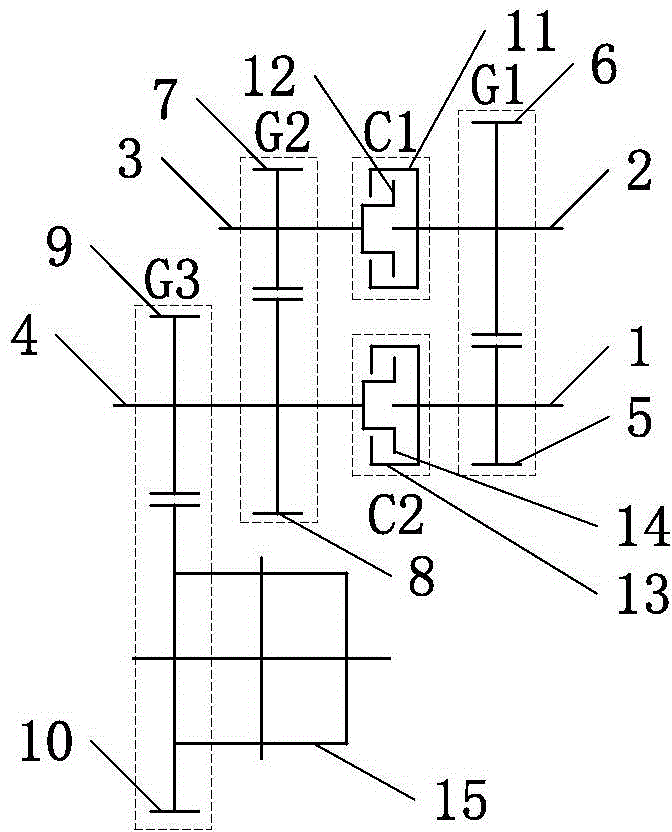

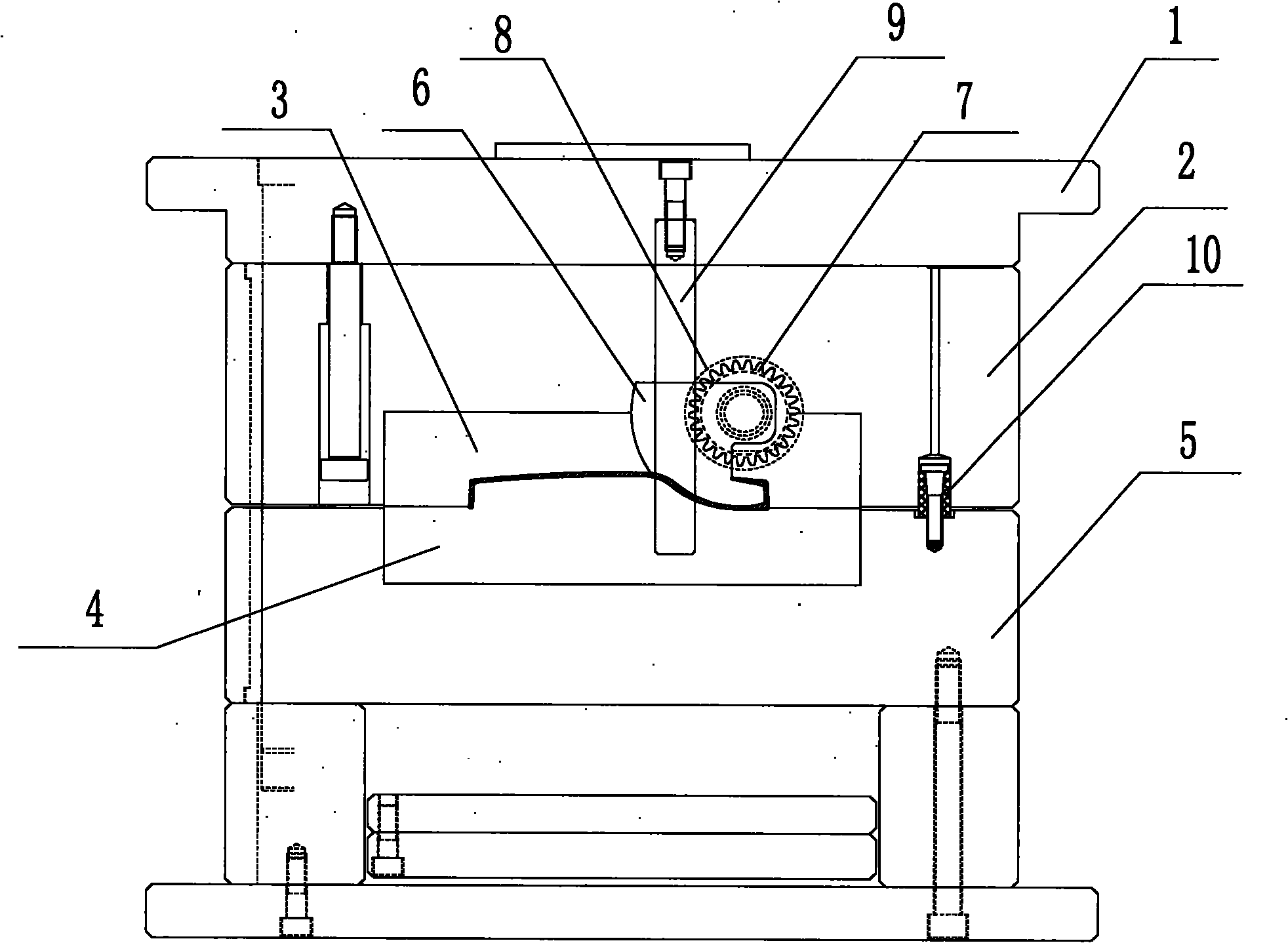

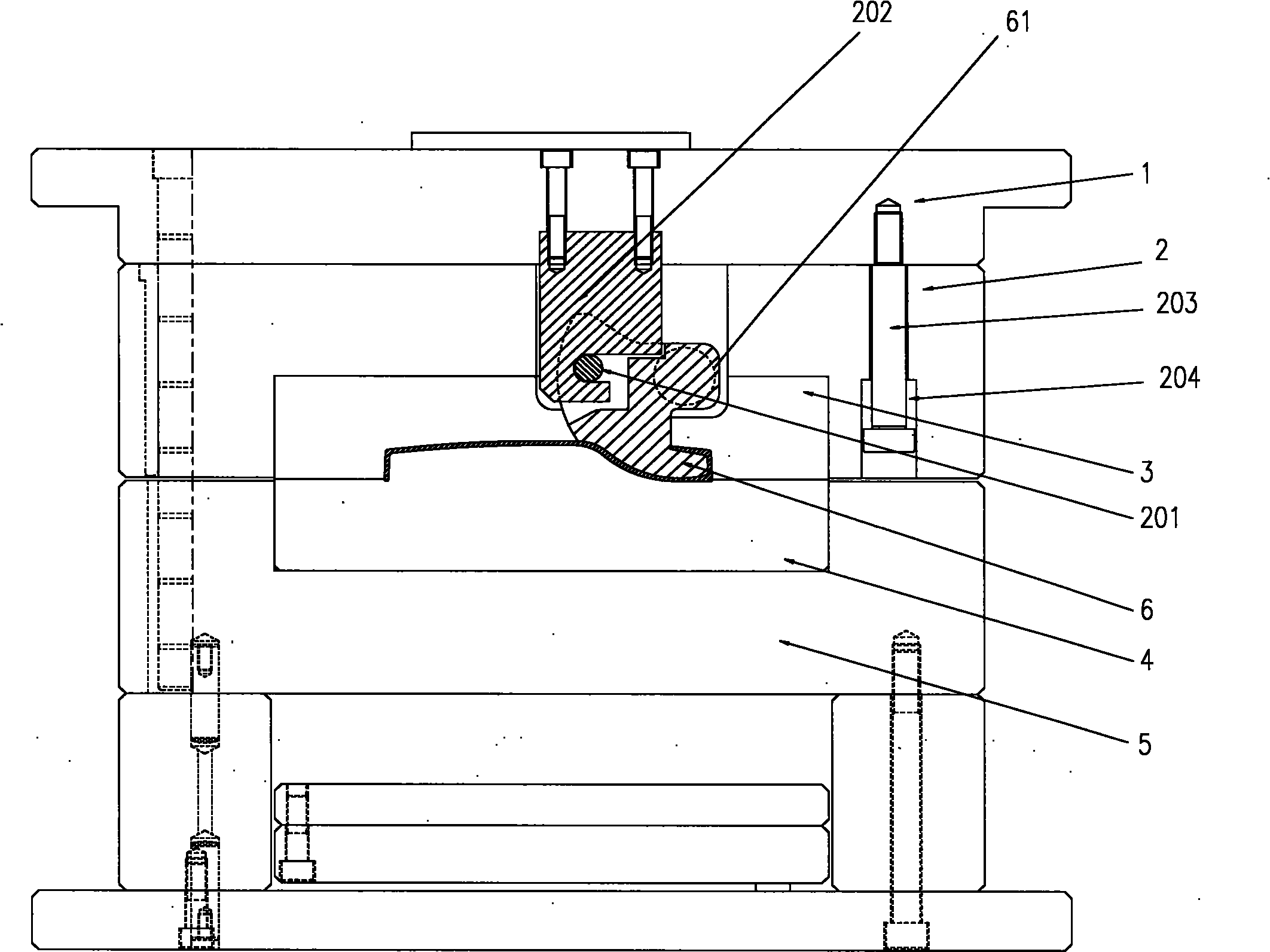

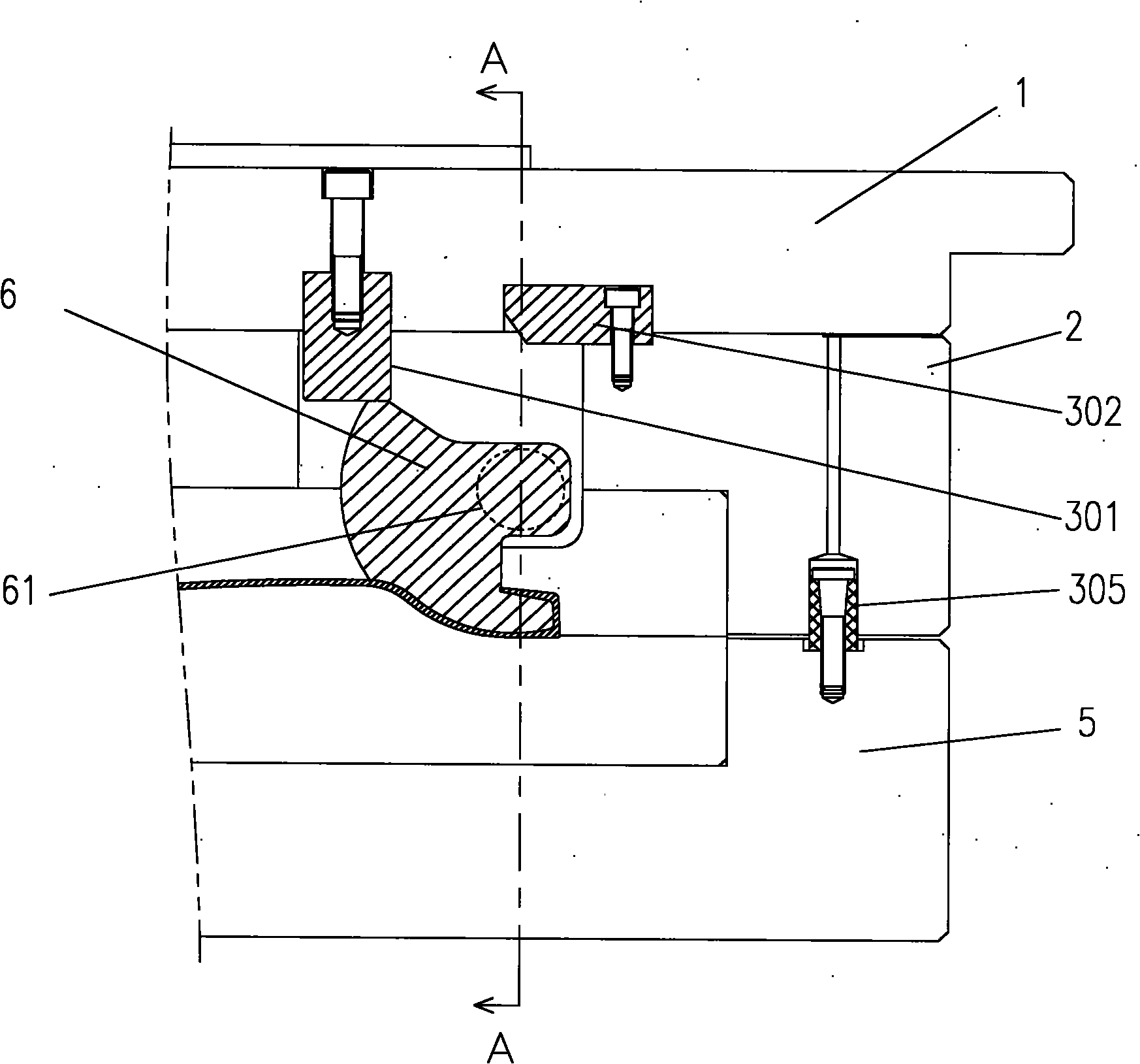

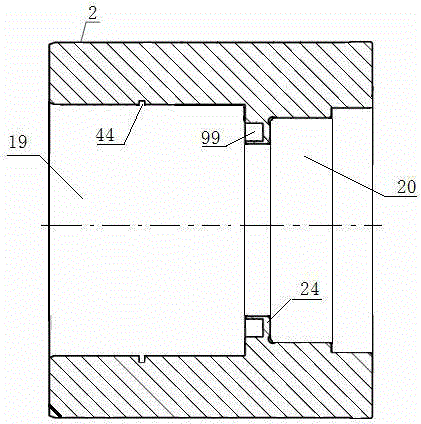

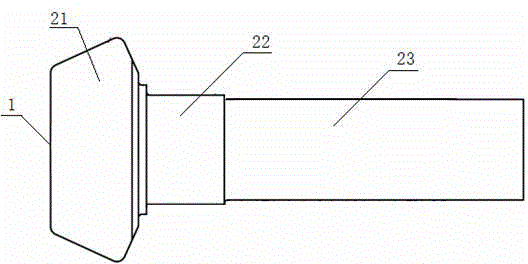

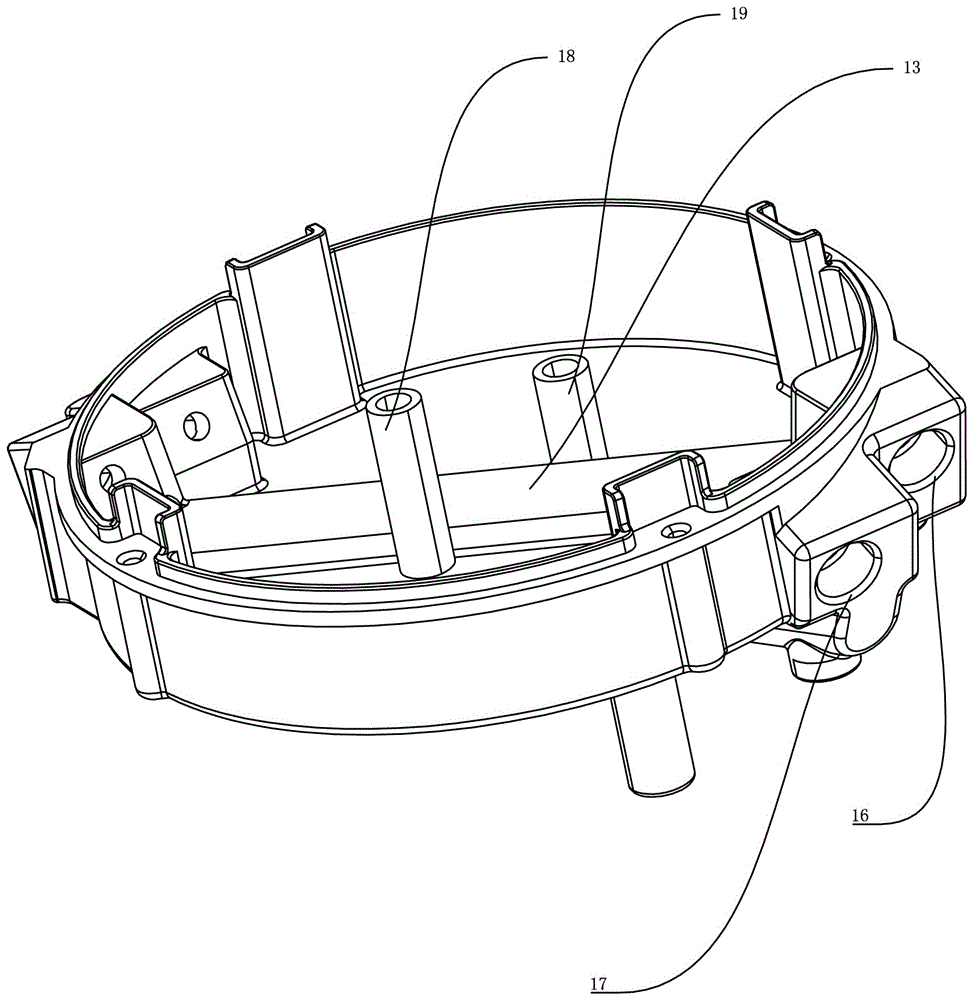

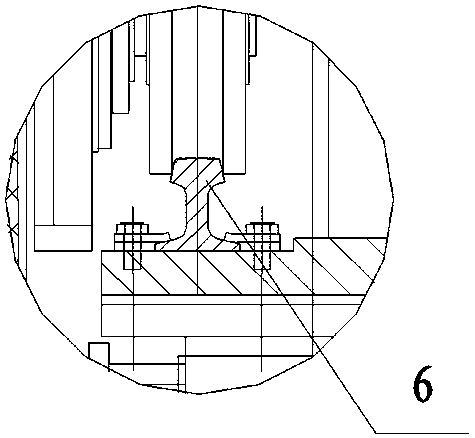

Arc shaped slider core puller and mold using same

The invention discloses a mold using an arc shaped slider core puller, which comprises an upper panel, a mold cavity fixing plate, a mold cavity, a mold core, a mold core fixing plate, an arc shaped slider, a location pin and a barb, wherein the location pin is fixed on the arc shaped slider, and the barb is fixed on the upper panel and is connected with the location pin. In the mold, by the matching of the barb and the location pin, the arc shaped slider completes arc shaped core pulling movement. Compared with a mold of the prior art, which uses a rack wheel to drive the arc shaped slider to complete the arc shaped core pulling movement, the mold provided by the invention uses simple parts of the barb and the location pin so that the production and assembly of the mold can be realized easily with reduced cost; and moreover, since the barb and the location pin have simple structure and high strength and can not be damaged easily, the mold is easy to maintain, thereby greatly reducing the maintenance cost.

Owner:SHENZHEN SILVER BASIS TECH

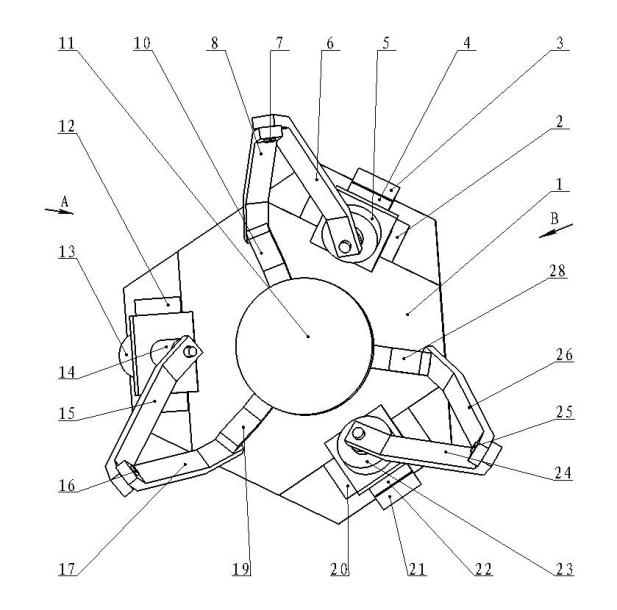

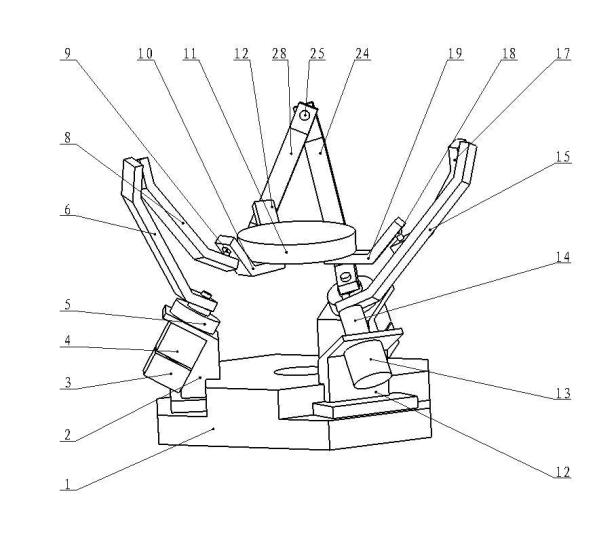

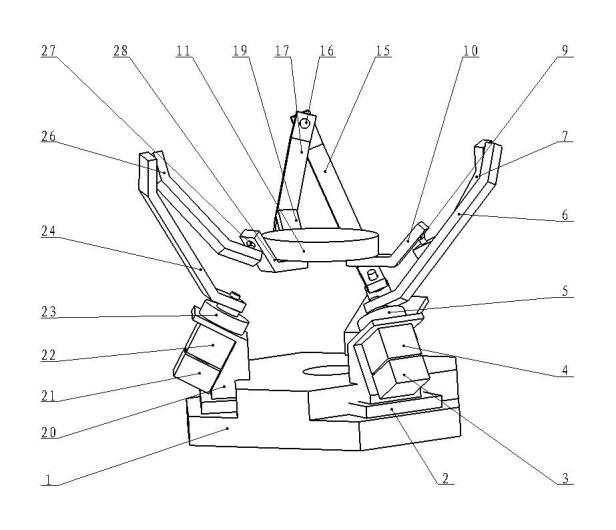

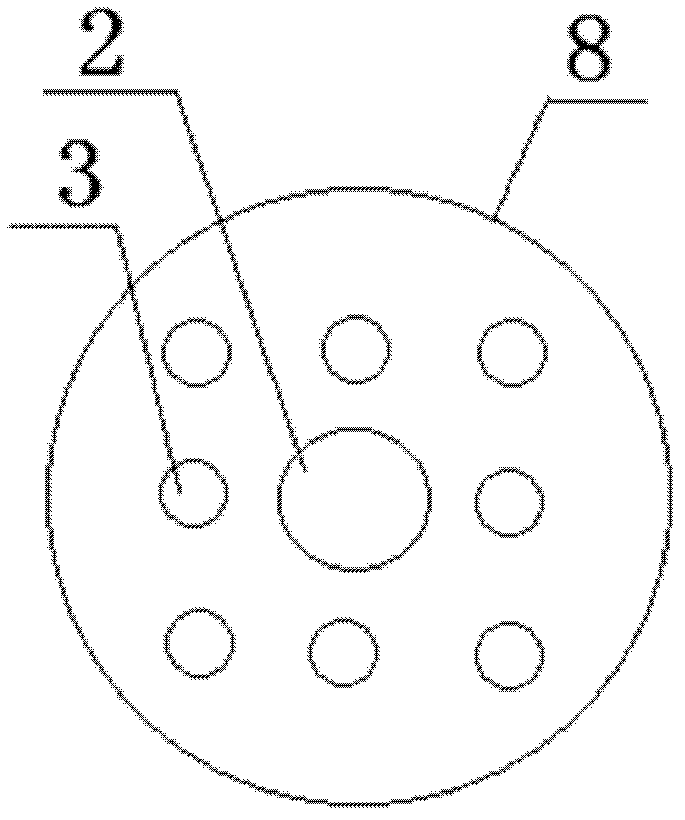

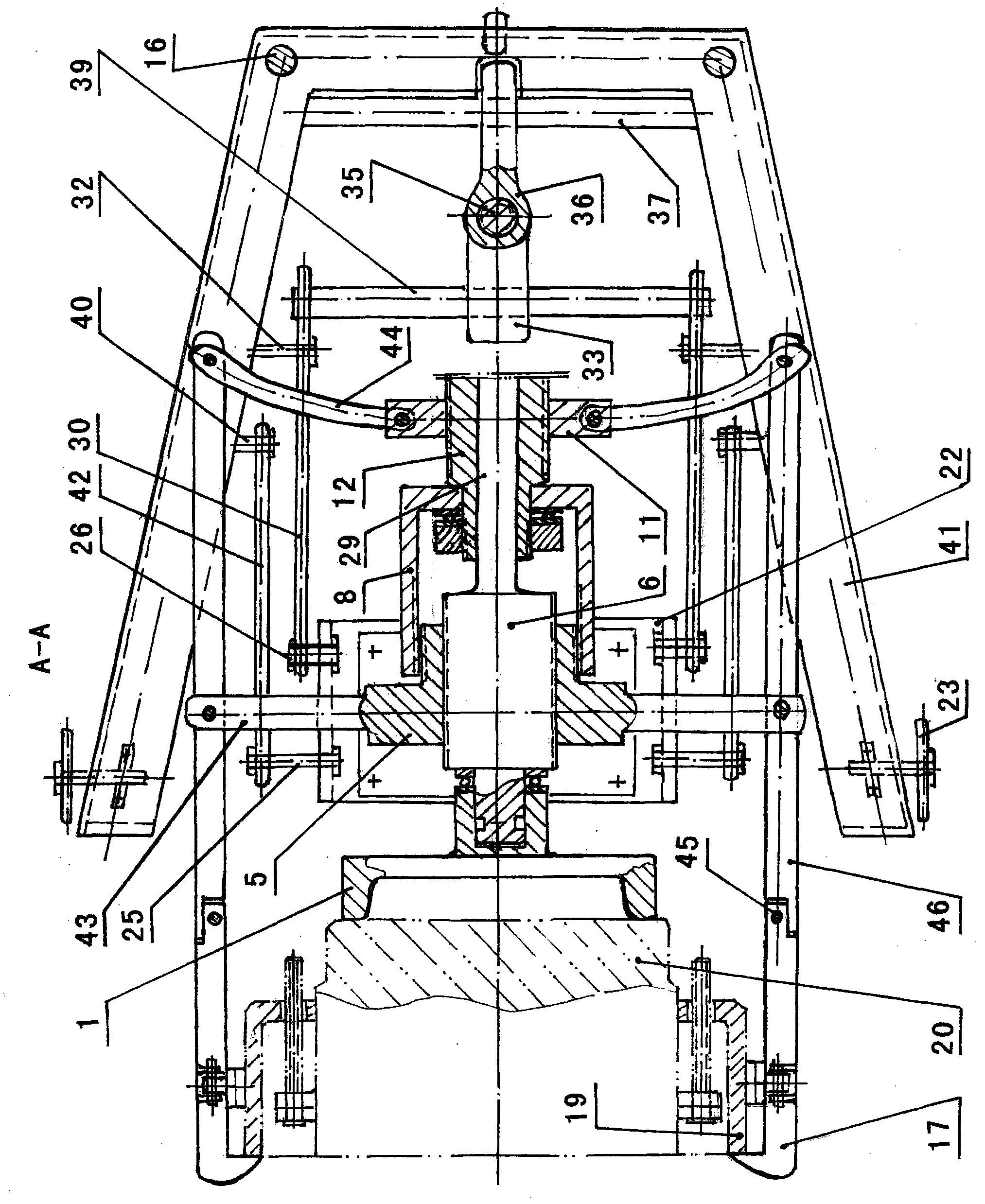

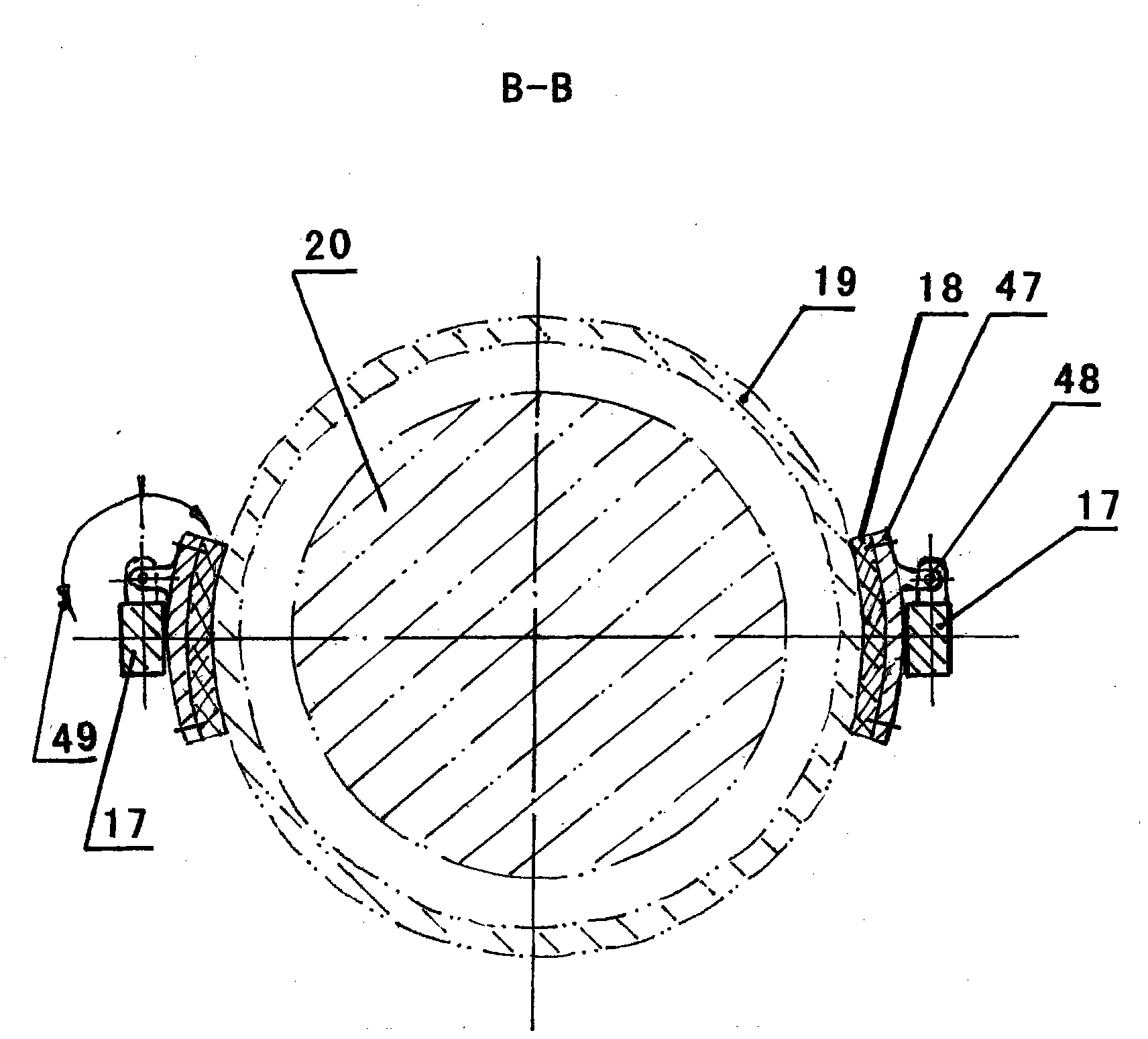

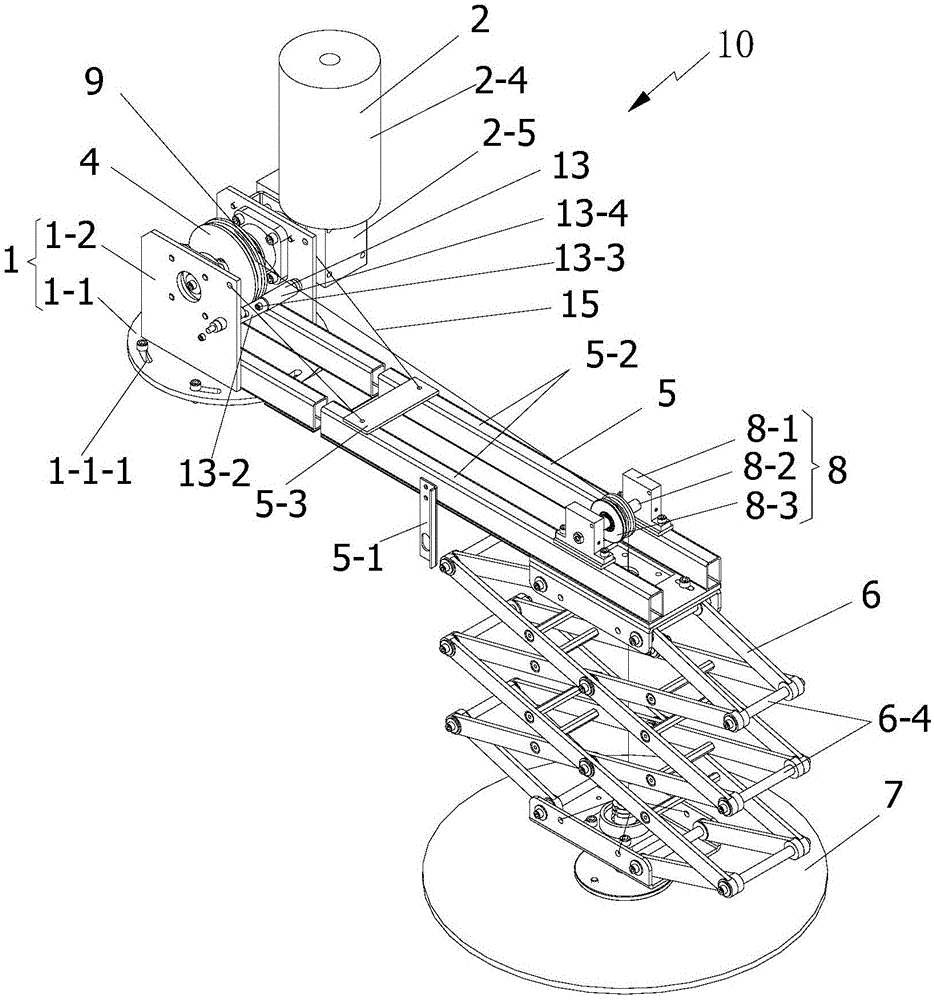

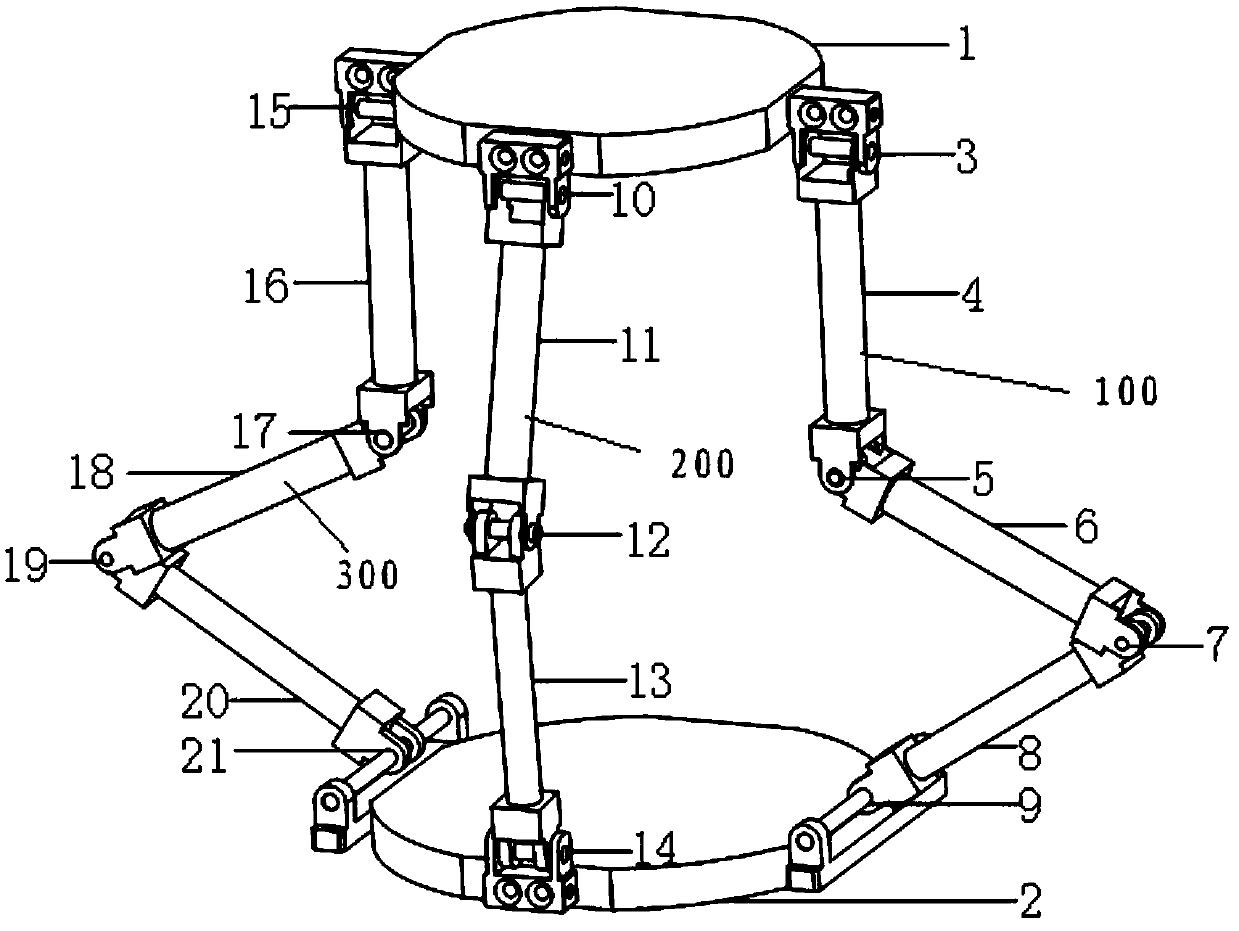

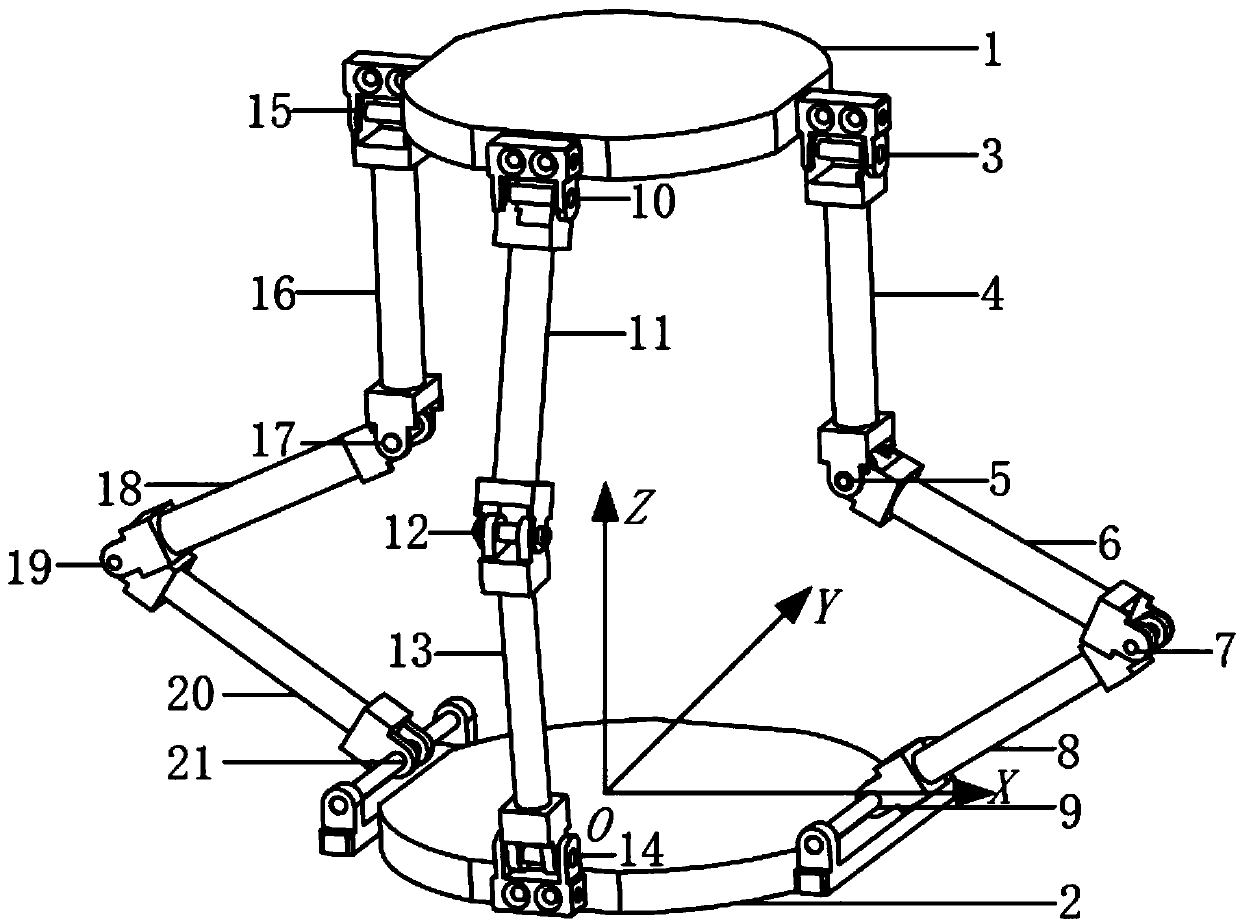

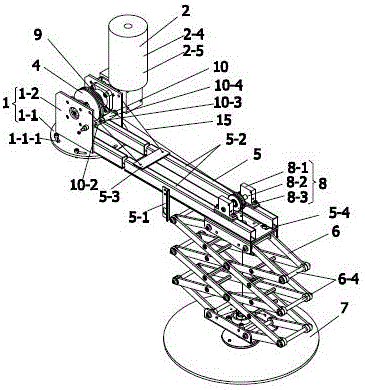

Novel three-degrees-of-freedom under-actuated mechanism

InactiveCN102554914ASimple manufacturing and assemblyHigh precisionProgramme-controlled manipulatorThree degrees of freedomEngineering

The invention relates to a novel three-degrees-of-freedom under-actuated mechanism. The mechanism comprises a base, a movable platform, three branch chains having an identical structure and distributed in axial symmetry, two power sources and a position detection device. The three branch chains are movably connected with the movable platform, the movable platform sinks towards the direction of the base and is in an inward concave shape, the two driving power sources directly drive the two moving branch chains to form the third moving branch chain, namely, the under-actuated mechanism, so that the movable platform moves in three degrees of freedom; and the position detection device is connected with the under-actuated moving branch chains to realize position detection. The mechanism is easy to machine and assemble, flexible in movement, compact in structure and good in rigidity; and as an under-actuated manner is adopted, the cost is lowered, the weight of the wrist part is reduced, and the mechanism can be used in occasions such as parallel robots, micro-robots and the like.

Owner:SHANGHAI UNIV

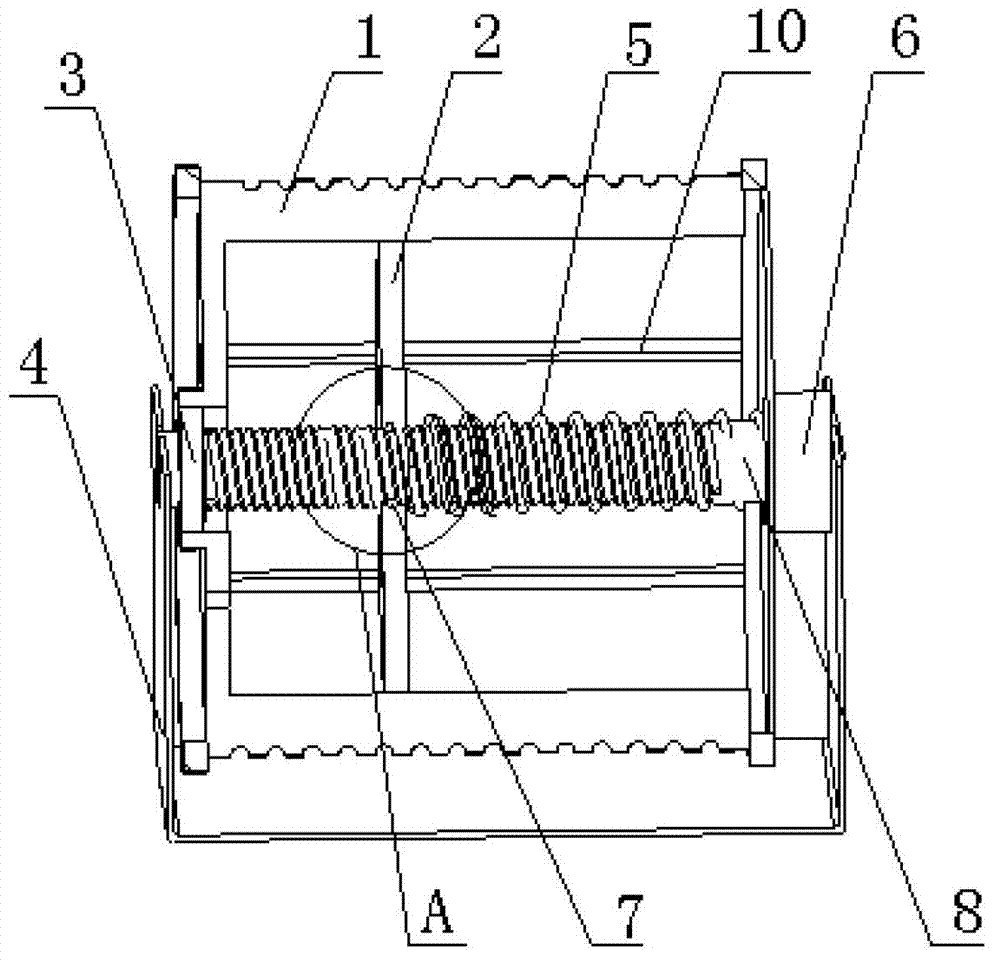

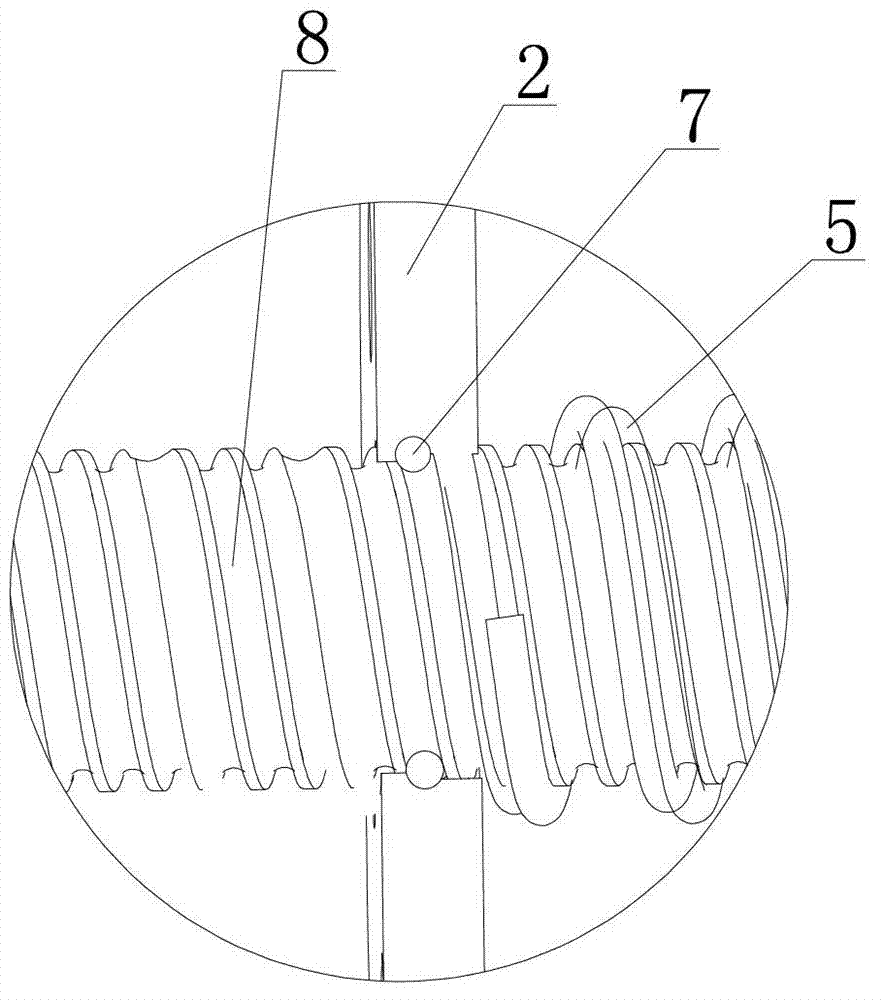

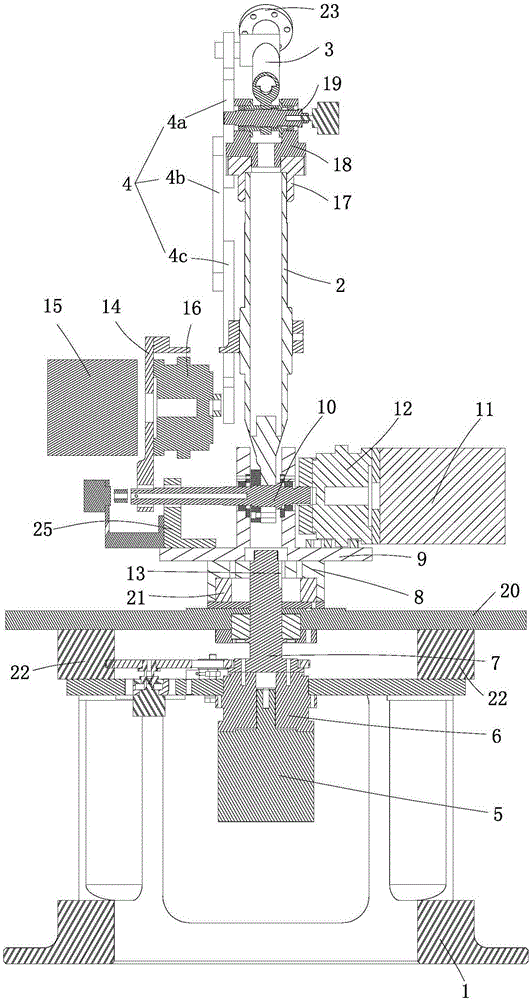

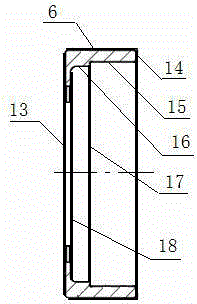

Automatic retraction mechanism of cables

The invention discloses an automatic retraction mechanism of cables. The automatic retraction mechanism is composed of a winding drum, a rotating disc, a stabilizing frame, a reset spring and a ball screw. Two ends of the ball screw are fixed on the stabilizing frame, the reset spring is sleeved on the ball screw, the winding drum is connected with the ball screw through a rolling bearing, the rotating disc is in sliding connection with the winding drum through a sliding groove on the winding drum and is in matched with the ball screw through rolling balls for transmission, and the automatic retraction mechanism resets automatically under thrust of the reset spring, so that the winding drum achieves automatic retraction on cables or pipelines. The automatic retraction mechanism achieves retraction on the cables or pipelines through matching transmission of the rolling balls and the ball screw, achieves automatic reset through the reset spring, requires no additional external force for driving, is simple in structure, small in number of parts, easy to manufacture and assemble, strong in practical applicability, convenient and fast to operate and free of maintenance and greatly reduces production cost.

Owner:贵州航天特种车有限责任公司

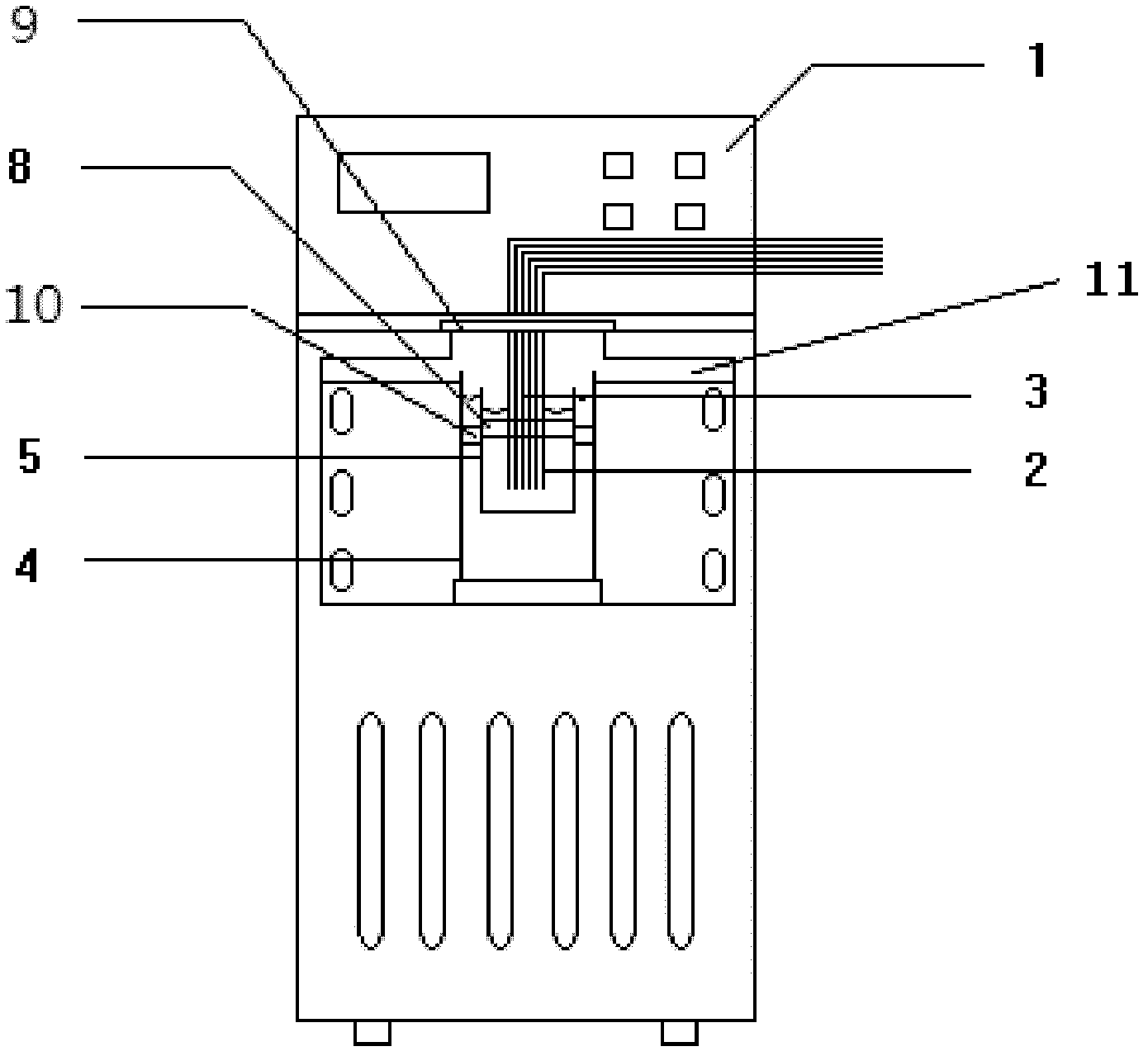

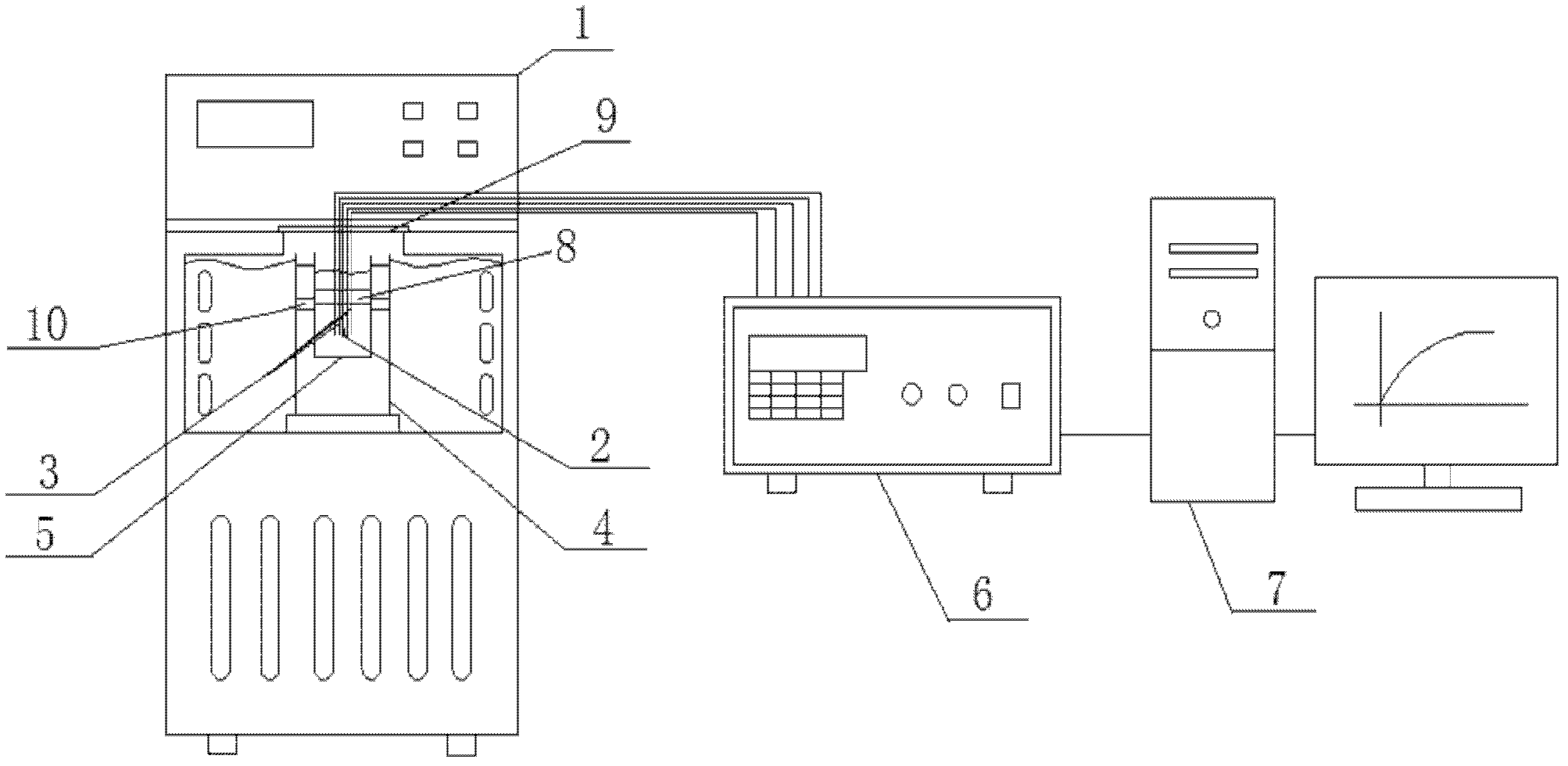

Multi-point temperature calibration device for accurately controlling temperature fluctuation of thermostatic water bath box and operation method thereof

InactiveCN102494807ASimple structureSimple manufacturing and assemblyThermometer testing/calibrationWater bathsData acquisition

The invention discloses a multi-point temperature calibration device for accurately controlling temperature fluctuation of a thermostatic water bath box. The multi-point temperature calibration device comprises a thermostatic water bath box. An insulation can body and an insulation cover that is matched with the insulation can body are arranged inside the thermostatic water bath box; a temperature balance outer tube is arranged inside the insulation can body; a temperature balance inner tube is arranged inside the temperature balance outer tube; a platinum resistor and a T type thermocouple are arranged inside the temperature balance inner tube; and a support, which is arranged at a tube entrance of the temperature balance inner tube, is used for fixing the platinum resistor and the T type thermocouple in the temperature balance inner tube without the bottom and the sidewalls of the temperature balance inner tube contacted. Besides, the platinum resistor and the T type thermocouple are connected with a data acquisition instrument that is connected with a computer. According to the invention, beneficial effects are as follows: calibration can be carried out rapidly and conveniently; precision is high; and the apparatus and the method are suitable for a plurality of kinds of thermocouples including a K type thermocouple.

Owner:SHANGHAI OCEAN UNIV

Two-gear automatic gearbox for pure electric vehicle

ActiveCN104565226ACompact structureLight in massElectric propulsion mountingToothed gearingsElectricityAutomatic transmission

The invention relates to a two-gear automatic gearbox for a pure electric vehicle. The two-gear automatic gearbox comprises an input shaft, a first middle shaft, a second middle shaft, a first cylinder gear pair, a second cylinder gear pair, a third cylinder gear pair, a first torque transferring device, a second torque transferring device and a differential mechanism assembly, wherein the rotating central lines of the input shaft, the second middle shaft and the differential mechanism assembly are parallel to one another. The two-gear automatic transmission is adopted by the two-gear automatic gearbox, so that the driving ratio scope is widened, the performance demand on a driving motor is greatly reduced, the high-efficiency and light driving motor is allowed to be adopted, and the total volume, the total mass and the total cost of the two-gear automatic gearbox for the pure electric vehicle are further reduced.

Owner:绿传(北京)汽车科技股份有限公司

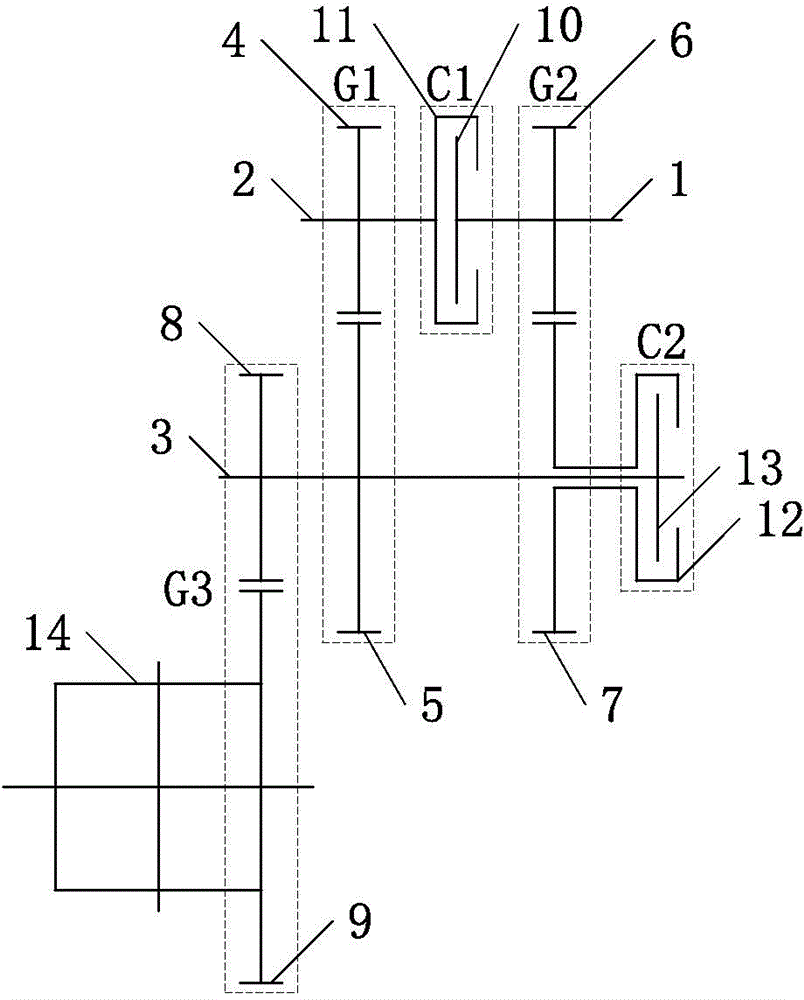

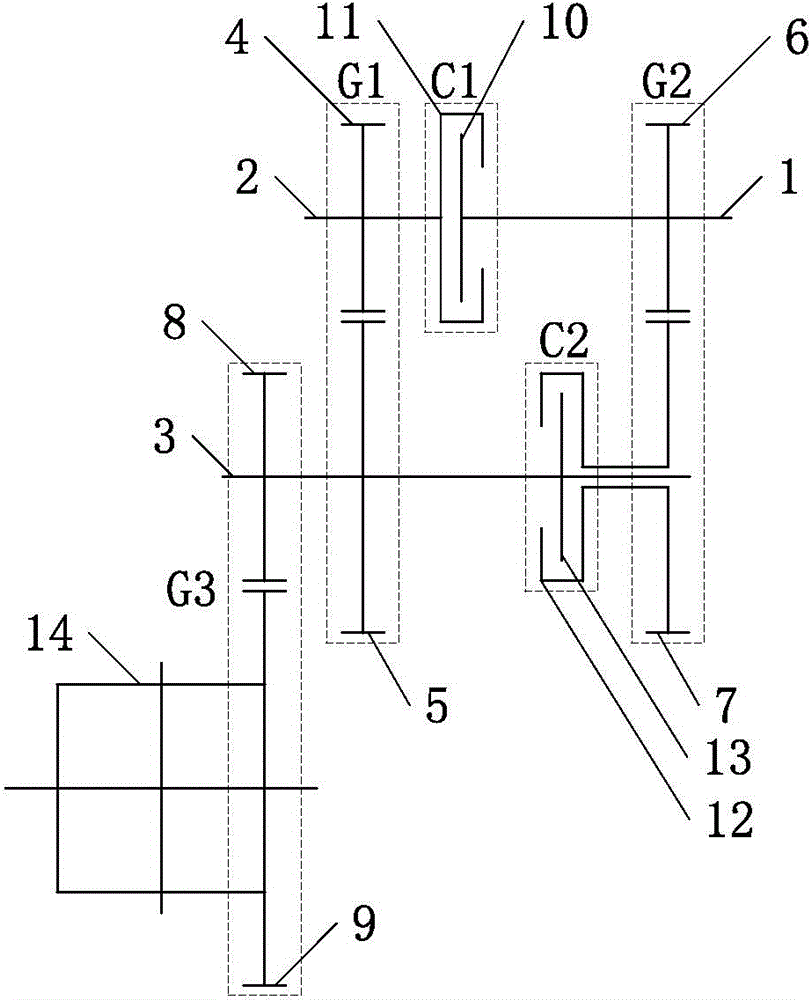

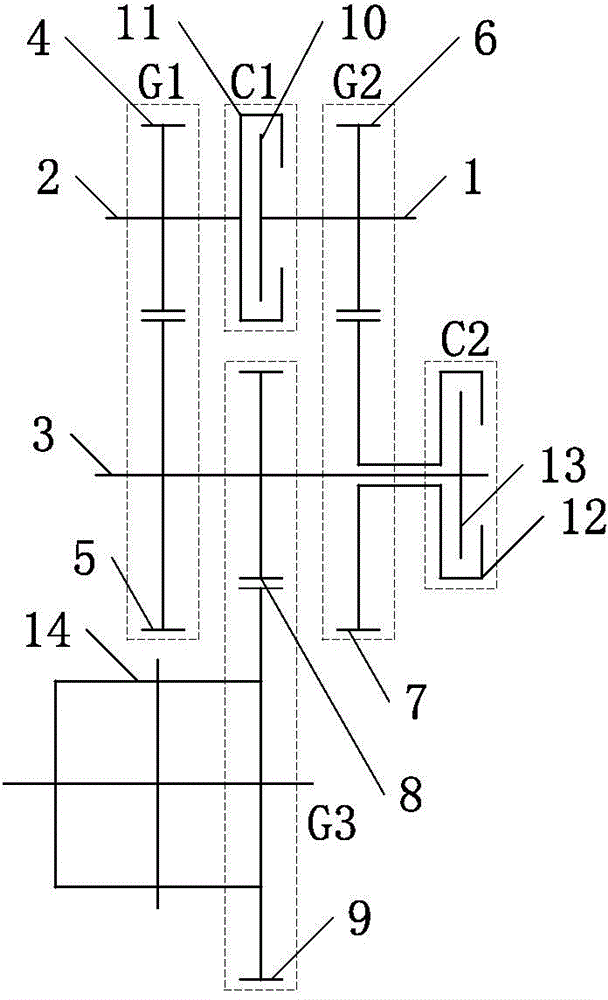

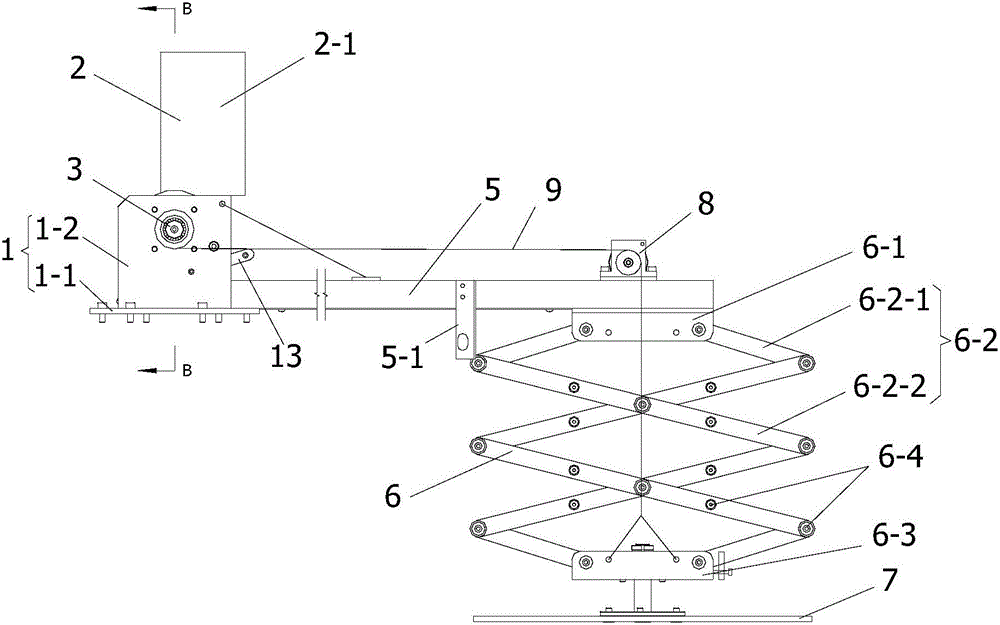

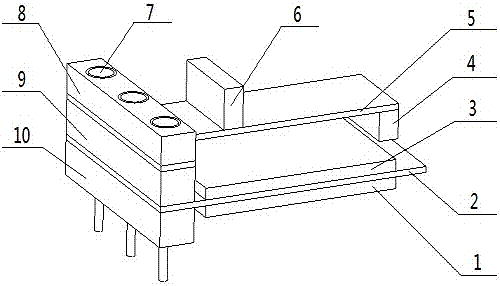

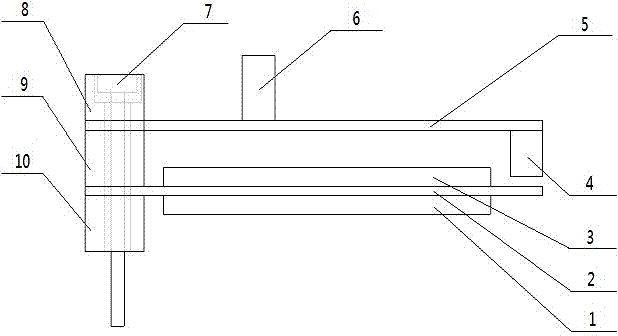

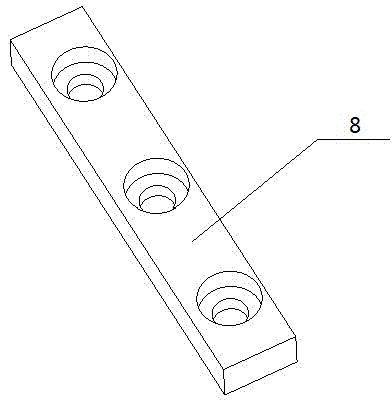

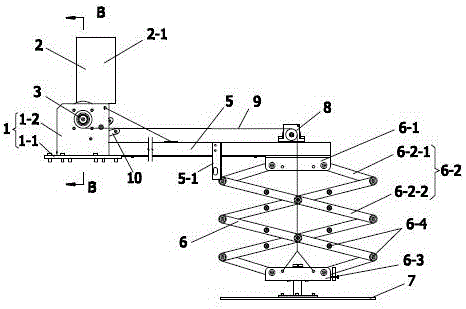

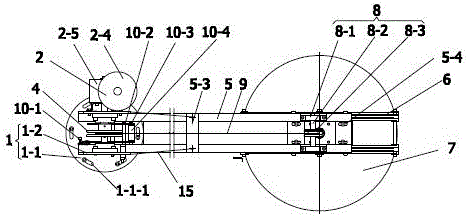

Parallel mechanism to implement tri-translation and mono-rotation

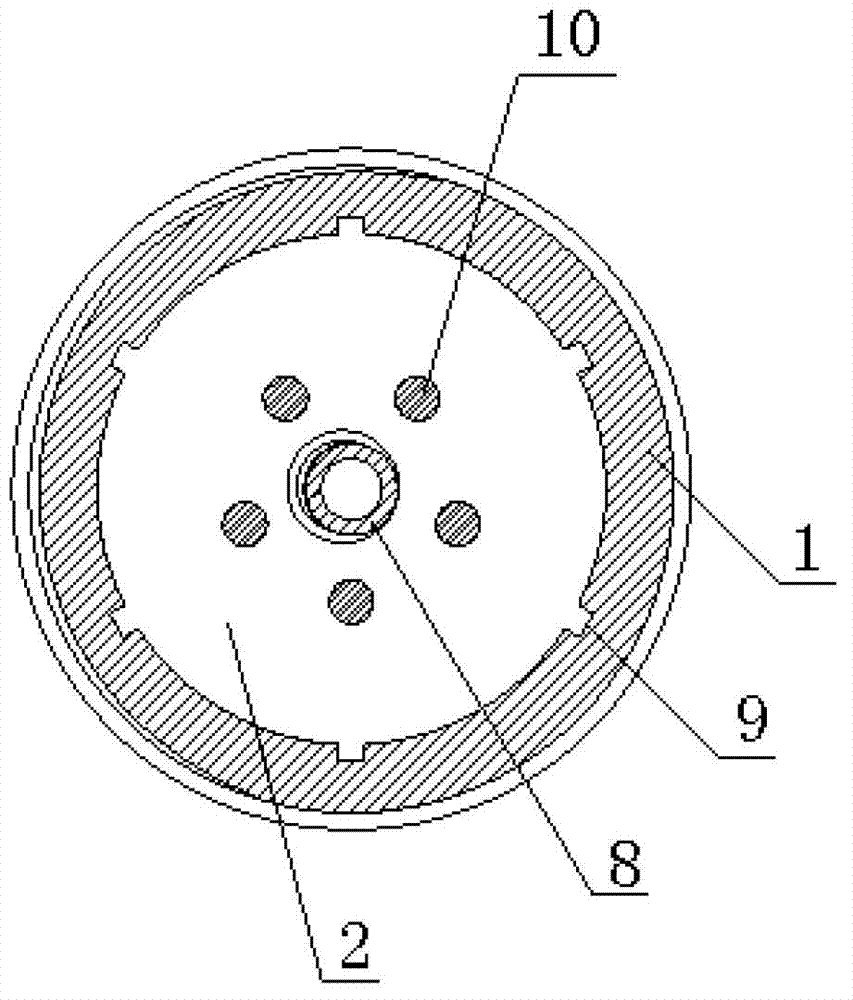

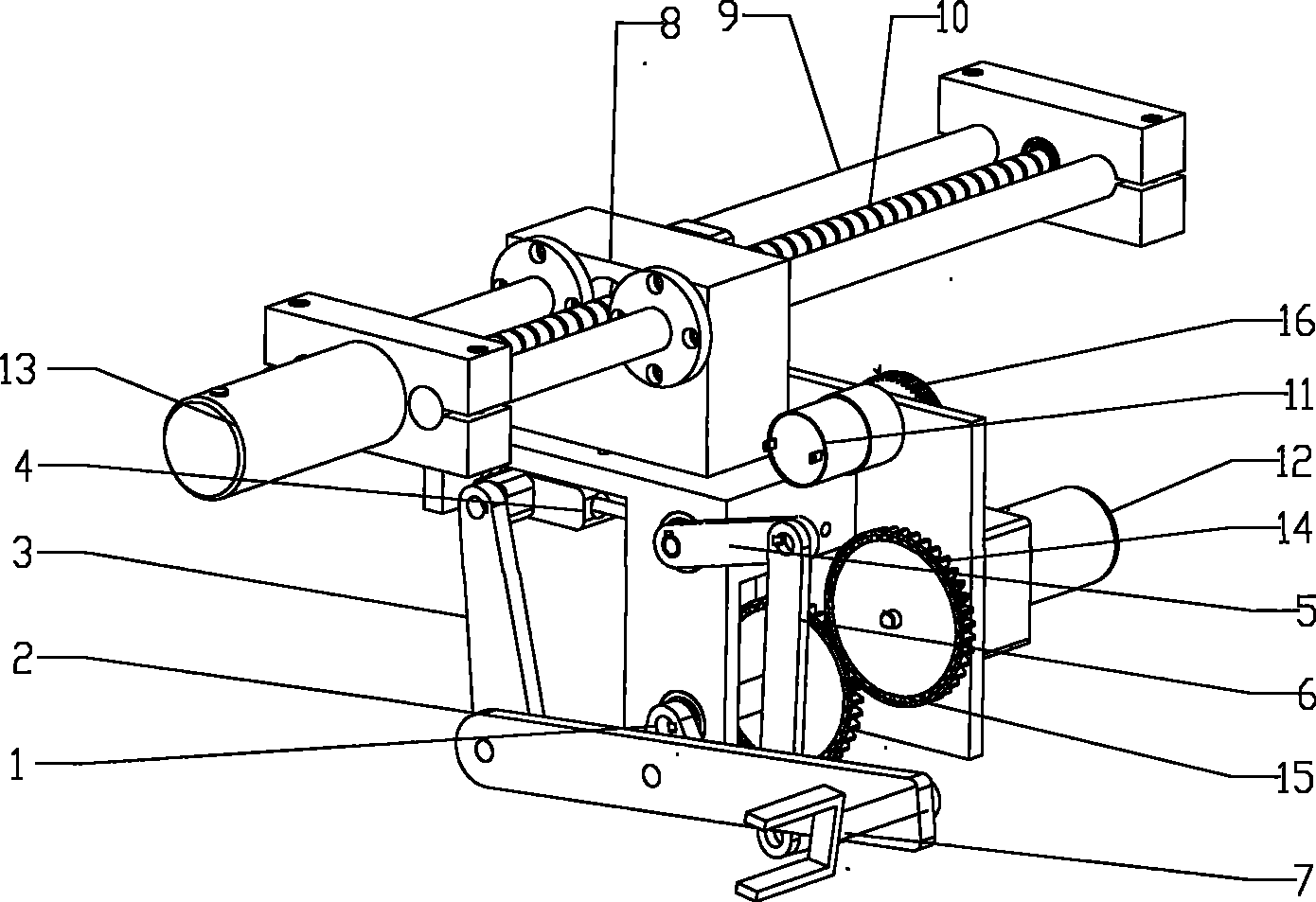

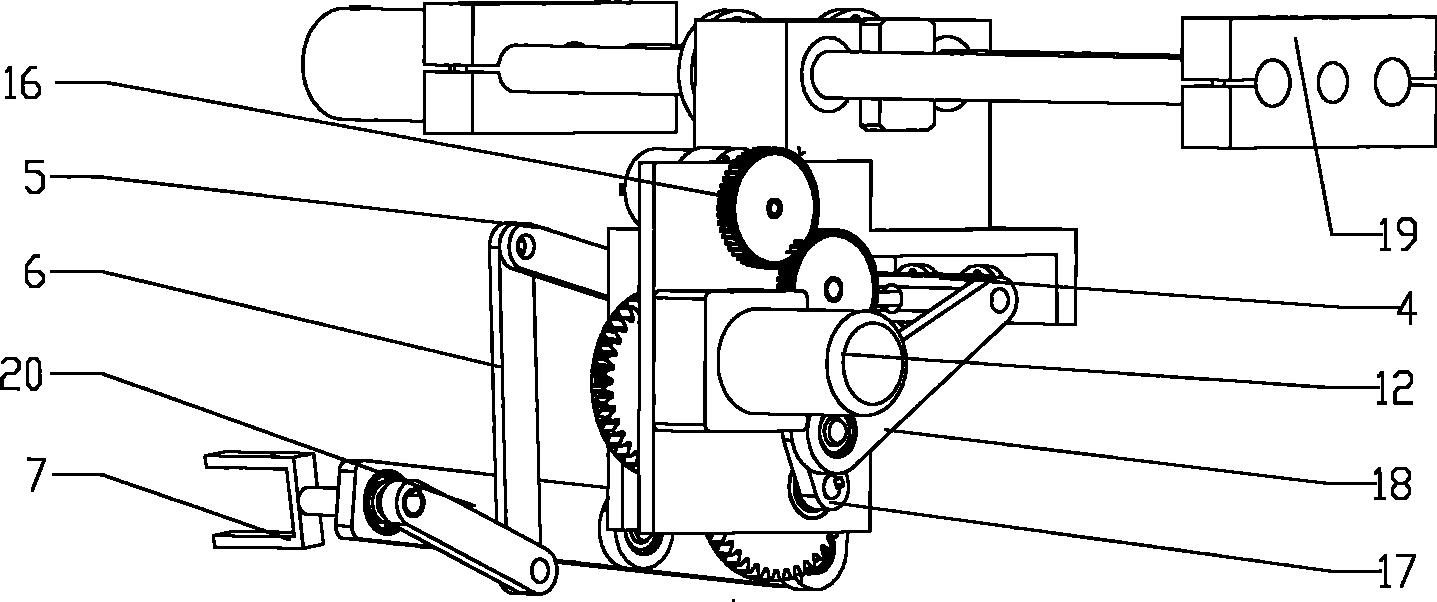

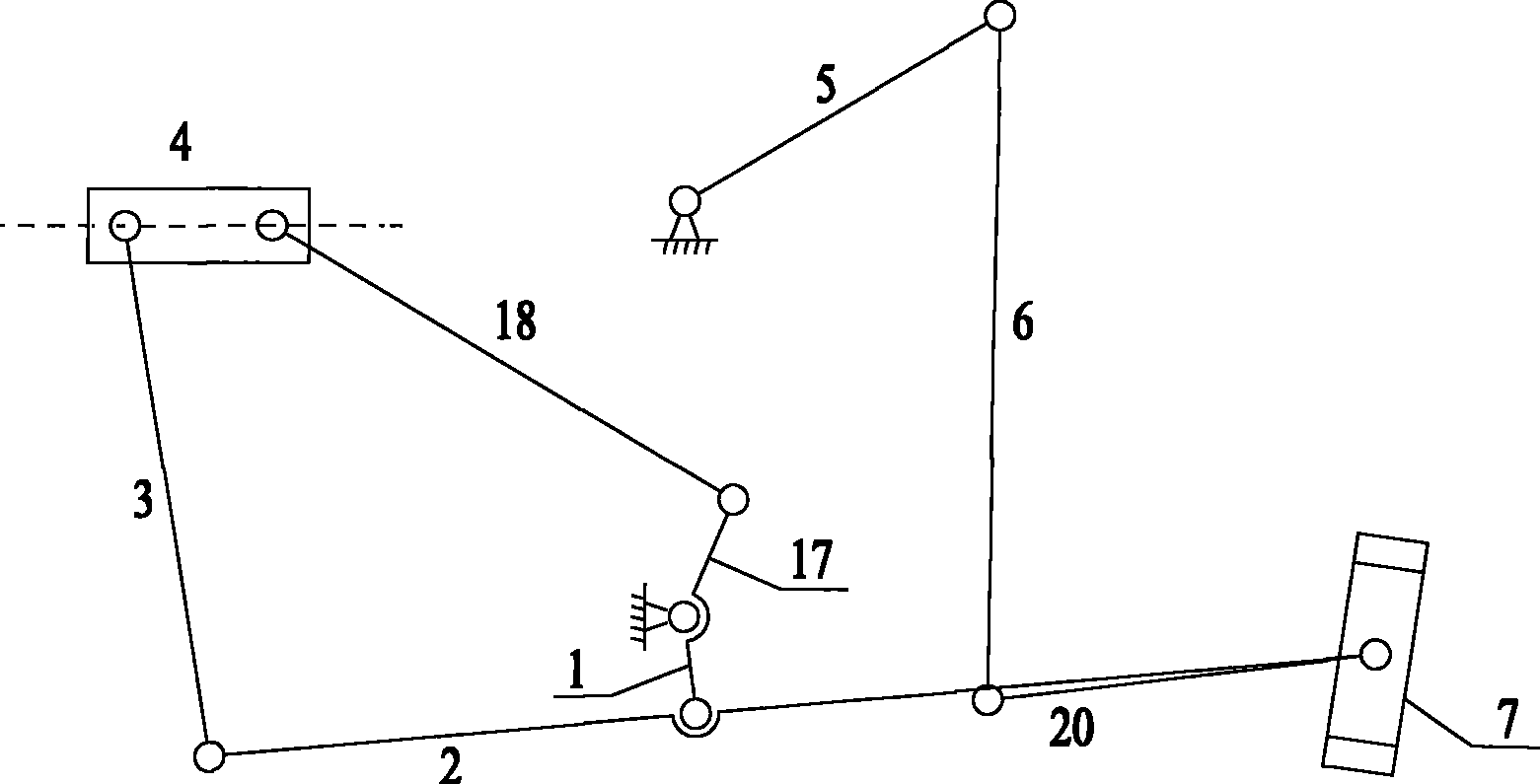

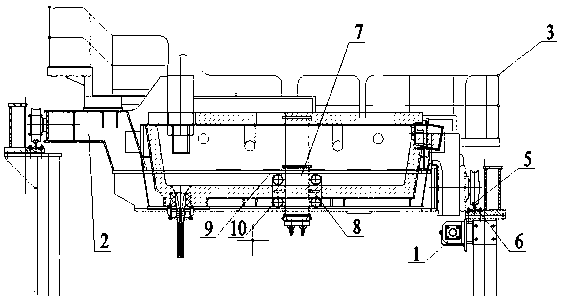

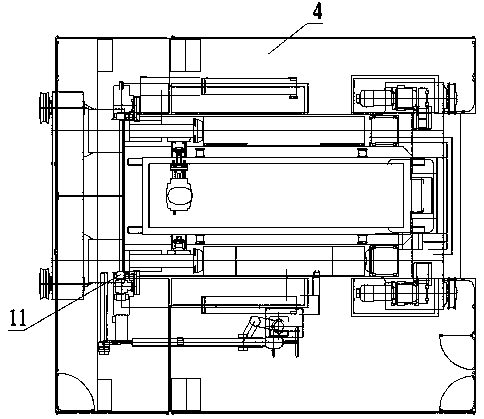

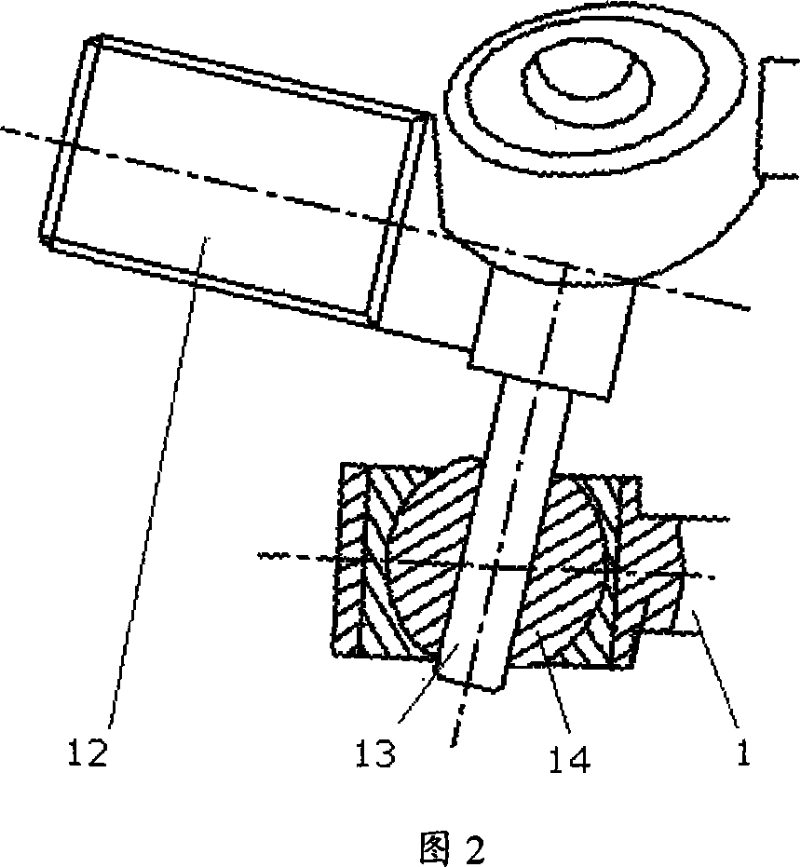

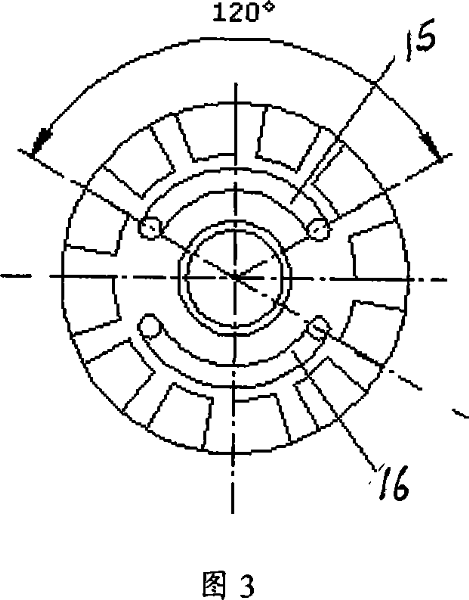

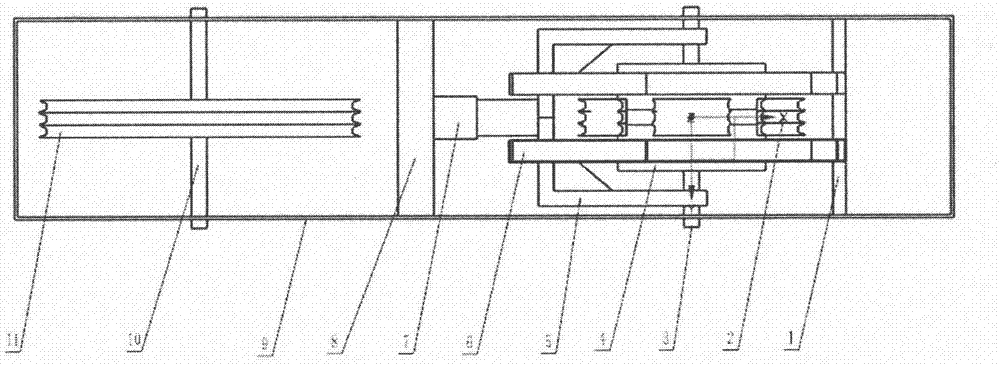

InactiveCN101531003ANovel and compact structureSimple manufacturing and assemblyManipulatorBall screwReciprocating motion

The invention relates to a parallel mechanism to implement tri-translation and mono-rotation, consisting of a slider (8) and an end effector (7), and three groups of planar linkage mechanisms connecting said two, where the three groups include a five bar slider mechanism, a slider-crank mechanism and a plane four bar mechanism. The plane four bar mechanism consists of a driving element (5) and a driven element (6, 20). The end effector (7) has a rotary shaft connected to a connecting bar (2), while the driven element (20) of the plane four bar mechanism is connected with the end effector. The five bar slider mechanism and the slider-crank mechanism share a slider (4) and a drive motor (12), while the slider (4) is served as a driving element of the five bar slider mechanism. The slider-crank mechanism and the five bar slider mechanism form a planar combination mechanism to implement two degrees of freedom (DOF) motion required by the end effector by use of a drive motor (12). The plane four bar mechanism formed by a driving element (5) and a driven element (6, 20) can implement a function of rotation for the end effector. Furthermore, the slider (8) can implement straight reciprocating motion by means of a ball screw (10). Therefore, the mechanism can implement four DOF motion with tri-translation and mono-rotation, and implement four DOF motion of tri-translation and mono-rotation by means of three drive motor.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

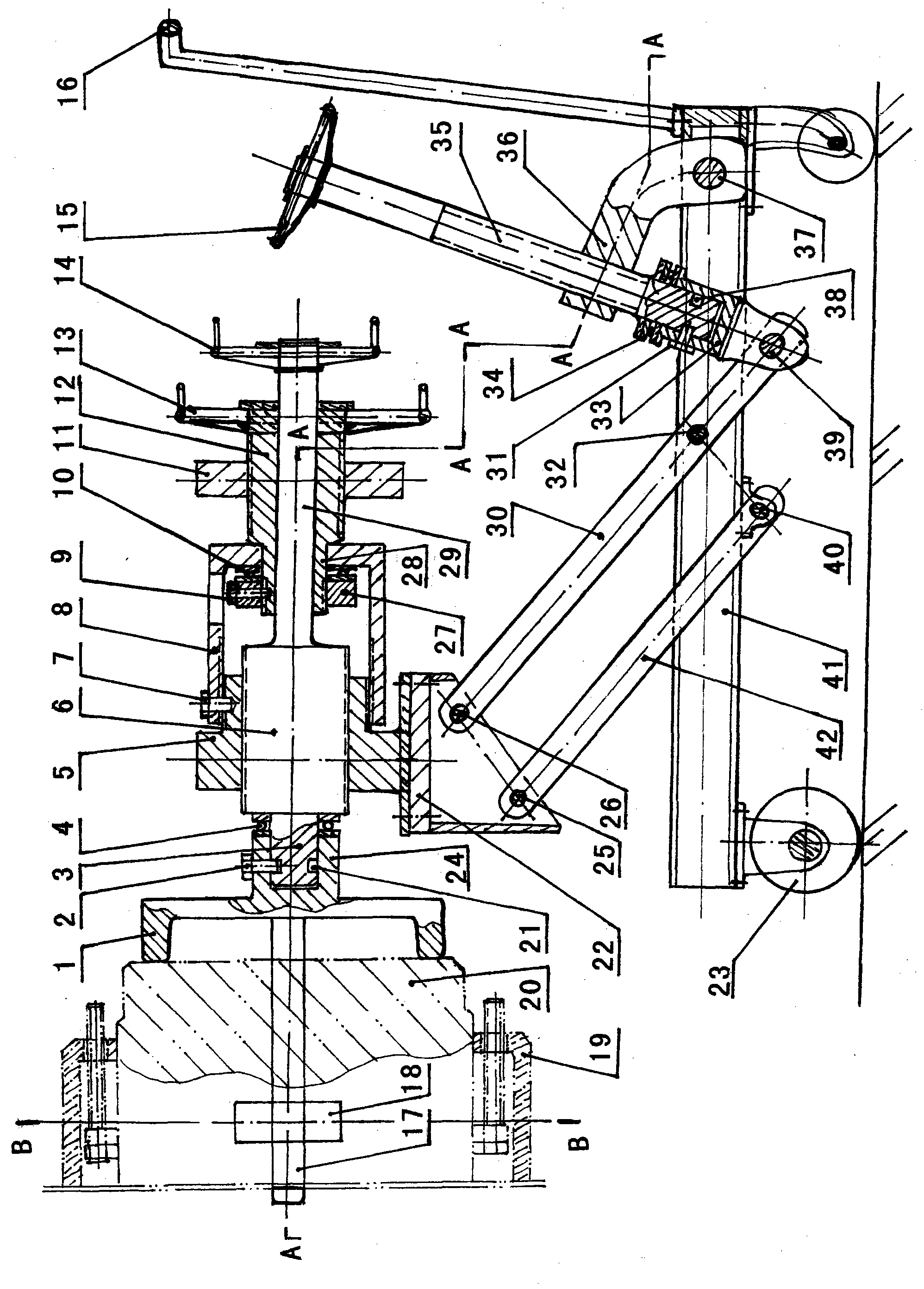

Automobile brake drum disassembling and assembling machine

The invention provides an automobile brake drum disassembling and assembling machine, which mainly comprises a lifting work platform, a support seat, a disassembling and assembling screw, a hook screw and a disassembling and assembling roof rack, and has the following structural characteristics that: the lifting work platform is supported by a parallelogram connecting rod mechanism to a stander, so the lifting work platform can be in a horizontal position status when working at any altitude; by a lever type clamping mechanism consisting of a support rod and a support seat side arm hinged witha disassembling and assembling hook lever, the brake drum to be disassembled and assembled can be firmly clamped by a pull drum hook; and by a static roof pressure structure consisting of the disassembling and assembling screw and the disassembling and assembling roof rack, roof pressure formed by the disassembling and assembling screw can be converted into axial tensile force of the disassembling and assembling brake drum, and the operation of disassembling and assembling the brake drum can be convenient to finish. By the invention, the traditional beat and impact operation mode is radicallyabandoned; the disassembling and assembling machine has the remarkable advantages of low manufacture cost, convenience of assembling operation, short automobile repairing time, and low automobile repairing fee, and has strong practicability and extremely good market prospect in the automobile repairing industry.

Owner:曾柏林

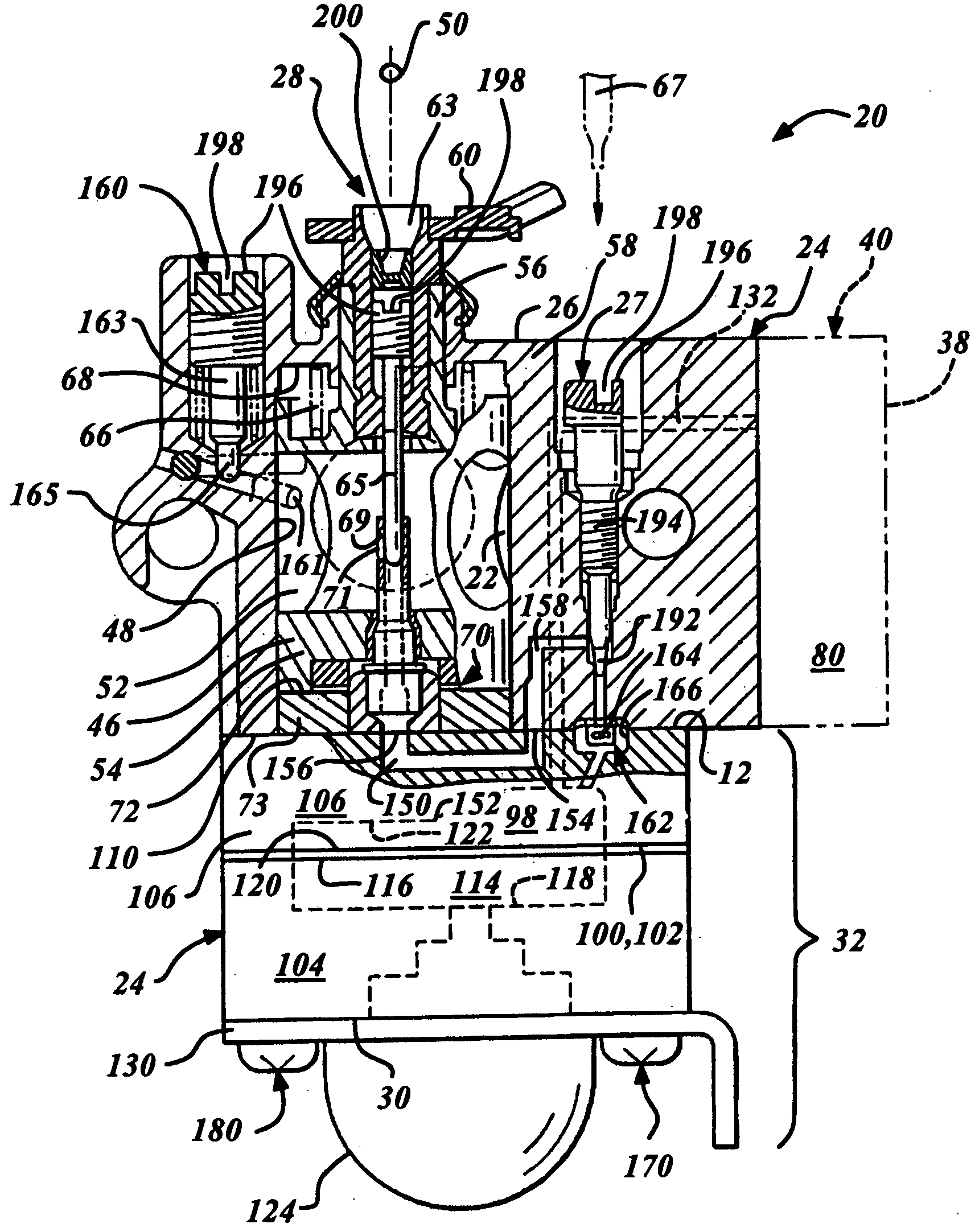

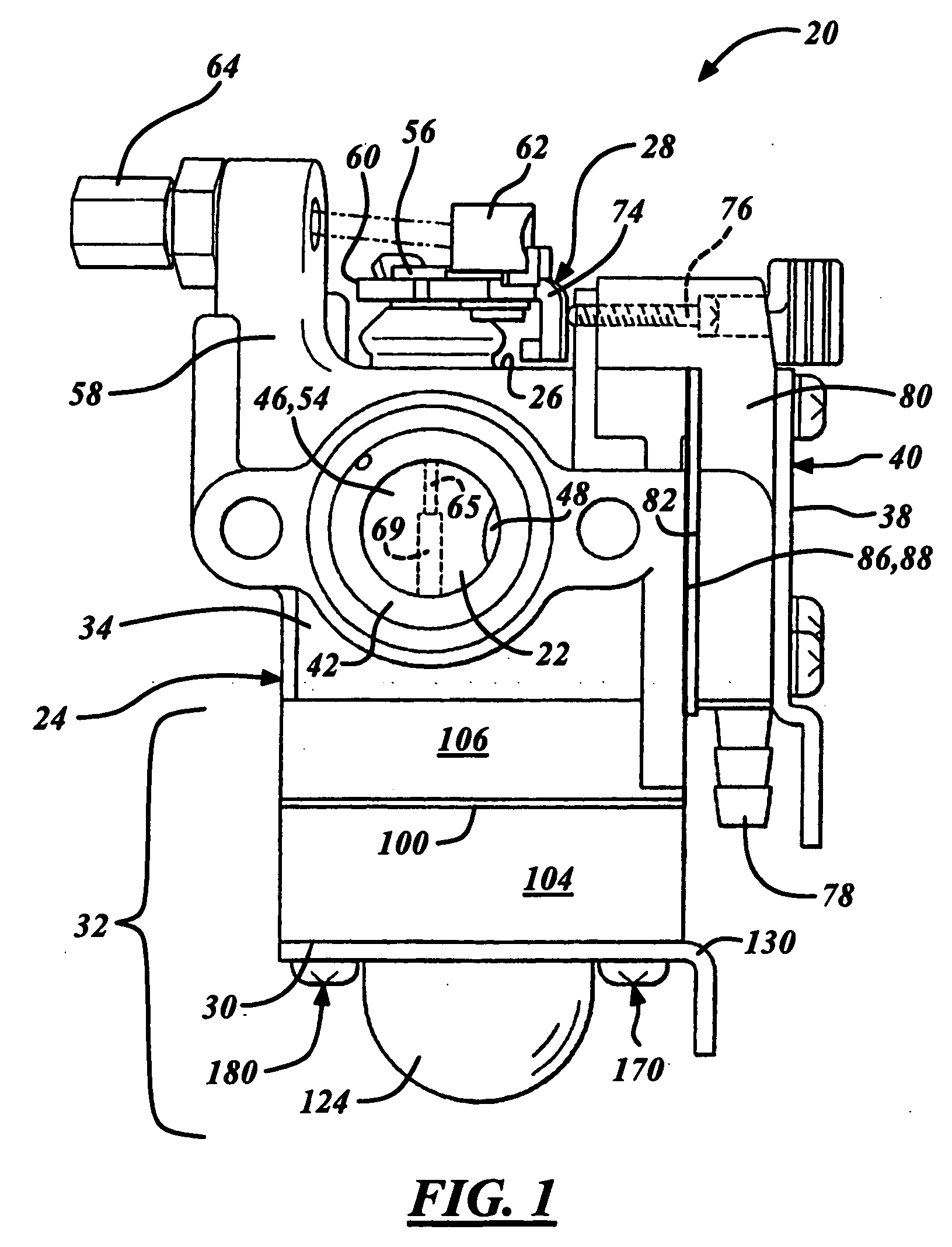

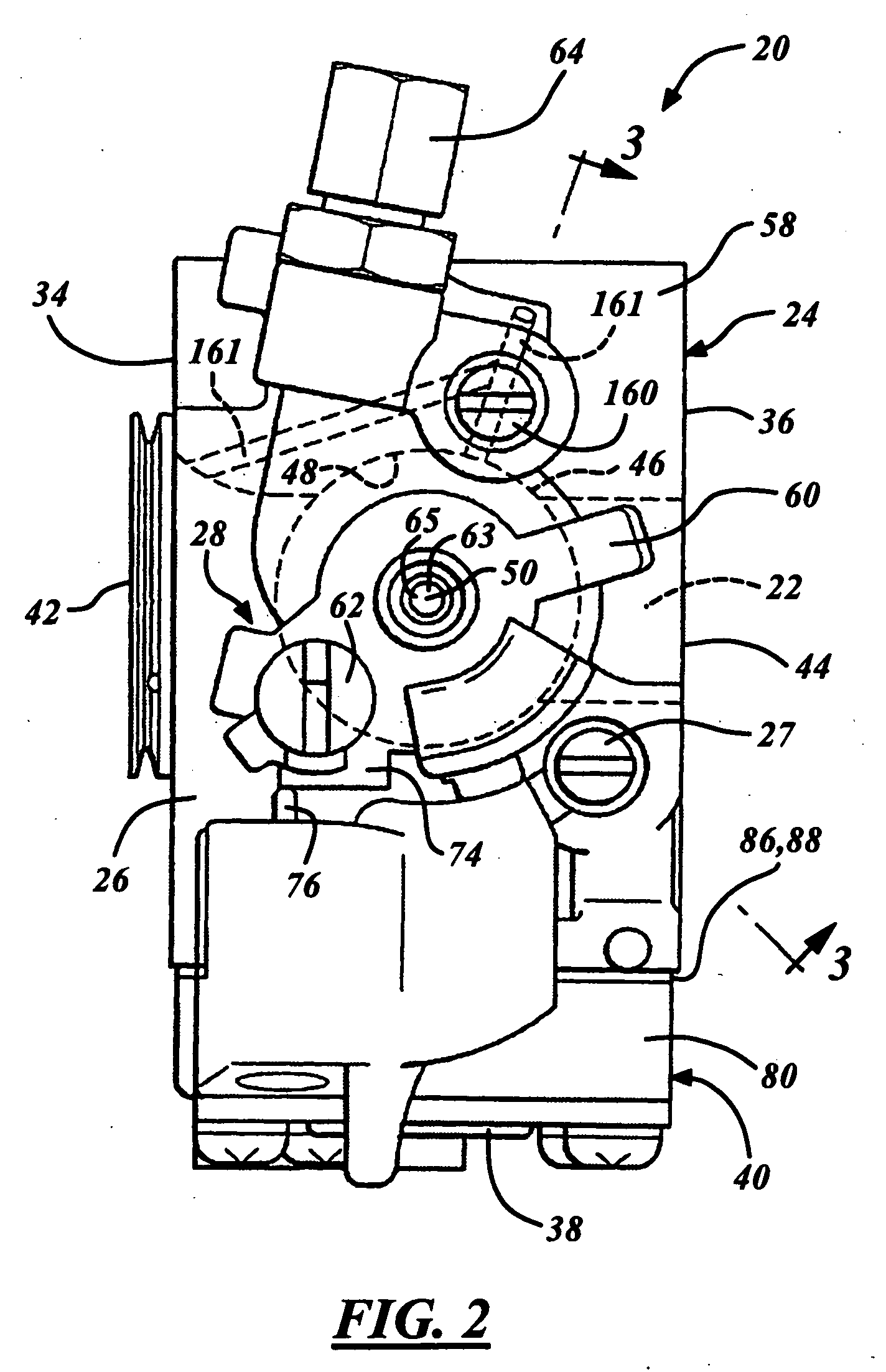

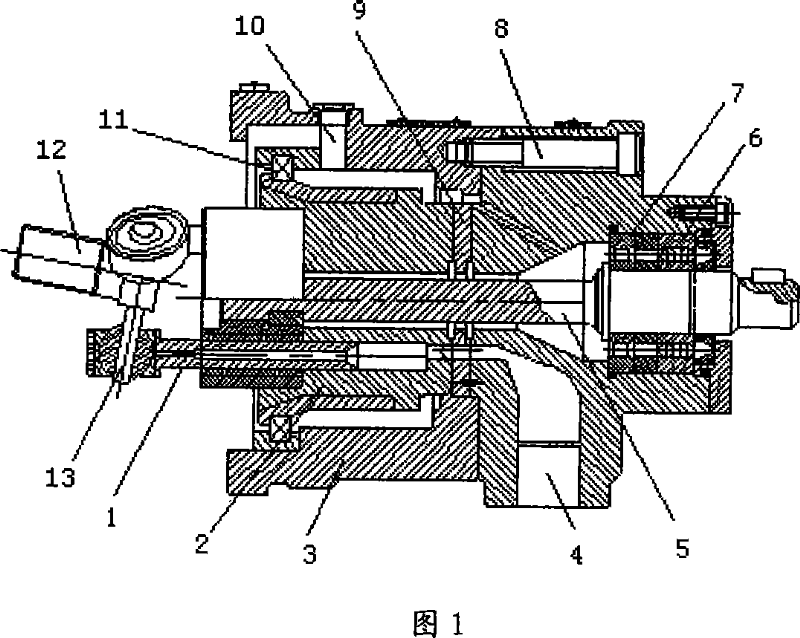

Rotary carburetor

InactiveUS20060151893A1Improve versatilitySimple manufacturing and assemblyLighting and heating apparatusUsing liquid separation agentEngineeringCarburetor

A versatile rotary carburetor has an idle adjustment needle, a high speed adjustment needle, and preferable an air bypass screw which are substantially parallel to one another and are axially exposed for adjustment in a substantially common direction. Preferably a cammed rotary throttle valve is seated in a body of the carburetor for rotation about and axial movement along an axis. The rotary throttle valve intersects a mixing passage in the body, and carries a through-bore that variably generally aligns to the mixing passage upon rotation of the throttle valve. The throttle valve projects axially through an external surface of the body and threadably receives the idle adjustment needle oriented concentrically to the axis. A primary fuel feed tube disposed concentrically to the axis projects into the through-bore to receive the idle adjustment needle at an open distal end which variably obstructs an orifice in a cylindrical wall of the tube that generally communicates with the through-bore for delivering liquid fuel to the mixing passage. The high speed adjustment needle is preferably threaded to the body for adjustably intersecting and obstructing a fuel passage in the body that flows liquid fuel to the fuel feed tube for the flow of liquid fuel. Preferably, the air bypass screw threads into the body for adjustably intersecting and obstructing an air bypass passage in the body communicating at both ends with the mixing passage for generally bypassing the rotary throttle valve when in an idle position.

Owner:WALBRO ENGINE MANAGEMENT

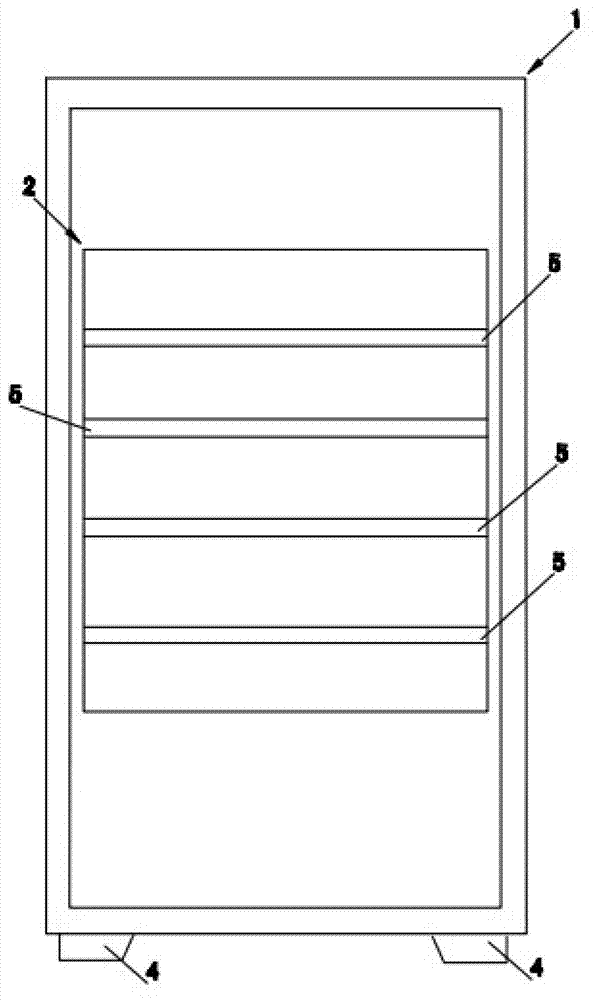

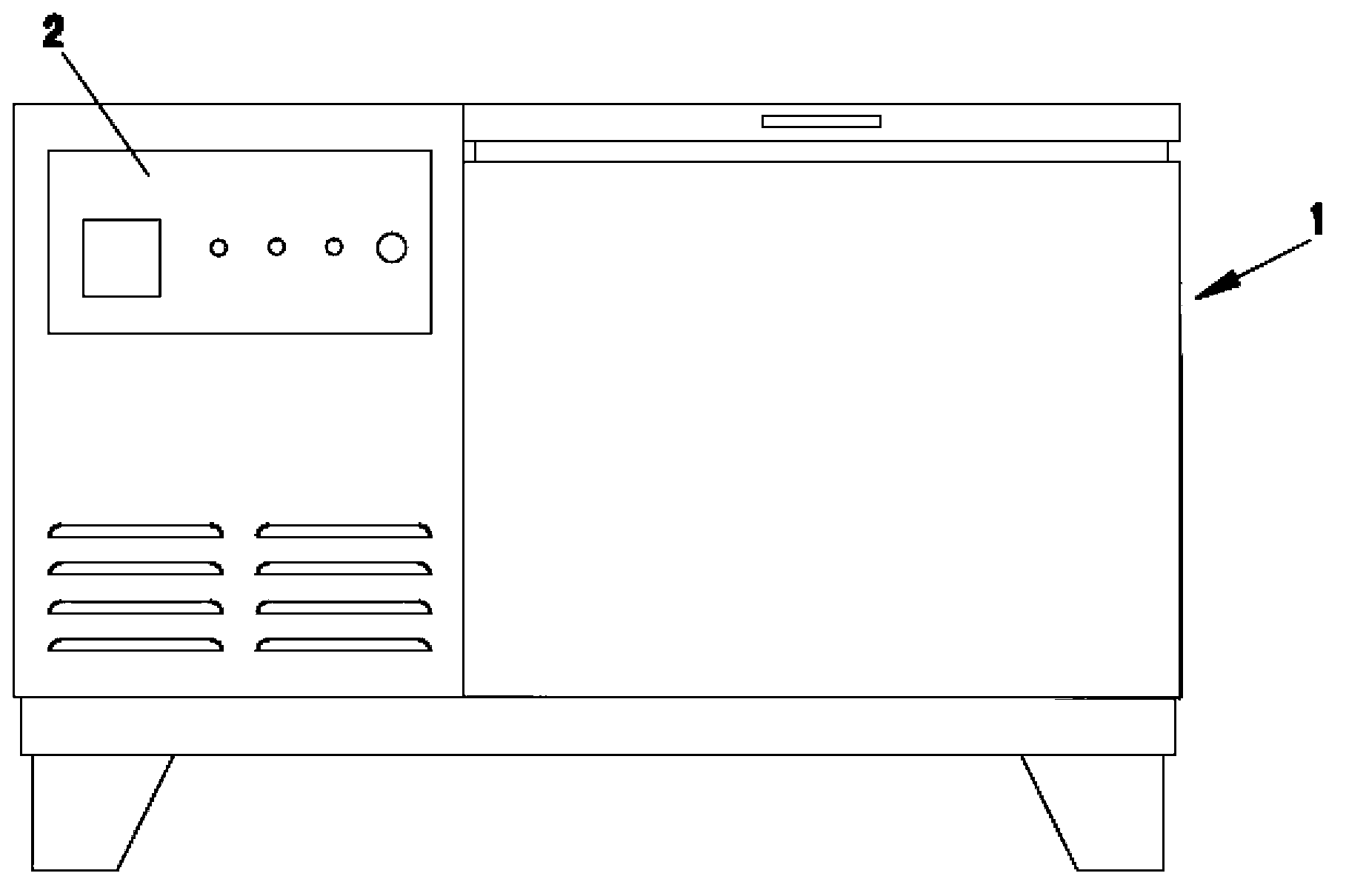

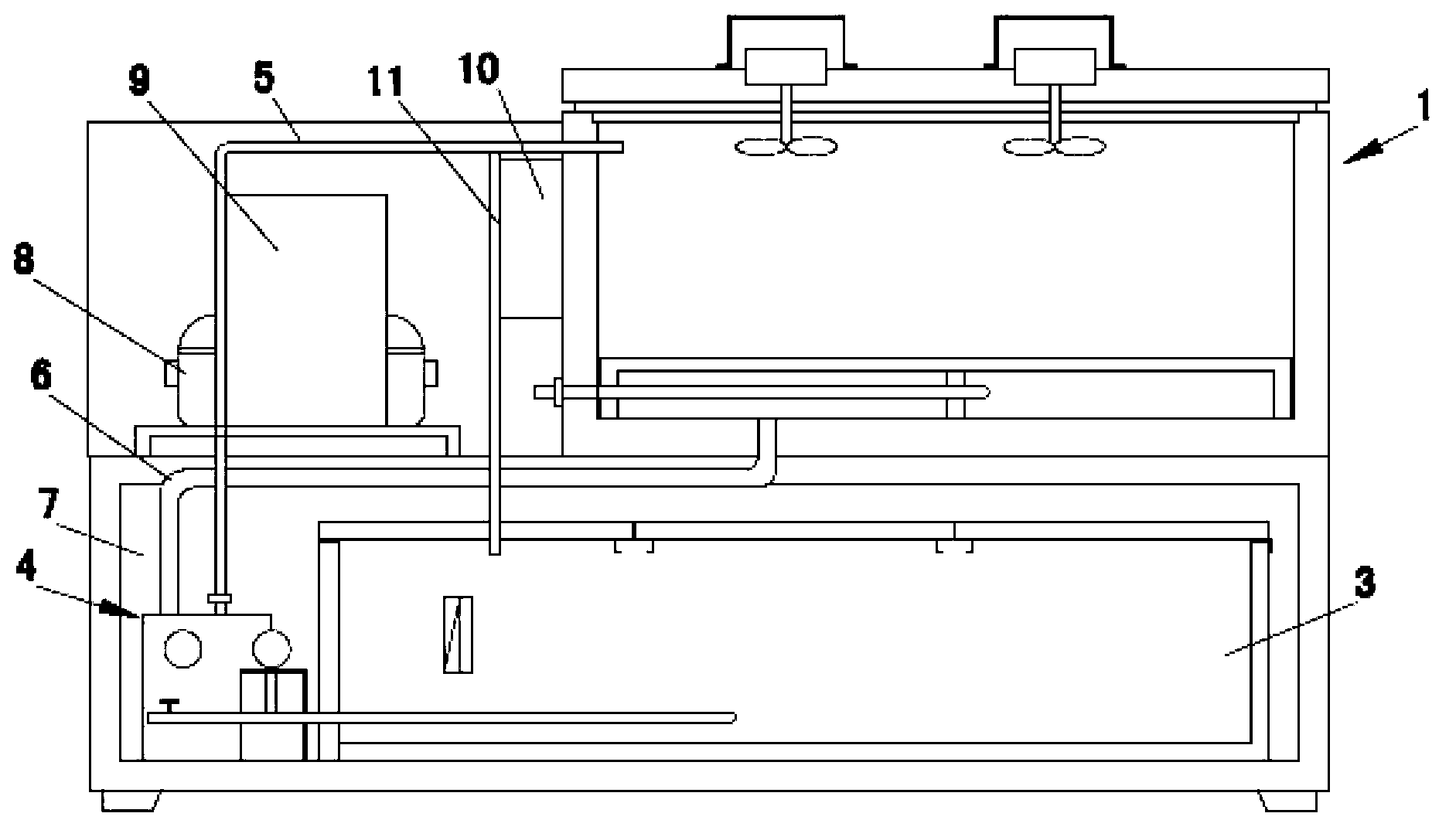

Constant-temperature constant-humidity test chamber

InactiveCN103048428ASimple structureSimple manufacturing and assemblyMaterial analysisTest sampleEngineering

The invention discloses a constant-temperature constant-humidity test chamber comprising a case body inside which a working chamber, a refrigerating component, a heating component, a humidifying component and an electrical component are arranged. The test chamber further comprises a circulating air system, the circulating air system is arranged at the top of the case body, an air outlet is formed at the top of the case body, the working chamber is arranged inside the case body and positioned at the rear part of the door of the case body, a test sample holder is arranged inside the working chamber, the test sample holder comprises a plurality of horizontal grid plates which are arranged with a certain distance from up down inside the working chamber, an air supply passage and a return air passage are formed on two sides of the test sample holder, and the heating component is arranged beside the air outlet which is formed at the top of the case body. The constant-temperature constant-humidity test chamber has a simple structure, is convenient for fabrication and assembly, reduces the running cost during use, and has a long service life, and high precision of temperature and humidify control.

Owner:SUZHOU DONGHUA TESTING INSTR

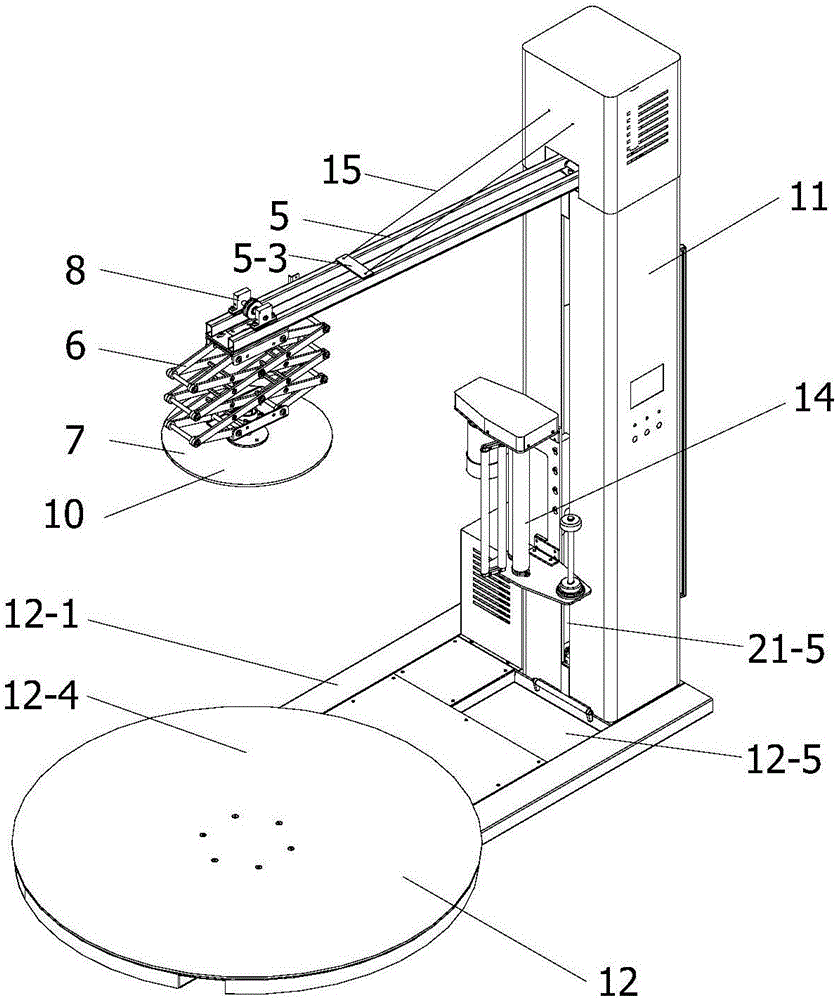

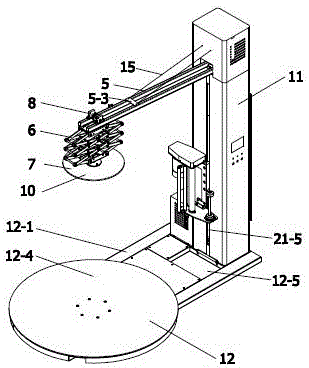

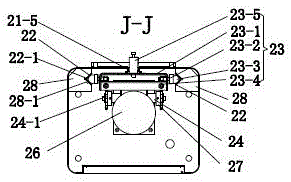

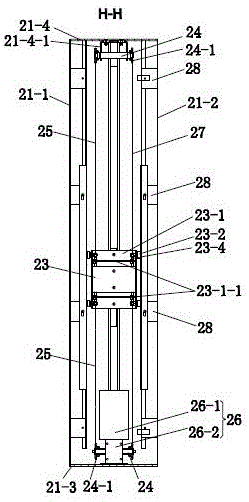

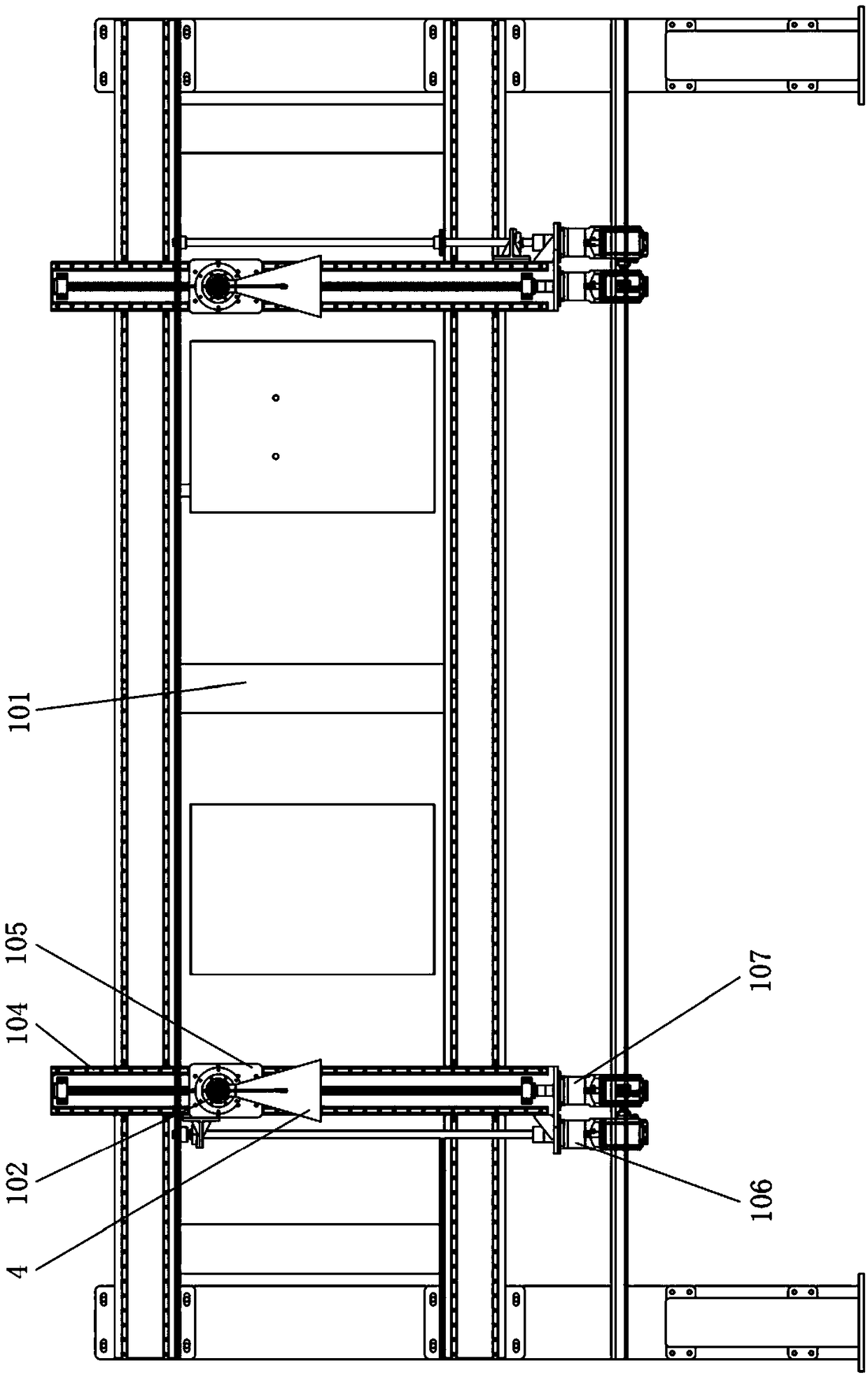

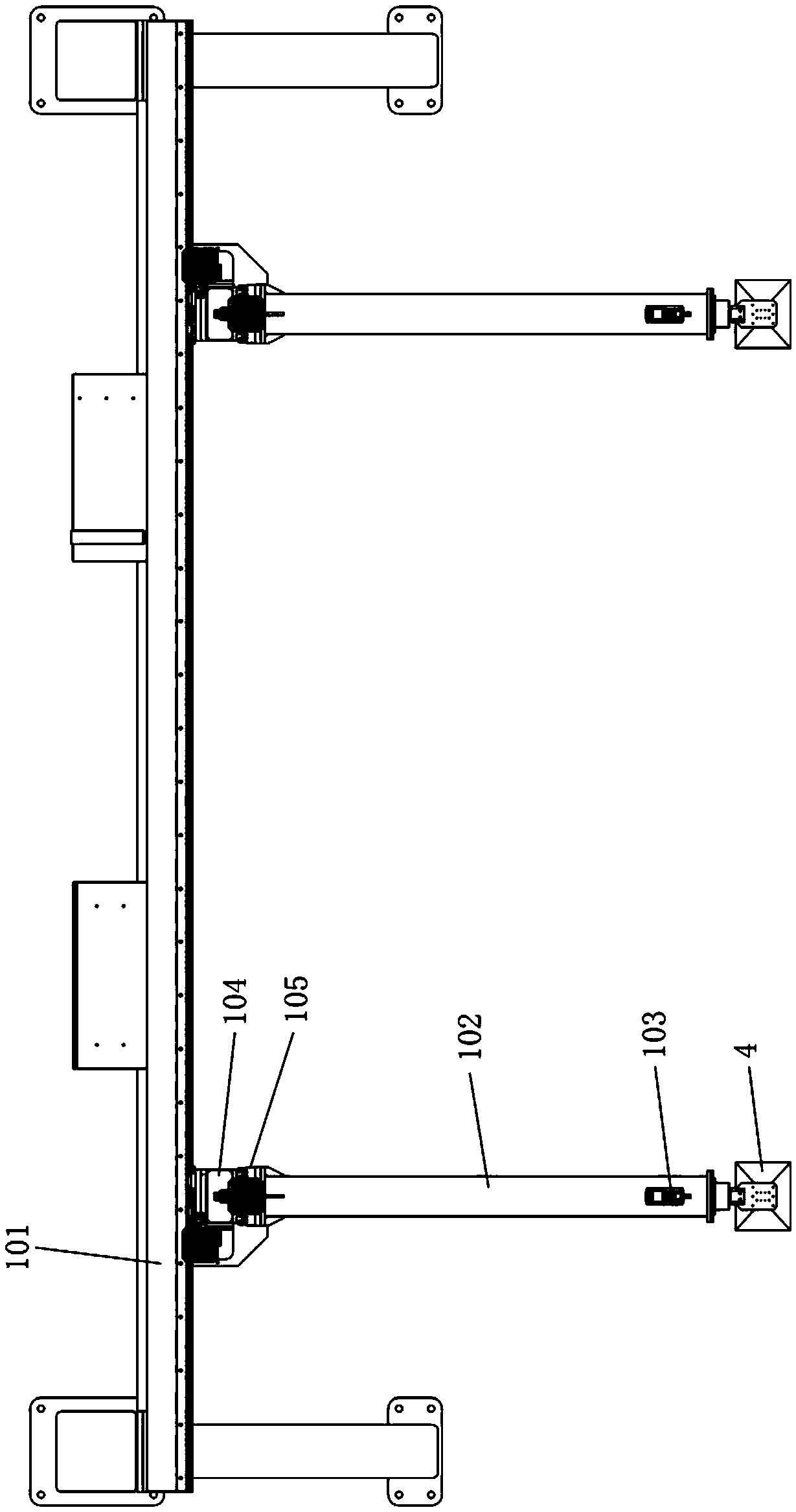

winding machine

ActiveCN105691687BExtended service lifeImprove reliabilityWrapping with article rotationWinding machineEngineering

A winding machine is provided with a top pressing mechanism, a stand column and a base plate. The stand column is mounted on the base plate. The top pressing mechanism is mounted on the upper portion of the stand column and is provided with a drive mechanism, a support and a top pressing disc. The stand column is provided with a shell. A drive mechanism, a transmission mechanism and a slip trolley are mounted in the shell. The slip trolley comprises a lifting slip plate, ball sockets and rolling balls. The two sides of the lifting slip plate are each provided with the corresponding ball sockets. One side of each rolling ball is located in the corresponding ball socket, and the other side of each rolling ball is located in a corresponding guide groove of a guide rail. The corresponding drive mechanism is in transmission connection with the slip trolley through the transmission mechanism to drive the slip trolley to ascend and descend. The top pressing mechanism is easier to manufacture and assemble, mechanism operation is easier, the service life is longer, and reliability is higher. In the stand column of the winding machine, original multiple pairs of guide wheels are replaced with the rolling balls, so that the structure is simple, the production cost is low, the service life of the stand column is longer, and reliability is higher.

Owner:常州光明包装机械有限公司

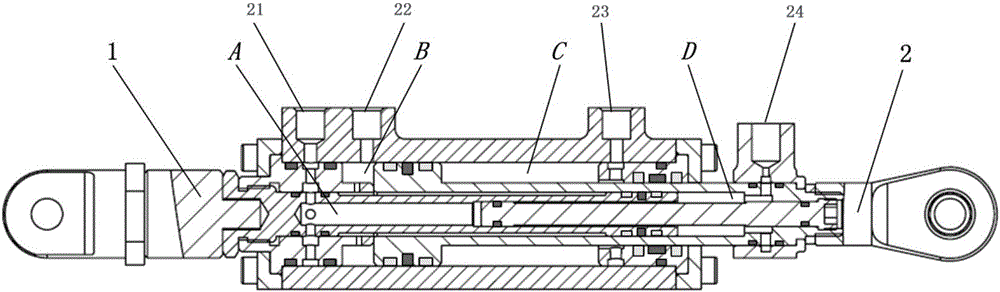

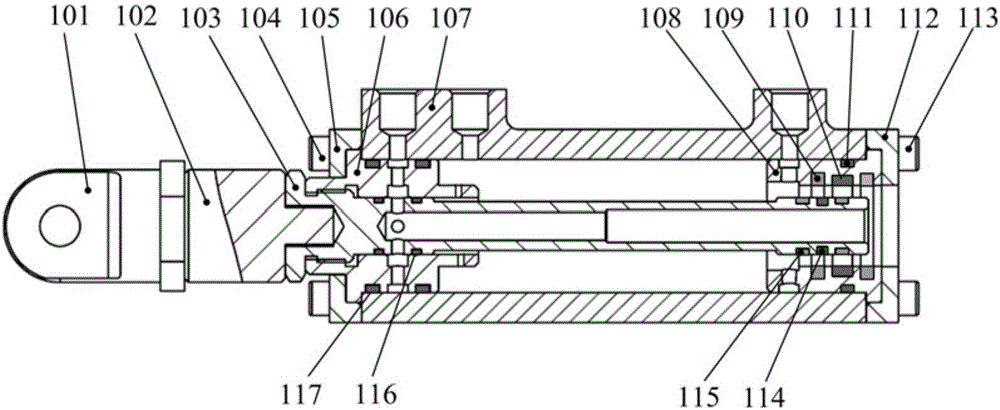

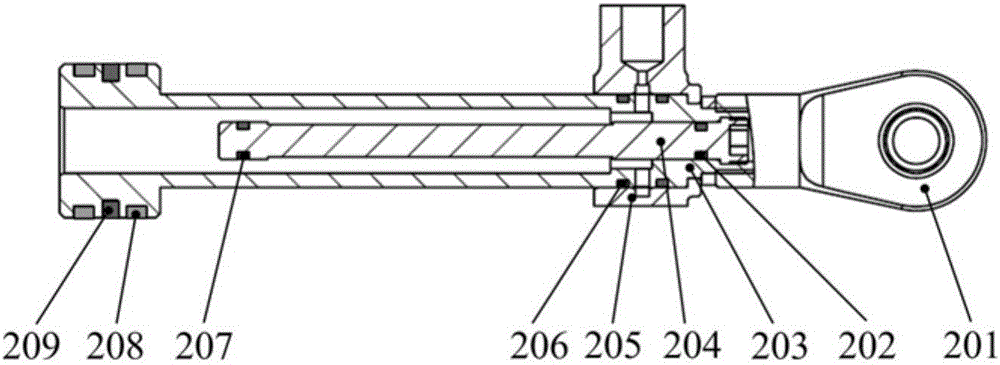

Multi-cavity hydraulic cylinder and control system and method thereof

ActiveCN105782164AImprove efficiencyRealize energy saving and environmental protectionServomotorsHydraulic cylinderCarrying capacity

Disclosed is a multi-cavity hydraulic cylinder. The multi-cavity hydraulic cylinder comprises a combined cylinder barrel and a combined piston rod. The cylinder barrel and the piston rod form four enclosed cavities A, B, C and D. According to a hydraulic cylinder control system and method, the system comprises four plug-in type two-position three-way electromagnetic switch valves connected with the four cavities of the multi-cavity hydraulic cylinder and a proportional throttle valve connected with four electromagnetic switch valves. By controlling the two-position three-way electromagnetic switch valves and a three-position four-way servo valve which is the proportional throttle valve, whether the four enclosed cavities A, B, C and D communicate with an oil outlet P and an oil tank oil return port T of a pump or not can be selected, and therefore, different effective action areas are obtained. A carrying capacity sensor is arranged on the piston rod and used for measuring loads on the piston rod in real time, that is to say, loads of the multi-cavity hydraulic cylinder. According to load feedback, through control over the group of electromagnetic switch valves and a servo valve group, the appropriate effective action areas are selected, match of the maximum output force and the carrying capacity of the hydraulic cylinder is achieved, and finally, high-precision position or force control is achieved through a proportional throttle function of the servo valve.

Owner:NAT UNIV OF DEFENSE TECH

Winding machine

ActiveCN105691687AExtended service lifeImprove reliabilityWrapping with article rotationWinding machineEngineering

A winding machine is provided with a top pressing mechanism, a stand column and a base plate. The stand column is mounted on the base plate. The top pressing mechanism is mounted on the upper portion of the stand column and is provided with a drive mechanism, a support and a top pressing disc. The stand column is provided with a shell. A drive mechanism, a transmission mechanism and a slip trolley are mounted in the shell. The slip trolley comprises a lifting slip plate, ball sockets and rolling balls. The two sides of the lifting slip plate are each provided with the corresponding ball sockets. One side of each rolling ball is located in the corresponding ball socket, and the other side of each rolling ball is located in a corresponding guide groove of a guide rail. The corresponding drive mechanism is in transmission connection with the slip trolley through the transmission mechanism to drive the slip trolley to ascend and descend. The top pressing mechanism is easier to manufacture and assemble, mechanism operation is easier, the service life is longer, and reliability is higher. In the stand column of the winding machine, original multiple pairs of guide wheels are replaced with the rolling balls, so that the structure is simple, the production cost is low, the service life of the stand column is longer, and reliability is higher.

Owner:常州光明包装机械有限公司

Piezoelectric generating device based on stair

InactiveCN103178747AAvoid pedaling impactAvoid direct contactPiezoelectric/electrostriction/magnetostriction machinesEngineeringCopper

The invention discloses a piezoelectric generating device based on a stair. The piezoelectric generating device based on the stair comprises two parts, namely a rotor and a stator, wherein the rotor consists of a pedal (6) and positioning pins (5) linked on the pedal (6), and is arranged above the stator; the stator consists of a base plate (1), supporting and limiting strips (2), springs (3) and piezoelectric generating units (4); the supporting and limiting strips (2), the springs (3) and the piezoelectric generating units (4) are mounted on the base plate (1); each piezoelectric generating unit (4) consists of an upper press plate (48), a T-shaped elastic rod (45), a driving press block (46) arranged at the upper side of the T-shaped elastic rod (45) near the upper press plate (48), a driven press block (44) arranged at the end part of the lower side of the T-shaped elastic rod (45), a supporting board A (40), a supporting board B (49), a linkage piece (47), a copper pole plate (42), an piezoelectric ceramic piece A (41) and a piezoelectric ceramic piece B (42); the piezoelectric ceramic piece A (41) and the piezoelectric ceramic piece B (42) are adhered to the upper face and the lower face of the copper pole plate (42); and the piezoelectric generating units (4) are fixed on the upper surface of the base plate (1) through the linkage pieces (47).

Owner:SUZHOU UNIV OF SCI & TECH

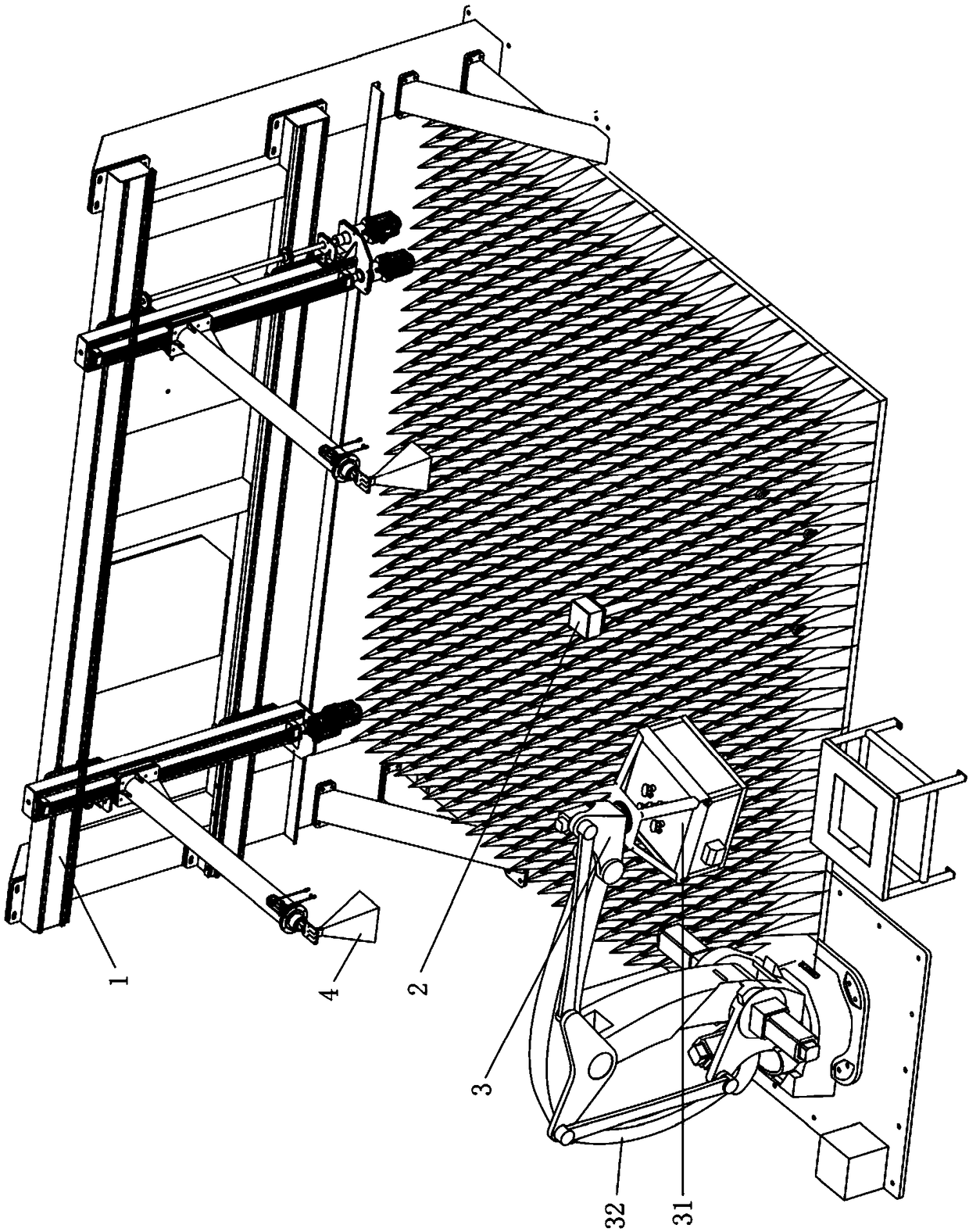

System and method for testing reflectivity of wave-absorbing material

ActiveCN109507212ASimple structureLow costMaterial analysis using microwave meansVertical planeTest sample

The invention discloses a system and method for testing reflectivity of a wave-absorbing material. The reflectivity testing system comprises an incident angle adjusting device, a workpiece bearing platform and a correlation antenna, wherein the incident angle adjusting device comprises a bracket, a cantilever and a rotary drive part; the cantilever is mounted on the bracket by virtue of a verticalsurface automatic displacement component and can be driven to move in a vertical plane by the vertical surface automatic displacement component; the rotary drive part is mounted on the cantilever; the correlation antenna is connected with a drive end of the rotary drive part and can be driven to rotate around a horizontal axis by the rotary drive part. The testing method comprises the following steps: driving a heating furnace to move by a manipulator, enabling the workpiece bearing platform to stretch into a furnace mouth, opening the heating furnace to heat to-be-tested sample plates and maintain the temperature, driving the heating furnace to move by the manipulator so as to enable the heating furnace to be far away from the workpiece bearing platform, and opening the correlation antenna to test the reflectivity. The system disclosed by the invention has the advantages of being simple in structure, low in cost, stable and reliable in operation, high in regulation precision, long inservice life, easy to manufacture and assemble and the like.

Owner:CHANGSHA JINGYOU NEW MATERIAL TECH CO LTD

Desktop Industrial Robot

ActiveCN103978476BAvoid couplingFlexible working statusProgramme-controlled manipulatorReducerEngineering

The invention discloses a desktop industrial robot. According to the desktop industrial robot, a first driving motor is vertically arranged in a base frame, is reduced by the first reducer in speed and then drives a big-arm turntable and a big-arm base bracket to do 360-degree rotary motion through a main transmission connecting disc, a big-arm rotating shaft which is horizontally arranged is mounted on the big-arm base bracket, a second driving motor is arranged at one end of the big-arm rotating shaft, is reduced by the second reducer in speed and then drives a big arm and a motor mounted hanging plate to synchronously swing through the big-arm rotating shaft, the big arm and the motor mounted hanging plate are respectively extended upwardly and are parallel to each other, a third driving motor is horizontally arranged on the motor mounted hanging plat, is reduced by the third reducer in speed and then drives a connecting rod to swing, the upper end of the connecting rod is hinged to the rear end of a small arm, the front end of the small arm is used for mounting a mechanical claw, and the upper end of the big arm is hinged to a position, close to the rear end of the small arm, of the small arm. The desktop industrial robot has the advantages of simple structure, convenience in machining and higher flexibility.

Owner:重庆市口天科技有限公司

Gear transmission shaft device

InactiveCN104315111AExtended service lifeSimple structurePortable liftingTransmission elementsDrive shaftEngineering

The invention relates to a gear transmission shaft device. The gear transmission shaft device comprises a box body and a gear transmission shaft which is arranged in the box body, and is characterized in that the gear transmission shaft consists of a gear, a large shaft and a small shaft, the gear transmission shaft is sequentially provided with a cylindrical roller bearing, a spacing sleeve, a conical roller bearing A, a spacing ring and a conical roller bearing B, which are tightened onto the gear transmission shaft; a convex ring of an inner cavity of the box body is provided with a spring concave cavity for installing a spring and a circumferential annular groove which is provided with a retainer ring. The gear transmission shaft device is simple in structure and easy to manufacture and assemble; by adopting the supporting of the cylindrical roller bearing and two back-to-back conical roller bearings, the gear transmission shaft can bear large radial force and axial force at the high rotation speed, the gear transmission has good engagement characteristics, the transmission efficiency of the gear transmission shaft is improved, the service life of the gear transmission shaft is prolonged, the application and maintenance expense of the gear transmission shaft device is reduced, and the reliability and economical performance are good.

Owner:HUNAN NANFANG AVIATION HIGH ACCURATE DRIVE

Industrial joint robot body

ActiveCN103978483AAvoid couplingFlexible working statusProgramme-controlled manipulatorMotor driveDrive motor

The invention discloses an industrial joint robot body. The industrial joint robot body is characterized in that a base frame is internally and vertically provided with a first driving motor, the first driving motor drives a big arm rotating disk and a big arm base support to do 360-degree rotational motion through a main transmission connecting disk after the first driving motor is decelerated by a first speed reducer, the big arm base support is provided with a big arm rotating shaft which is horizontally arranged, one end of the big arm rotating shaft is provided with a second driving motor, the second driving motor drives a big arm and a motor installation hanging plate to swing synchronously through the big arm rotating shaft after the second driving motor is decelerated by a second speed reducer, the big arm and the motor installation hanging plate respectively and upwards stretch and are parallel to each other, the motor installation hanging plate is horizontally provided with a third driving motor, the third driving motor drives a connecting rod to swing after the third driving motor is decelerated by a third speed reducer, the upper end of the connecting rod is hinged to the rear end of a small arm, the front end of the small arm is used for installing a mechanical gripper, and the upper end of the big arm is hinged to a position, which is close to the rear end, on the small arm. The industrial joint robot body disclosed by the invention has the advantages that the structure is simple, the processing is convenient, and the flexibility is higher.

Owner:重庆市口天科技有限公司

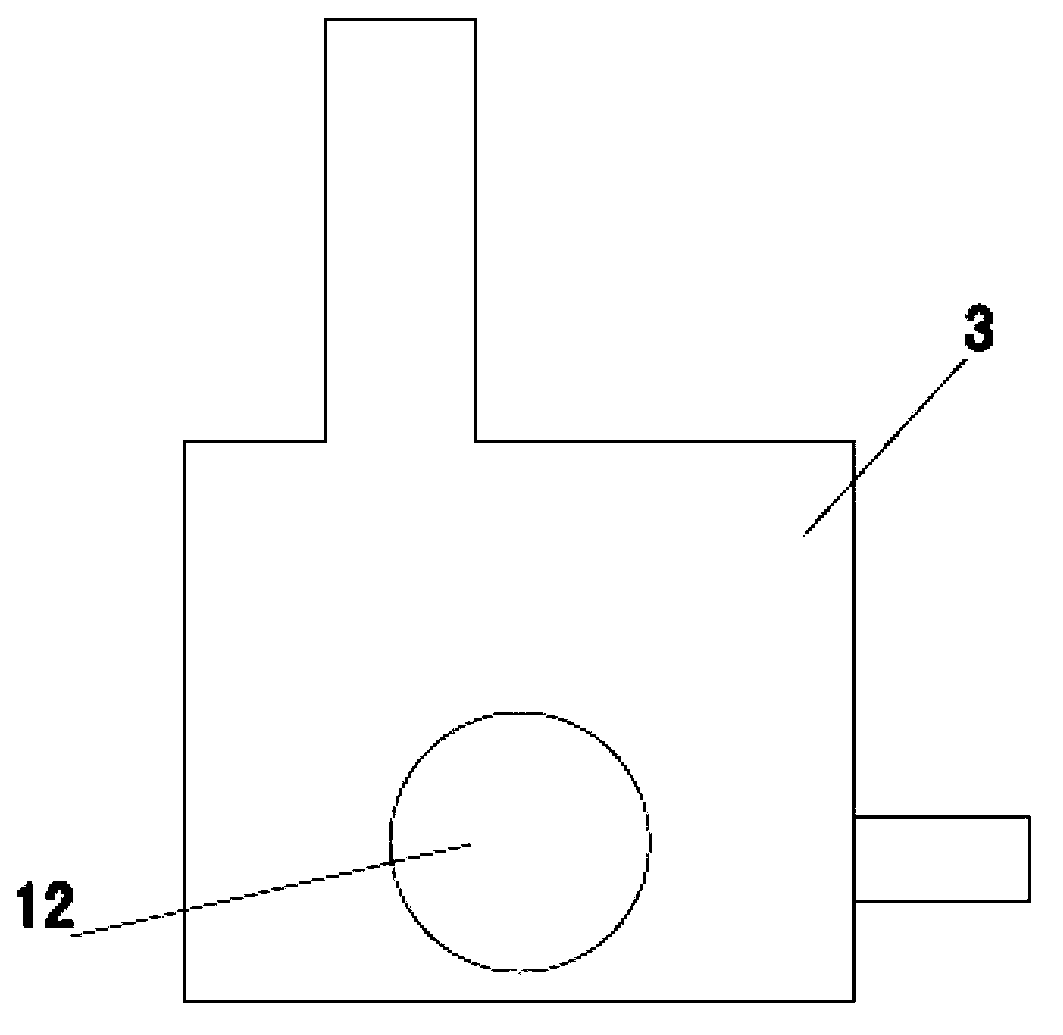

Freezing-thawing test machine with blowdown device

The invention relates to a freezing-thawing test machine with a blowdown device. The freezing-thawing test machine comprises a test piece box, a control cabinet, a water tank, a cycle water pump and a refrigeration system. The control cabinet is disposed at the side of the test piece box, the refrigeration system is also disposed at the side of the test piece box, the water tank is disposed under the test piece box, the side wall of the test piece box is provided with a box body water inlet pipe, the bottom of the test piece box is provided with a box body water outlet pipe, the box body water inlet pipe and the box body water outlet pipe are communicated with the water tank through the cycle water pump, and the test piece box also comprises a filter tank which is disposed between the box body water outlet pipe at the bottom of the test piece box and the cycle water pump. By additionally arranging the filter box between the test piece box and the cycle water pump, water flowing out of the test piece tank need to firstly pass through the filter tank and then enter into the cycle water pump, thereby guaranteeing the cycle water pump not to be blocked and prolonging the service life of the cycle water pump.

Owner:SUZHOU DONGHUA TESTING INSTR

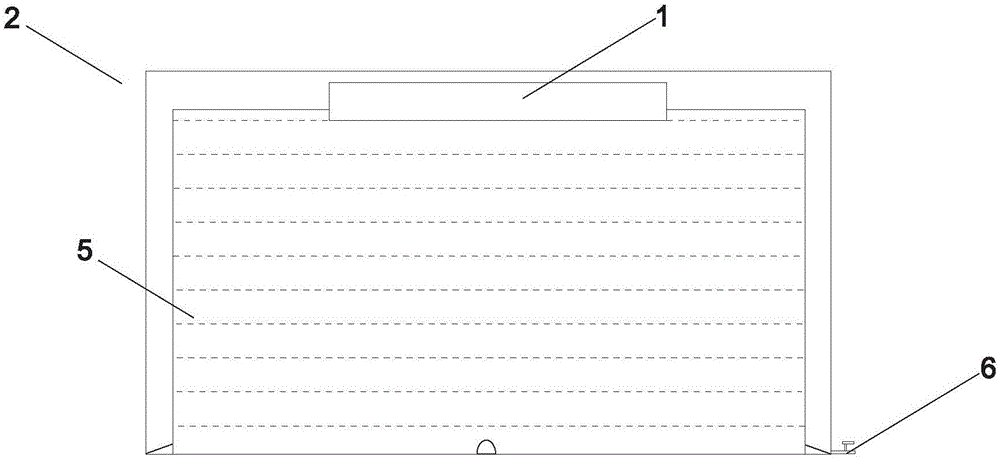

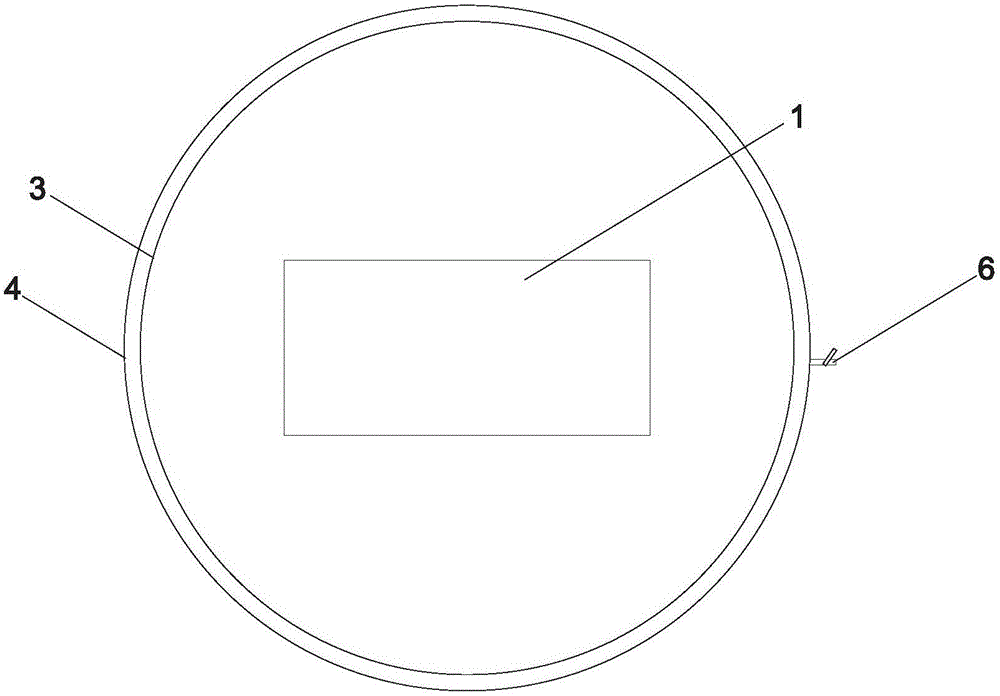

Vibration test method for mobile phone vibration motors

ActiveCN106248329AEasy to operateSimple manufacturing and assemblySubsonic/sonic/ultrasonic wave measurementVibration testingEngineeringUltimate tensile strength

The invention discloses a vibration test method for mobile phone vibration motors, comprising the following steps: making a test tool, wherein the test tool includes a mobile phone simulation tool and a double-layer container cup, the double-layer container cup includes an inner cup and an outer cup which are concentric, and the mouth of the inner cup is lower than the mouth of the outer cup; installing a mobile phone vibration motor to be tested on the mobile phone simulation tool, and filling the inner cup with test liquid; stably placing the mobile phone simulation tool on the surface of the test liquid in the inner cup, keeping the mobile phone simulation tool afloat, and discharging the test liquid overflowing into the outer cup; and starting the mobile phone vibration motor, and when the surface of the test liquid in the inner cup is stable, measuring the amount of liquid discharged to the outer cup after the start of the mobile phone vibration motor. According to the invention, the vibration strength of the mobile phone vibration motor is measured by the amount of liquid discharged to the outer cup, devices for implementing the method are simple, easy to manufacture and assembly and very low in purchase cost, the test result can be obtained only by measuring the amount of liquid in the outer cup, operation is convenient, and the test result can be read visually.

Owner:ZHEJIANG DONGYANG CHENGJI ELECTRO MECHANICS CO LTD

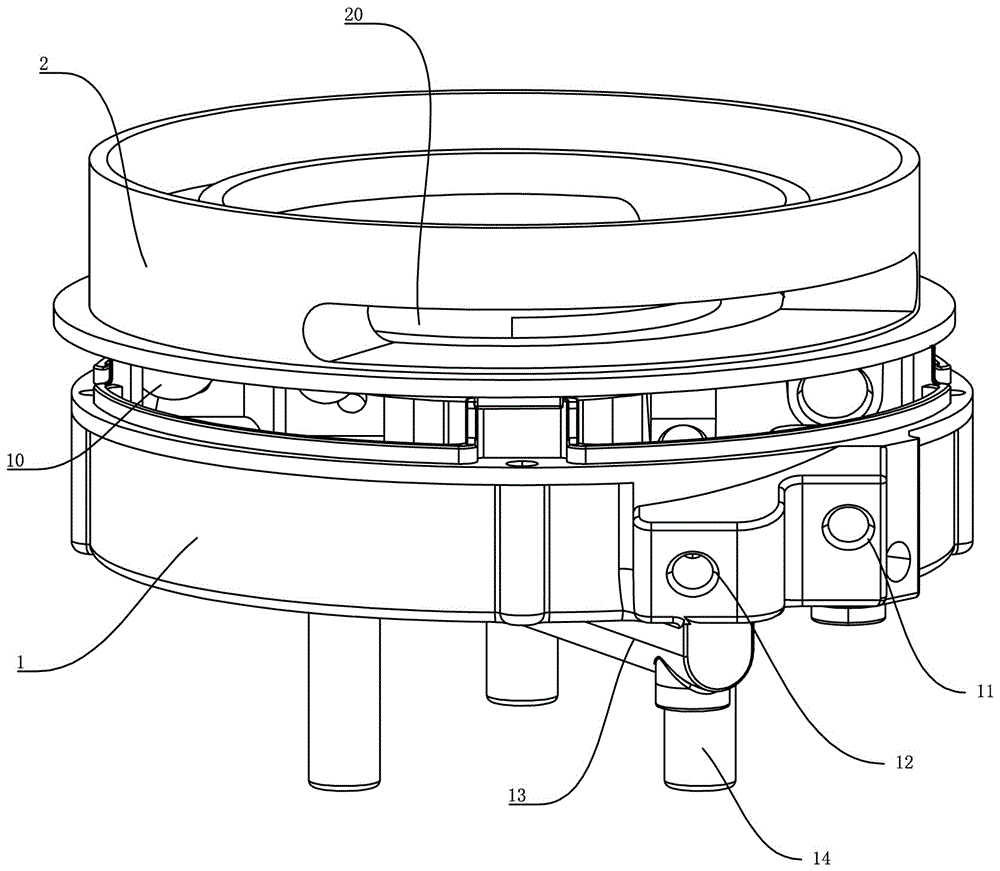

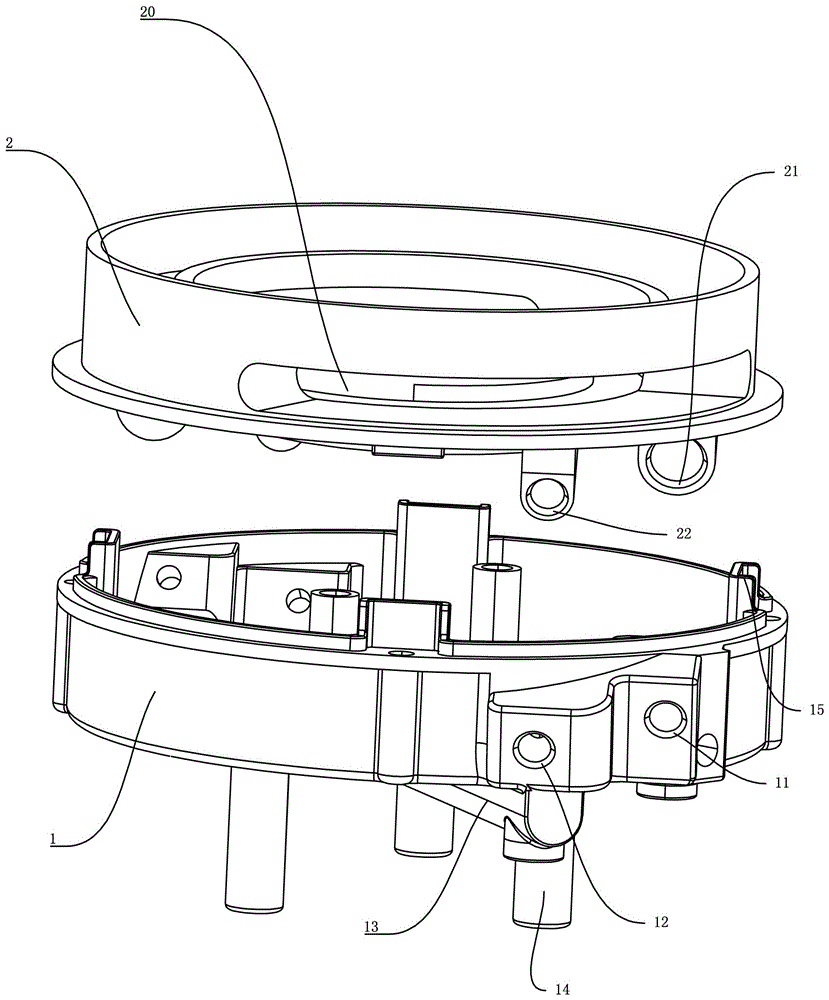

Two-translation one-rotation partial decoupling parallel mechanism

ActiveCN109571444ASimple structureSimple manufacturing and assemblyProgramme-controlled manipulatorNon symmetricEngineering

The invention provides a two-translation one-rotation partial decoupling parallel mechanism. The parallel mechanism comprises a movable platform, a fixed platform and a plurality of moving branched chains used for connecting the movable platform and the fixed platform; the plurality of moving branched chains comprise a first moving branched chain, a second moving branched chain and a third movingbranched chain, the first moving branch chain and the third moving branch chain are symmetrically arranged on the two sides of the movable platform and the fixed platform respectively, the second moving branch chain is arranged between the first moving branch chain and the third moving branch chain, the first moving branch chain and the third moving branch chain comprise upper connecting rods, middle connecting rods and lower connecting rods; the second moving branched chain comprises then upper connecting rod and the lower connecting rod. The translation and rotation parallel mechanism has the advantages of being simple in structure, easy to manufacture and assemble, high in transmission precision and low in cost. The mechanism belongs to an asymmetric parallel mechanism and is large in working space and good in motion flexibility compared with a symmetric parallel mechanism.

Owner:YANSHAN UNIV

Two-time upside-entrainment burner

ActiveCN106369603APrevent leakageIncrease air intakeGaseous fuel burnerEngineeringThermocouple device

The invention discloses a two-time upside-entrainment burner. The two-time upside-entrainment burner comprises a base and a support. Both the base and the support are integrally formed. The support is arranged on the base. Primary air inlets are formed between the base and the support. A thermocouple is arranged on the base. Outer air inlet nozzles and inner air outlet nozzles are obliquely arranged on the base. Outer ejecting pipes and inner injecting pipes are obliquely arranged on the support. The support is provided with an outer annular groove, a middle annular groove and an inner annular groove, wherein the outer annular groove communicates with the outer air inlet nozzles through the outer ejecting pipes, and the inner annular groove communicates with the inner air inlet nozzles through the inner ejecting pipes. The support is provided with a secondary air inlet which communicates with the middle annular groove. According to the two-time upside-entrainment burner, air input is large, an ejecting pipeline is long, and fuel gas is evenly mixed with air and can be burnt sufficiently; and the thermocouple is arranged on the base so that fuel gas leakage can be prevented. Furthermore, the base and the support are integrally formed, so that manufacturing and assembling are easy and convenient.

Owner:NINGBO FENGTENG GAS APPLIANCE CO LTD

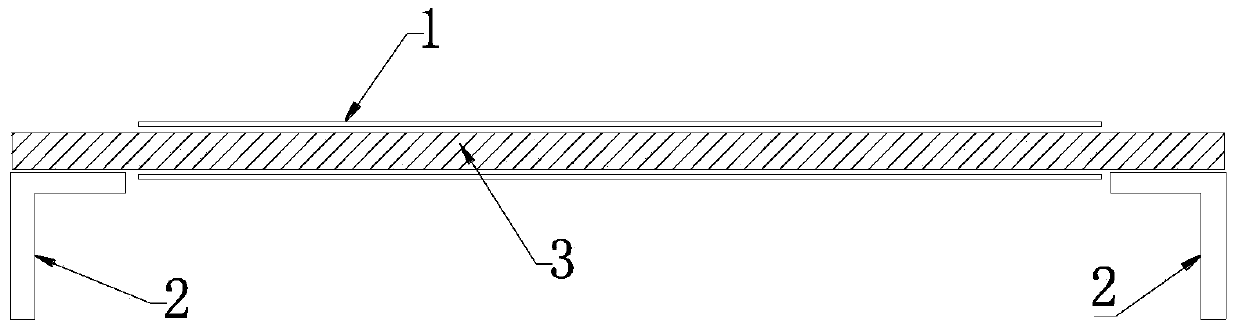

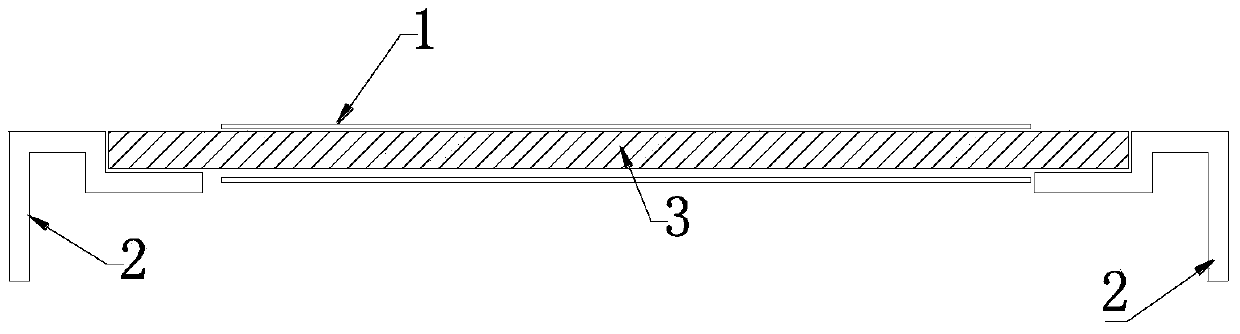

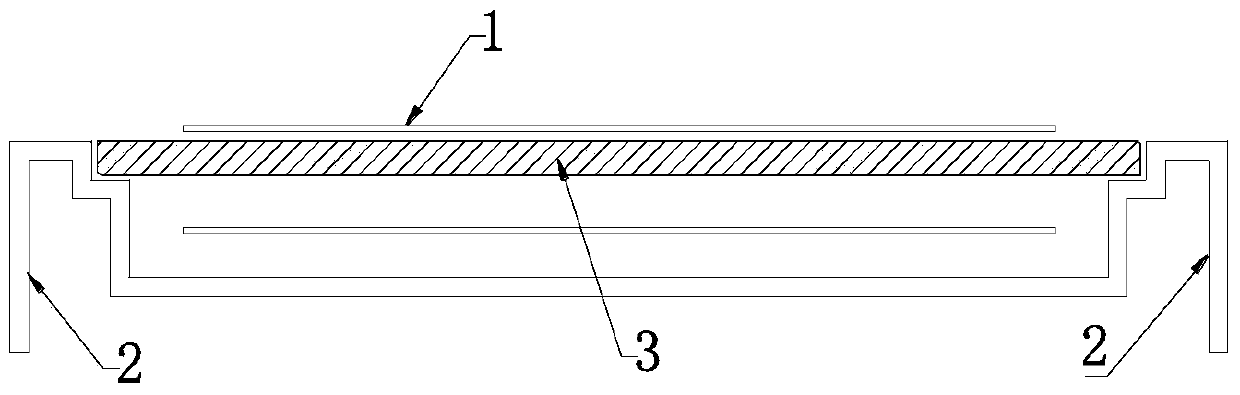

Manufacturing method of treadmill base and treadmill base structure

InactiveCN103736248AOvercome the disadvantages of complex structureLower skill requirementsMovement coordination devicesCardiovascular exercising devicesBiochemical engineeringPlastic materials

The invention provides a manufacturing method of a treadmill base and a treadmill base structure. The treadmill base is manufactured by means of integral forming. The manufacturing method is simpler for manufacturing and assembling as compared to existing welding processes, large-scale integral manufacturing is achieved, and production efficiency is higher. The treadmill base has such advantages that the base can be made of plastic material, the cost is lower, the weight is lighter and the base is convenient to transport and carry. Structurally a support or a pedal and a support in the treadmill base are designed into an integral formed structure, so that the defect that the existing treadmill base is complex in structure is overcome, high cost of welding assembly is saved, environmental pollution is reduced, the requirements on skill of personnel are low, assembly is simple and manufacturing cost is low.

Owner:深圳市畅为工业设计有限公司

Tundish car installation method for ultrathin strip production line

InactiveCN108380861AAdvanced production technologyPrecise dockingMelt-holding vesselsProduction lineDrive wheel

The invention specifically provides a tundish car installation method for an ultrathin strip production line. The tundish car installation method comprises the following installation steps that the elevation, the center line and the levelness of a rail on the side of a driving wheel are inspected and adjusted, and a buffer is positioned and installed according to requirements of a drawing; two tundish cars are assembled on the ground correspondingly; a main hook, crossing a travelling crane, of a casting machine is used for lifting the two tundish cars to the rail correspondingly, the tundishcar on the transmission side and the tundish car on the work side are arranged in place according to the requirements of the drawing, and the gap between a wheel body of the driving wheel and the railis measured; lead screw bearing seats on the transmission side and the work side of the tundish cars are detached, a loading arm is installed in place, the lead screw bearing seats are recovered, thegap among a loading arm upper rail, a loading arm lower rail and a guide rail is adjusted, and a loading arm synchronous transmission mechanism is installed; and a tundish car drag chain system is installed, and accessory installation of body piping is improved. By means of the installation method, time and the construction cost can be saved, and the casting precision requirement can also be metat the same time on the premise that the construction progress is met to the maximum degree.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD +1

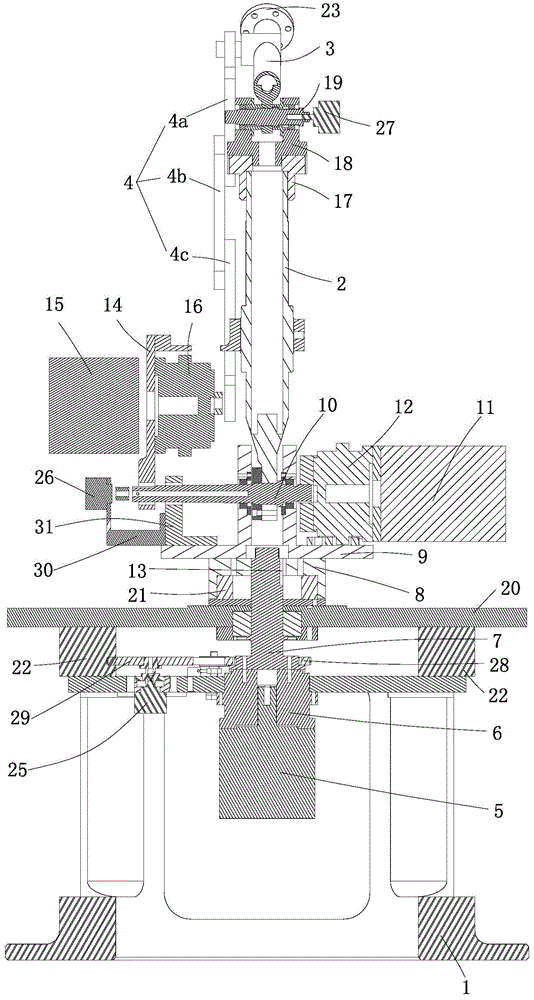

Three forks rod axial plunger pump

InactiveCN101042123AImprove performanceSimple structurePositive-displacement liquid enginesMulti-cylinder pumpsDrive shaftAngular velocity

It relates to an equal angular velocity, high efficient and high pressure three fork arm horizontal plunger pump, with the drive shaft horizontally passing through the oil distribution pan and the cylinder and moving with the cylinder, the oil distribution pan included between the cylinder and the shell, fixed by the positioning screw, two oil compression hole and oil drawing hole on the oil distribution pan connecting with the inlet and outlet respectively, cylindrical roller bearing and center adjusting spherical support drive shaft preventing the deviation of the drive shaft, cylindrical roller bearing is the support for the cylinder, passive shaft joint having three radial fork arm at one end within 120 degree, with each fork arm having concentrated joint bearing, the other end of the passive bearing center having cylindrical inner hole, with simple structure, synchronic feature, high efficiency, low cost, easy manufacturing and assembly.

Owner:QINGDAO UNIV OF SCI & TECH

Two-gear automatic transmission for pure electric vehicles

ActiveCN104565264ACompact structureLight in massElectric propulsion mountingToothed gearingsAutomatic transmissionElectric machine

Disclosed is a two-gear automatic transmission for pure electric vehicles. The two-gear automatic transmission is characterized by comprising an input shaft, a first intermediate shaft, a second intermediate shaft, a first cylindrical gear pair, a second cylindrical gear pair, a third cylindrical gear pair, a first torque transmission device, a second torque transmission device and a differential assembly; rotary center lines of the input shaft, the second intermediate shaft and the differential assembly are parallel to one another. The two-gear automatic transmission solves the problem that the existing two-gear automatic transmission for pure electric vehicles has high requirements on a driving motor and a battery, the driving motor is low in operational efficiency and the like, and power performance and economical efficiency of the pure electric vehicles are improved.

Owner:BEIHANG UNIV

Top pressing mechanism of winding machine

ActiveCN105668326AEasy to operateExtended service lifeFilament handlingFunction indicatorsWinding machineDrive wheel

The invention discloses a top pressing mechanism of a winding machine. The top pressing mechanism comprises a drive mechanism, a bracket and a top pressing plate, and further comprises a mounting base, a main shaft, a driven wheel and a telescoping mechanism as well as a traction rope, wherein the main shaft is mounted on the mounting base, and one end of the main shaft is connected to the drive mechanism; the drive mechanism can drive the main shaft to rotate; a driven wheel is fixedly connected on the main shaft; one end of the bracket is fixedly connected to the mounting base; the other end of the bracket is fixedly connected to the upper part of the telescoping mechanism; the other end of the bracket is further provided with a steering mechanism; the lower part of the telescoping mechanism is connected to the top pressing plate; one end of the traction rope is fixedly connected to the main shaft or the driven wheel; and the other end of the traction rope is fixedly connected to the lower part of the telescoping mechanism after being steered along a steering wheel. The top pressing mechanism is simpler to manufacture and assemble, and simpler to operate; self-weight type top pressing is adopted, so that the pressure of the top pressing mechanism is always kept constant and pressure exceeding expectation is not generated, and therefore, the service life of the machine is longer, and the reliability is higher.

Owner:常州光明包装机械有限公司

Industrial table type mechanical arm

ActiveCN103978480AAvoid couplingFlexible working statusProgramme-controlled manipulatorMotor driveElectric machinery

The invention discloses an industrial table type mechanical arm. The industrial table type mechanical arm is characterized in that a base frame is internally and vertically provided with a first driving motor, the first driving motor drives a big arm rotating disk and a big arm base support to do 360-degree rotational motion through a main transmission connecting disk after the first driving motor is decelerated by a first speed reducer, the big arm base support is provided with a big arm rotating shaft which is horizontally arranged, one end of the big arm rotating shaft is provided with a second driving motor, the second driving motor drives a big arm and a motor installation hanging plate to swing synchronously through the big arm rotating shaft after the second driving motor is decelerated by a second speed reducer, the big arm and the motor installation hanging plate respectively and upwards stretch and are parallel to each other, the motor installation hanging plate is horizontally provided with a third driving motor, the third driving motor drives a connecting rod to swing after the third driving motor is decelerated by a third speed reducer, the upper end of the connecting rod is hinged to the rear end of a small arm, the front end of the small arm is used for installing a mechanical gripper, and the upper end of the big arm is hinged to a position, which is close to the rear end, on the small arm. The industrial table type mechanical arm disclosed by the invention has the advantages that the structure is simple, the processing is convenient, and the flexibility is higher.

Owner:重庆科博蓄电池有限公司

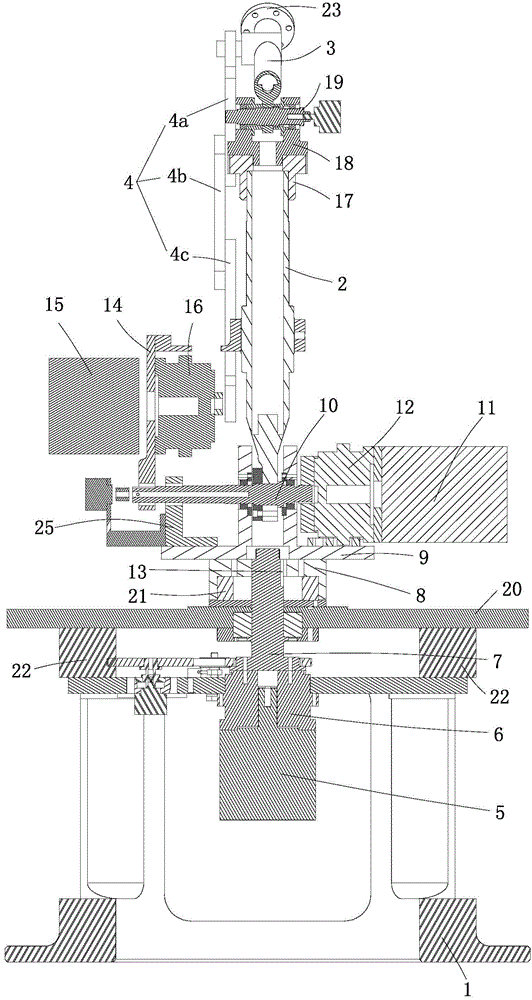

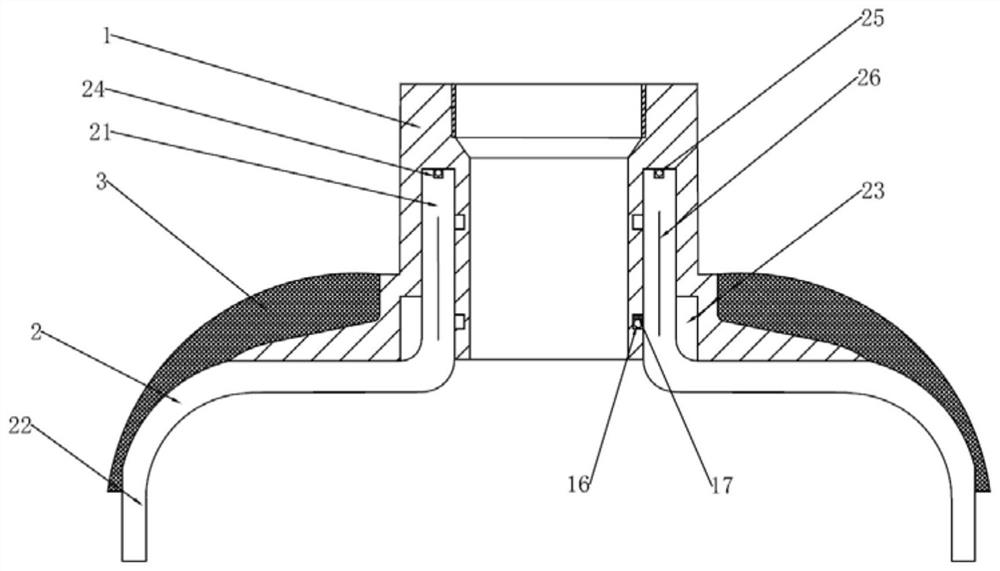

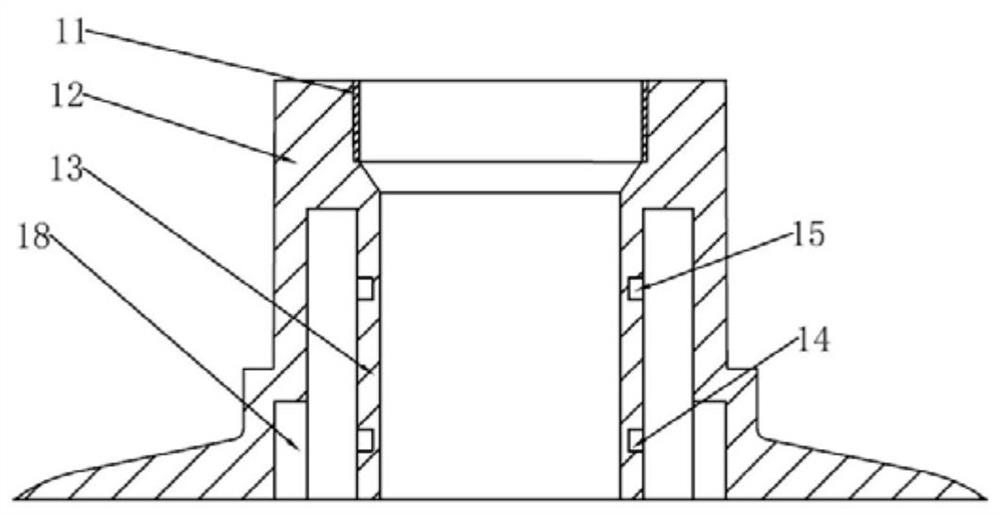

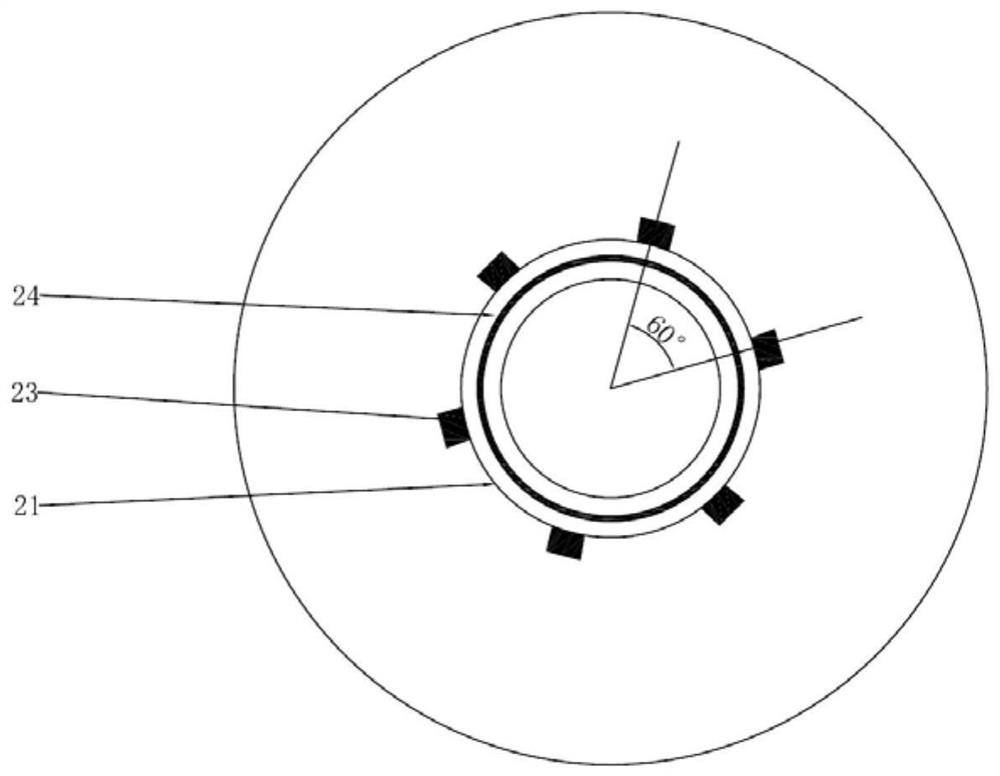

Sealing structure suitable for high-pressure plastic inner container carbon fiber full-winding gas cylinder and application

PendingCN112762356AStable structureSimple manufacturing and assemblyContainer filling methodsPressure vesselsFiberCarbon fibers

The invention discloses a sealing structure suitable for a high-pressure plastic inner container carbon fiber full-winding gas cylinder. The sealing structure comprises an annular inner cylinder body and an annular outer cylinder body which are coaxial, wherein the outer cylinder body is provided with an annular base which matching with the shoulder portion of the inner container needing to be sealed, an annular hollow structure in the middle is arranged between the inner cylinder body and the outer cylinder body and is used for embedding a bottle neck of the inner container needing to be sealed, a sealing groove is formed in the side, making contact with a bottle neck of the inner container needing to be sealed, of the inner barrel, and a sealing piece is arranged in the sealing groove to prevent gas from leaking from a gap between the inner barrel and the bottle neck of the inner container needing to be sealed, and a plurality of grooves matching with flanges on the outer surface of the inner container to be sealed are formed in the inner side of the base of the outer cylinder body. According to the sealing structure, the sealing reliability and stability of a high-pressure gas storage cylinder can be greatly improved, gas leakage caused by fatigue failure under the use working condition is avoided, meanwhile the sealing device has the advantage of being easy and convenient to assemble, and the sealing structure can be applied to a vehicle-mounted high-pressure hydrogen storage bottle.

Owner:TONGJI UNIV

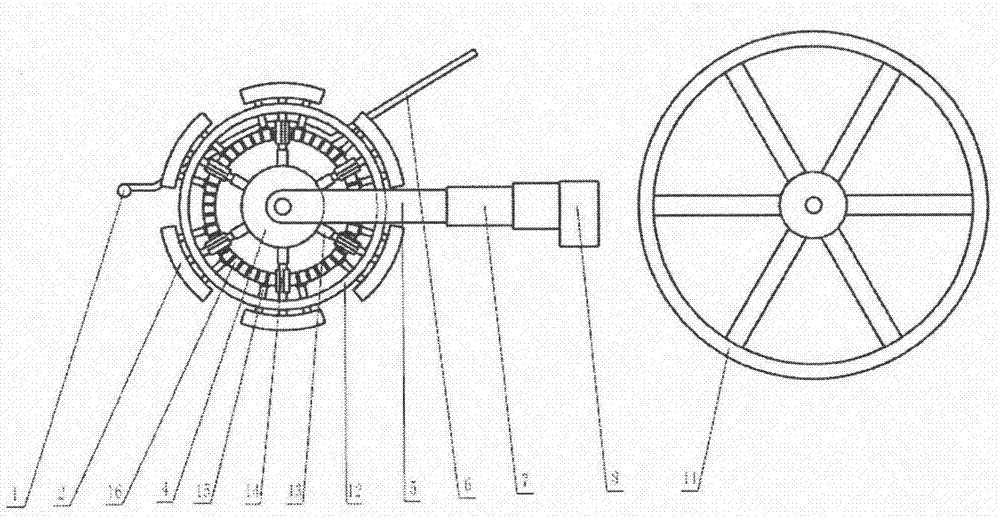

Novel infinitely-variable-speed belt wheel device

PendingCN107120399AChange speedIncrease or decrease in diameterGearingRotational axisHydraulic cylinder

The invention relates to a novel infinitely-variable-speed belt wheel device, and belongs to the mechanical field. The device comprises brake handles, a brake handle rotary shaft, a drive belt wheel, a general supporting plate, a drive belt wheel shaft, a belt wheel connector, hydraulic supporting rods, a brake disc gear, a hydraulic cylinder, a hydraulic supporting transverse rod, a driven wheel shaft, a driven wheel, a bracket wheel disc, a fixed threaded sleeve, a rotary gear shaft and drive wheel fixed connectors, wherein the hydraulic cylinder is a constant-pressure type hydraulic cylinder, and supporting force, on the drive belt wheel, of the hydraulic cylinder is constant; and the hydraulic cylinder also can be shortened as a result of stress of the drive belt wheel. Each part of the drive belt wheel can move in the radial direction due to a mode that the rotary gear shaft rotates around the fixed threaded sleeve, so that a transmission ratio is changed, and rotation speed of the driven wheel is changed in case of keeping rotation speed of the drive wheel unchanged. The brake disc gear and the drive belt wheel rotate at the same angular velocity when the brake handles are not pressed down; when the brake handles are pressed down, the rotary gear shaft is in engaged rotation with the brake disc gear, and the drive belt wheel extends in the radial direction; and two pairs of brake handles are arranged, so that the diameter of the drive belt wheel is reduced. The device can be mounted in a using occasion that rotation speed of the driven belt wheel needs to frequently change, and torque of the driven belt wheel is not very great, for example metallurgy and assembly line plant.

Owner:NANJING AGRICULTURAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com