Three forks rod axial plunger pump

A technology of axial piston pumps and fork rods, which is applied in the direction of pumps, multi-cylinder pumps, liquid displacement machines, etc., can solve the problems of high environmental conditions, complex manufacturing processes, low pressure and efficiency, and achieve manufacturing and assembly Easy, simple structure, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

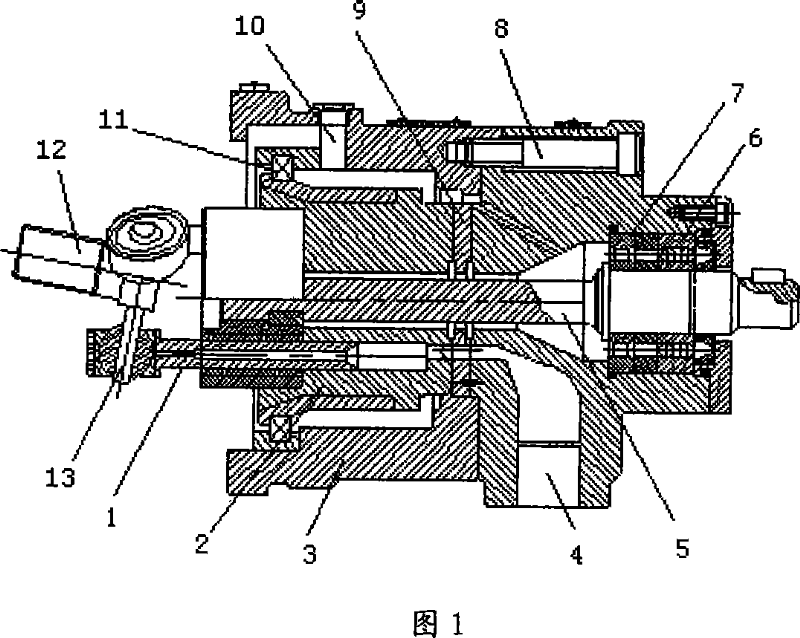

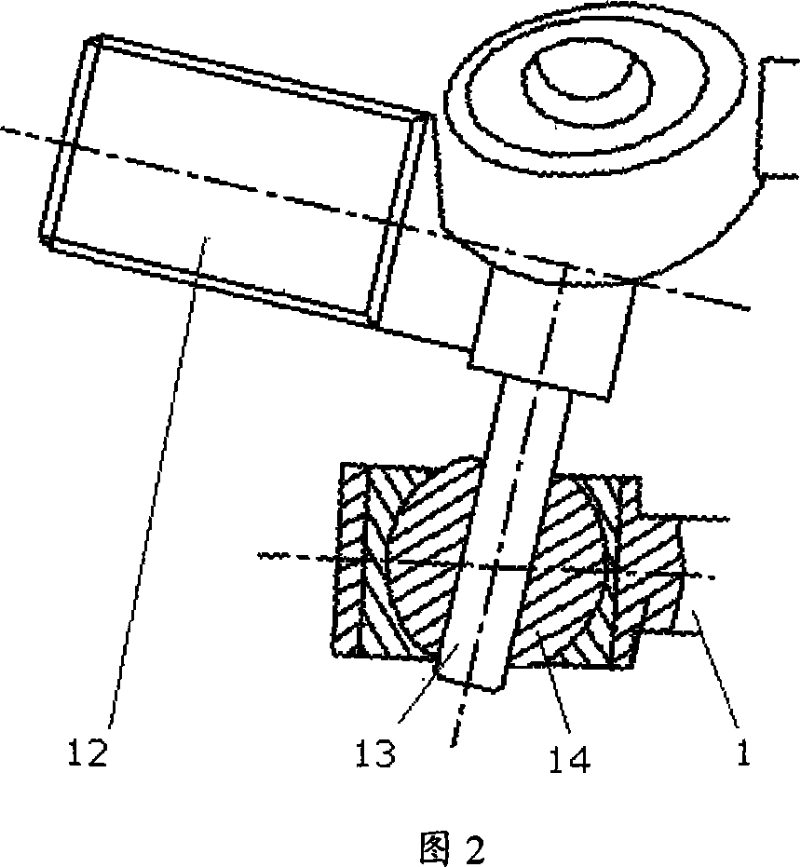

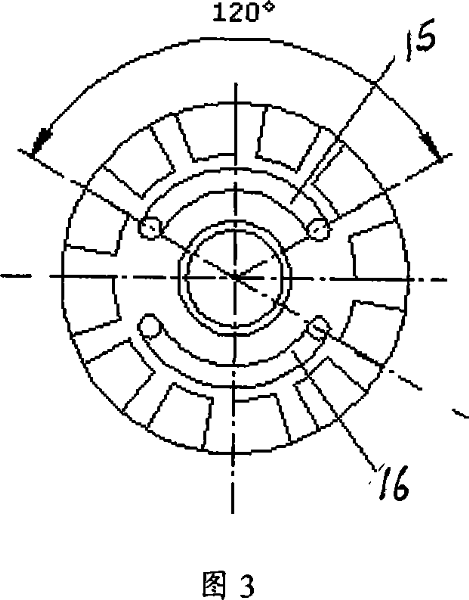

[0011] When the present invention is implemented, its main structure includes plunger (slider) 1, cylinder block 2, housing 3, inlet 4, transmission shaft 5, self-aligning ball bearing 6, cylindrical roller bearing 7 and 11, set screw 8, matching Oil pan 9, outlet 10, driven shaft joint 12, radial fork rod 13, radial joint bearing 14, oil pressure port 15, oil suction port 16 and other components. The transmission shaft 5 crosses the oil distribution plate 9 and the cylinder body 2, and is linked with the cylinder body 2. The oil distribution plate 9 is sandwiched between the cylinder body 2 and the housing 3, fixed by the positioning screw 8, and does not move during the working process. Yes, the two waist-shaped oil pressure ports 15 and oil suction ports 16 on the oil distribution plate 9 communicate with the inlet 4 and the outlet 10 respectively; the cylindrical roller bearing 7 and the self-aligning ball bearing 6 support the transmission shaft 5 and prevent the transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com