Tundish car installation method for ultrathin strip production line

An installation method and production line technology, which can be used in casting molten material containers, metal processing equipment, casting equipment, etc., can solve the problem of insufficient accuracy of tundish vehicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is further illustrated below by specific examples.

[0022] A method for installing a tundish car on an ultra-thin belt production line, comprising the following installation steps;

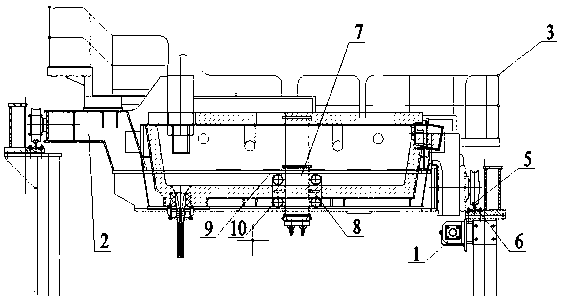

[0023] Step 1. Check and adjust the elevation, center line and levelness of the side track of the driving wheel, and position and install the buffer 1 according to the drawing requirements;

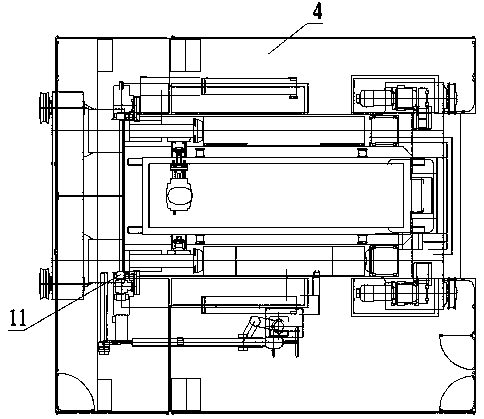

[0024] Step 2. Assemble the two tundish vehicles 2 on the ground, including body piping, platform 4 and connecting rod 3;

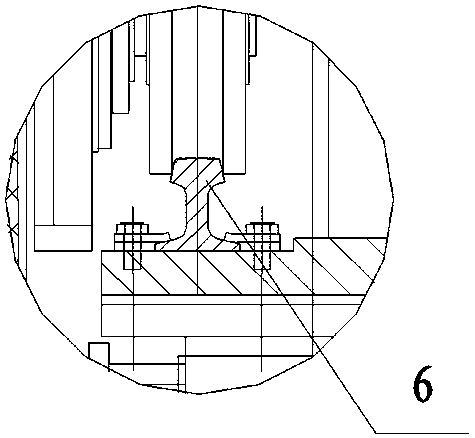

[0025] Step 3. Hoist the two tundish cars to the track with the main hook of the straddle carriage of the casting machine, respectively place the driving side tundish car and the working side tundish car in place according to the requirements of the drawing, and measure the driving wheel wheel 5 and the track gap 6 ;

[0026] Step 4. Remove the screw bearing housings on both sides of the drive side and the working side of the tundish car, install the loadi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com