Automobile brake drum disassembling and assembling machine

A technology of automobile braking and disassembling machine, which is applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of collision and damage to the brake drum body, harsh working environment, failure and scrap, etc., and achieves easy manufacturing and assembly, The effect of expanding adaptability and easy operation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

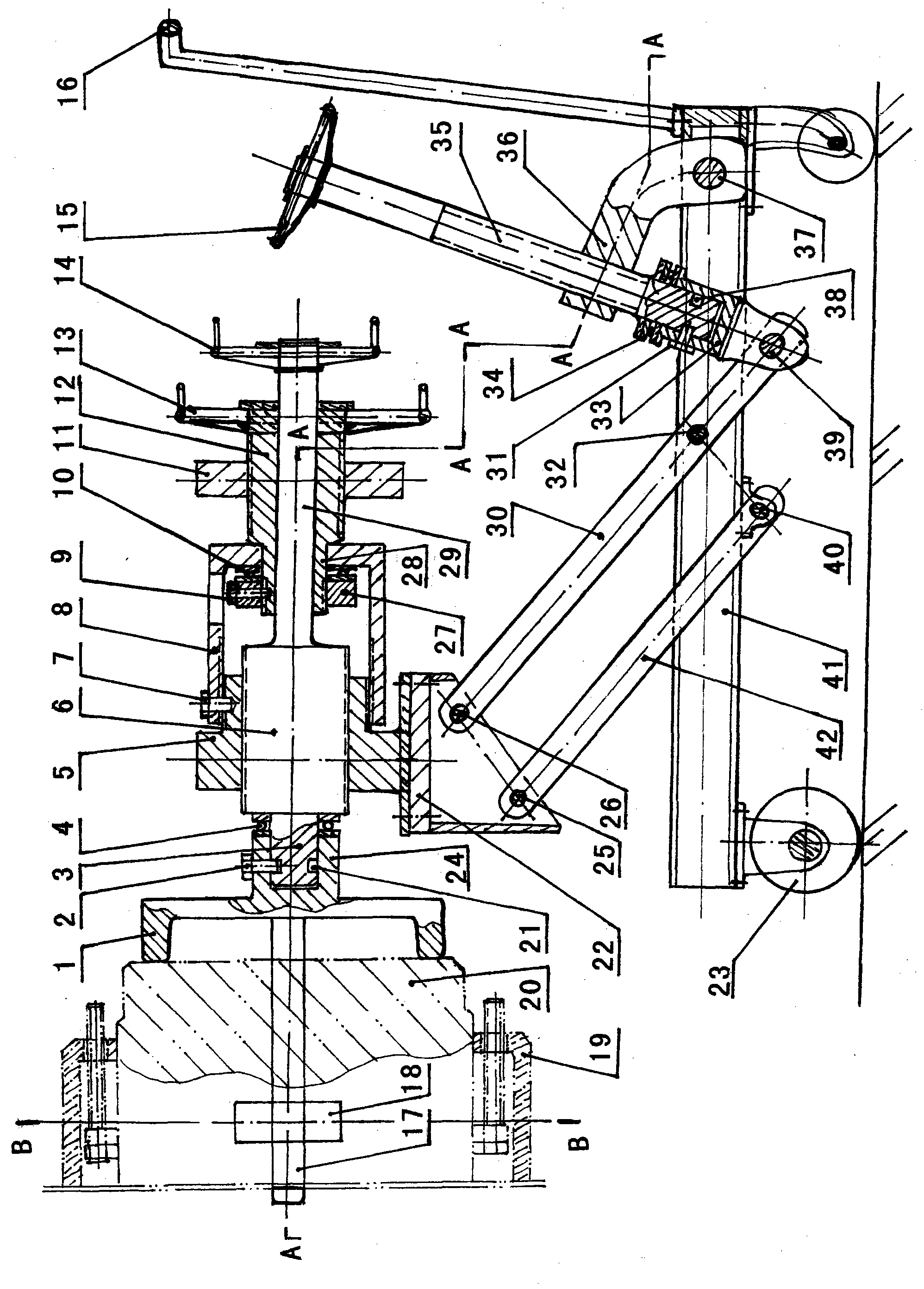

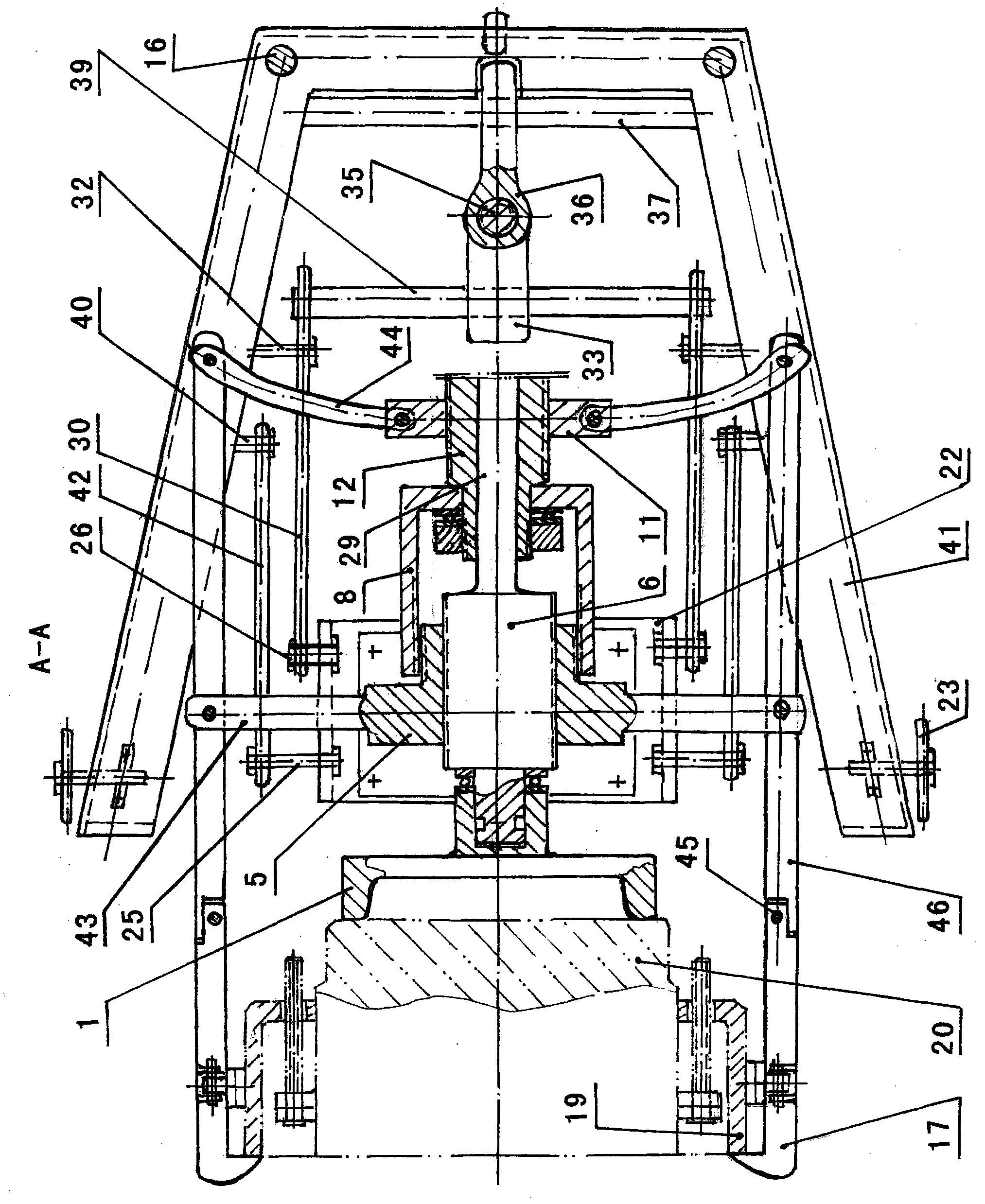

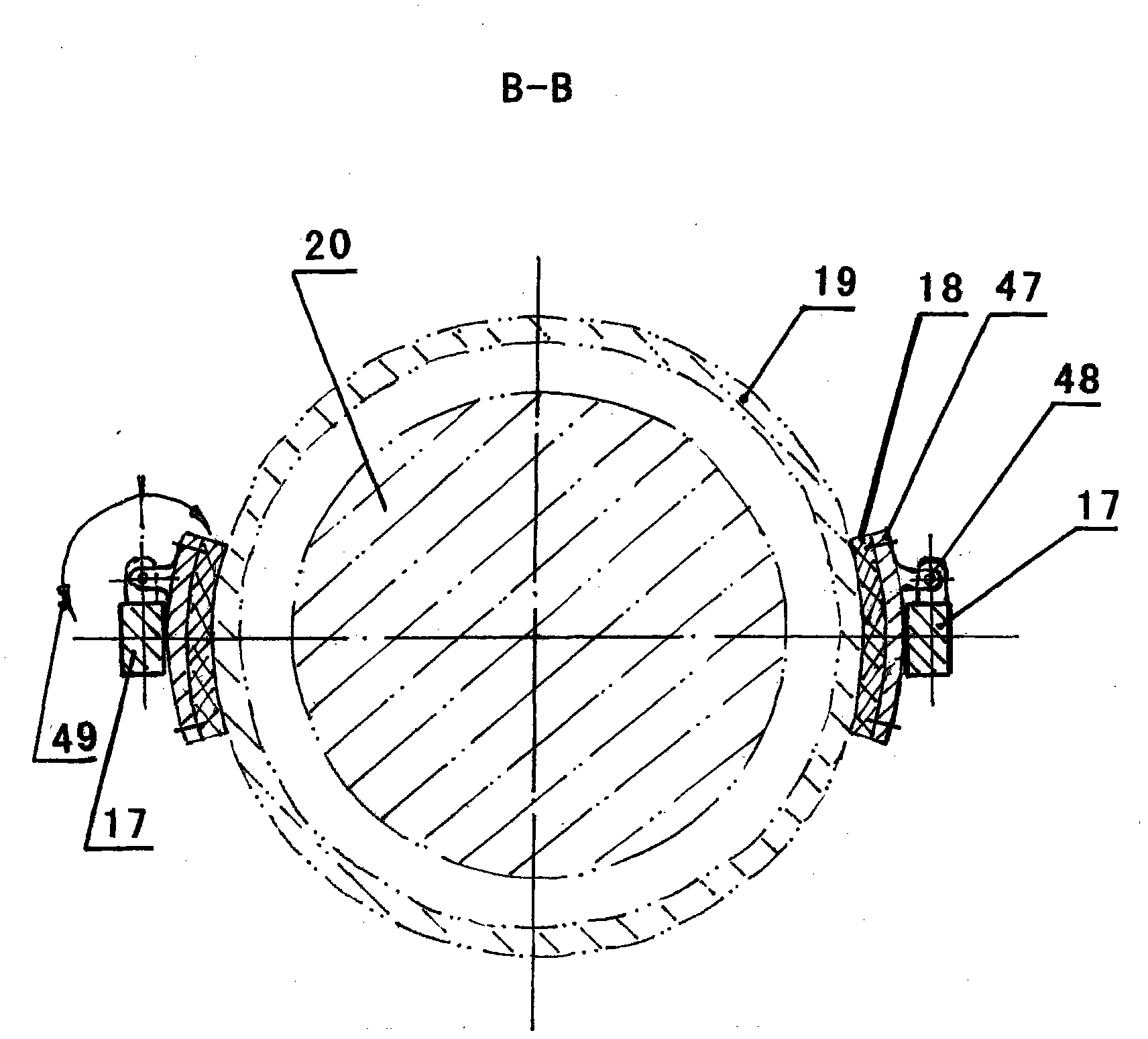

[0026] Embodiments of the present invention are described below in conjunction with the accompanying drawings:

[0027]A kind of automobile brake drum dismantling machine that the present invention proposes, it mainly is equipped with the frame 41 of roller 23, lift work platform 22, is installed on the support base 5 of lift work platform 22, becomes threaded cooperation with support base 5 The assembly and disassembly screw rod 6, the connecting sleeve 8, the hook screw rod 12 and the disassembly and assembly top frame 1 fitted on the assembly and disassembly screw rod 6 are composed of the upper shaft pins 25, 26 and the lower shaft pins 40, 32 of the lifting work platform 22. The parallelogram connecting rod elevating mechanism formed by hinged parallel connecting rods 30, 42 is supported on the frame 41, and the elevating shaft 33 is set on the elevating shaft 39 of the parallel connecting rod 30. Fitted in the lifting shaft sleeve 33, the positioning head of the position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com