Lathe center

A tip and lathe technology, applied in the direction of tailstock/top, turning equipment, toolholder accessories, etc., can solve the problems of small application range of the tip of ordinary lathes, and the ineffective clamping of large inner diameter steel pipes, etc., to achieve easy disassembly and easy realization , Improve production efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

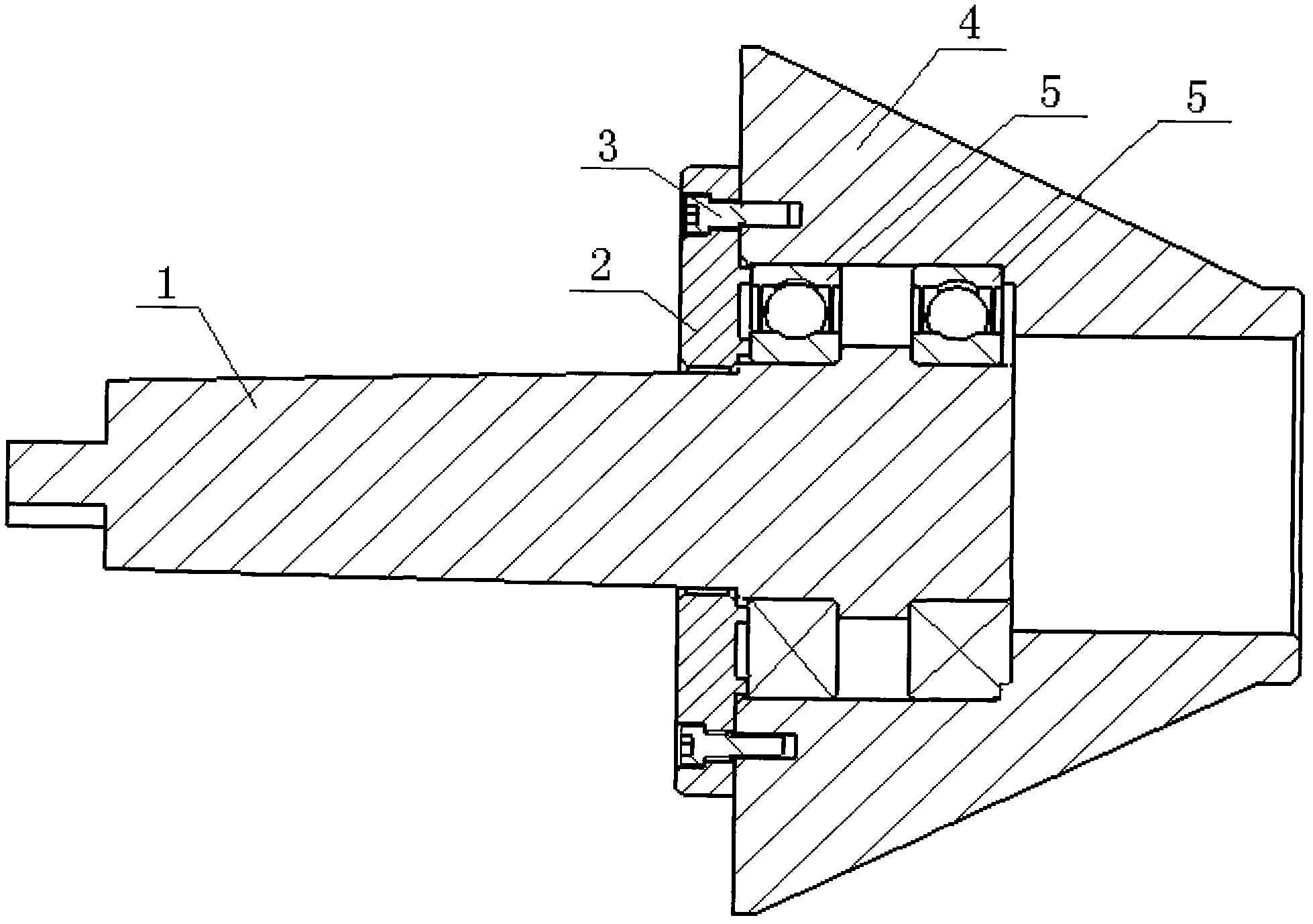

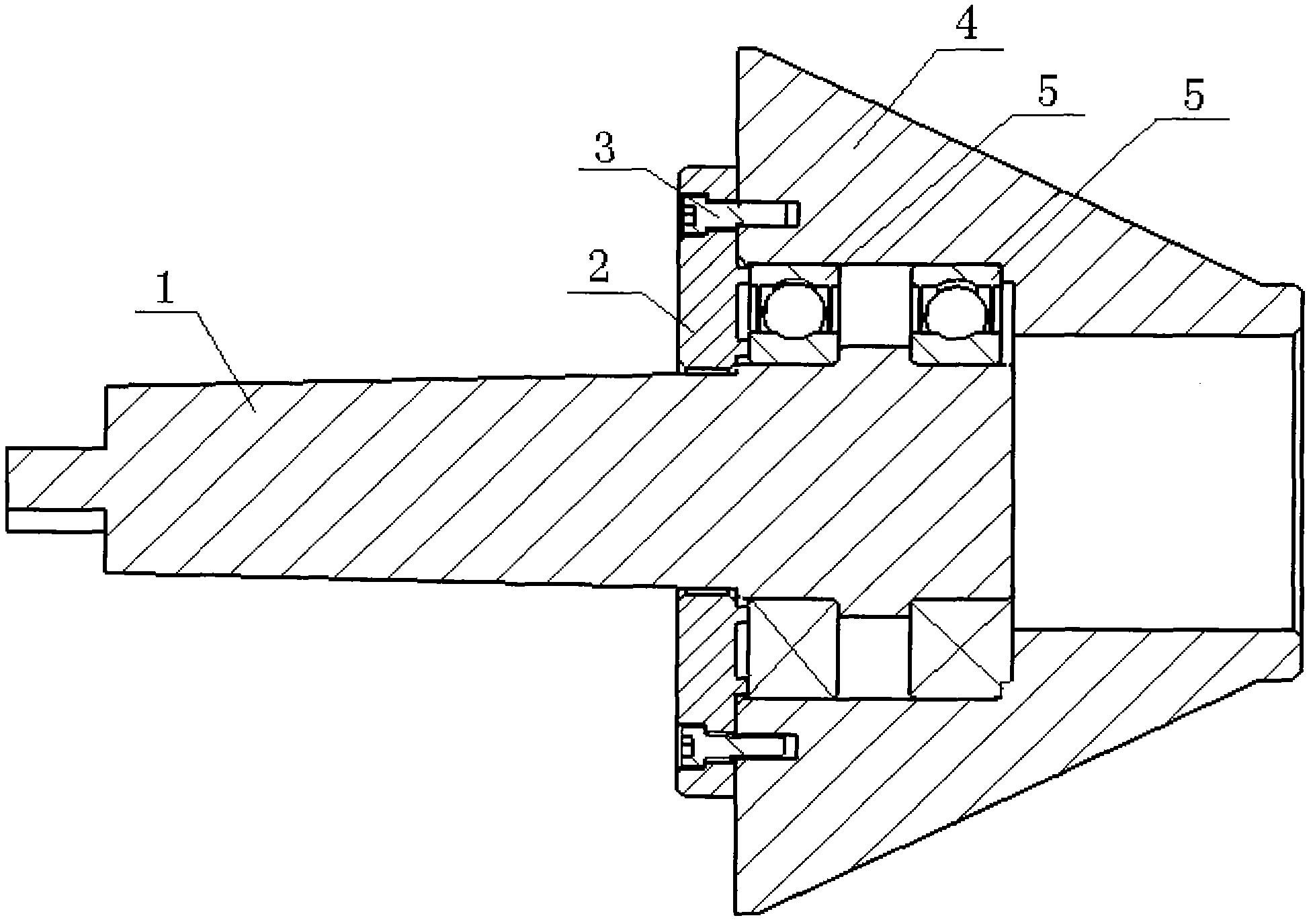

[0013] like figure 1 As shown, a specific embodiment of the present invention is given. In the figure, the plug 4 is a cone with a flat end surface at the top. One end of the assembly shaft 1 is inserted into the stepped hole at the big end of the plug 4, and is installed with the plug 4 through two intervals. The bearing 5 is connected, and the outer side of the bearing 5 is equipped with a gland 2 fixedly installed on the top 4 by screws 3. During processing, the force of the plug 4 is almost all on the inner and outer rings of the bearing 5, avoiding dry friction between the plug 4 and the steel pipe, and greatly extending the service life, and the concentricity of the plug 4 can be guaranteed through the positioning of the outer rings of the two bearings .

[0014] The present invention is easy to install and easy to realize. The common tip of the lathe is replaced by a vertebral head 4 with a flat top, and is connected with the assembly shaft 1 through two bearings 5. F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com