Parallel mechanism to implement tri-translation and mono-rotation

A technology of three-translational and planar four-bar mechanism, which is applied in the direction of manipulators and manufacturing tools, can solve the problems of large working space, small working space, high rigidity, etc., and achieve the effect of simple processing, manufacturing and assembly, compact structure and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

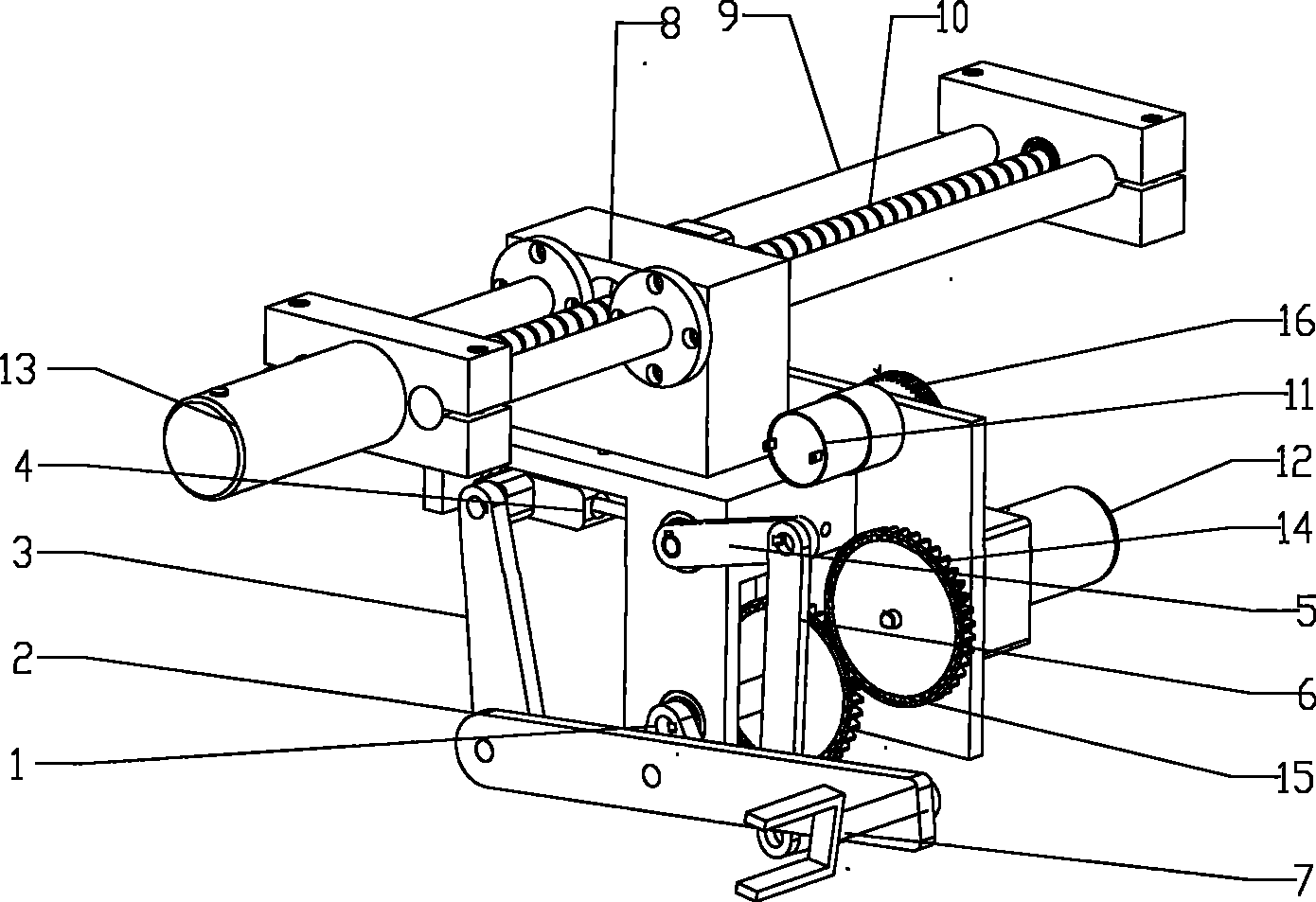

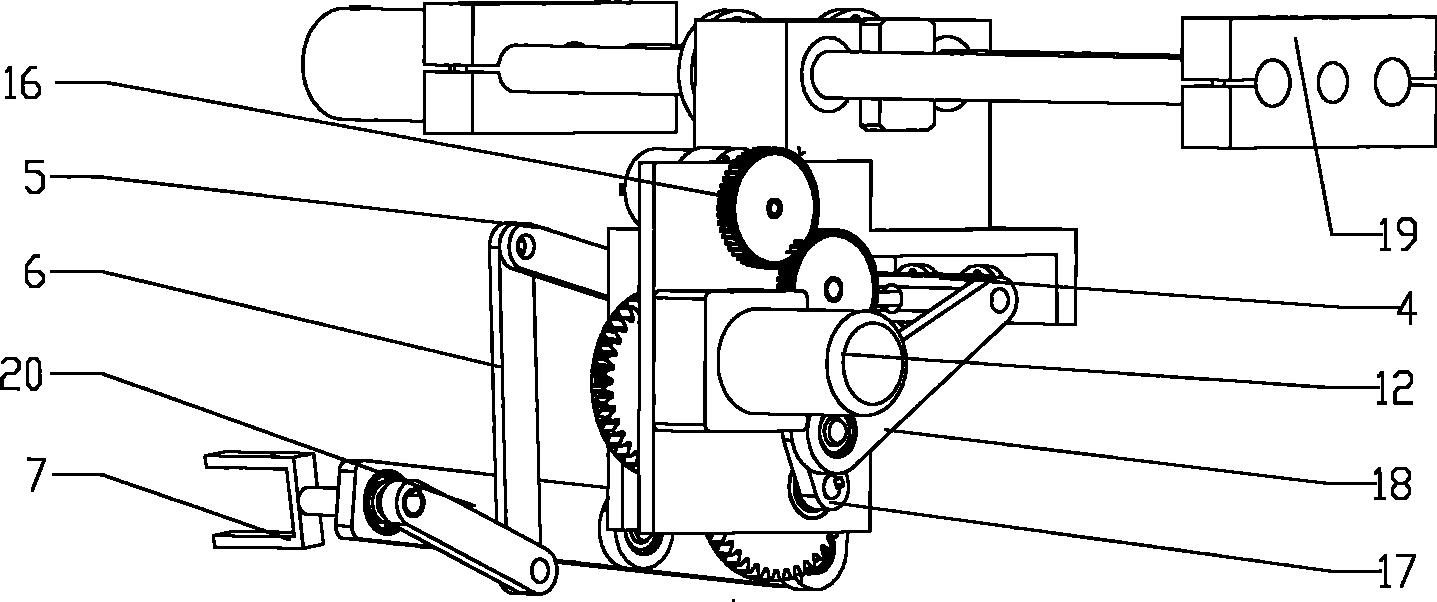

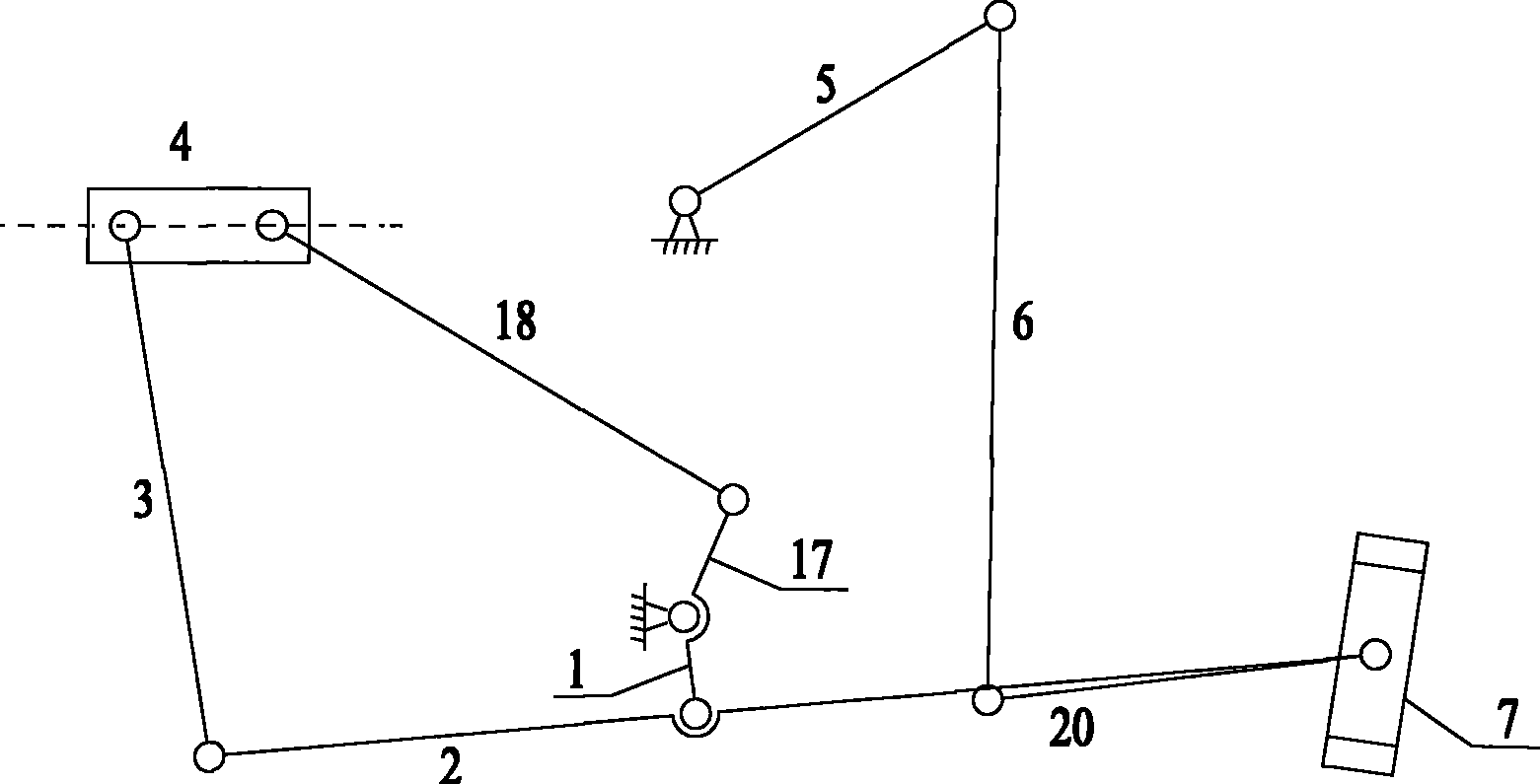

[0021] Example 1: A four-degree-of-freedom parallel mechanism composed of a five-bar slider mechanism, a crank-slider mechanism, and a planar four-bar mechanism

[0022] attached figure 1 And attached figure 2 It is a side view of Embodiment 1 of the present invention, wherein the drive motor 12 simultaneously drives the active part 1 of the five-bar slider mechanism and the active part 17 of the crank slider mechanism through a pair of gears 14 and 15, and the active part 17 drives the driven part 18 And the slider 4, and the linear motion of the slider 4 and the driving part 1 jointly drive the driven parts 2 and 3, so that the driven part 2 can realize the motion trajectory and acceleration required by the end effector. The motor 11 drives the driving part 5 of the planar four-bar mechanism through the gear 16, and the driving part 5 drives the driven parts 6 and 20, and the rotation of the driven part 20 can realize the rotation of the end effector. 13 is the driving mo...

Embodiment 2

[0024] Embodiment 2: A four-degree-of-freedom parallel mechanism composed of a five-bar mechanism, a crank-rocker mechanism and a planar four-bar mechanism

[0025] attached Figure 4 And attached Figure 5 It is a side view of Embodiment 2 of the present invention, wherein the drive motor 27 simultaneously drives the active part 21 of the five-bar mechanism and the active part 28 of the crank-rocker mechanism through a pair of gears 25 and 26, and the active part 28 drives the driven part 29 and the rocker The rocker 32 and the swing of the rocker 32 and the driving part 21 jointly drive the driven parts 23 and 24, so that the driven part 24 realizes the movement trajectory and acceleration required by the end effector. The motor 11 drives the active part 5 of the planar four-bar mechanism through the gears 30 and 31, and the active part 5 drives the driven parts 6 and 20, and the rotation of the driven part 20 can realize the rotation of the end effector. 13 is the driving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com