Manufacturing method of treadmill base and treadmill base structure

A manufacturing method and treadmill technology are applied in the field of treadmill base manufacturing and base structure, which can solve the problems of complicated welding, manufacturing and processing operations and high cost of metal materials for treadmill bases, and achieve simple manufacturing and assembly, light weight and low manufacturing cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

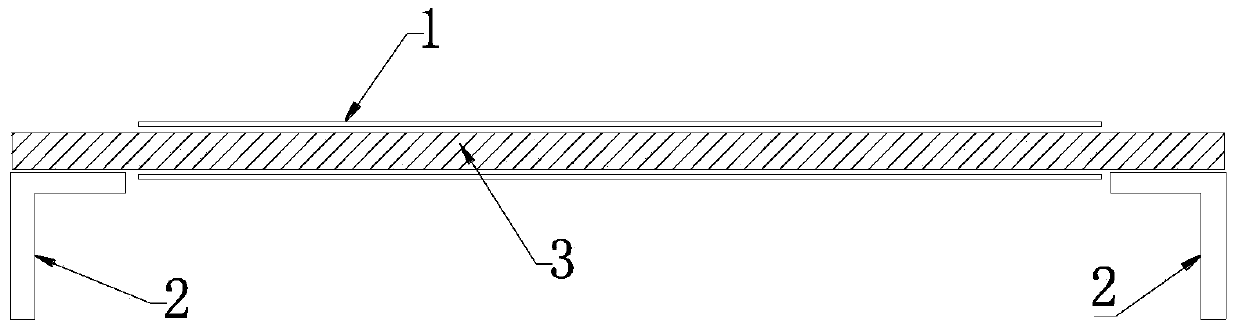

[0035] The structural diagram of the treadmill base structure of this embodiment refers to the attached figure 1 , including a running belt 1, a support seat 2 and a pedal 3, the support seat 2 is an integrated double-rail structure, the rail section of the double-rail structure is a right-angle structure, the pedal 3 is placed on the top of the support seat 2, and the running belt 1 is covered Rotate around the pedal 3 on the pedal 3.

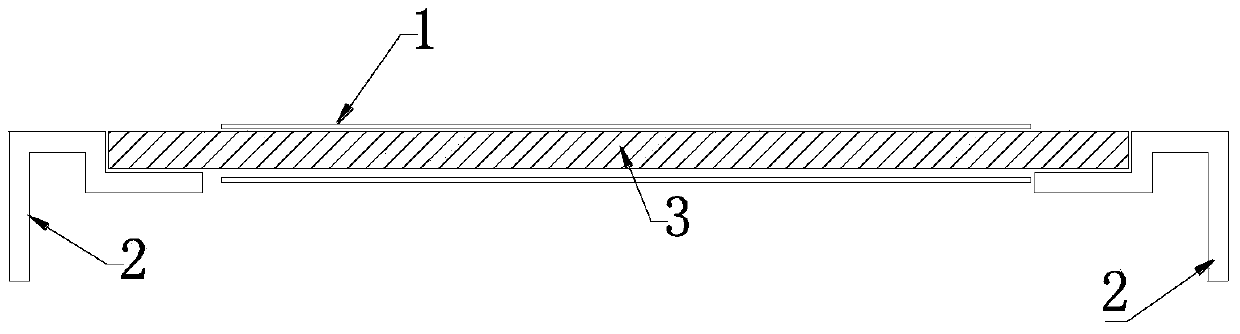

[0036] As a structural diagram of one of the deformations of embodiment 1, refer to figure 2 , the cross-section of the rail portion of the double-rail structure is similar to a right-angled structure, and a bent portion is designed on the upper part, and the pedal 3 is placed on the bent portion.

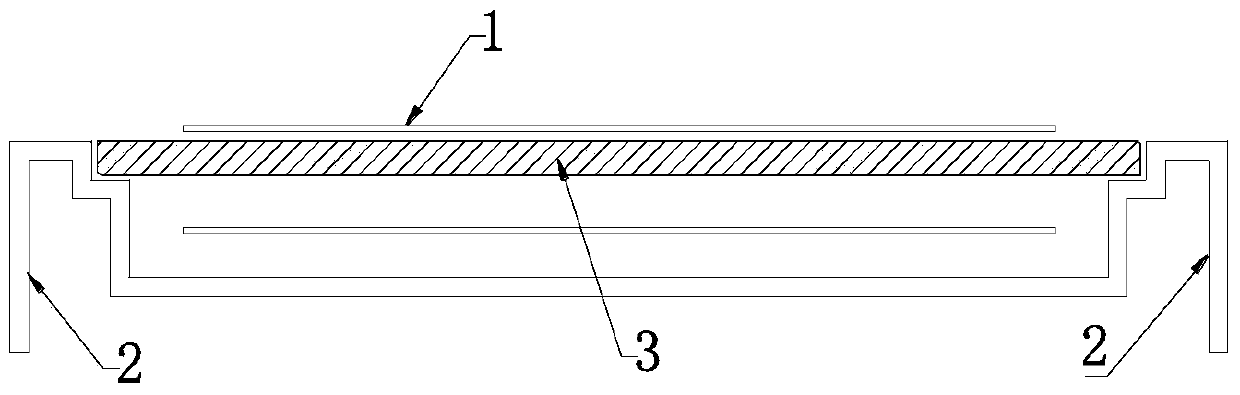

[0037] As the structural diagram of the second modification of embodiment 1, refer to the image 3 , the cross-section of the rail portion of the double-track structure is similar to a right-angled structure, and its upper part is designed with ...

Embodiment 2

[0040] The structural diagram of the treadmill base structure of this embodiment refers to the attached Figure 5 , including a running belt 1, a support seat 2 and a pedal 3, the support seat 2 is an integrally formed double-rail structure, the cross section of the rail part of the double-rail structure is a square structure, and the square structure is a Tian-shaped structure, and there are internal reinforcing ribs 4 in the rail part , used to improve the mechanical strength of the support seat.

[0041] As a deformation of embodiment 2, the deformation structure diagrams of the other two treadmill base structures refer to the attached Image 6 And attached Figure 7 .

Embodiment 3

[0043] The structural diagram of the treadmill base structure of this embodiment refers to the attached Figure 8 , including a running belt 1, a support base 2 and a pedal 3, the support base 2 is an integrally formed open structure, the bottom of the open structure is a flat plate, and the pedal 3 is fixed on the support base 2. As a deformation of this embodiment, the deformation structure diagram of its treadmill base structure refers to the attached Figure 9 , there are reinforcing ribs 4 in the open structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com