Constant-temperature constant-humidity test chamber

A constant temperature and humidity test and box technology, used in measuring devices, instruments, scientific instruments, etc., can solve the problems of high price, high operating cost, high power consumption, etc., and achieve easy manufacturing and assembly, low operating cost, and service life. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

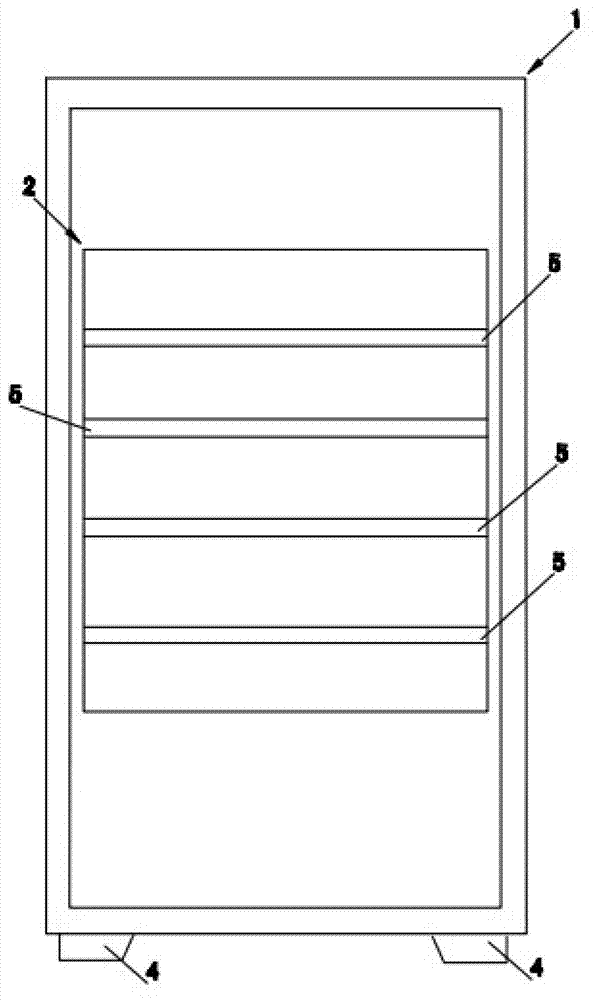

[0017] like Figure 1~2 As shown, a constant temperature and humidity test chamber includes a box body 1, a working chamber 2, a refrigeration assembly, a heating assembly, a humidifying assembly and an electrical assembly; It is arranged inside the box 1; it also includes a circulating air system, which is arranged on the top of the box 1; and an air outlet is provided on the top of the box 1; the working room 2 is set in the box 1, the working room 2 is provided with a test piece rack 5; the test piece rack 5 is a plurality of horizontal grid plates, which are arranged at intervals from top to bottom in the working room 2; the grid plate test piece rack 5 The air supply channel and the air return channel are formed on both sides of the box body 1;

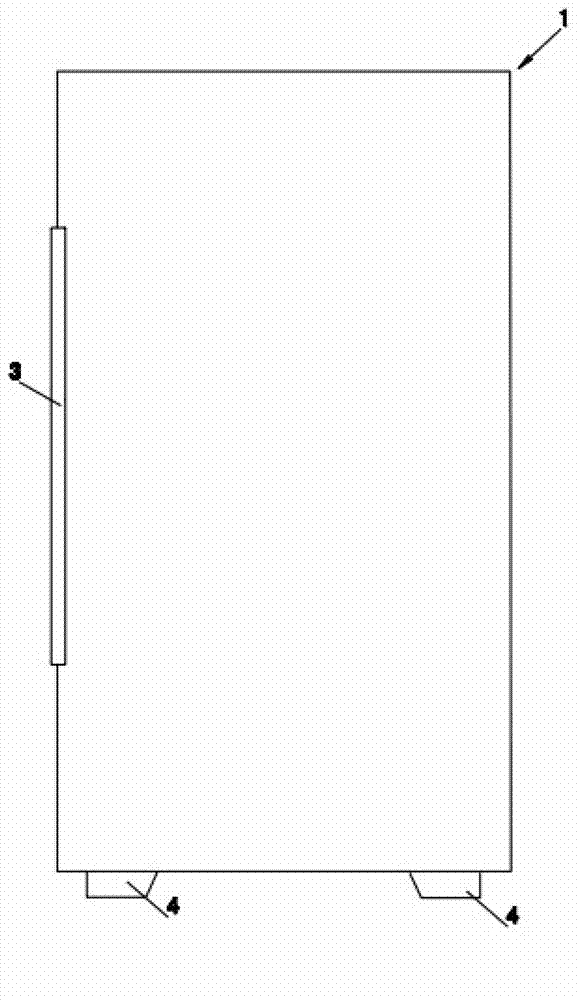

[0018] The front part of the box body 1 is provided with a box door 3 with an observation window, which is convenient for the operator to observe the test piece in the workpiece chamber 2;

[0019] The refrigeration assembly is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com