Novel infinitely-variable-speed belt wheel device

A stepless speed change, pulley technology, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of low speed change efficiency, complicated structure of stepless speed changer, etc., to achieve high safety, high practical value, maintenance Easy maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

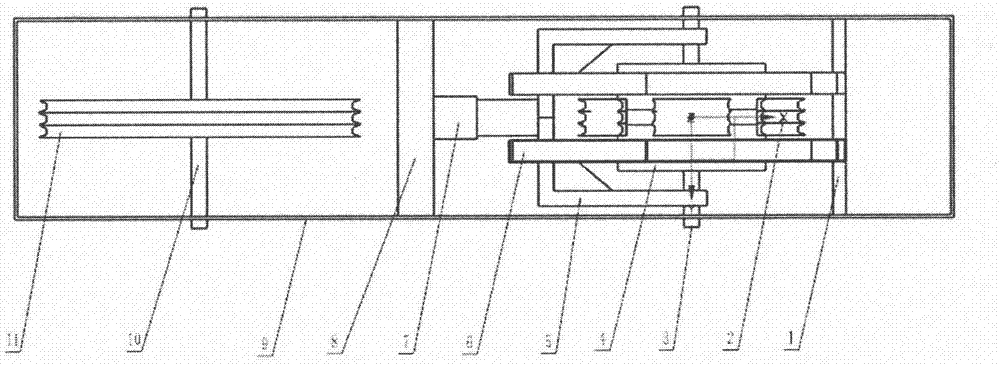

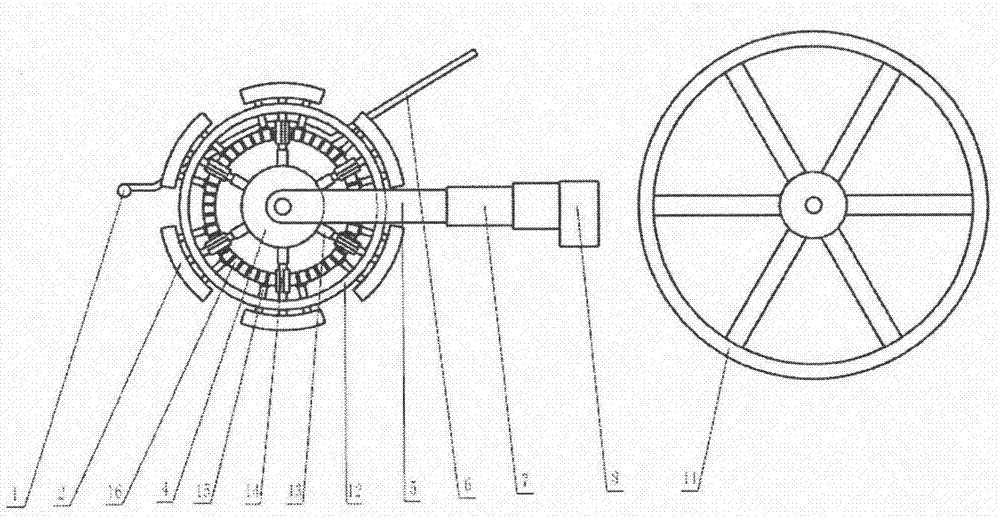

[0020] The technical solution of the present invention will be described in detail below with reference to the accompanying drawings.

[0021] In the continuously variable pulley device, the driving pulley is connected electrically or with other driving devices, the driving pulley drives the driven pulley through the V-belt, and the driven pulley shaft is connected with other working media. At the beginning of the work, the brake disc gear and the driving pulley rotate at the same angular velocity. Pressing one of the brake handles will make the brake disc gear rotate at a slower speed than the driving pulley, so that the rotating gear shaft and the brake disc gear will mesh and rotate. The end of the rotating gear shaft is threaded with the fixed threaded sleeve. Because the threaded sleeve is fixed, the rotating gear shaft can only move radially, so that each part of the driving pulley moves radially and changes its radius of rotation, thereby changing the device. gear ratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com