Gear transmission shaft device

A gear transmission and shaft device technology, which is applied to transmission parts, hoisting devices, transmission components, etc., can solve the problem of not meeting the requirements of bearing service life and high speed at the same time, the support span of the gear transmission shaft is small, and the bearing life is long It achieves the effect of simple structure, good reliability and economy, and easy manufacturing and assembly without meeting the requirements and other problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

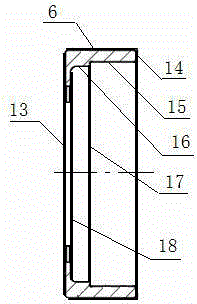

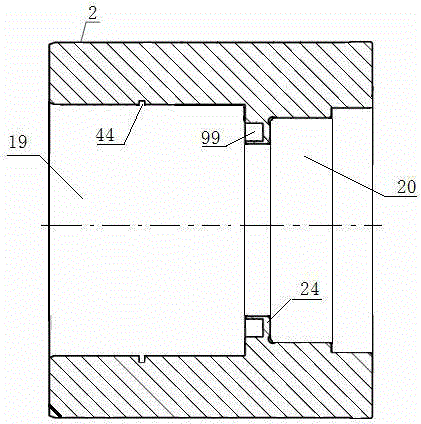

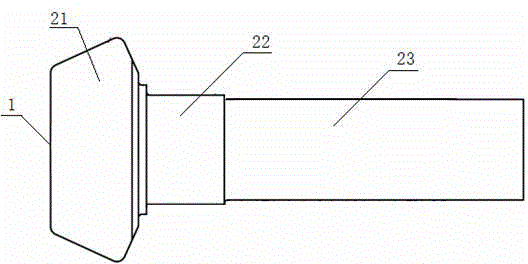

[0019] The gear transmission shaft device of the present invention includes a box body 2 and a gear transmission shaft 1 arranged in the box body 2 . The box body 2 is composed of a first inner cavity 19 and a second inner cavity 20 . The gear transmission shaft 1 is composed of a gear 21 , a large shaft 22 and a small shaft 23 . A cylindrical roller bearing 3 , a tapered roller bearing A7 and a tapered roller bearing B8 are sequentially arranged on the gear transmission shaft 1 . The cylindrical roller bearing 3 is placed between the inner ring 31 of the cylindrical roller bearing and the outer ring 32 of the cylindrical roller bearing. The inner ring 31 of the cylindrical roller bearing is sleeved on the large shaft 22 , and the outer ring 32 of the cylindrical roller bearing is in contact with the inner peripheral surface of the first inner cavity 19 of the box body 2 . The tapered roller bearing A7 is placed between the inner ring 71 of the tapered roller bearing A and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com