Imperfect cigarette collating and tobacco shred recycling integrated equipment

A technology for defective cigarettes and shredded tobacco, which is applied in the field of integrated equipment for straightening out shredded cigarettes and recycling shredded tobacco, can solve the problems of secondary pollution, huge equipment structure, labor-intensive and other problems, and achieves convenient maintenance, huge economic benefits, Overcome the effect of long paths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

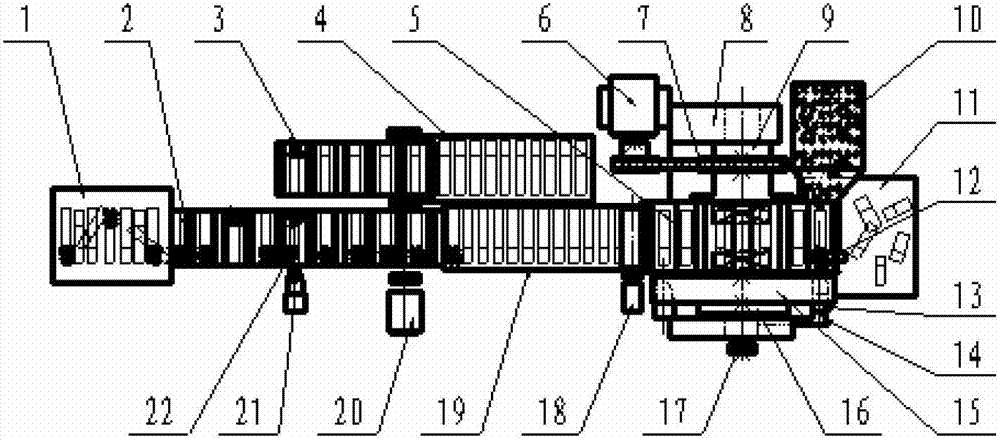

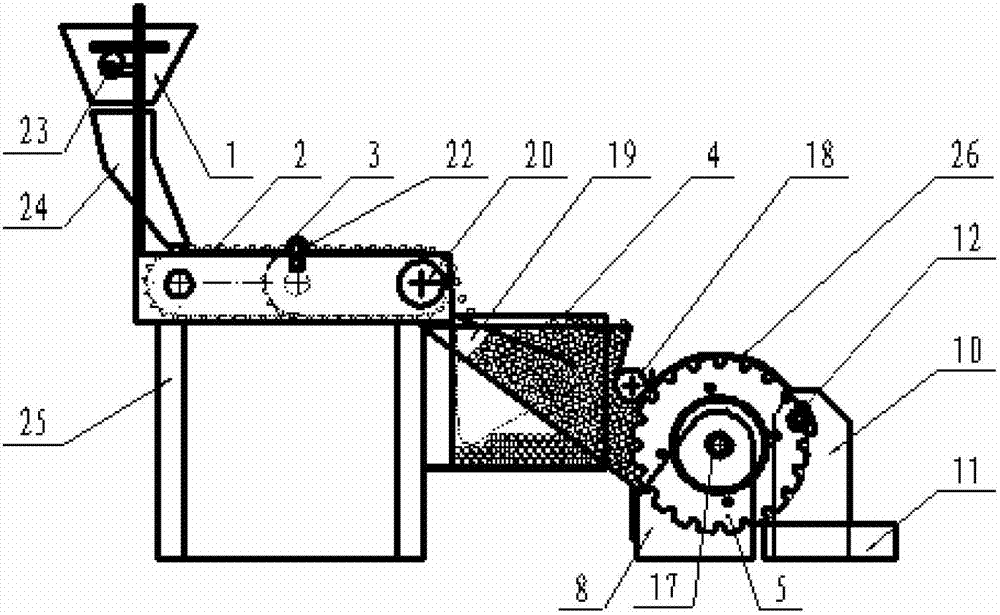

[0015] Example: Integrative equipment for straightening out defective cigarettes and recycling shredded tobacco

[0016] The specific structure is that on the top of the support 25 of the rationalized conveying system, there is a vibrating blanking bin 1 for receiving defective cigarette collection devices, and there are multiple side-by-side slides 24 connected to it, and the exit of the slides corresponds to No. 1 tooth-shaped conveying Belt 2, No. Ⅱ toothed conveyor belt 3 is arranged side by side with it, and the two are equipped with a common drive motor 20, and the No. Ⅱ toothed conveyor belt 3 is connected with a cigarette collecting bucket 4, and No. There is a feeding bin 19, and the feeding bin 19 has a cigarette outlet corresponding to the toothed roller 5, the toothed roller is installed on the roller support 8 through the fixed hollow shaft 16, and the top of the fixed hollow shaft 16 is provided with a compressed air source for quick insertion The joint 17, the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com