Digital pressure regulating device of optical fiber grinding miller

The technology of a pressure regulating device and a grinding machine, which is applied in the field of pressure regulating devices, can solve the problems of time-consuming and laborious, low grinding yield, and inability to ensure the accuracy of pressure adjustment, etc., and achieves convenient use, high grinding yield, and compact and novel structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

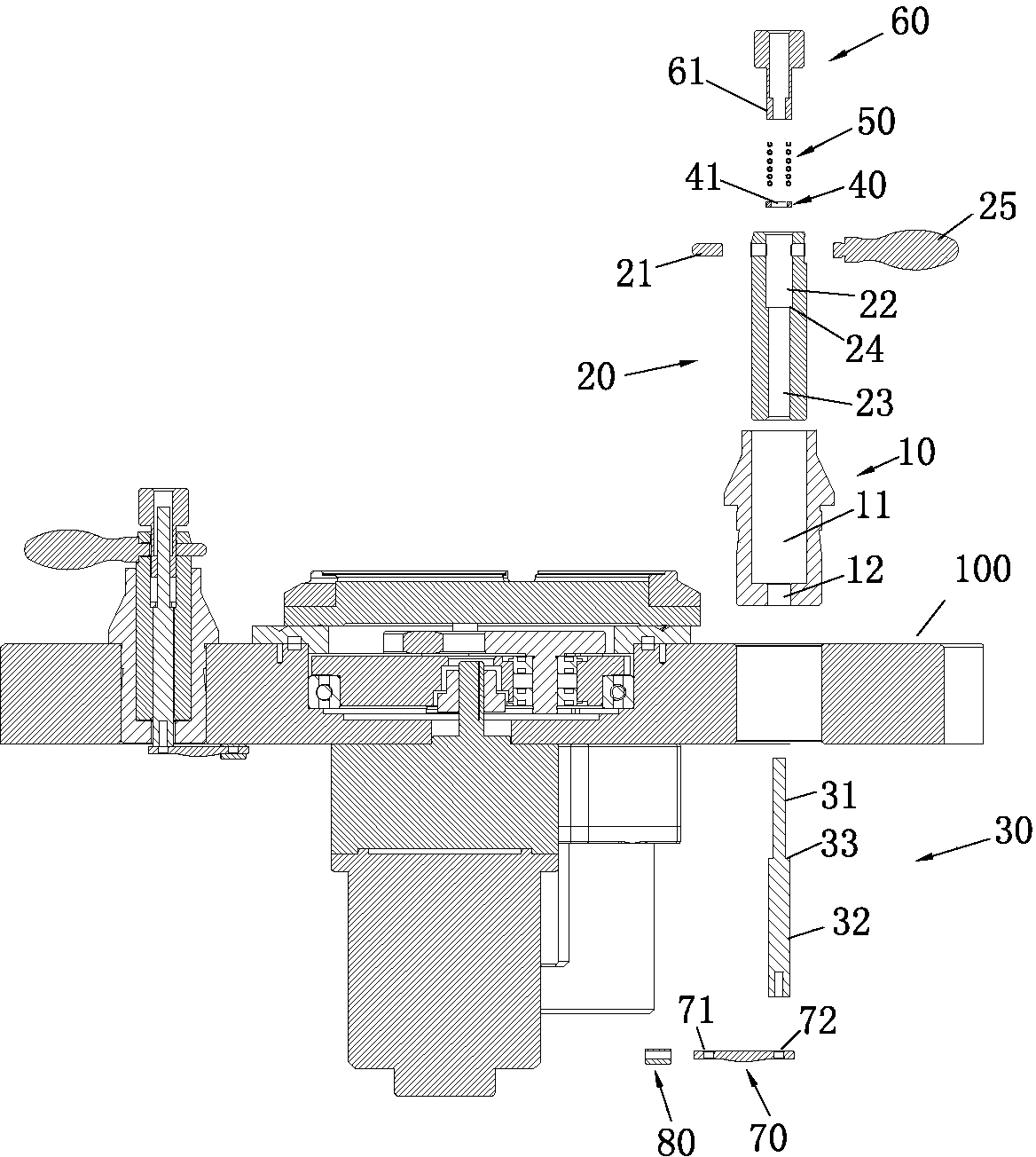

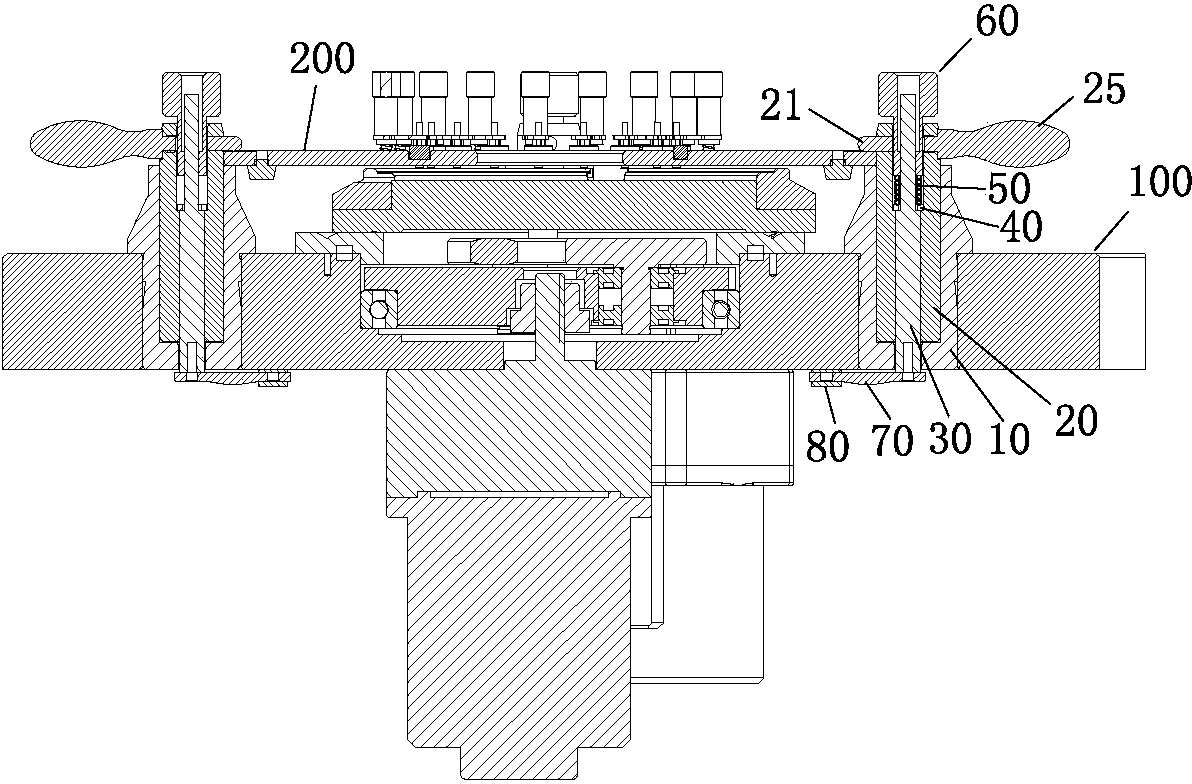

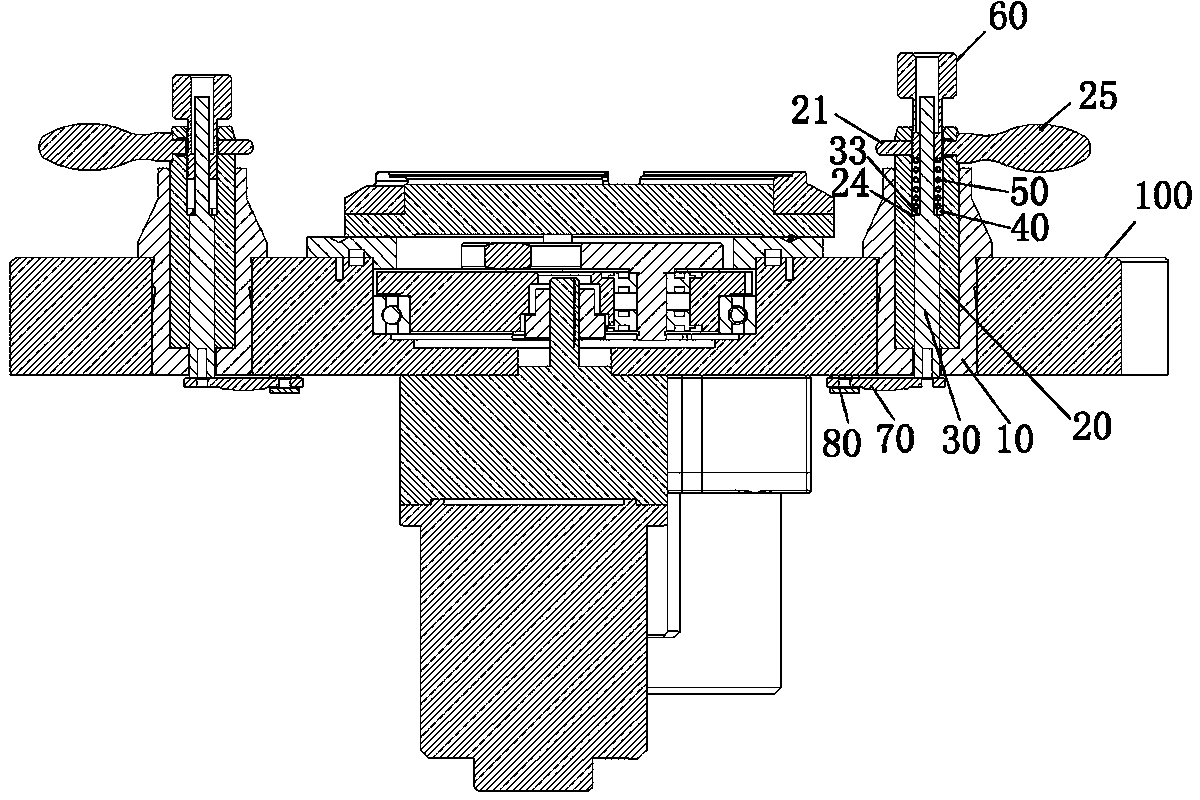

[0023] Such as Figure 1-4 As shown, a digital voltage regulating device for an optical fiber grinder includes:

[0024] A fixture positioning support 10, the fixture positioning support 10 is fixedly arranged on the installation hole of the working platform 100 or integrally formed with the working platform 100, the fixture positioning support 10 is provided with an upper sliding cavity 11 communicating with each other from top to bottom. Lower through hole 12;

[0025] A pressure applying part main body 20, the shape of the pressing part main body 20 matches the upper sliding cavity 11, the pressing part main body 20 is provided with a pressing end acting on the optical fiber grinding disc 200, and the pressing part main body is provided with A stepped through hole, the upper part of the stepped through hole is a large-diameter stepped hole 22, the lower part of the stepped through-hole is a small-diameter stepped hole 23, and the upper end of the large-diameter stepped hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com