Patents

Literature

42results about How to "Guaranteed free rotation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

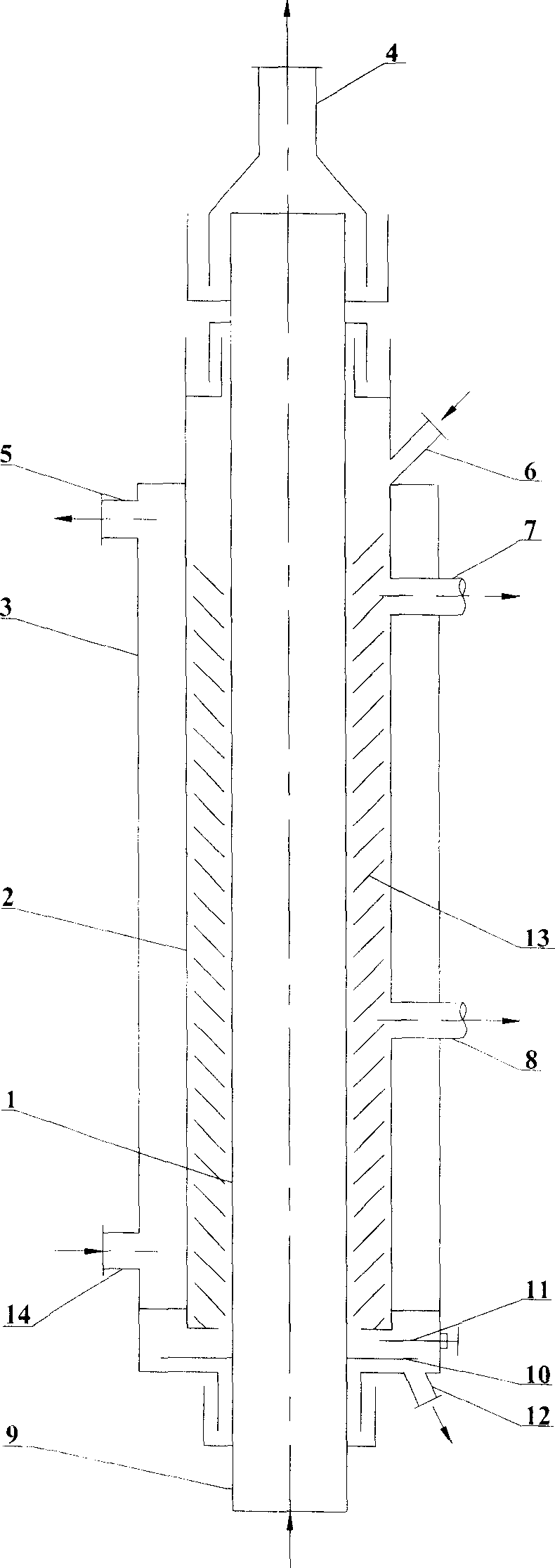

Low temperature distillation method and device for high volatile component weak viscosity coal

InactiveCN1865398AEvenly heatedAvoid stickingLiquid hydrocarbon mixture productionSpecial form destructive distillationWater vaporTar

The invention discloses a low-temperature retorting method of high-volatile flux fine particle, which is characterized by the following: the method adopts vertical pipe with inner, middle and outer concentric casing to move two sides of outer heat retort furnace, which produces char coal, gas and tar; the needed energy of retorting is provided by fine grain coal in the middle casing ring-shaped space from inner and outer casing high-temperature gas, which proceeds drying and charring steps; the steam and char volatile product are guided out of upper segment steam and lower segment char hole separately; the char coal falls in the char furnace chassis discharger, which is discharged from outlet.

Owner:FUZHOU UNIV

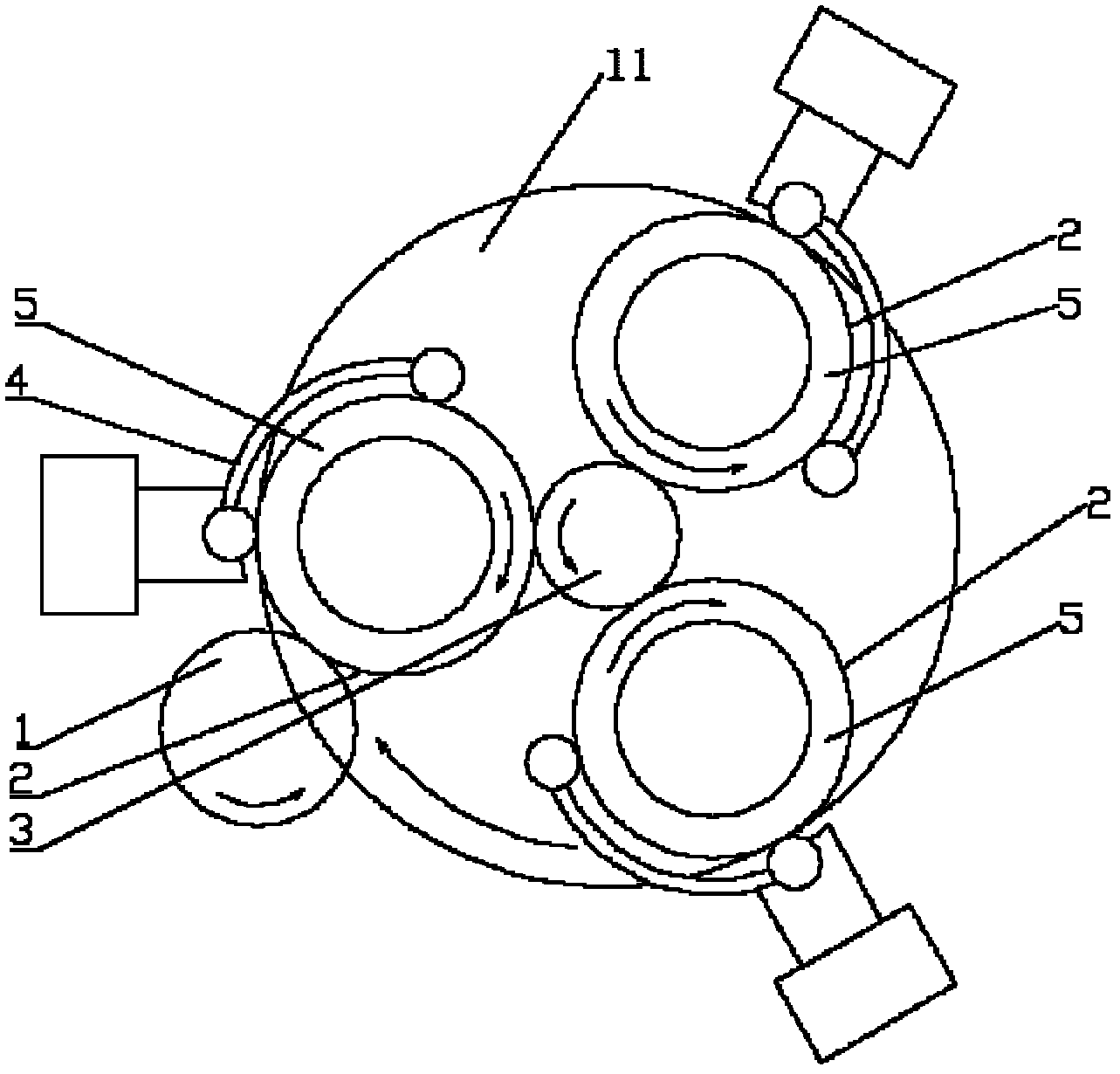

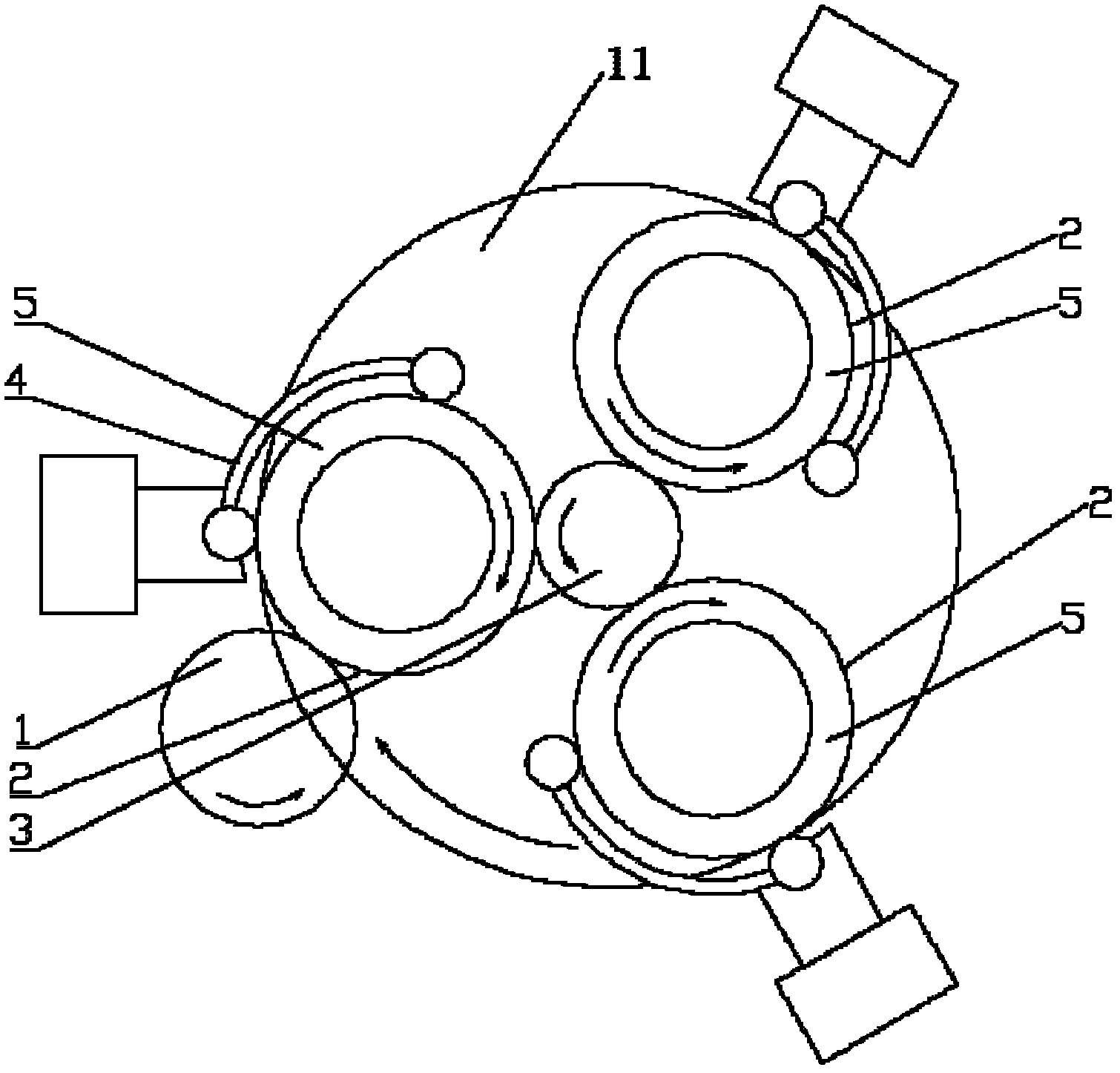

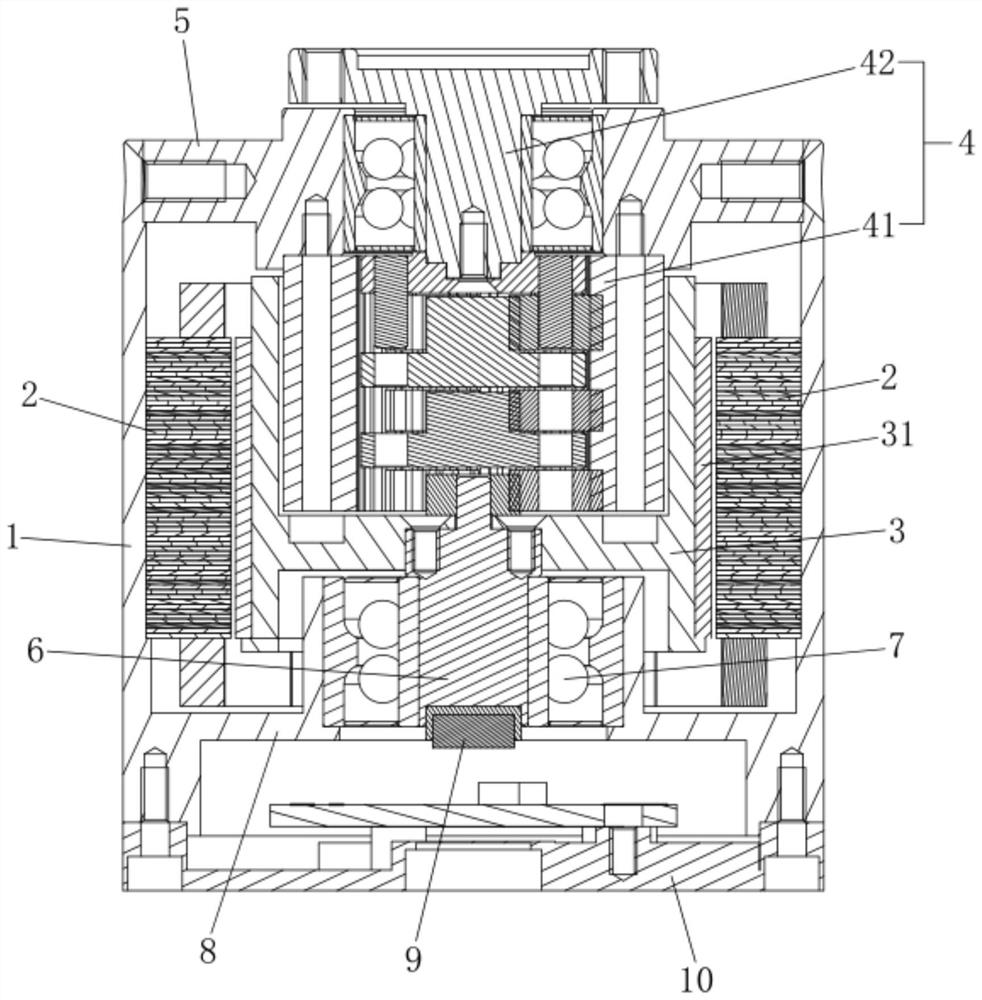

Active-driving grinding device

ActiveCN102601724AEasy to installGuaranteed uniformityLapping machinesAbrasive surface conditioning devicesGear wheelElectric machinery

The invention discloses an active-driving grinding device, which comprises a trimming ring, a base disc and a grinding disc and also comprises a driving motor, an output gear, three stressed gears and an auxiliary gear that can rotate freely, wherein the driving motor is arranged on a base, the output gear is connected with the driving motor and is meshed with the stressed gear, the stressed gear is fixedly connected with the trimming ring by a bolt, the trimming ring is fixed on the grinding disc by a trimming ring fixing part and can rotate around a fixed center line, the base disc is clamped in the trimming ring, a screw hole is arranged in the grinding disc, the auxiliary gear is positioned in the centers of the three stress gears and is meshed with the stressed gears, and the lower parts of the auxiliary gear is fixed on the grinding disc through the screw hole. According to the device, the machining efficiency and the machining quality are improved; meanwhile, the rotation speed of the motor can be regulated, and the machining efficiency can be flexibly regulated, and therefore, the device is a novel driving mechanism with high grinding accuracy and low cost.

Owner:ZHEJIANG UNIV OF TECH

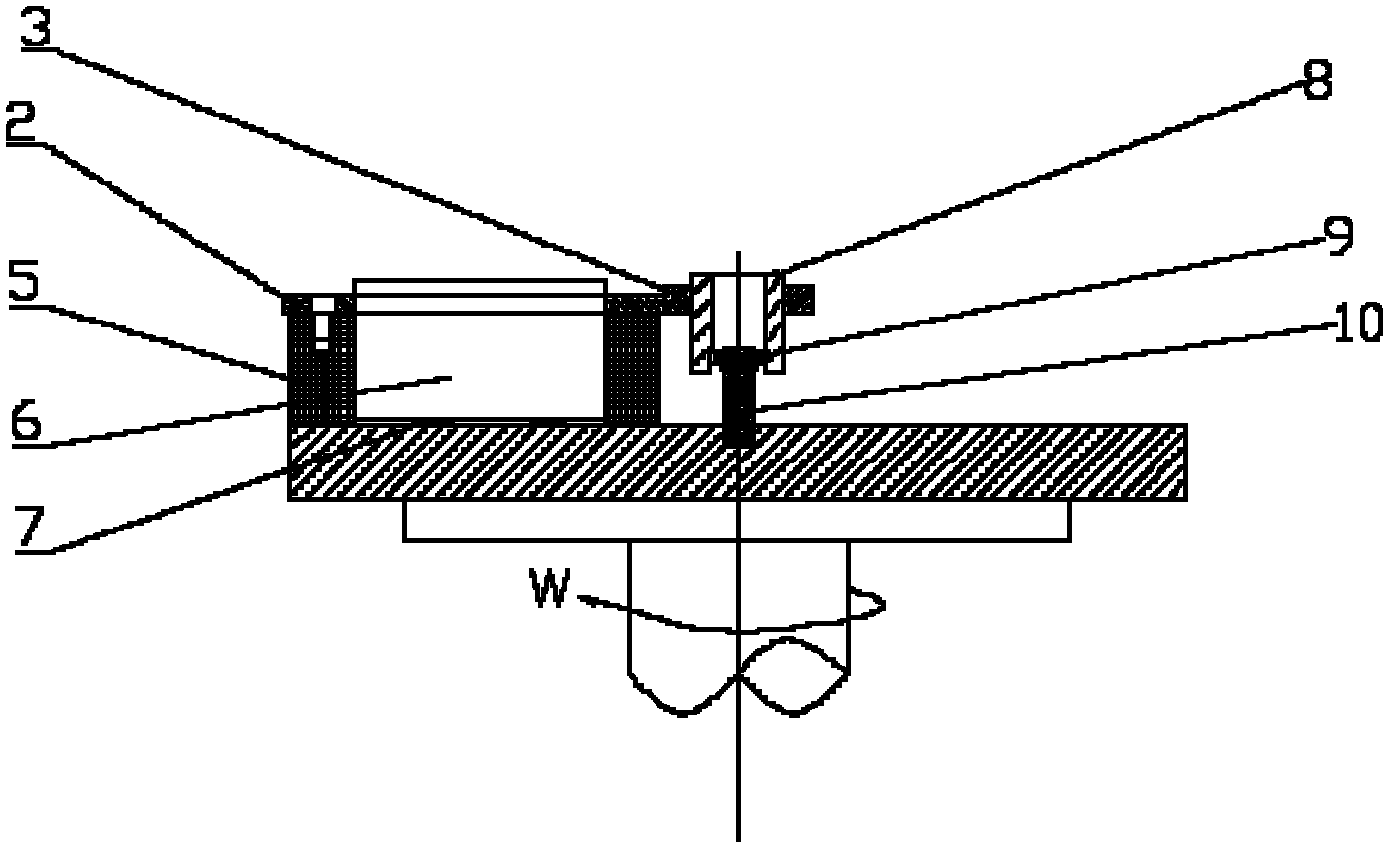

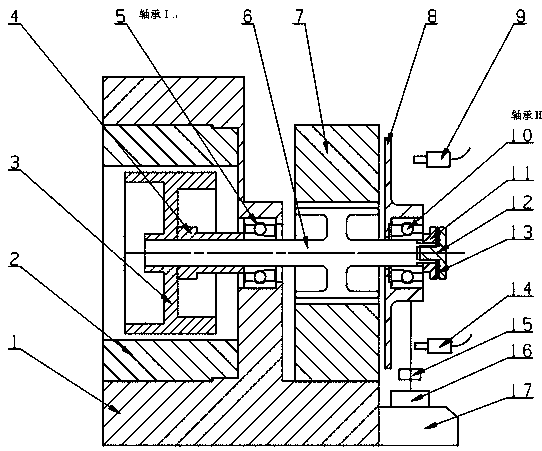

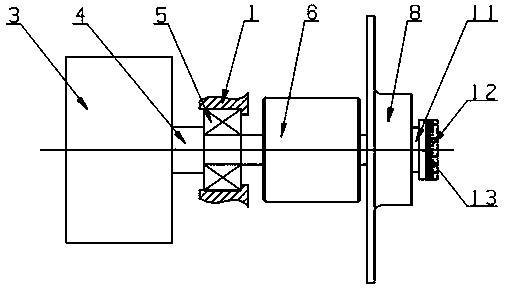

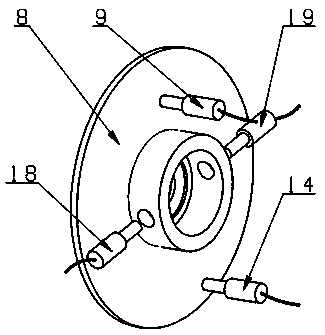

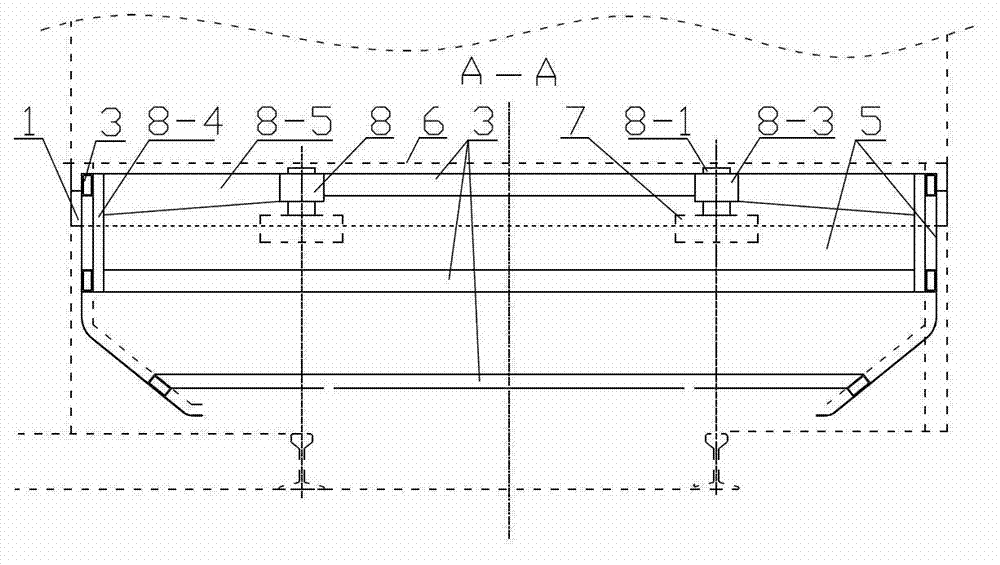

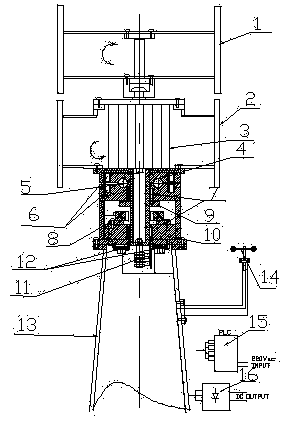

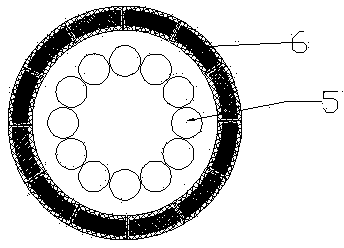

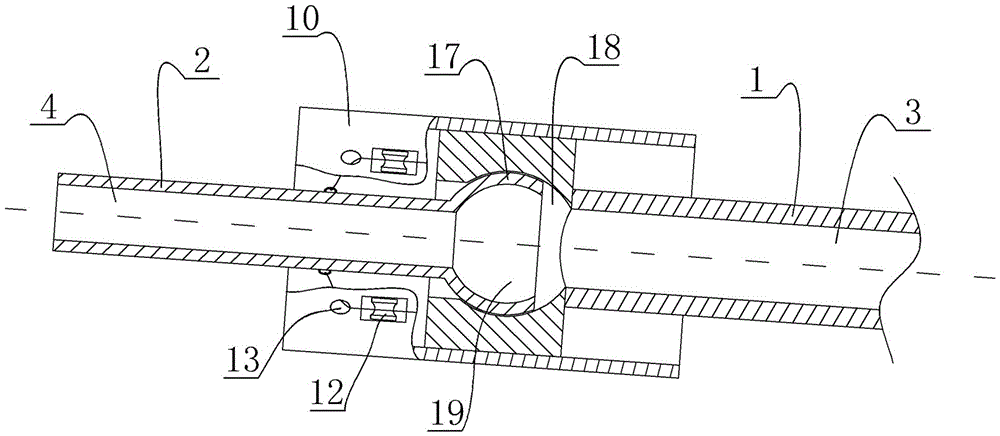

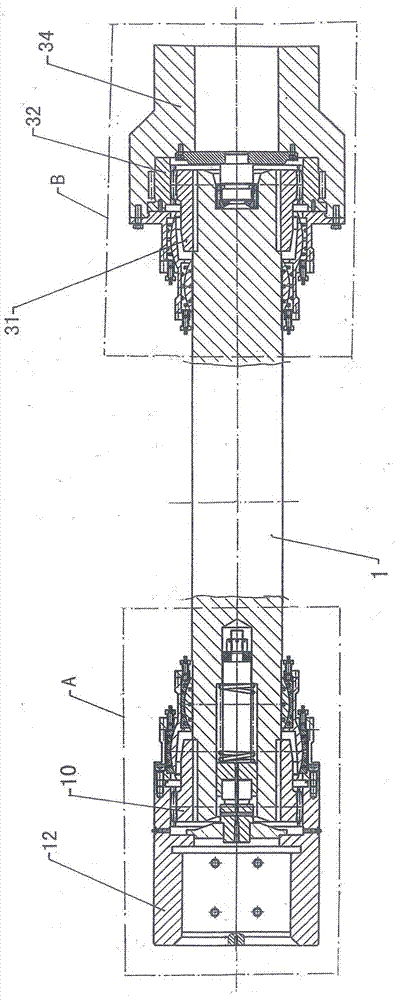

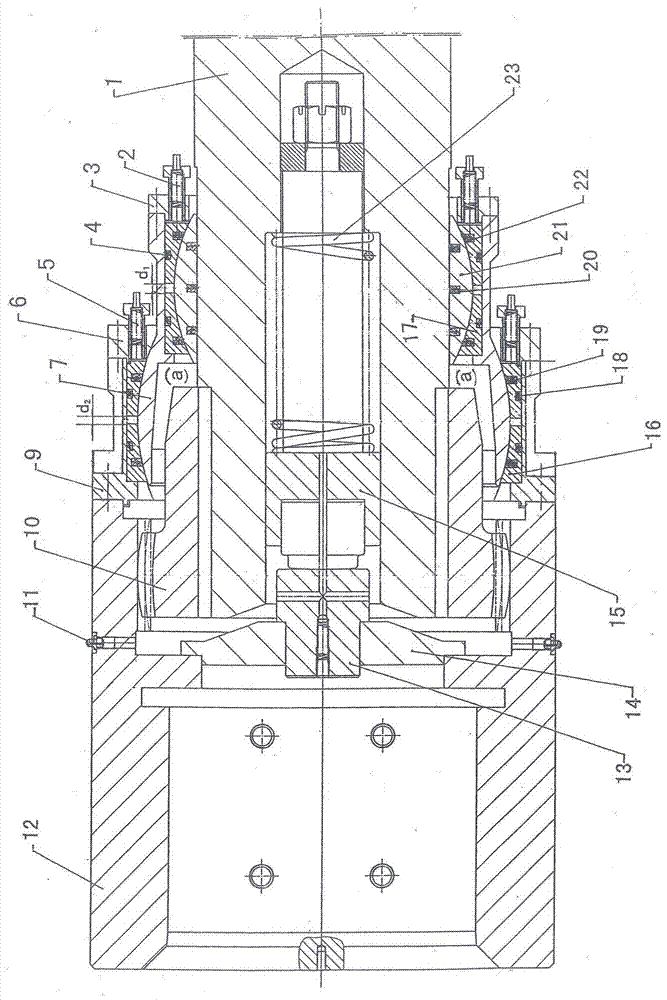

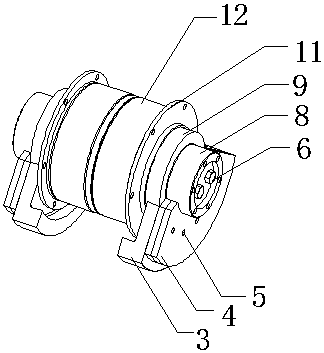

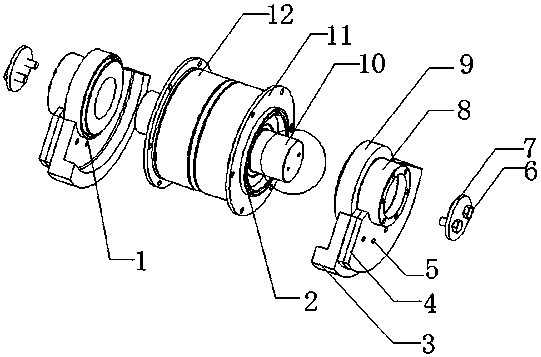

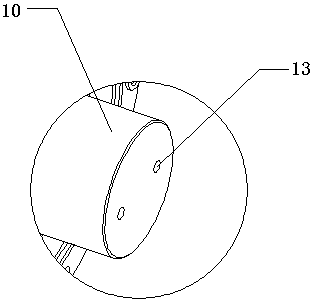

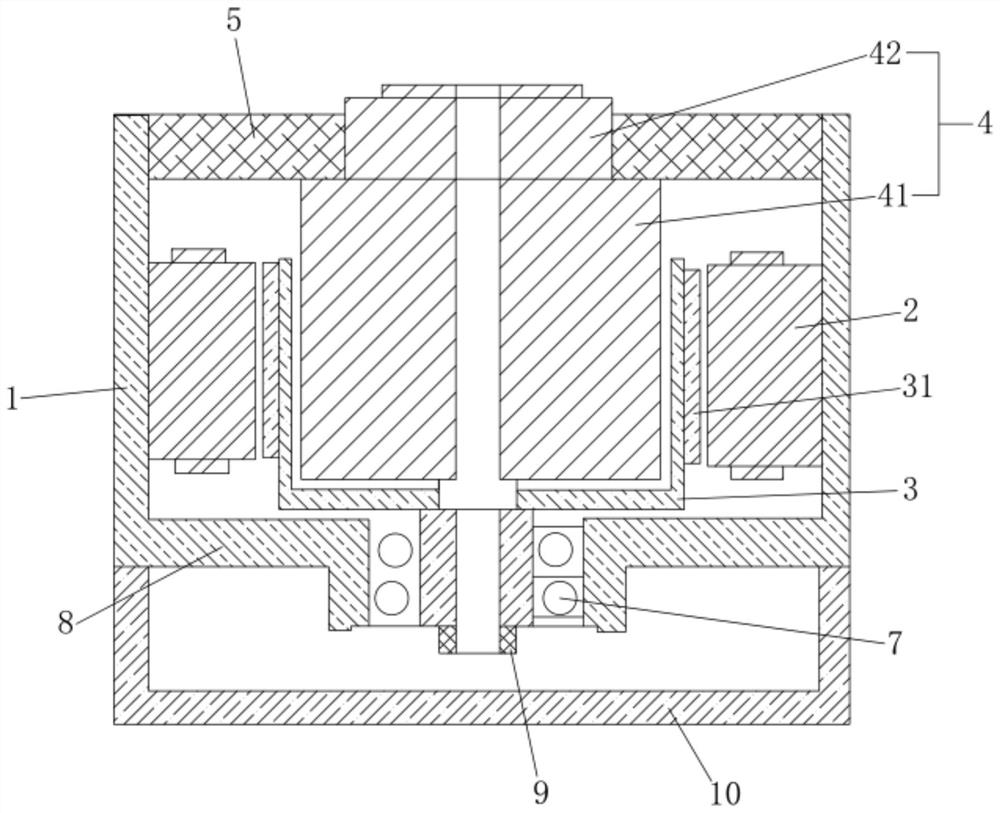

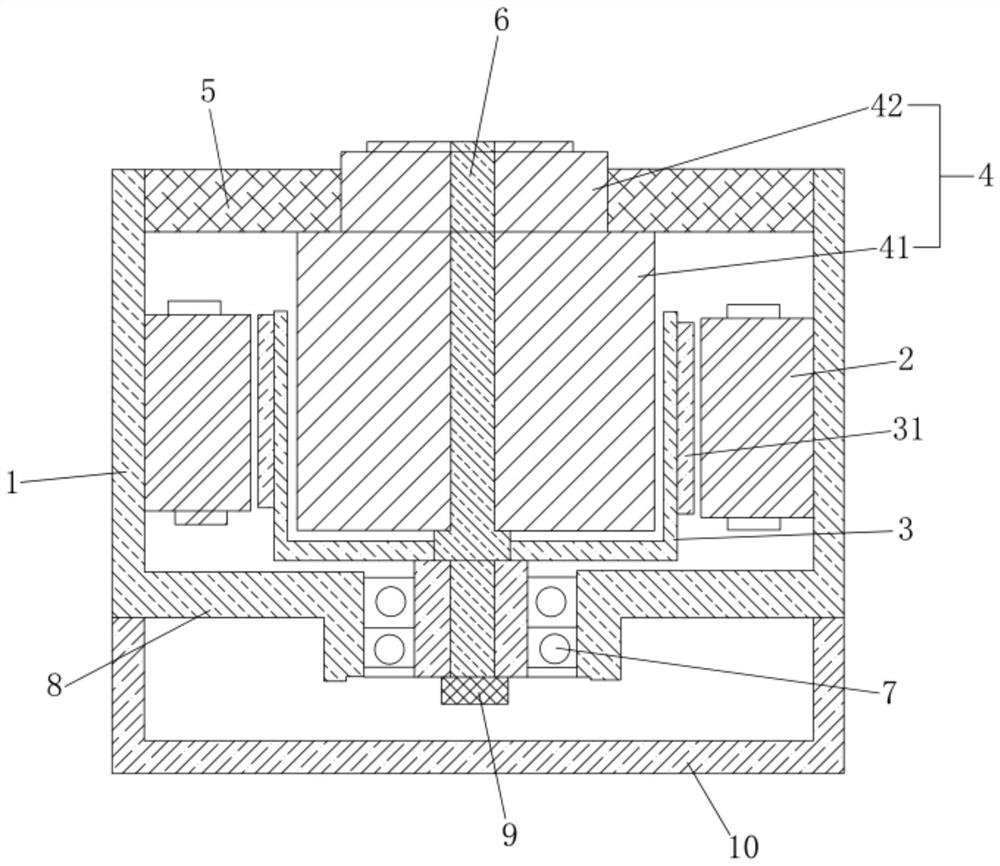

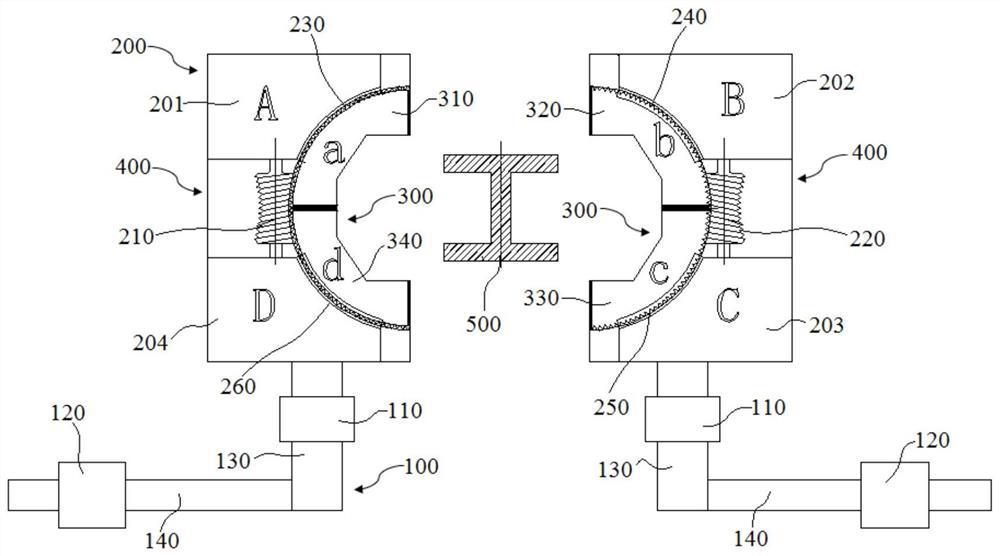

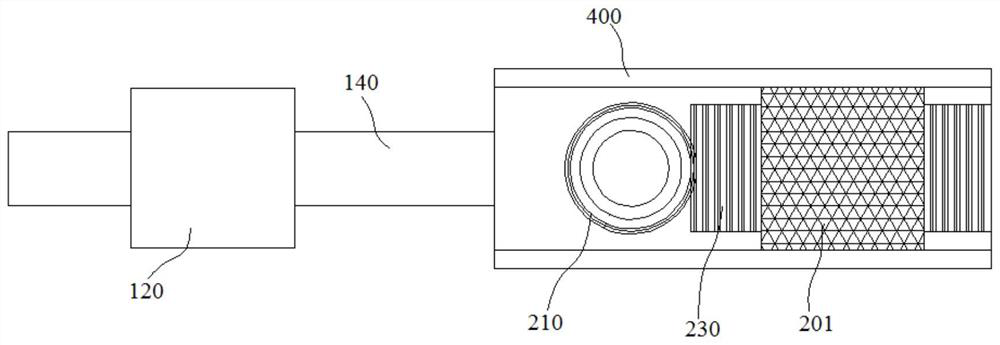

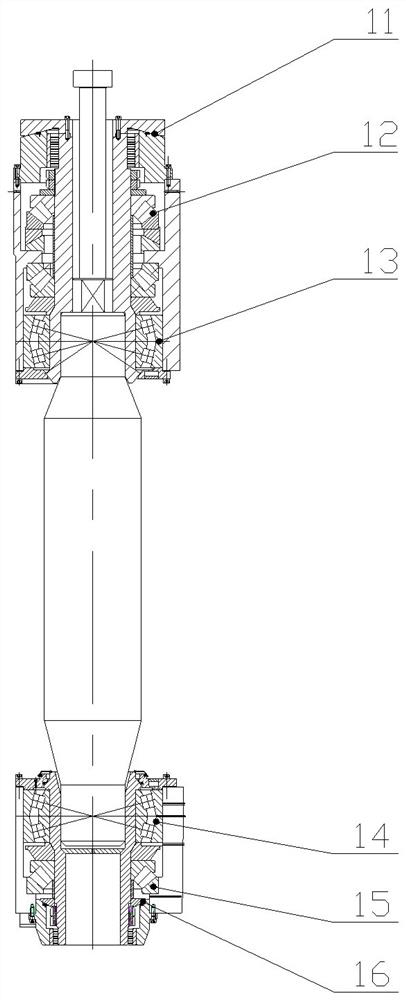

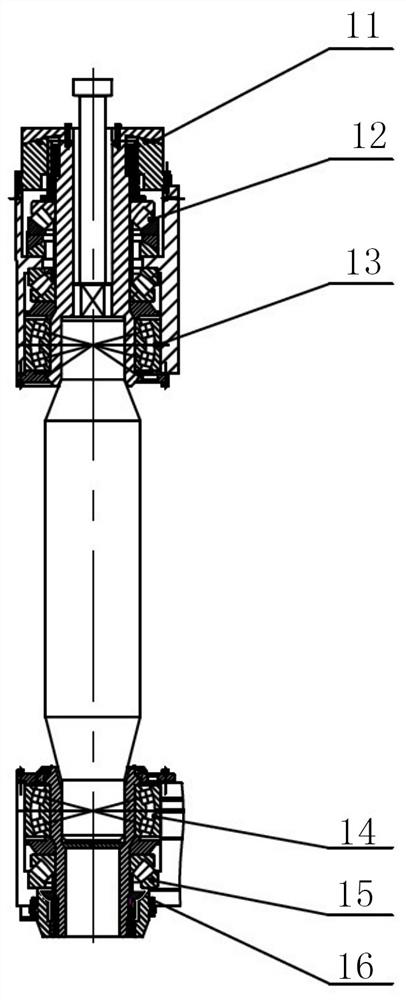

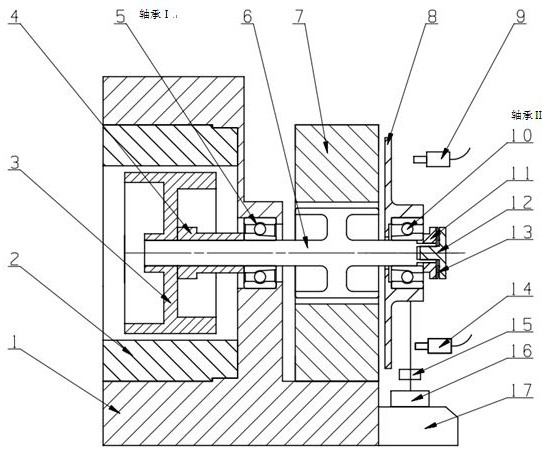

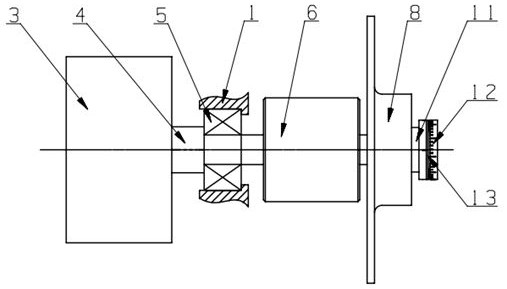

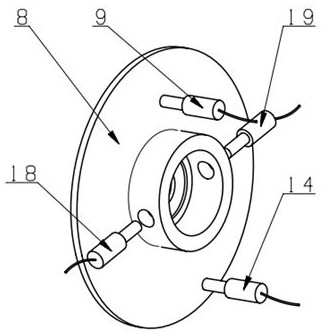

On-line testing device for dynamic friction performance of paired angular contact ball bearings

ActiveCN109959514AOvercoming Disadvantages of InterferenceGuaranteed free rotationMachine bearings testingAir bearingBall bearing

The invention relates to an on-line testing device for the dynamic friction performance of paired angular contact ball bearings. On the basis of the principle of air suspension, the non-contact axialloading of a tested bearing II is obtained while the ultra-low friction support of the high-speed rotating spindle is realized by combining the measurement and adjustment technologies of precision displacement; and the friction torque of the tested bearing II is measured by using a friction torque measuring device put forward by the patent named as "high-speed miniature bearing dynamic friction torque measuring instrument" with the application number of 201610639490.9 in the research group, thereby realizing simultaneous on-line measurement of the friction torque, vibration, temperature and wearing amount of a single precision bearing. Since the outer ring of a partner tested bearing I is fixed on a base, right movement of the shafting is limited and when the shafting is in a static stateand does not work, the shafting, together with non-working faces of the radial-axial air bearing and the thrust disc, bears the shafting torque balancing after careful balance weight, thereby protecting the non-working surface of the high-precision radial-axial air bearing from being in contact for long time and being damaged.

Owner:SHANGHAI UNIV +1

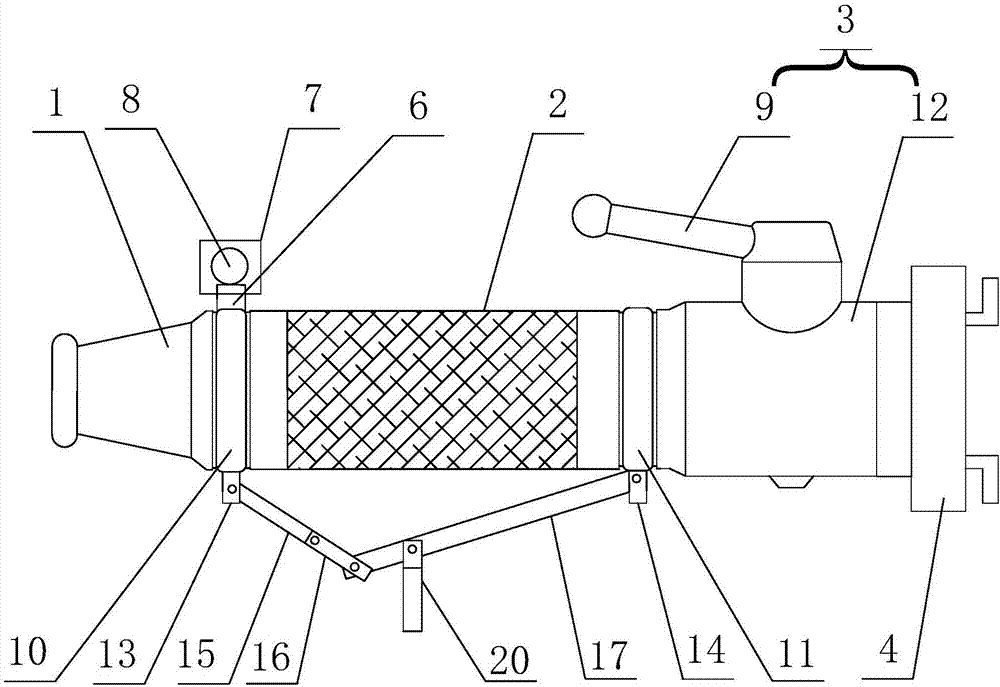

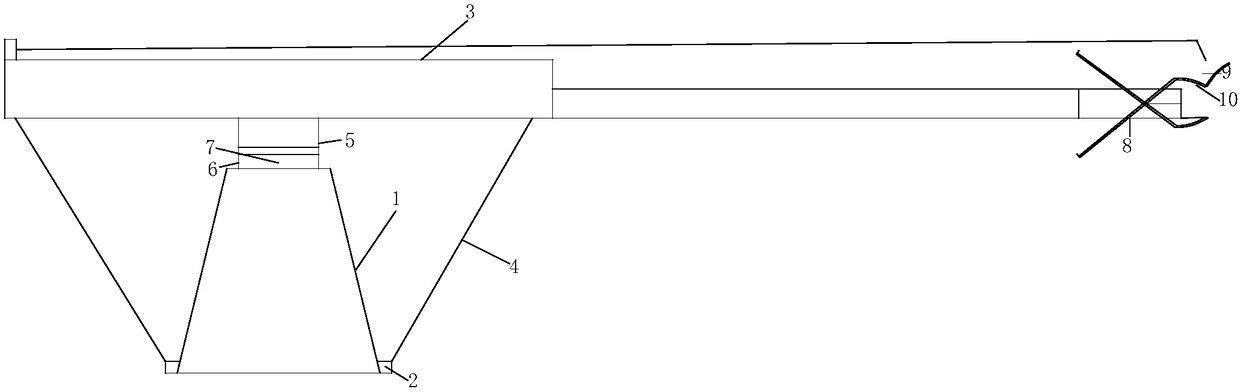

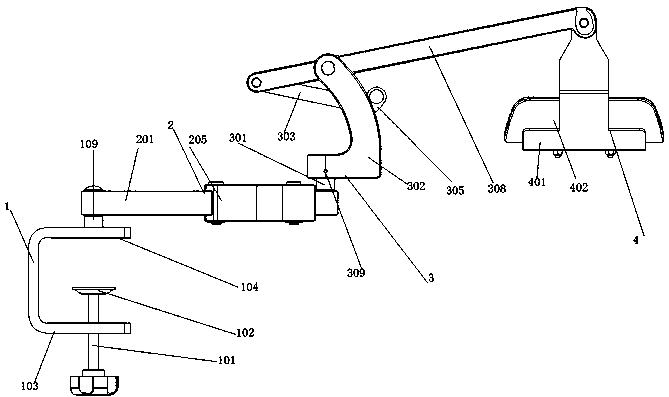

Visible universal fire-fighting lance

The invention discloses a visible universal fire-fighting lance which comprises a nozzle, a high pressure steel wire hose, a ball valve, a lance base and a direction adjusting rod. The two ends of the high pressure steel wire hose are provided with connectors correspondingly. The two connectors are in threaded connection with the nozzle and the ball valve correspondingly. The end, away from the corresponding connector, of the ball valve is in threaded connection with the lance base. The end, close to the nozzle, of the corresponding connector is provided with a first rotating shaft. The end, close to the ball valve, of the connector is provided with a second rotating shaft. The visible universal fire-fighting lance has the beneficial effects that when a fire of jet flow dead corners below a room beam, a window and the like needs to be put out by a firefighter on a fire field, the firefighter only needs to stand on a door or window, the wall of a building is used as a shield, the bending degree of the high pressure steel wire hose of the fire-fighting lance is adjusted through front-back pulling and retraction of the a handle, the water flow direction is changed, dead-corner-free fire extinction is achieved, safety of the firefighter is protected, meanwhile, a wireless camera collects images in real time and transmits the images to the firefighter, and the accurate position and fire intensity of a fire point are commanded.

Owner:李伟 +1

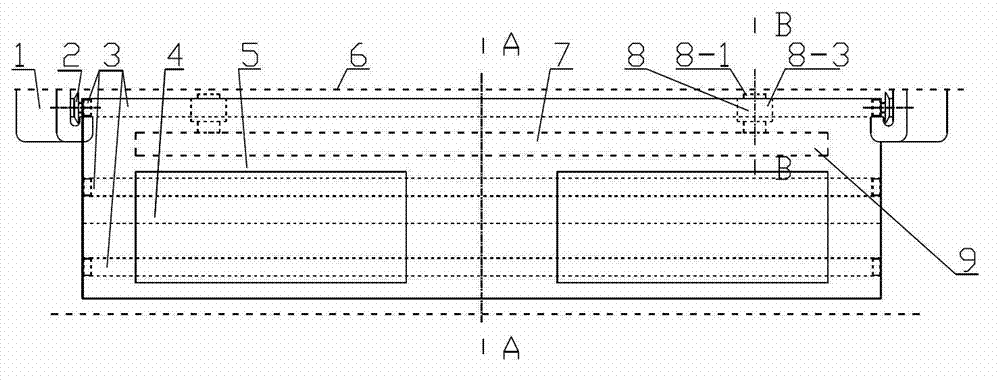

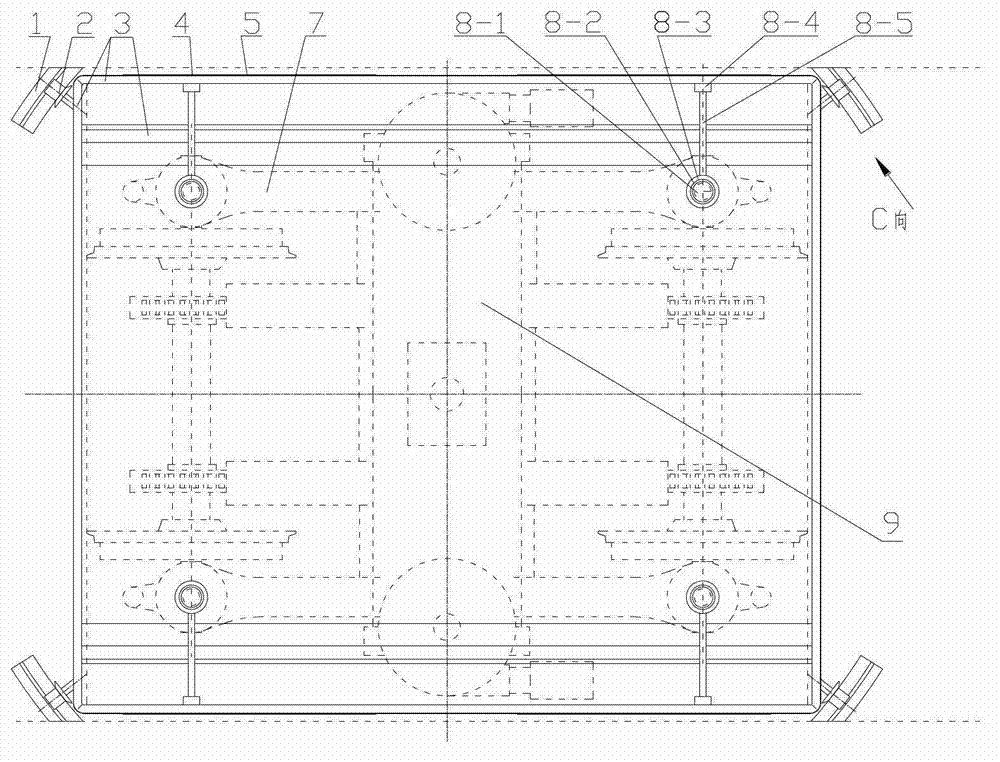

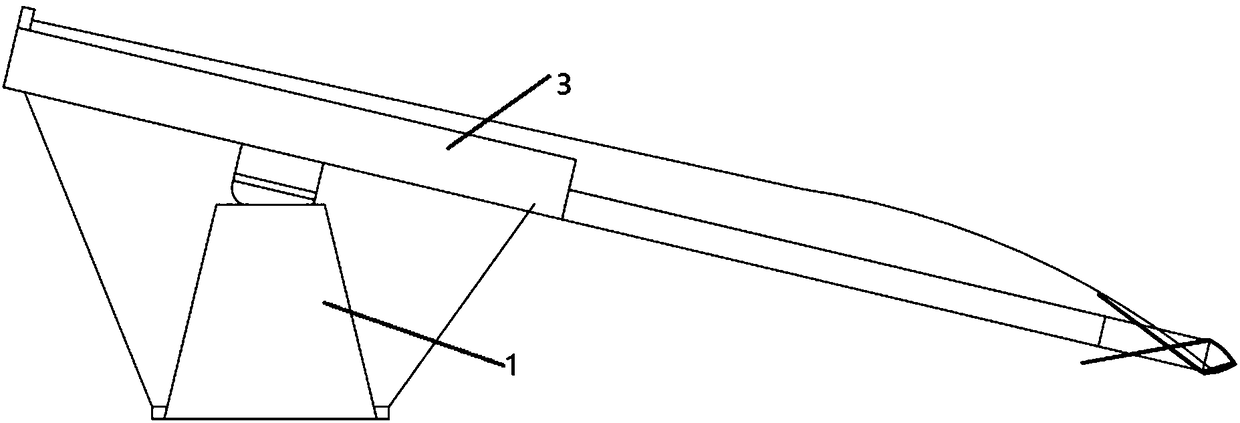

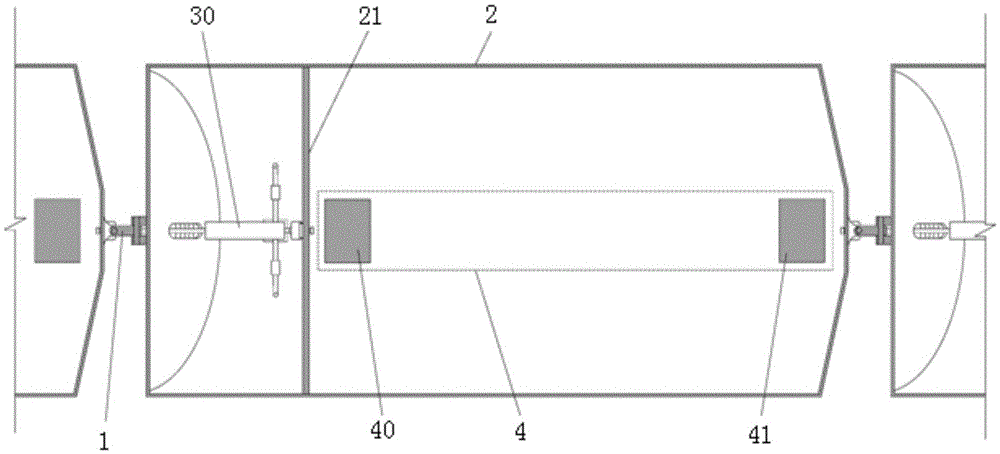

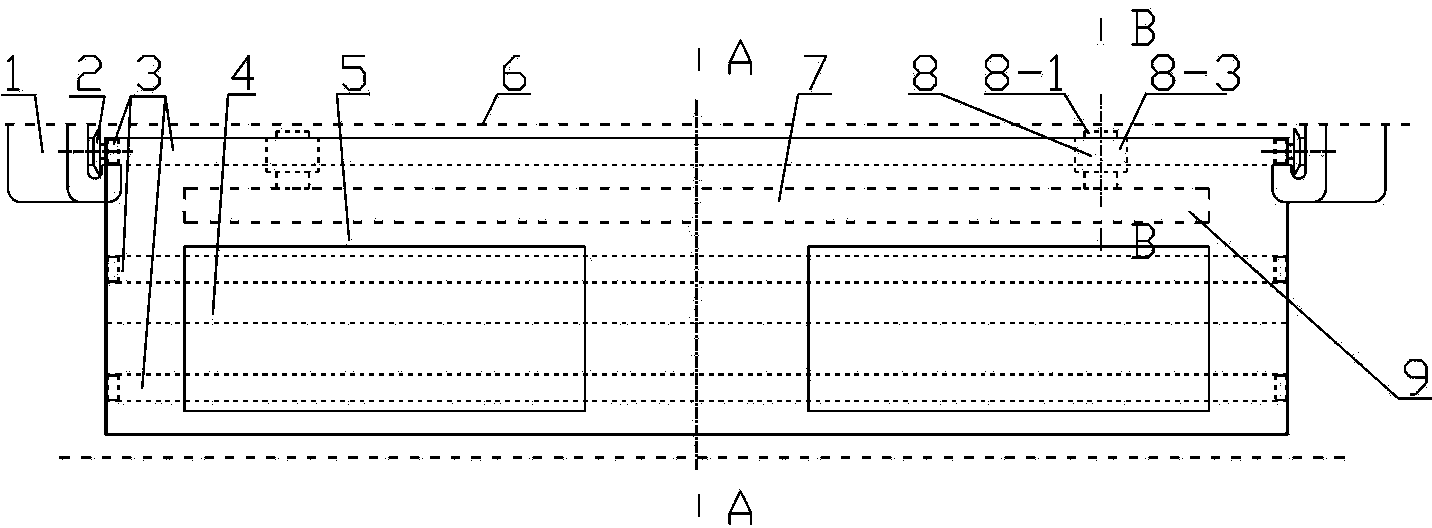

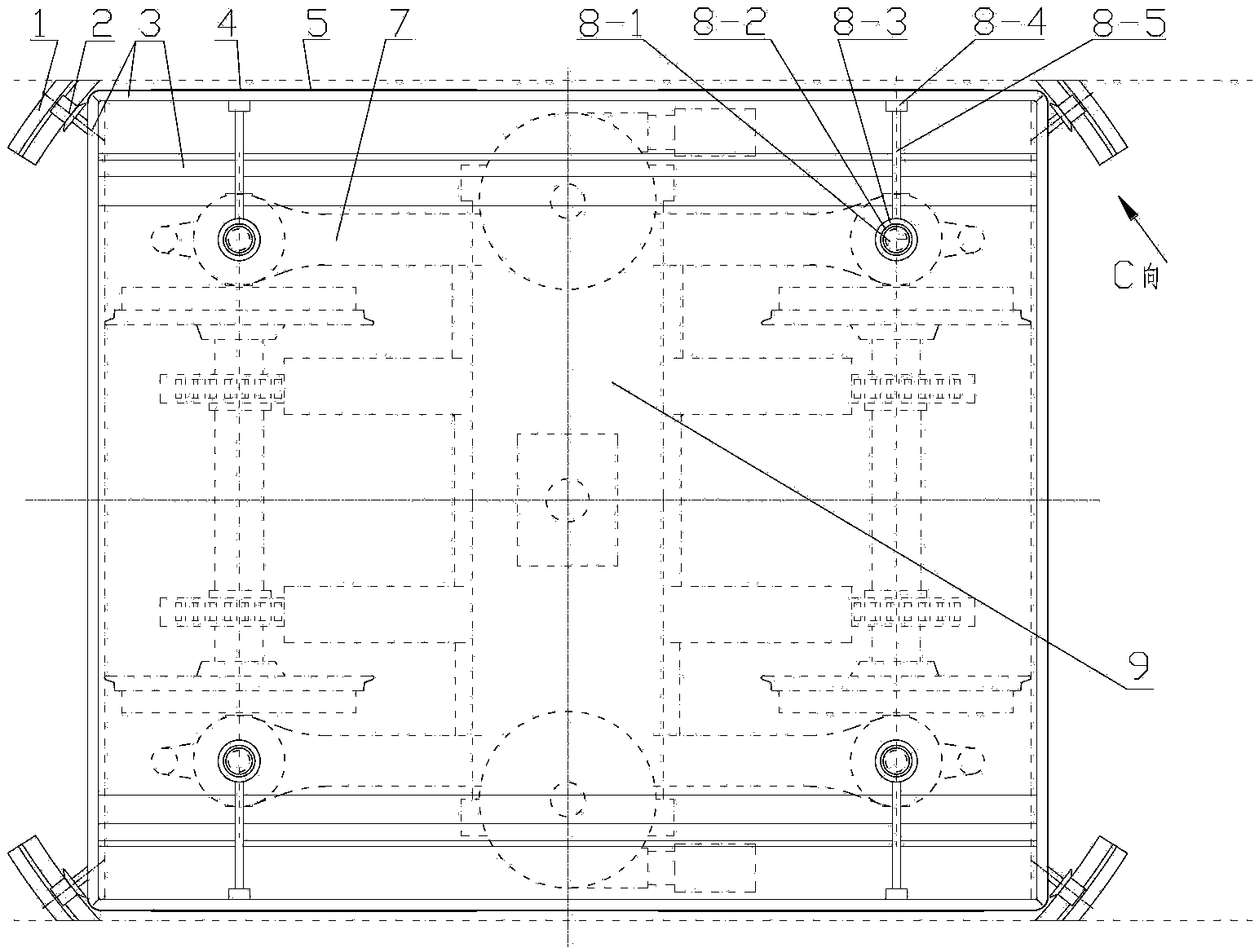

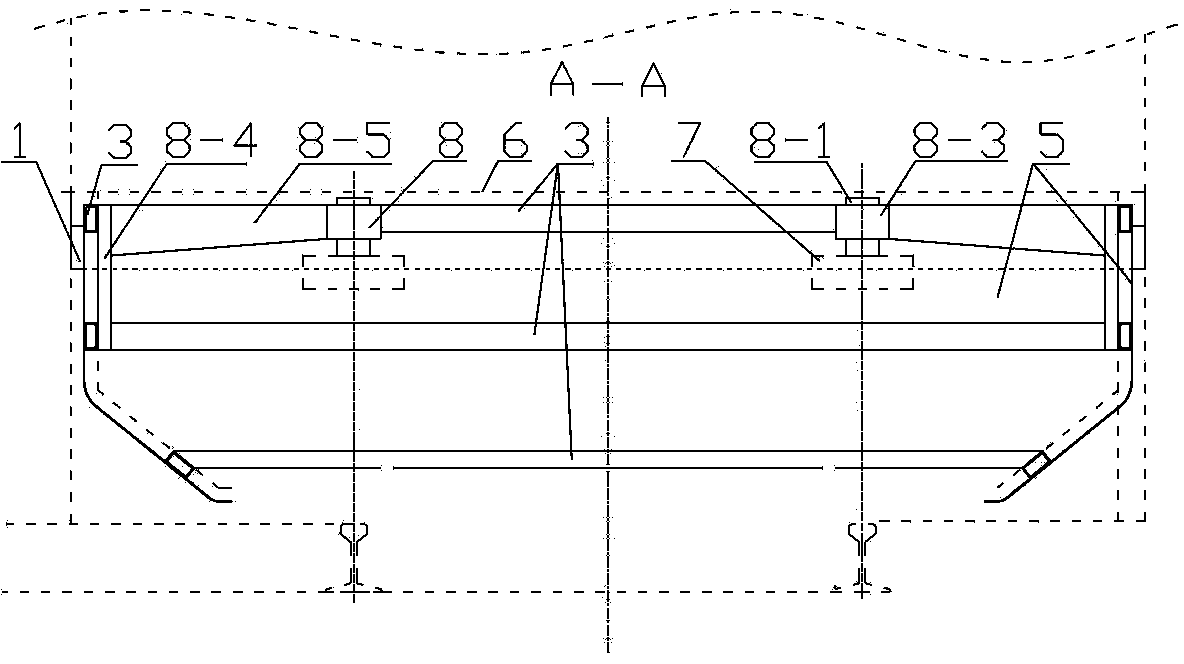

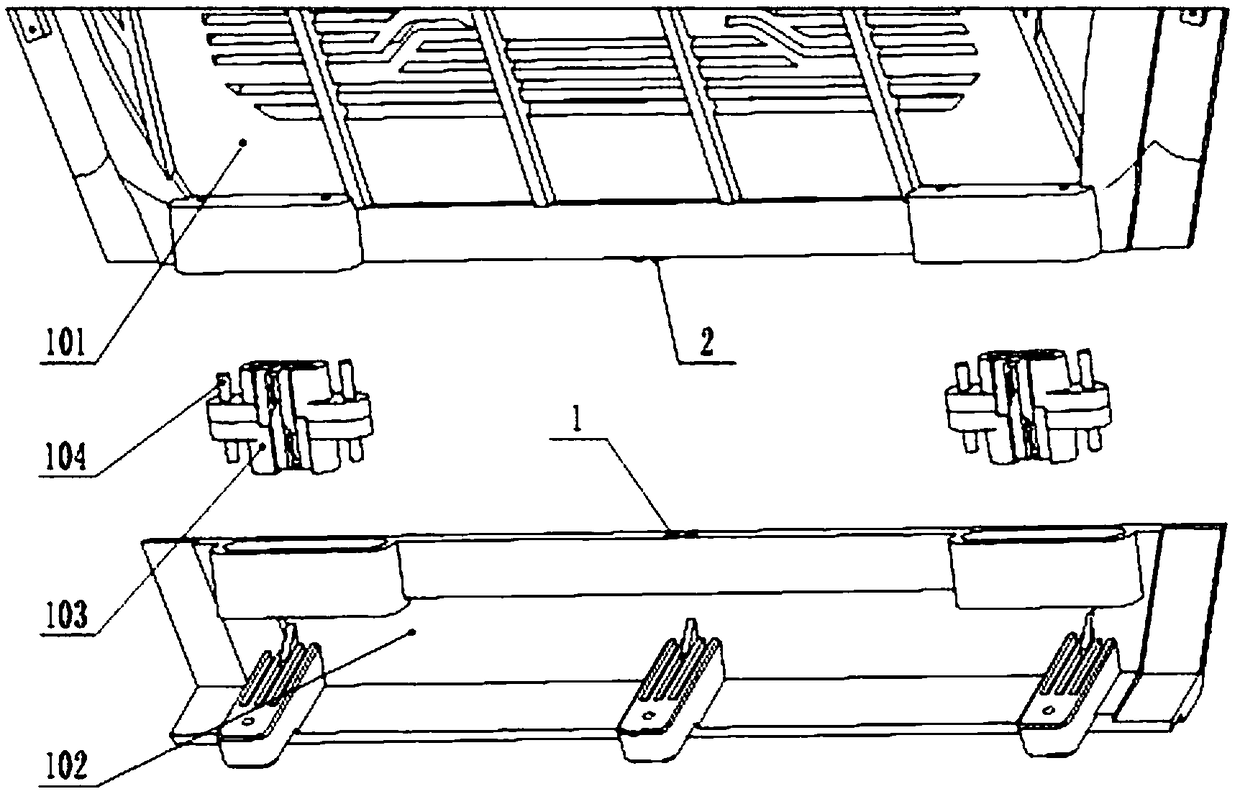

Train bogie rectifying device

The invention relates to a train bogie rectifying device and relates to the technical field of train rectifying. The train bogie rectifying device comprises a dome track, dome wheels, a casing frame, an access door, a dome outer casing, a carriage vehicle bottom, a bogie side frame, a guide device, a guide shaft, a guide shaft rubber sleeve, a guide sleeve, a guide sleeve seat, a guide sleeve seat board and a bogie. The train bogie rectifying device is characterized in that the dome outer casing is in a box shape with an upper opening and a lower opening, the dome outer casing is covered outside the bogie, the dome wheels are installed on two sides of the front upper portion and the rear upper portion of the outside covered dome outer casing, the dome outer casing is connected with the dome track through the dome wheels, and the dome track is connected with the carriage vehicle bottom. According to the train bogie rectifying device, on the premise that movement performances of train operation are not changed, air resistance of train operation is reduced, energy consumption is reduced, or train operation speeds are increased; free rotation of the bogie and relative movement of the bogie and a wagon box in an upward and downward direction are guaranteed; radiating during braking is guaranteed; loads are not added to the bogie; and the train bogie rectifying device is convenient to maintain.

Owner:苗泽旺

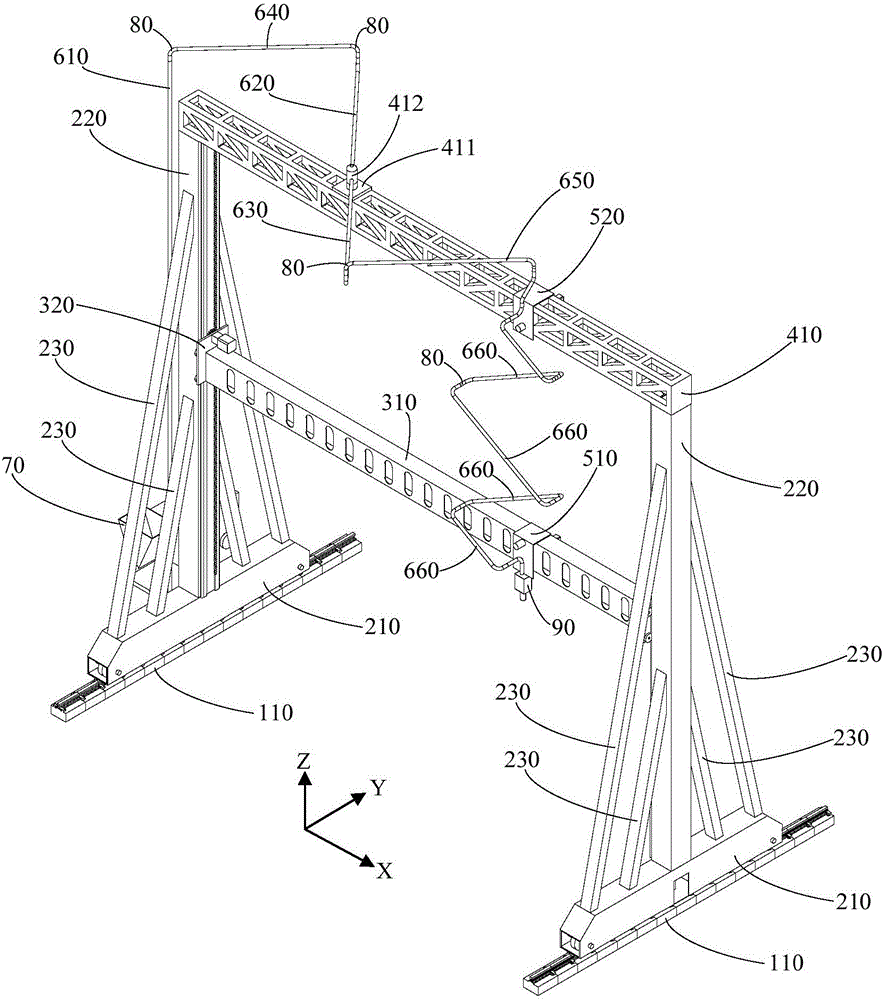

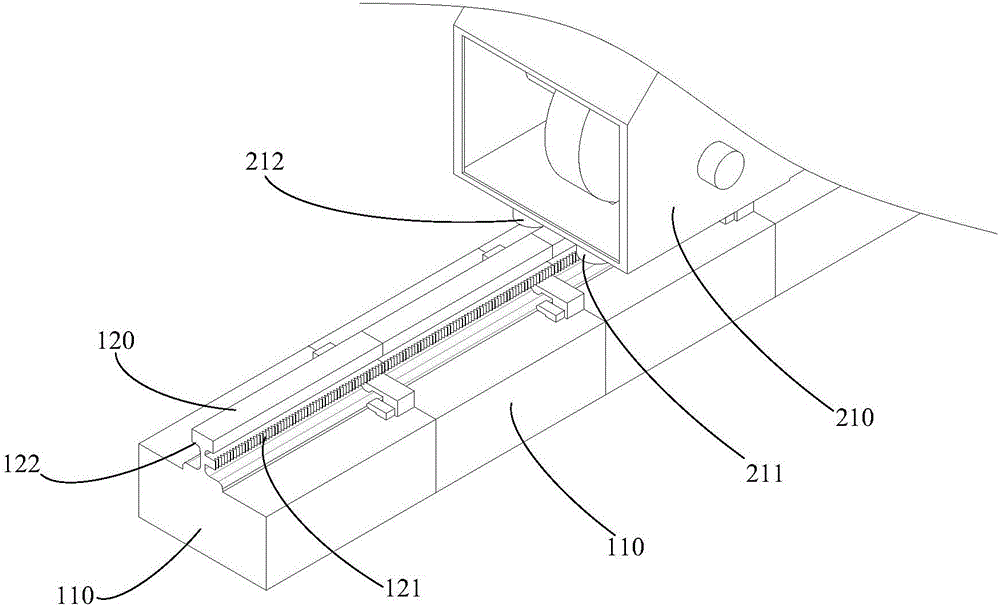

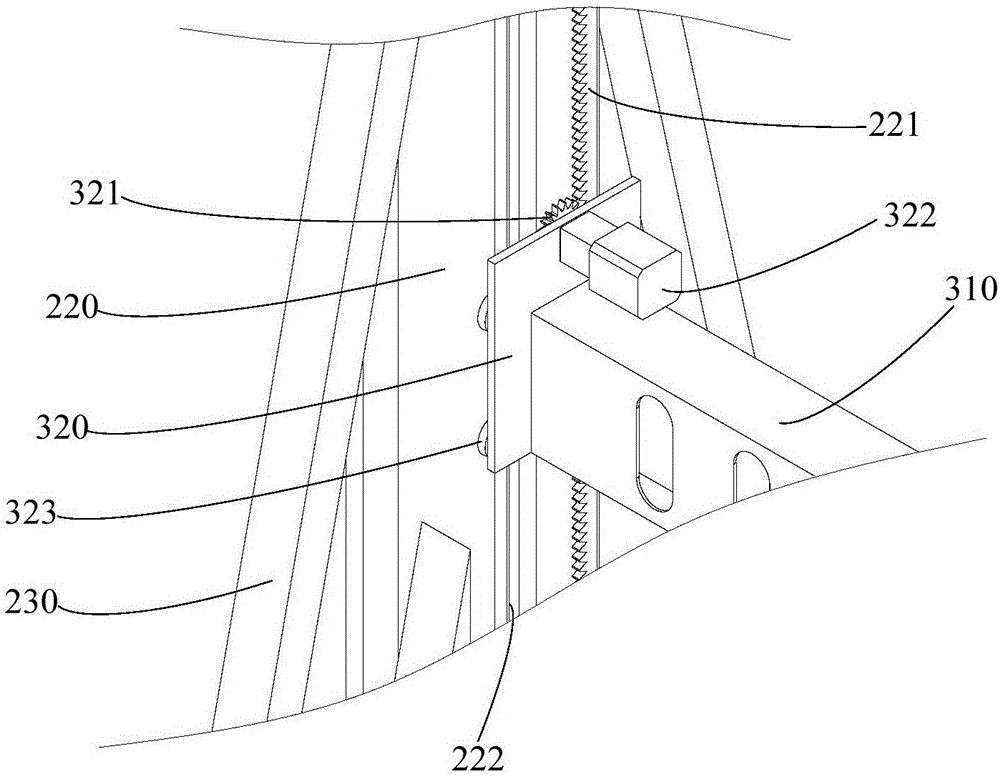

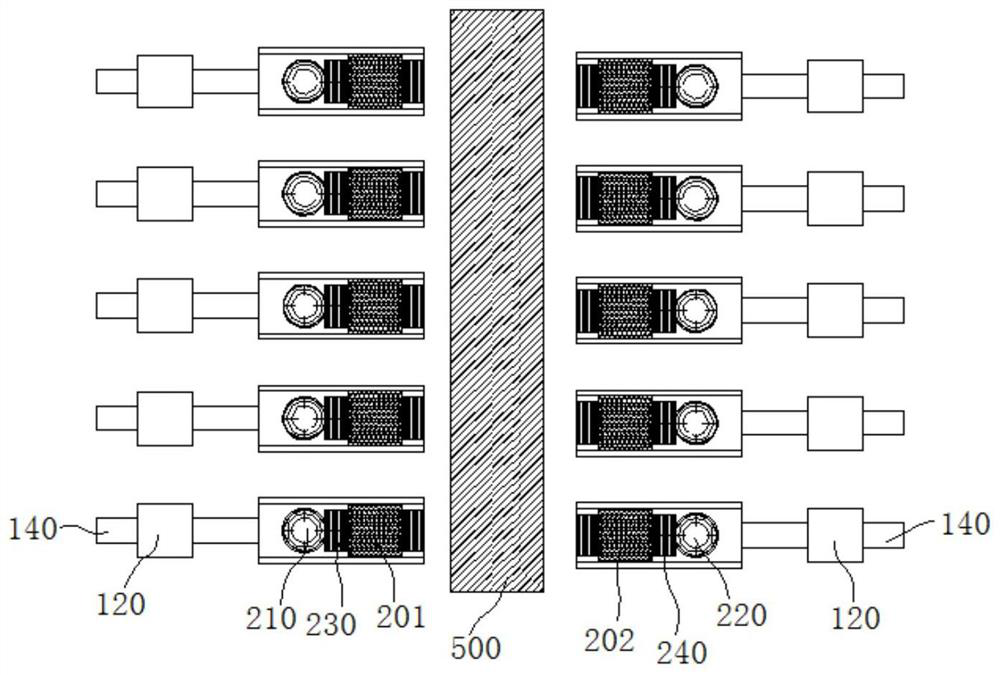

Dismountable easy-to-clean pipeline system for conveying building 3D printing material

ActiveCN105804405AAvoid cloggingEasy to moveBuilding material handlingEngineeringConstruction 3D printing

The invention discloses a dismountable easy-to-clean pipeline system for conveying a building 3D printing material. The system comprises two first guide rail mechanisms, two second guide rail mechanisms, a third guide rail mechanism, a fourth guide rail mechanism, a first connection mechanism, a second connection mechanism and a plurality of feeding pipes, wherein the two first guide rail mechanisms are arranged parallel to a first horizontal direction; the two second guide rail mechanisms are arranged along a vertical direction and are respectively connected with the two first guide rail mechanisms in a sliding manner along the first horizontal direction; the third guide rail mechanism is arranged along a second horizontal direction vertical to the first horizontal direction, is erected between the two second guide rail mechanisms and is connected with the two second guide rail mechanisms in a sliding manner along the vertical direction; the fourth guide rail mechanism is arranged along the second horizontal direction, is arranged at the upper part of the third guide rail mechanism and is fixedly connected between the two second guide rail mechanisms; the first connection mechanism is connected with a printer head and is connected with the third guide rail mechanism in a sliding manner along the second horizontal direction; the second connection mechanism is connected with the fourth guide rail mechanism; the feeding pipes are connected with each other via a bent pipe bearing, are communicated with the printer head and are used for conveying the printing material to the printer head; the feeding pipes are connected with each other via the bent pipe bearing, so that the feeding pipes are capable of freely rotating and are low in possibility of damage.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD +1

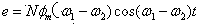

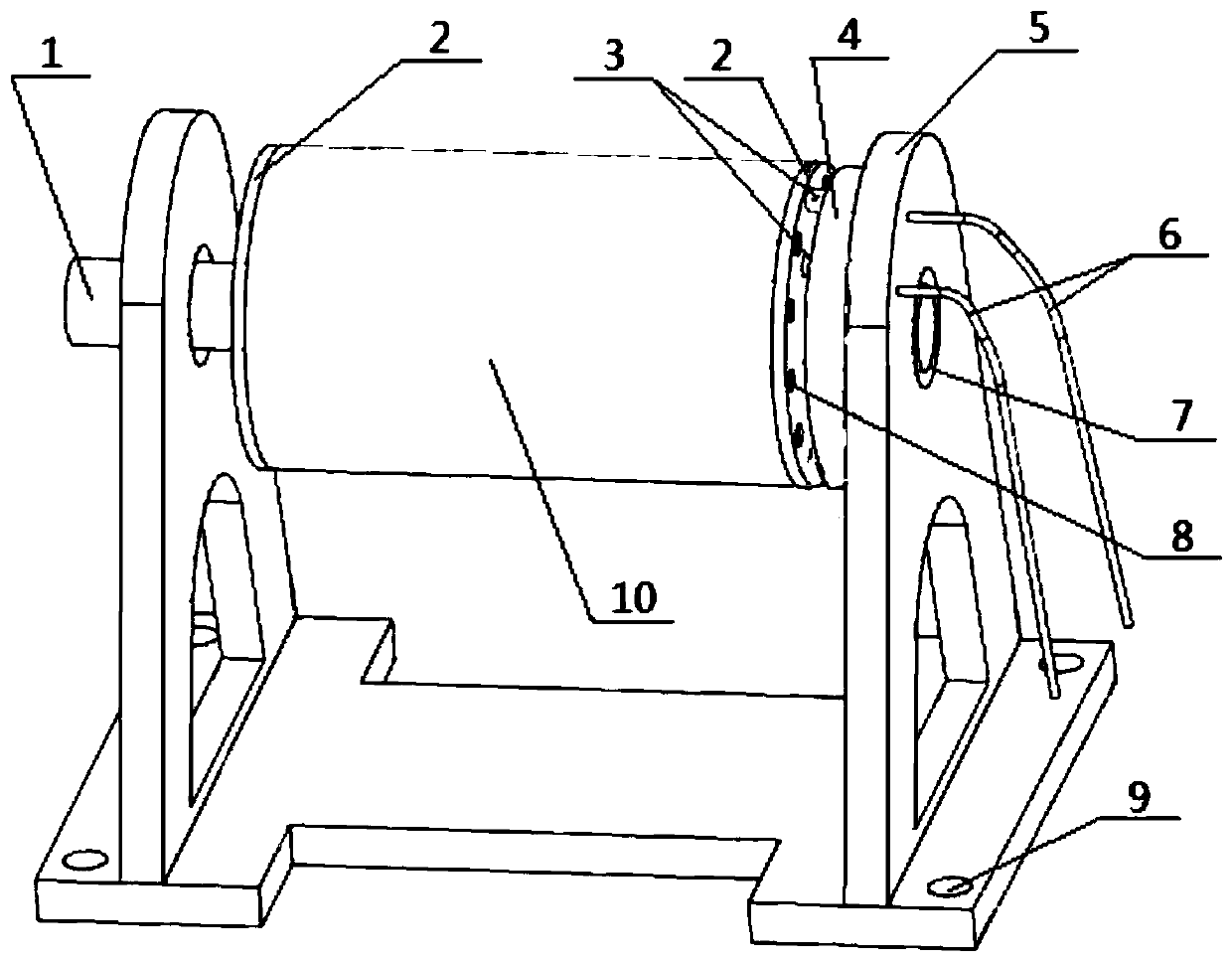

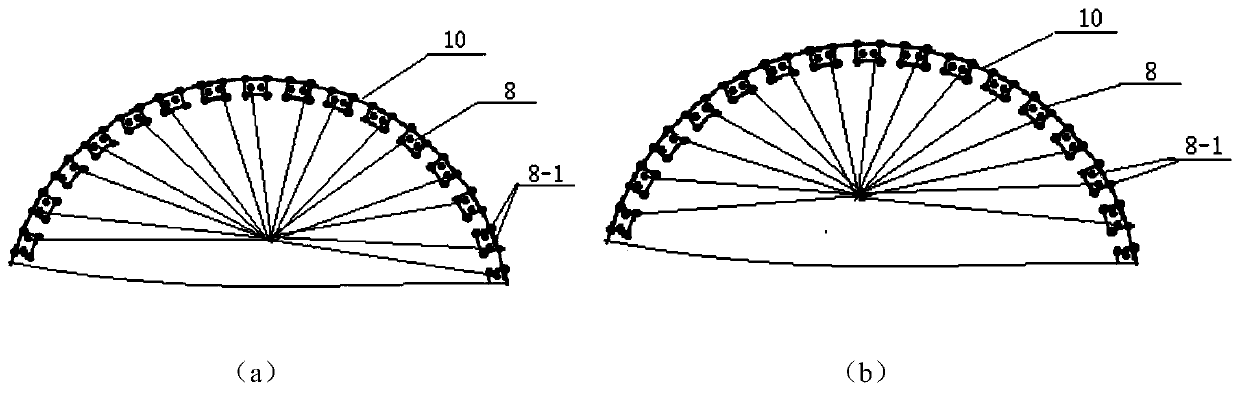

Vertical-axis wind power generation system working according to double-wind-turbine double-wind-speed power curves

InactiveCN104121146AGuaranteed free rotationImprove performanceWind motor controlFinal product manufactureFree rotationTurbine blade

The utility model discloses a vertical axis wind power generation system working on a double wind speed power curves. Two groups of Darrieus wind wheels are designed, one group of Darrieus wind wheel is arranged on a rotor of a generator and the other group of Darrieus wind wheel is arranged on a stator of the generator, however, rotating directions of the Darrieus wind wheels are just opposite. The bottom of the generator is fixed on a rotating body; the rotating body can freely rotate around a center axis of the generator in a magnetic suspension non-friction mode; at a low wind speed, double wind wheels work; at a high wind speed, only the rotor wind wheel works; according to variation of the wind speed, the wind power generation system is controlled to circulate the two working modes by a PLC (Programmable Logic Controller) and double-power-curve working of the system on the low-wind-speed power curve and the high-wind-speed power curve; and the start wind speed is low; and the working wind speed range is wide. The vertical axis wind power generation system is particularly suitable for vast areas with nonuniform annual wind speed distribution; and annual energy output can be improved severalfold. The wind power generation system disclosed by the utility model has reliable performance, is stable, has a simple structure, is easy to manufacture, is low in cost, is difficult to damage, is durable and is easy to maintain.

Owner:伍培云

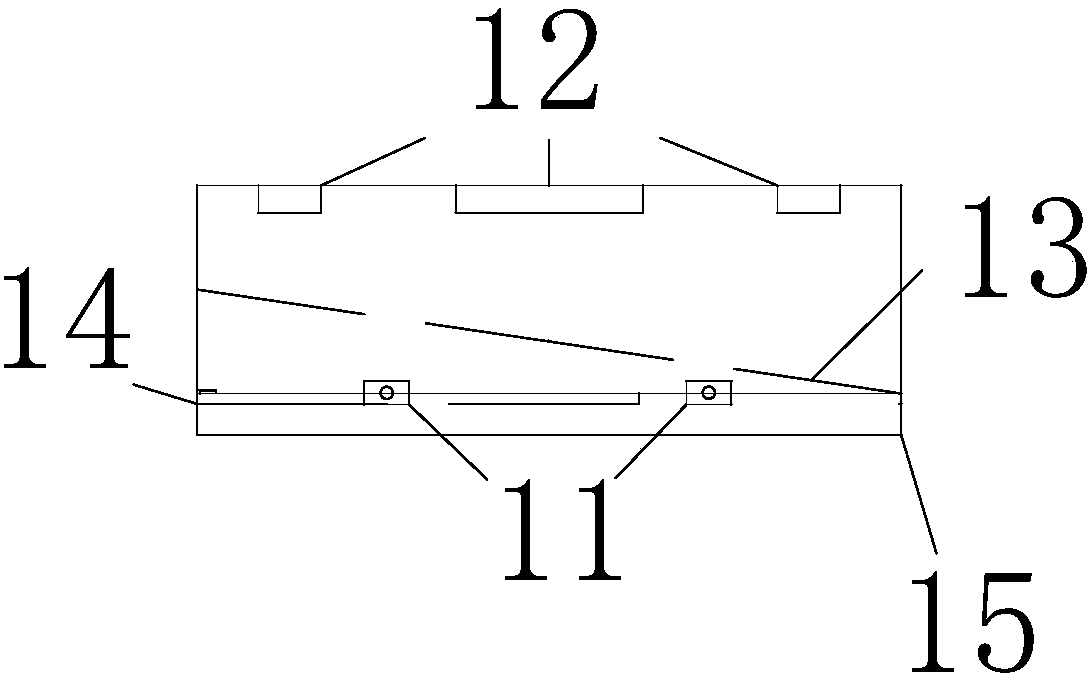

Electromagnetic separation device for treating solid garbage

PendingCN110694794AImprove incineration efficiencyAvoid damageMagnetic separationIncinerator apparatusProduction lineBrush

The invention provides an electromagnetic separation device for treating solid garbage. The electromagnetic separation device comprises a support, a magnet assembly, an end plate flange, a power supply polar plate, a carbon brush electrode, a power input shaft, a magnetic separation roller and the like. The magnet assembly mainly comprises an electrode lead, a connecting shaft, a coil and an ironcore and is fixedly connected with end plate flanges at the two ends of the magnetic separation roller through the connecting shafts at the two ends. An outer electrode plate and an inner electrode plate are arranged on the power supply electrode plate; when garbage is magnetically separated, magnetic garbage is attracted to the surface of the roller through the magnetic force of the electromagnet, after the attracted magnetic garbage rotates along with the roller and passes through the partition plate, the electromagnet disappears in magnetic force due to power failure, the magnetic garbage falls into the magnetic garbage conveying belt due to the gravity effect, and separation of the magnetic garbage is achieved. According to the electromagnetic separation device, energy is saved, the garbage sorting and treating cost is reduced, magnetic garbage is prevented from being mechanically scraped off from a high-intensity magnetic field, damage of the magnetic garbage to the incinerator isavoided, the incineration efficiency of solid garbage is improved, the service life of solid garbage magnetic separation equipment is prolonged, and the reliability and economic benefits of a production line are improved.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

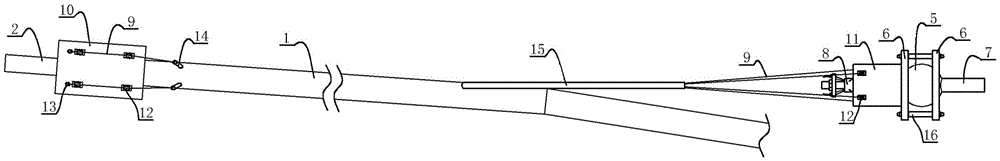

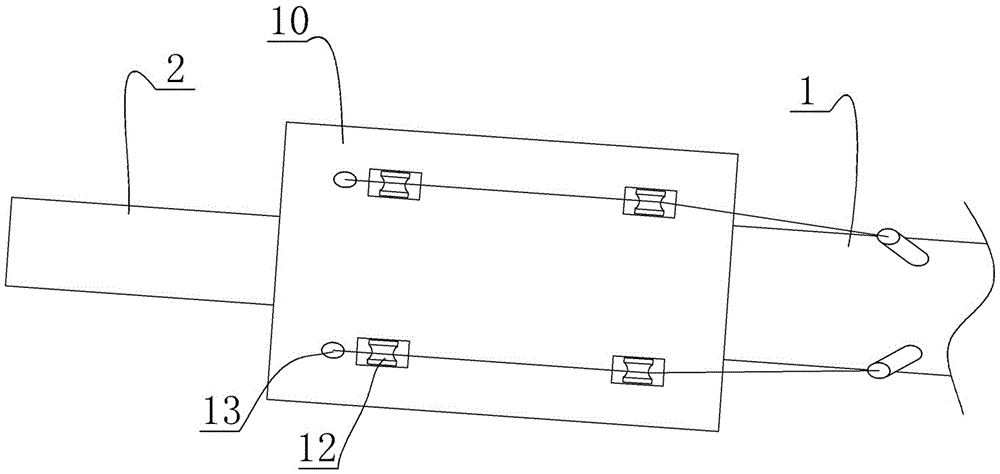

Fluid jet direction adjusting device

The invention provides a fluid jet direction adjusting device which comprises a fluid pipeline, an injector head, a driving ball and multiple stay wires. The fluid jet direction adjusting device is characterized in that the driving ball is located at the rear end of the fluid pipeline, a handle is fixed to the rear end of the driving ball, a supporting rod is fixed to the front end, a front outer cylinder is arranged on the periphery of the injector head, a rear outer cylinder is arranged on the periphery of the supporting rod, the front ends of the stay wires are fixed to the periphery of the injector head, and the rear ends of the stay wires are fixed to the periphery of the supporting rod. The stay wires are in a tension state so that the direction of the injector head can change along with changing of the direction of the supporting rod, the injector head can rotate along with the supporting rod, and the jet direction of the injector head can be adjusted so as to carry out effective extinguishment operation. The fluid jet direction adjusting device has the advantages of being simple and reasonable in structure, low in manufacturing cost, flexible to control, remarkable in benefit effect and suitable for application and popularization.

Owner:张正泉

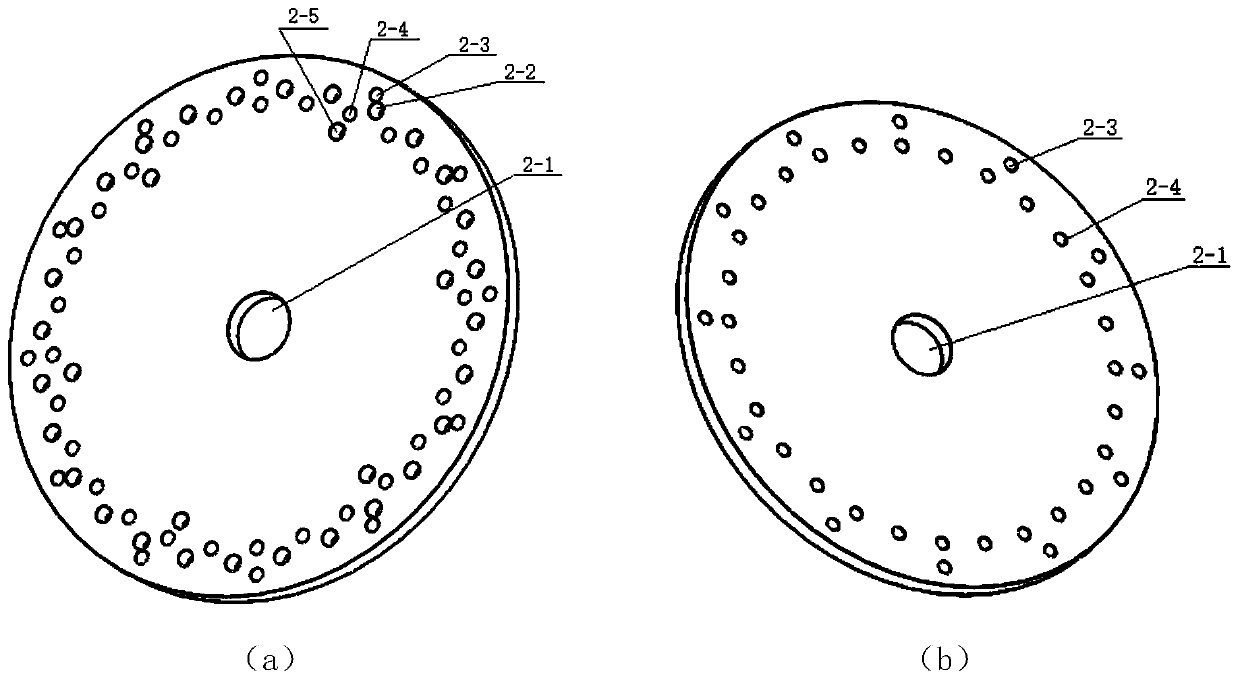

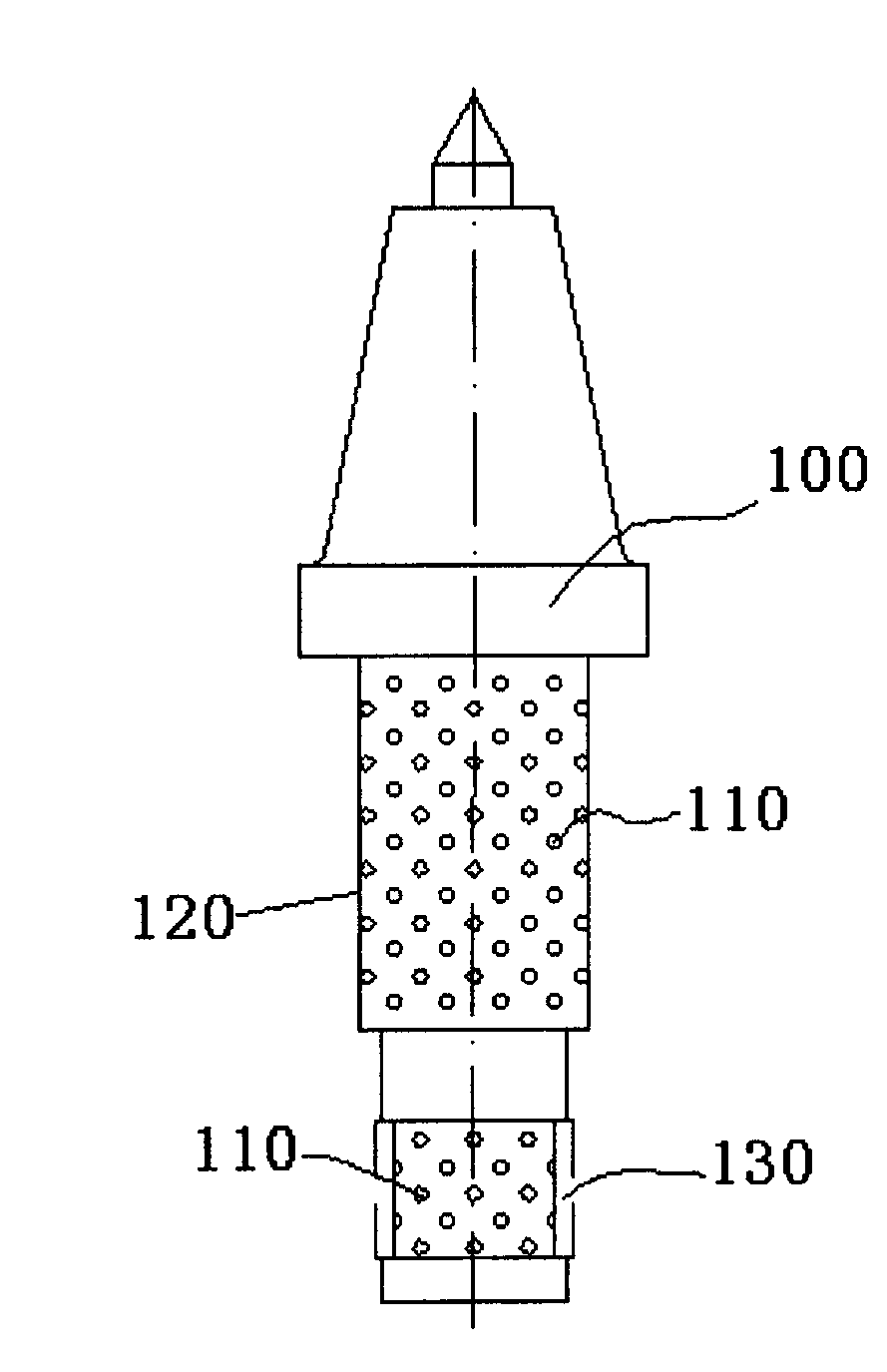

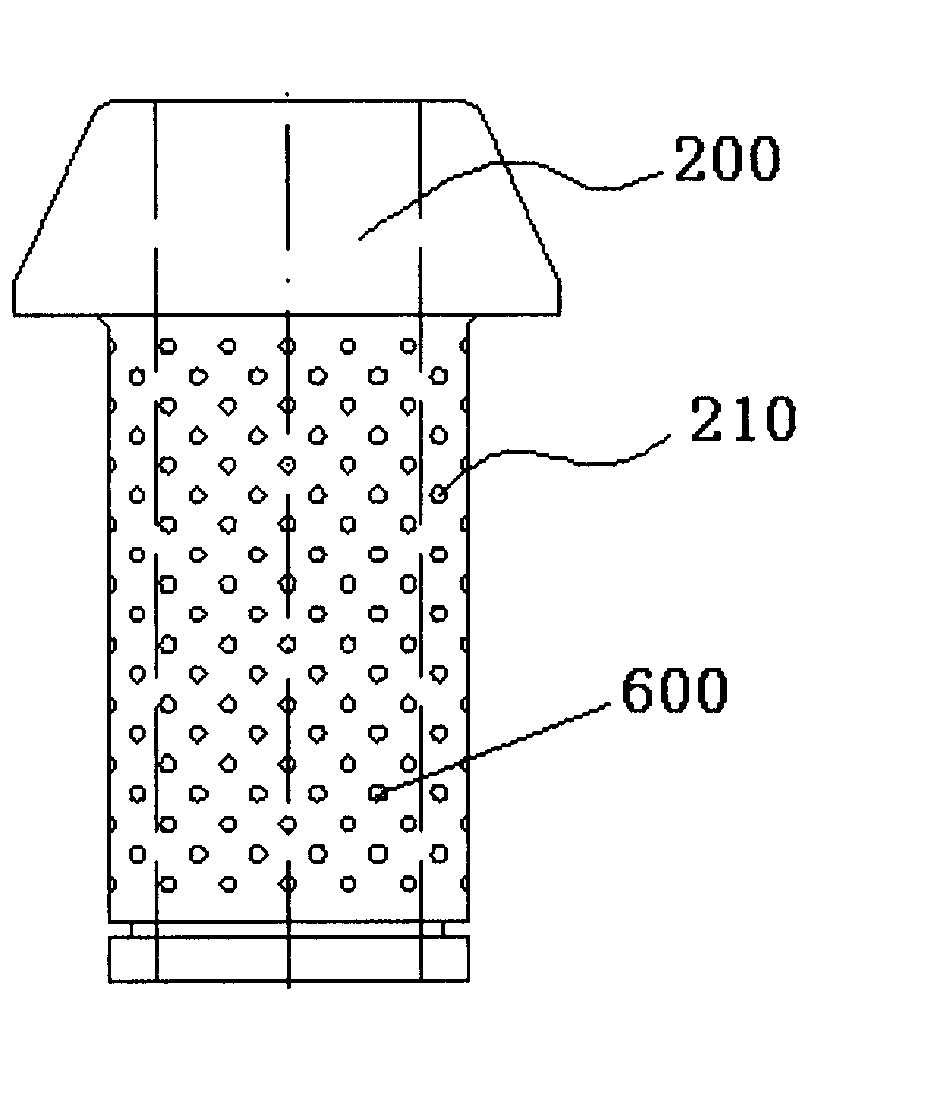

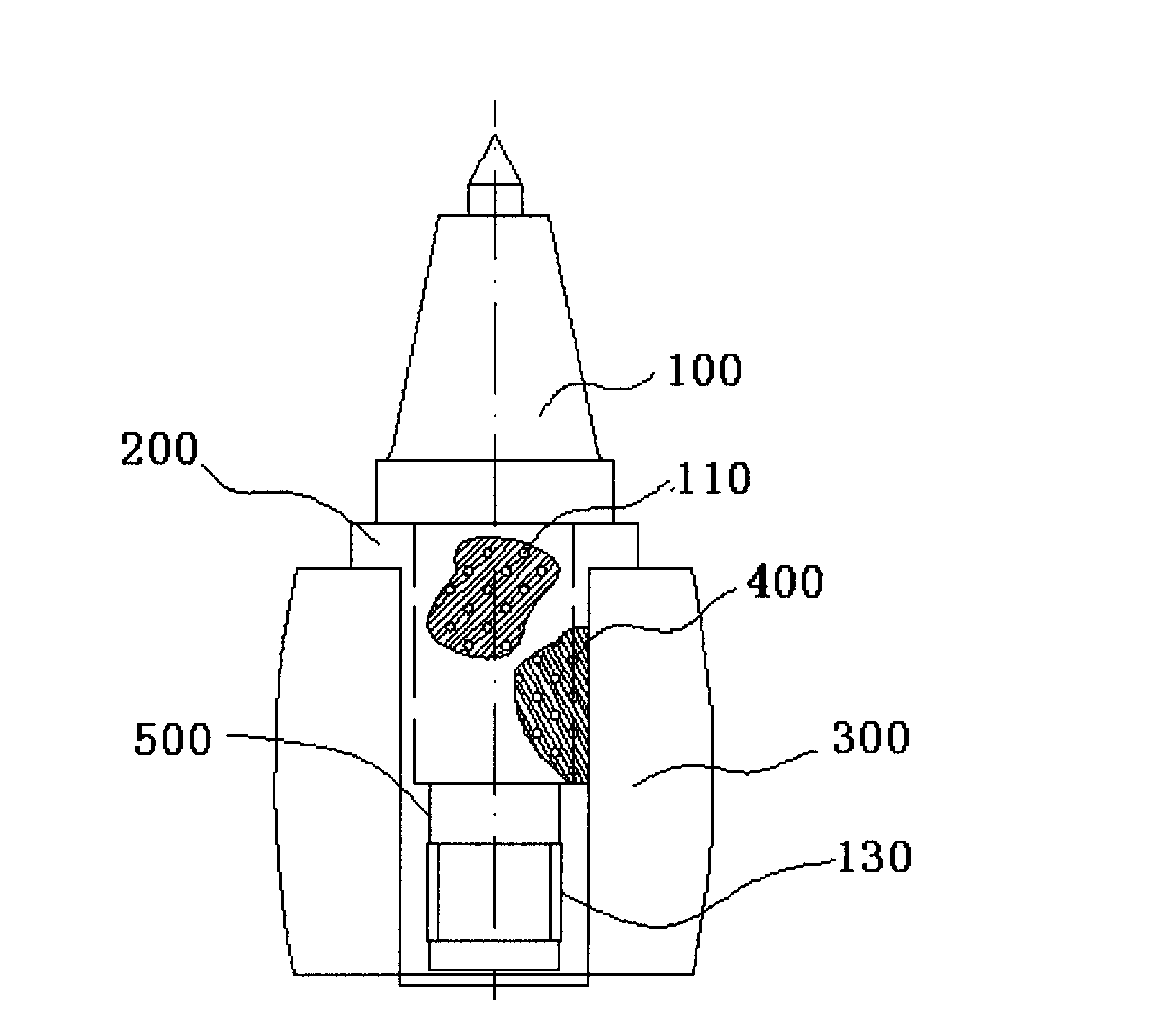

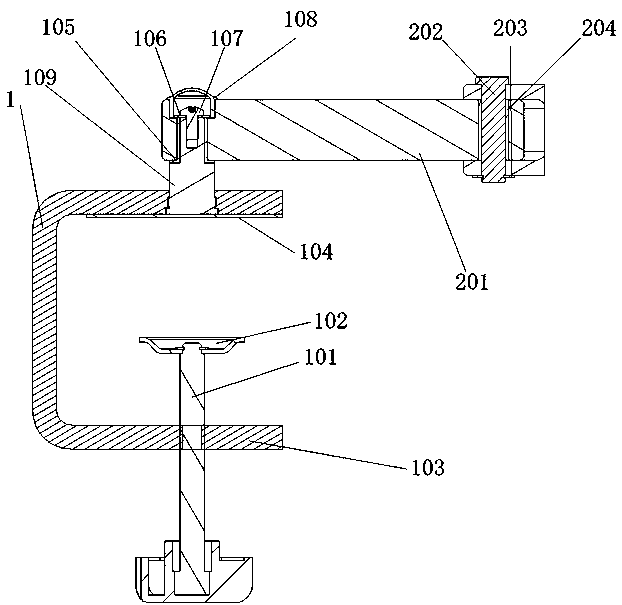

Lurking type composite solid lubrication cutting tooth component of coal cutter and lurking type composite solid lubrication cutting tooth component method

InactiveCN103174420AExtended service lifeSave manufacturing resourcesCutting machinesEngineeringLubrication

The invention relates to the technical field of coal mining, and in particular relates to a lurking type composite solid lubrication cutting tooth component of a coal cutter and a lurking type composite solid lubrication cutting tooth component method. The component comprises a cutter tooth, a cutter tooth sleeve and a cutter tooth base, wherein the upper end of the cutter tooth is a tapered body; the lower end of the cutter tooth is formed into a cutter tooth handle by a cylindrical body; the cutter tooth sleeve is sleeved at a cutter tooth handle end of the cutter tooth; the cutter tooth sleeve is located and assembled inside the cutter tooth base; and a gap coaxial body is formed by the cutter tooth, the cutter tooth sleeve and the cutter tooth base. The component is characterized in that at least one gap surface of the cutter tooth and the cutter tooth sleeve and a gap surface of the cutter tooth sleeve and the cutter tooth base are provided with lurking pits; and a waterproof, dustproof and long-acting composite solid lubricant special for a GR cutter tooth is filled into the gap between the cutter tooth and the cutter tooth sleeve and inside the lurking pits. The invention provides the lurking type composite solid lubrication cutting tooth component of the coal cutter and the lurking type composite solid lubrication cutting tooth component method, so that the problems that the parts between the cutter tooth and the cutter tooth sleeve and between the cutter tooth sleeve and the cutter tooth base are severely abraded in the prior art are solved, and the service lives are short.

Owner:西安奥奈特固体润滑工程学研究有限公司

Portable sediment sampler and sampling method

ActiveCN108332990AEasy to operateSolve the current situation that it is difficult to collect sedimentWithdrawing sample devicesEngineeringBall joint

The invention discloses a portable sediment sampler and a sampling method. The sampler comprises a fixed support, a sampling rod and a sampler, wherein the fixed support is connected with a fixing device, the sampling rod is connected with a sleeve, the sleeve is ball-jointed on the fixed support, a detachable cylinder is also mounted below the sleeve, one end of the cylinder is located on the fixed support, the sampling rod comprises a fixed rod and a telescopic rod, the sampler is mounted at one end of the telescopic rod, a sampling shovel is mounted at one end of the sampler and connected with the fixed rod through a string, the sampling shovel comprises an upper clamping piece and a lower clamping piece which are mounted on the sampler through hinged shafts, and tail ends of the upperclamping piece and the lower clamping piece are connected through a spring. The string is tensioned, the sampling shovel is opened, the sampler works, after the sampler finishes the work, the string is loosened, and the sampling shovel is closed. The portable sediment sampler can sample riverbed sediment at different depths, ensure that the sampling rod rotates freely and keep stable.

Owner:HOHAI UNIV

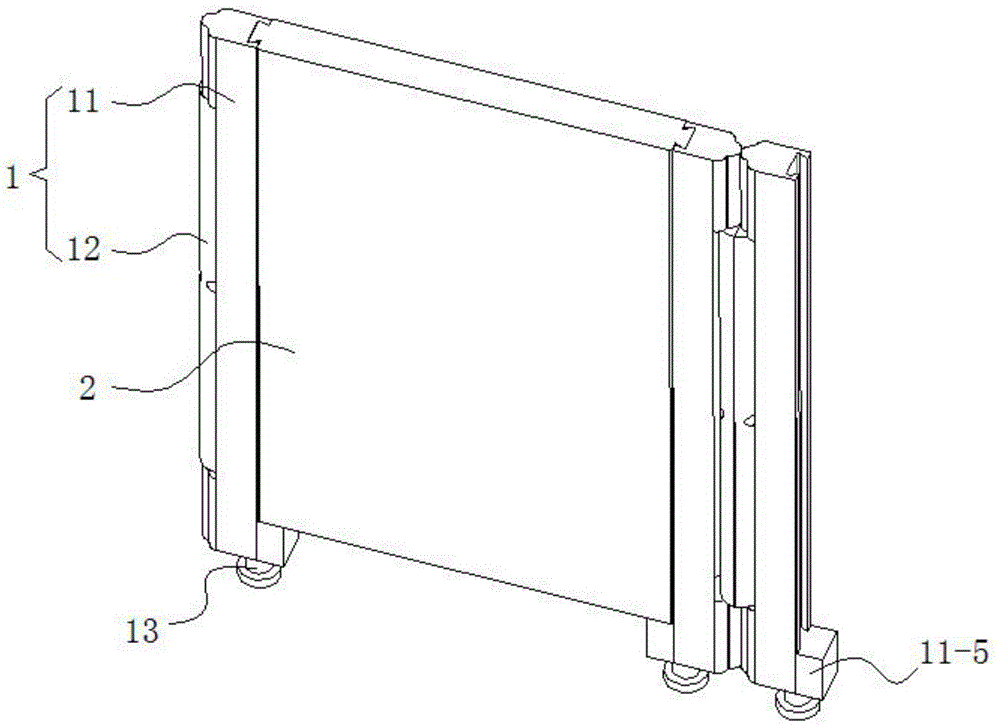

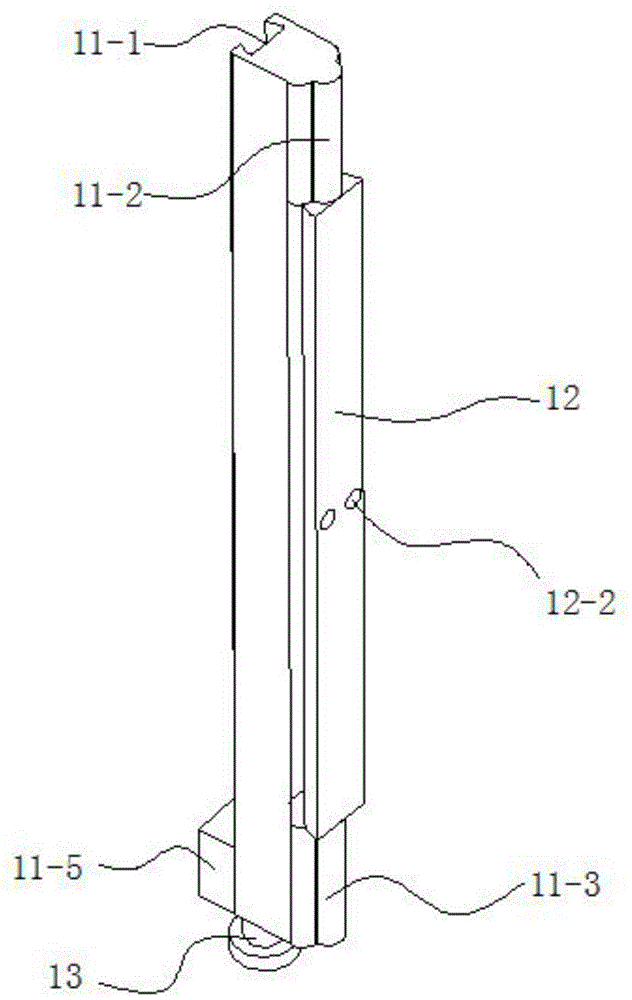

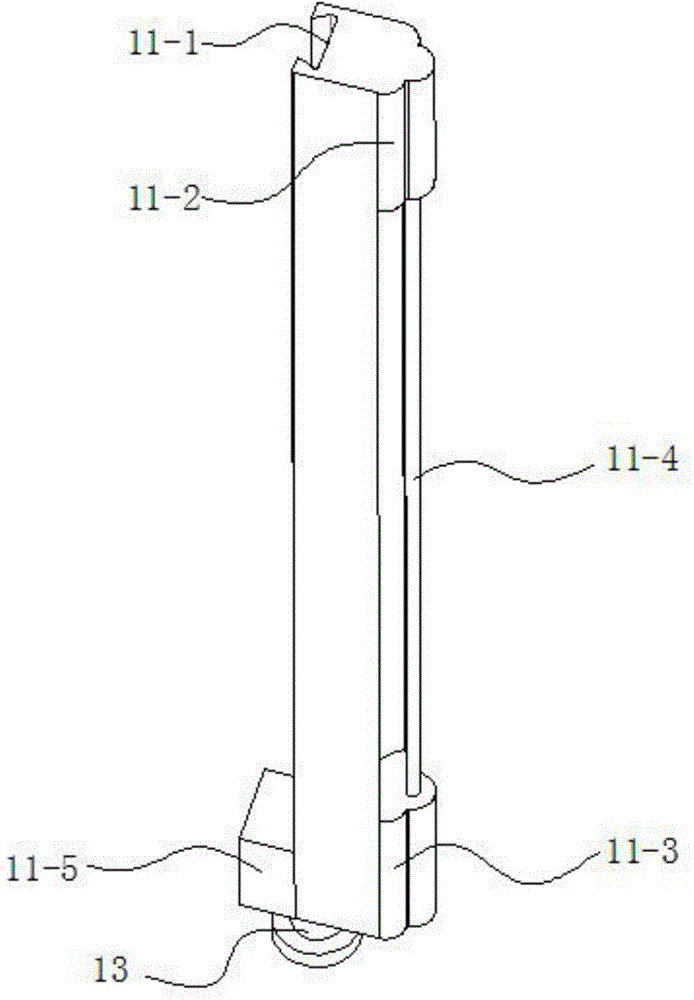

Combined type showing stand

InactiveCN105615412AGuaranteed free rotationIncrease the number ofShow shelvesShow hangersDisplay boardEngineering

The invention relates to a combined type showing stand. The combined type showing stand comprises multiple combined frames connected together. Each combined frame comprises two display racks and a display board. Each display rack comprises a rack body and a semicircular rotary shaft, wherein an insertion groove allowing the corresponding display board to be inserted therein is formed in one side face of the rack body, an upper lug and a lower lug are arranged on the side face, opposite to the insertion groove, of the rack body, the upper lug is arranged at the upper end of the rack body, the lower lug is arranged at the lower end of the rack body, a rotary shaft is fixedly arranged between the upper lug and the lower lug, the semicircular rotary shaft comprises a semicircular shaft body and a rotary shaft hole penetrating through the shaft body, the rotary shaft is sleeved by the semicircular rotary shaft in a rotary mode, and the semicircular rotary shaft is located between the upper lug and the lower lug. Insertion blocks matched with the corresponding insertion grooves are arranged on the two sides of each display board, and the two sides of each display board are each provided with one display rack in a matched mode. The semicircular rotary shafts on adjacent display racks of adjacent combined frames are fixedly connected into a complete cylindrical rotary shaft. The combined type showing stand is ingenious in design, convenient to assemble and disassemble and capable of rotating freely for adjustment.

Owner:TAIZHOU XINYUAN TEXTILE CO LTD

Jaw crusher

PendingCN111468215AReduce the width of the crushing zoneThe output particle size is smallDirt cleaningGrain treatmentsStructural engineeringMechanical engineering

The invention provides a jaw crusher, and relates to the technical field of crushing equipment. The jaw crusher solves the technical problem of a limited granularity adjustment range. The jaw crushercomprises a rack, a movable jaw, a fixed jaw, a rotary driving device, a first toothed plate, a second toothed plate and a pushing device. The movable jaw and the fixed jaw are oppositely arranged onthe rack, a crushing area is formed between the movable jaw and the fixed jaw, and the first toothed plate and the second toothed plate are arranged on the sides, opposite to each other, of the fixedjaw and the movable jaw respectively; the rotary driving device is in transmission connection with the upper portion of the movable jaw and is used for driving the movable jaw to move close to, away from and up and down relative to the fixed jaw; and one end of the pushing device is fixed to the rack, and the other end of the pushing device rotationally abuts against the lower portion of the movable jaw. The jaw crusher also comprises a distance reducing assembly arranged between the fixed jaw and the first toothed plate, and the width of the crushing area between the movable jaw and the fixedjaw is reduced through the reducing assembly. The jaw crusher is used for material crushing, can adjust the discharge particle size through the distance reducing assembly, and has the characteristicof being large in adjustment range because the distance reducing assembly is arranged on one side of the fixed jaw.

Owner:BEIJING LIULIHE CEMENT

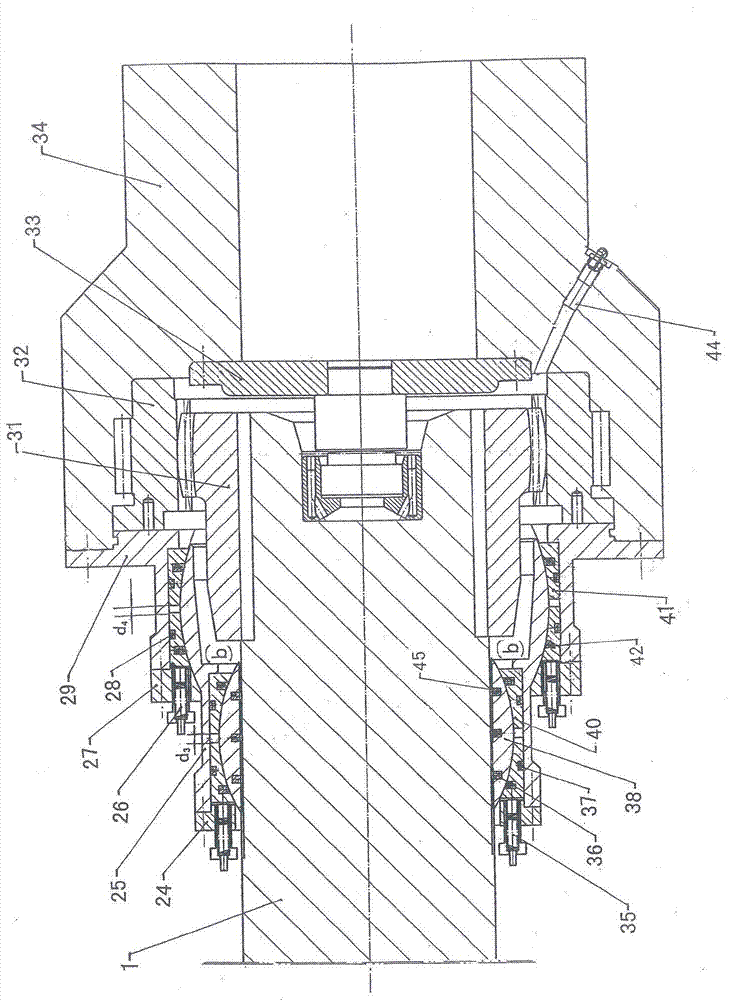

Crowned tooth universal drive shaft

ActiveCN107100944AGuaranteed free rotationPrevent leakageYielding couplingRolling mill drivesDrive shaftEngineering

The invention discloses a crowned tooth universal drive shaft. Left / right crowned tooth external toothed sleeves and left / right crowned tooth internal toothed rings matched with the left-right crowned tooth external toothed sleeves are installed on the peripheries of the two ends of a shaft body in a key-groove mode, and internal / external crowned teeth machined on the external toothed sleeves and the internal toothed rings are mutually engaged. Left / right internal convex spherical sleeves, external concave spherical sleeves and external convex spherical sleeves are symmetrically installed on the positions, close to the external toothed sleeves, on the periphery of the shaft body, and a plurality of layers of sealing rings are arranged among the left / right internal convex spherical sleeves, the left / right external concave spherical sleeves and the left / right external convex spherical sleeves. Left / right internal concave spherical sleeves and pressing rings are further installed on the spherical surfaces of the left / right external convex spherical sleeves, a plurality of elastic compensators are assembled on the pressing rings connected with the external convex spherical sleeves and the middle pressing rings so that appropriate intervals can be reserved between concave spherical movable sleeves and concave spherical fixed sleeves on the left / right concave spherical sleeves, and lubricating oil cavities are formed between the left / right external toothed sleeves and the external convex spherical sleeves. The drive shaft is driven by the crowned teeth so that universal drive can be achieved, the stress end and the force transmitting end of the drive shaft are sealed by double spherical surfaces, the sealing effect is good, oil leakage does not occur, running is stable, and the crowned tooth universal drive shaft has popularization value.

Owner:LOUDI JIAHUA MACHINERY

Power transmission line laying device for circuit construction

The invention discloses a power transmission line laying equipment for circuit construction, which comprises a bearing slot, a roller slot, a base, a fixing plate, a first fixing hole, a fixing screw, a rotating ring, a fixing shaft, a fixing bearing, a rotating Shaft, baffle plate, roller, second fixing hole, third fixing hole. The equipment has a simple structure and low cost. The bearing slot and the roller slot are flexibly connected, which ensures the free rotation of the roller when the equipment is in use, and effectively improves the stability and efficiency of the equipment. The bottom of the base is set in an arc shape. It can buffer the pulling force, effectively reduce the wear of the rotating shaft, and enhance the durability of the equipment. The rotating ring and the rotating shaft are fixedly connected under the action of the fixing screw and the second fixing hole, and the rollers are fixed to the baffle and the rotating shaft. The connection makes the overall structure of the equipment more compact and reliable, and the positions that are often touched during use, such as baffles and rollers, are all arc-shaped structures, which ensures the safety of the equipment.

Owner:李思模

Flat steering engine with inner rotor structure

PendingCN112234756ACompact structureShorten the axial lengthAssociation with control/drive circuitsMagnetic circuit rotating partsElectric machineryEngineering

The invention discloses a flat steering engine of an inner rotor structure. The flat steering engine comprises a steering engine shell, a motor stator fixed in the steering engine shell, a motor rotorcoaxially arranged in the motor stator in a sleeving mode, and a speed reducing mechanism, wherein the motor rotor is of a cylinder structure with an installation cavity inside, and a through hole isformed in the middle of the motor rotor in the direction of the central axis of the steering engine shell; the speed reducing mechanism is kept fixed relative to the steering engine shell through thesteering engine base, and is partially suspended in the mounting cavity of the motor rotor, and a central hole coaxial with the through hole is formed in the middle of the speed reducing mechanism; ashaft body matched with the through hole and the central hole is rotationally connected to the steering engine shell through a bearing; power of the motor rotor is transmitted to the input end of thespeed reducing mechanism through the shaft body. The flat steering engine is advantaged in that a part of the speed reducing mechanism is suspended in the mounting cavity of the motor rotor, so the axial length of the steering engine is shortened, the structure of the steering engine is more compact, and the steering engine further has the advantages of large output end torque, high transmissionefficiency, stable transmission, long service life and high integrity.

Owner:SHENZHEN TATFOOK NETWORK TECH

Protective device used for pulling large workpieces to move in machining workshop

InactiveCN106516876AAvoid Hard Collision DamageUniform reciprocating windingFilament handlingMachine shopControl theory

The invention discloses a protective device used for pulling large workpieces to move in a machining workshop. The protective device comprises a workbench and a mounting base, wherein brackets are fixedly arranged at the two sides of the mounting base separately; rollers are rotatably arranged on the brackets; a rotary disc is rotatably arranged on the mounting base; two regulating rollers are arranged on the rotary disc; two limiting slots are formed in the rotary disc; two fixing holes are formed in the mounting base; end part of a positioning rod perpendicularly and movably penetrates through the limiting slots, and then is connected with the fixing holes; a step motor is arranged in the workbench; a central shaft is connected with an output end of the step motor; travel switches are arranged at the two ends of each limiting slot; and the travel switches are connected with the step motor through controllers. When the positioning rod is in contact with the travel switches, the travel switches send a signal to the controller, the controller sends a control command to the step motor, and the step motor starts to rotate reversely, so that a traction rope is forced to change course again; and on the premise of preventing the positioning rod from being in hard contact with the rotary disc, the traction rope is guaranteed to uniformly roll on a rolling roller.

Owner:重庆淬智机械有限公司

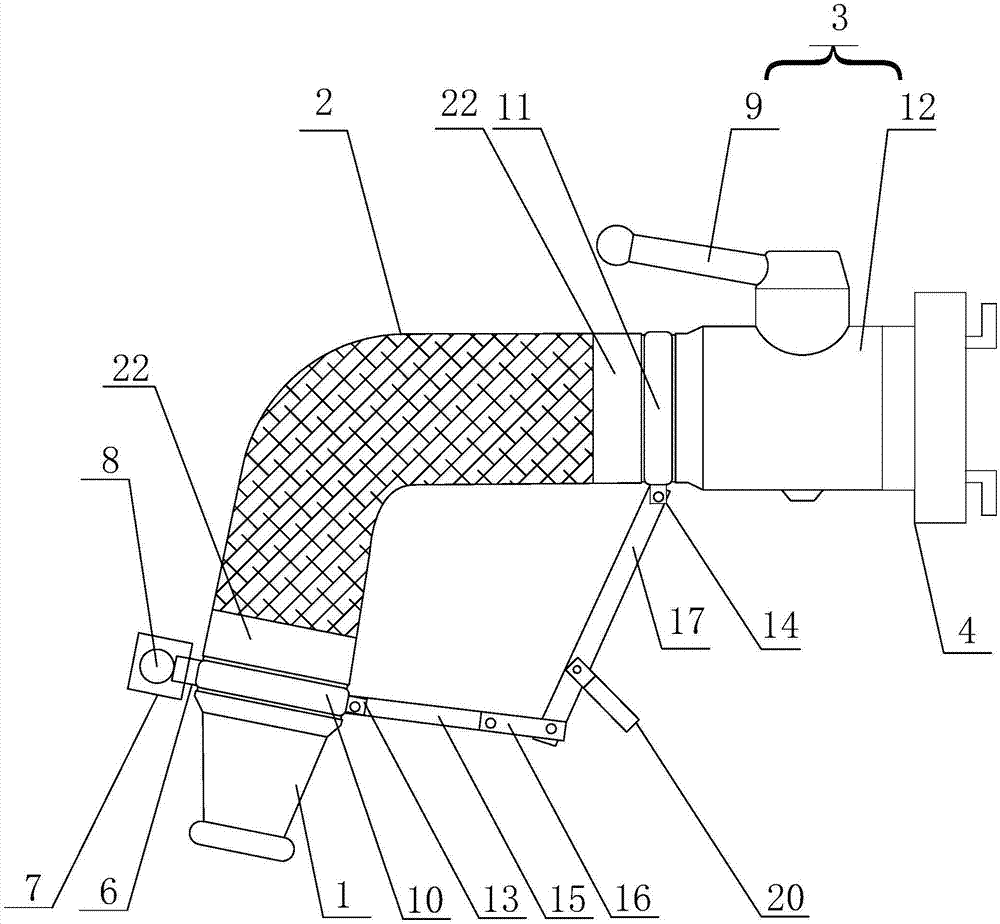

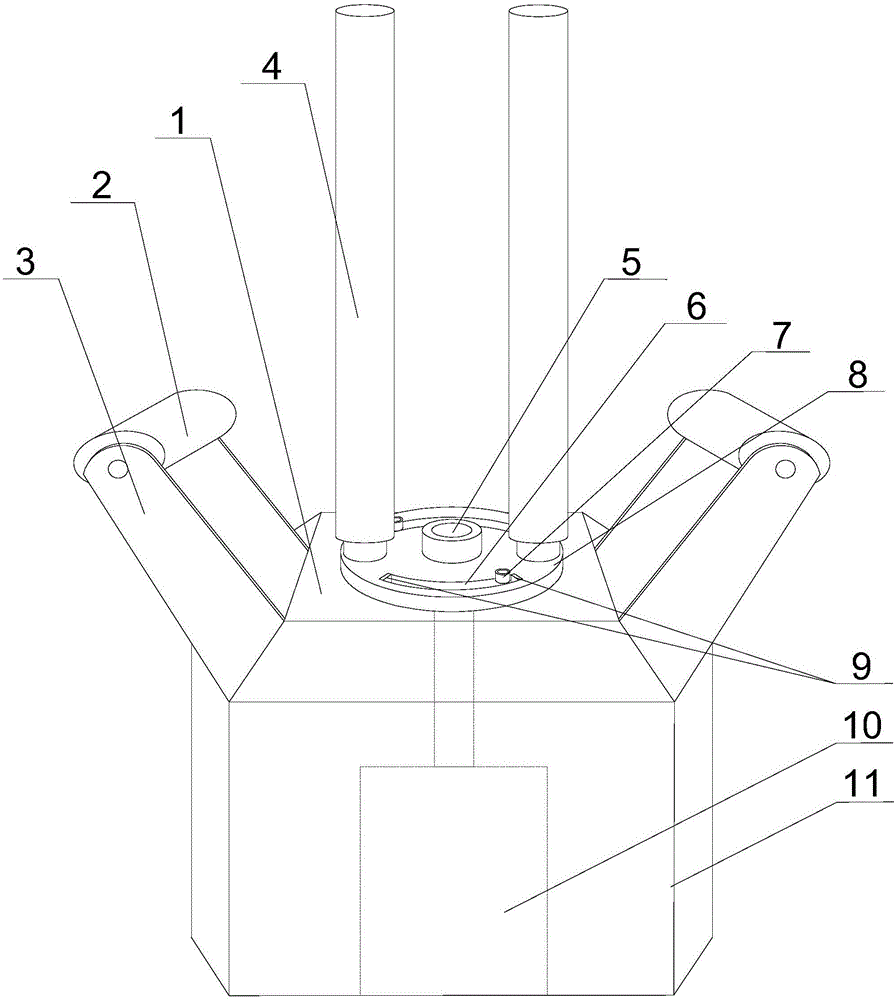

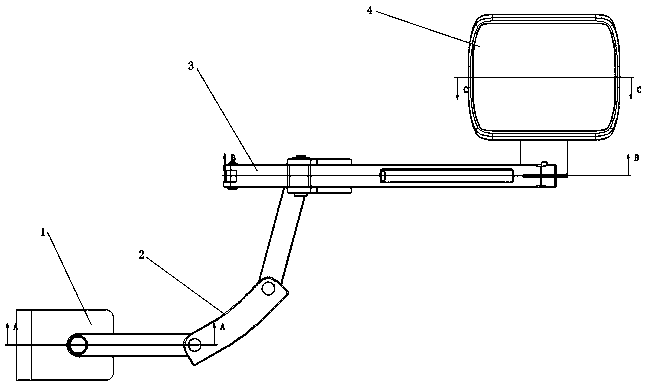

Adjustable upper limb arm bracket

PendingCN109731288AImprove comfortFlexible useMuscle exercising devicesMovement coordination devicesEngineeringUpper limb

The invention discloses an adjustable upper limb arm bracket. The arm bracket comprises a fixed seat component, a three connecting lever component, an adjustable lever component and a bracket component, wherein the three connecting lever component is arranged on the upper end of the fixed seat component and is rotatably connected with the fixed seat component; the adjustable lever component is arranged on the upper end of the three connecting lever component and is rotatably connected with the three connecting lever component; the bracket component is arranged on the upper end of the adjustable lever component and is rotatably connected with the adjustable lever component; and the adjustable lever component comprises a secondary fixed rod, a lever seat, a pull rod, a pull ring and a lever;the secondary fixed rod is fixed in the lever seat; the lever is arranged on the upper end of the lever seat; the pull rod is arranged on one end of the lever; the lever seat and the lever, the leverand the pull rod and the pull rod and the pull ring are respectively connected by secondary hinge pins; tertiary bearings sleeve on the secondary hinge pins; and the pull ring and the lever seat arefixedly connected by a bayonet. The arm bracket disclosed by the invention has the beneficial effects that the angle and the direction can be adjusted to balance the gravity force on an arm during training; the arm bracket is very flexible in use and high in structural strength; and the comfort feeling of a patient in rehabilitation training is improved.

Owner:JIANGSU CHENGKANG MEDICAL EQUIP CO LTD

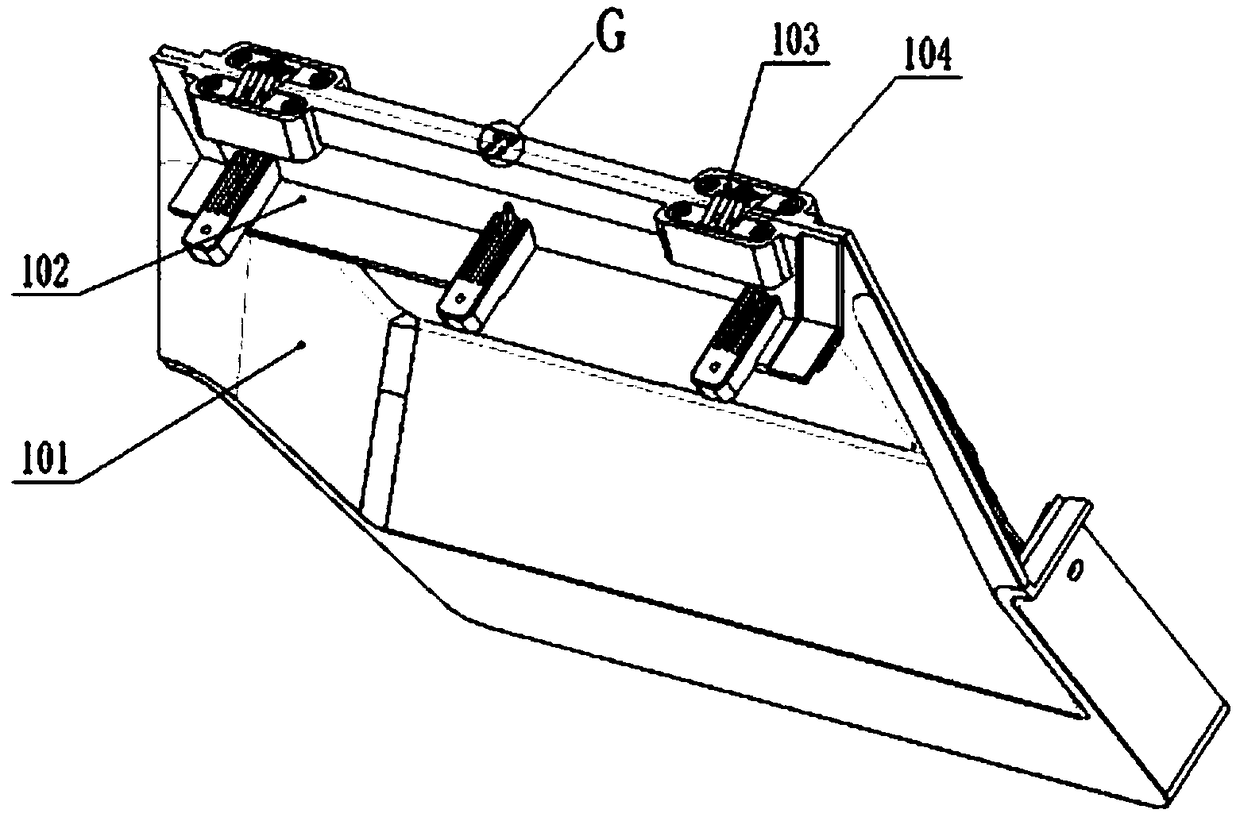

Automatic steel pushing and overturning device for profile steel

ActiveCN112058922AReduce the number of replacementsImprove rolling rhythmWork manipulationGear wheelScrew thread

The invention discloses an automatic steel pushing and overturning device for profile steel, and belongs to the technical field of metallurgy. The automatic steel pushing and overturning device comprises a left steel pushing and overturning mechanism and a right steel pushing and overturning mechanism which are horizontally arranged and symmetrically distributed, and the left steel pushing and overturning mechanism comprises a supporting unit, an executing unit and a displacement unit, the supporting unit is used for clamping the profile steel, the executing unit is used for controlling the supporting unit to rotate, and the displacement unit is used for controlling the supporting unit to move; and the supporting unit comprises two steel pushing plates which are arranged up and down and used for being matched with the section of the profile steel, the executing unit comprises two gear fixing grooves which are arranged up and down, fixing parts are arranged in the gear fixing grooves, rotating gears used for being in rotating fit with threaded lead screws are arranged at one ends of the fixing parts, and the other ends of the fixing parts are connected with the steel pushing plates.According to the automatic steel pushing and overturning device, the problems of centering and steel turning operation in the profile steel rolling process are solved, and not only can the steel turning angle be accurately controlled, but also rolled parts and contact equipment cannot be impacted.

Owner:MAANSHAN IRON & STEEL CO LTD

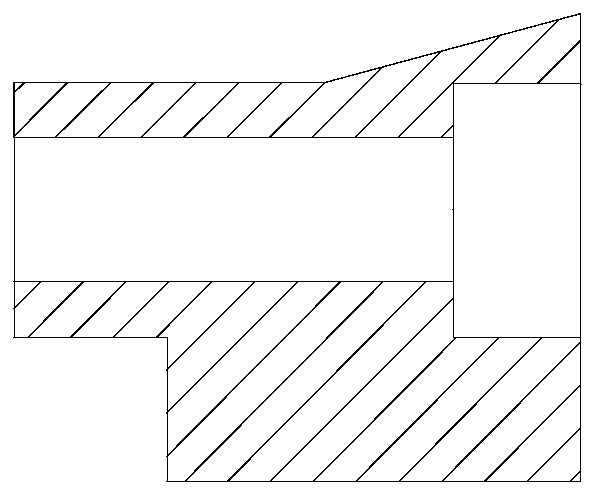

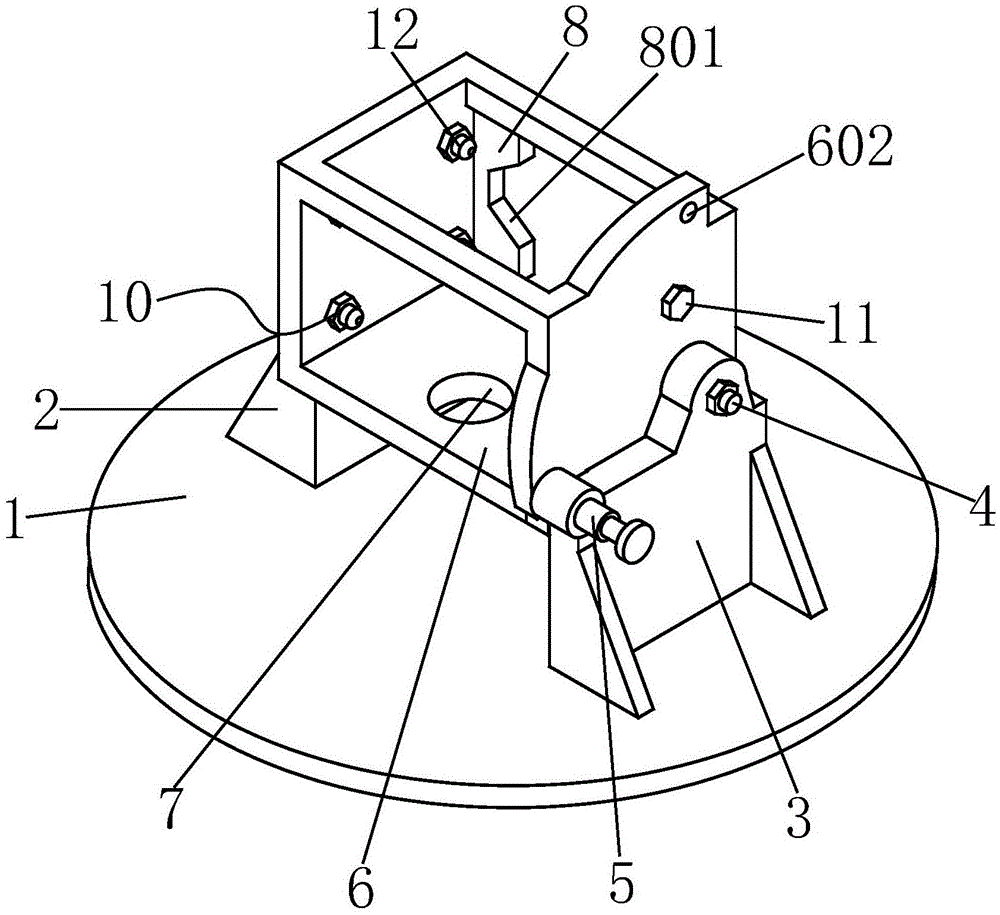

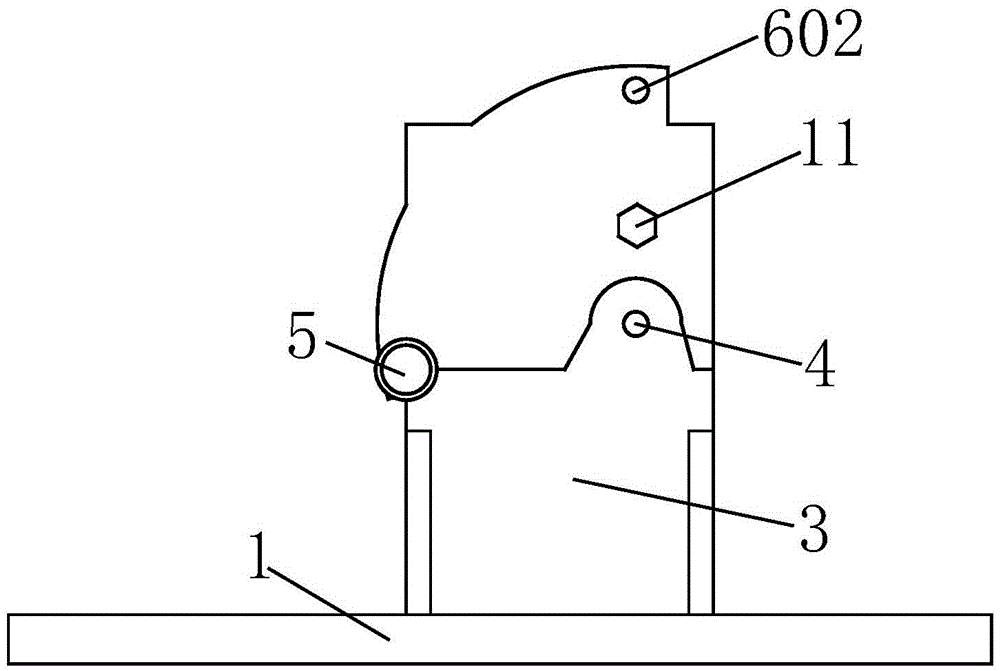

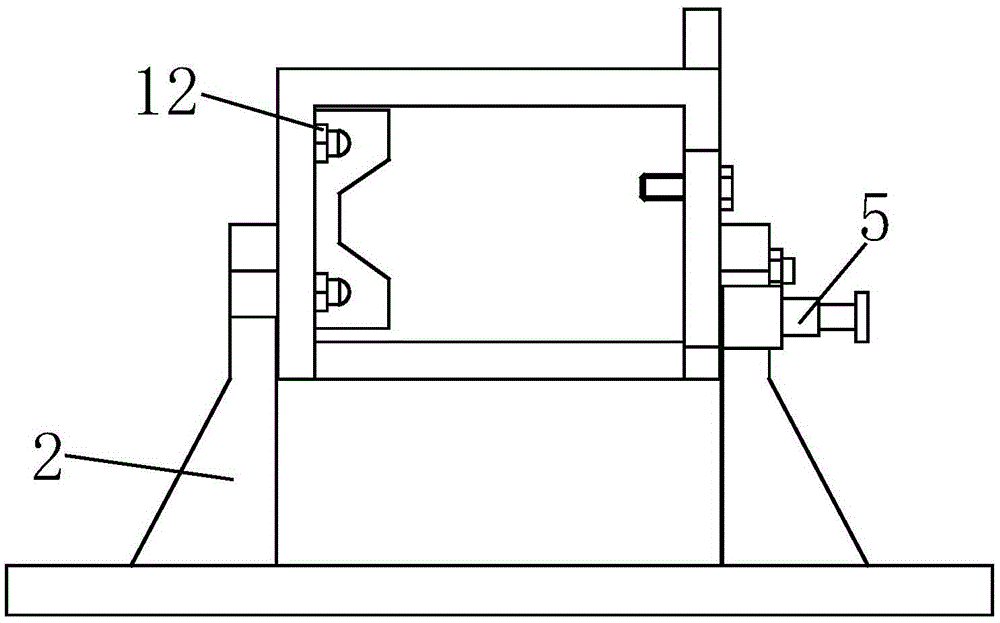

A 90-degree rotatable safety valve body fixture

ActiveCN104385170BProtectiveStable supportWork holdersPositioning apparatusMating connectionRear quarter

The invention relates to a safety valve body clamp capable of rotating by 90 degrees, and belongs to the technical field of clamps. The safety valve body clamp comprises a base plate; a left side plate and a right side plate are arranged on the left side and the right side of the base plate respectively; a convex round block is arranged on the inner side face of the left side plate; a connecting bolt is arranged on the rear side of the upper portion of the right side plate in a passing manner; an elastic pin is fixed to the front side of the upper portion of the right side plate; a sleeve valve frame is arranged between the left side plate and the right side plate; a bottom through hole is formed in a bottom plate of the sleeve valve frame; a side through hole is formed in the left end face of the sleeve valve frame; a bolt bearing set is arranged on the left end face of the sleeve valve frame in a passing manner; and a first positioning hole and a second positioning hole matched with elastic pins are correspondingly formed in the bottom of the front side of the right side face of the sleeve valve frame and the upper portion of the rear side of the sleeve valve frame respectively. The bolt bearing set is adopted to support a safety valve body; the extending length of bearing bolts is adjustable; and the safety effect on a safety valve body is achieved. The matched connection relation of the convex round hole and the side through hole is adopted, supporting of the convex round block for the sleeve valve frame is ensured, and it is also ensured that the sleeve valve frame can freely rotate.

Owner:WUHU HUAYI VALVE MFG

A swinging vibration energy harvesting device

ActiveCN106787591BEliminate positioning forceSmooth rotationDynamo-electric machinesRotor magnetsVibration energy harvesting

The invention discloses an oscillating type vibrating energy collecting device. The oscillating type vibrating energy collecting device comprises a casing, a stator assembly and a rotor assembly, wherein permanent magnets are vertically arranged in the stator assembly; the permanent magnets are arranged on circumferences of an external upper magnet yoke and an external lower magnet yoke at equal circular arc in a spacing manner; coils are arranged on an iron core in the rotor assembly; 2n iron cores are arranged on the circumferences of a rotor upper magnet yoke and a rotor lower magnet yoke at equal circular arc in the spacing manner; a shaft is arranged between the rotor upper magnet yoke and the rotor lower magnet yoke; 2n magnetic teeth are arranged on outer rings of the rotor upper magnet yoke and the rotor lower magnet yoke at equal circular arc in the spacing manner; the clearance of the magnetic teeth is greater than twice the width of each magnetic tooth; 3n magnetic teeth are arranged on inner rings of the external upper magnet yoke and the external lower magnet yoke at equal circular arc in the spacing manner; the width of each magnetic tooth is equal to the clearance between the magnetic teeth; the rotor upper magnet yoke is positioned in the external upper magnet yoke and the magnetic teeth between the rotor upper magnet yoke and the external upper magnet yoke make contact; the rotor lower magnet yoke is positioned in the external lower magnet yoke and the magnetic teeth between the rotor lower magnet yoke and the external lower magnet yoke make contact; the magnetic tooth width of the rotor magnet yoke is smaller than the magnetic tooth clearance of the external magnet yoke. The oscillating type vibrating energy collecting device disclosed by the invention is higher in collecting efficiency.

Owner:ZHEJIANG UNIV OF TECH

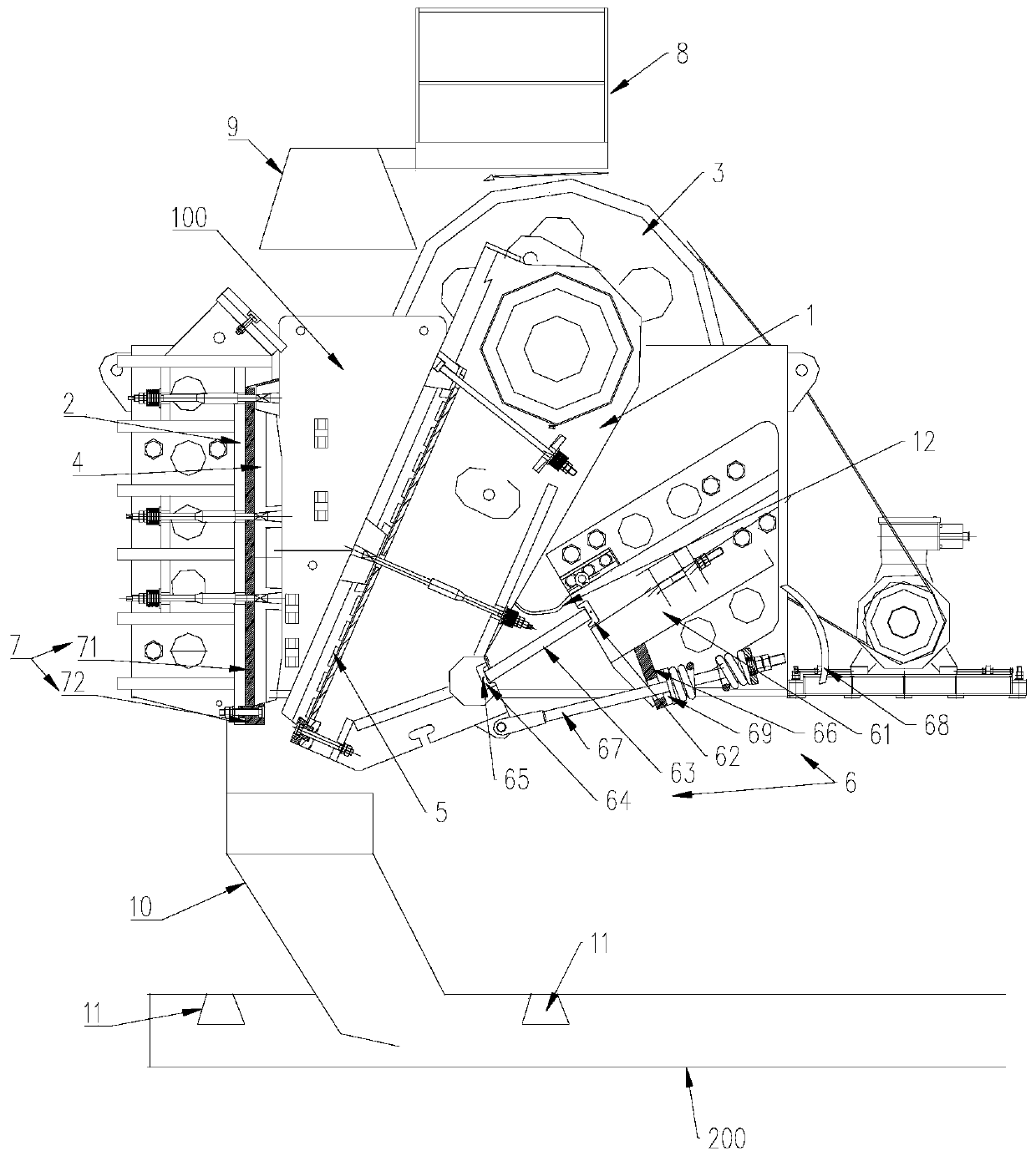

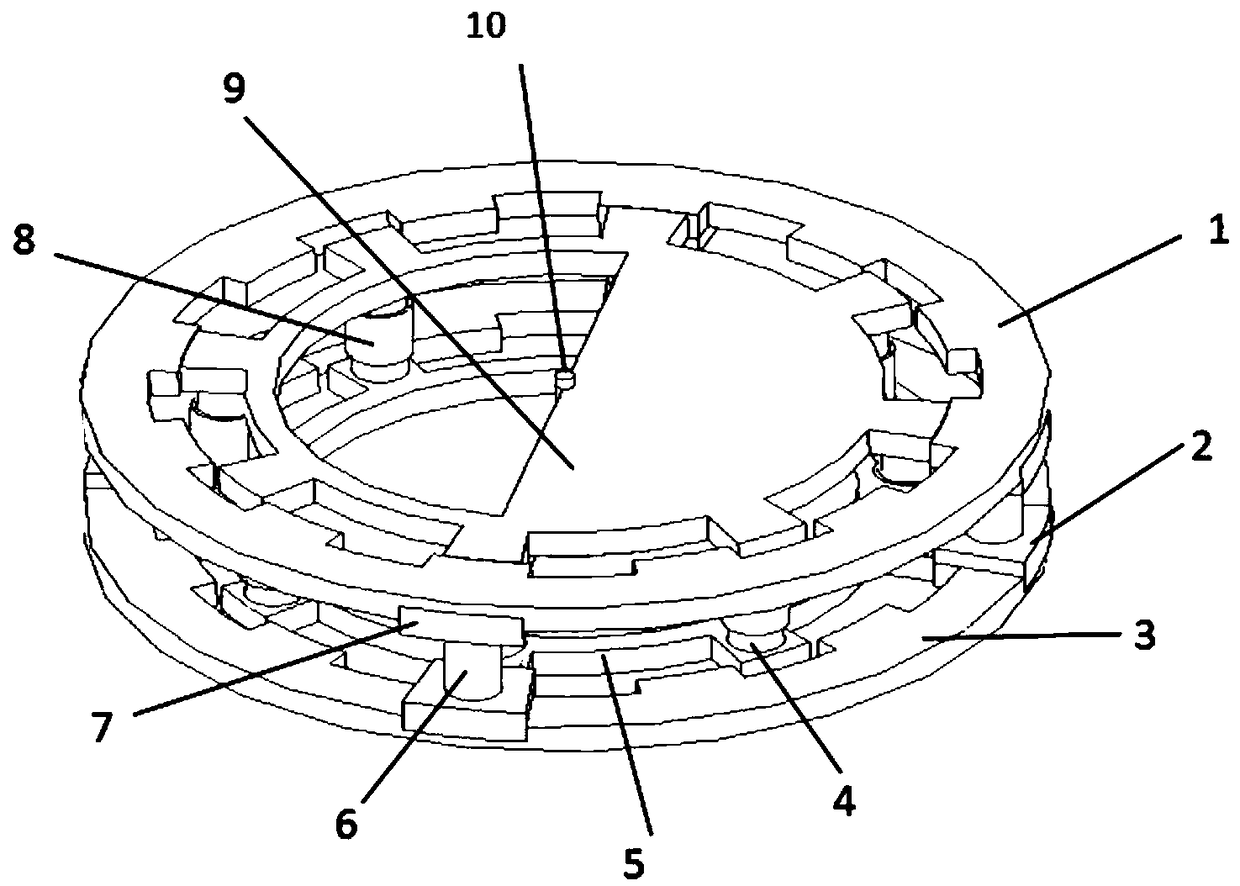

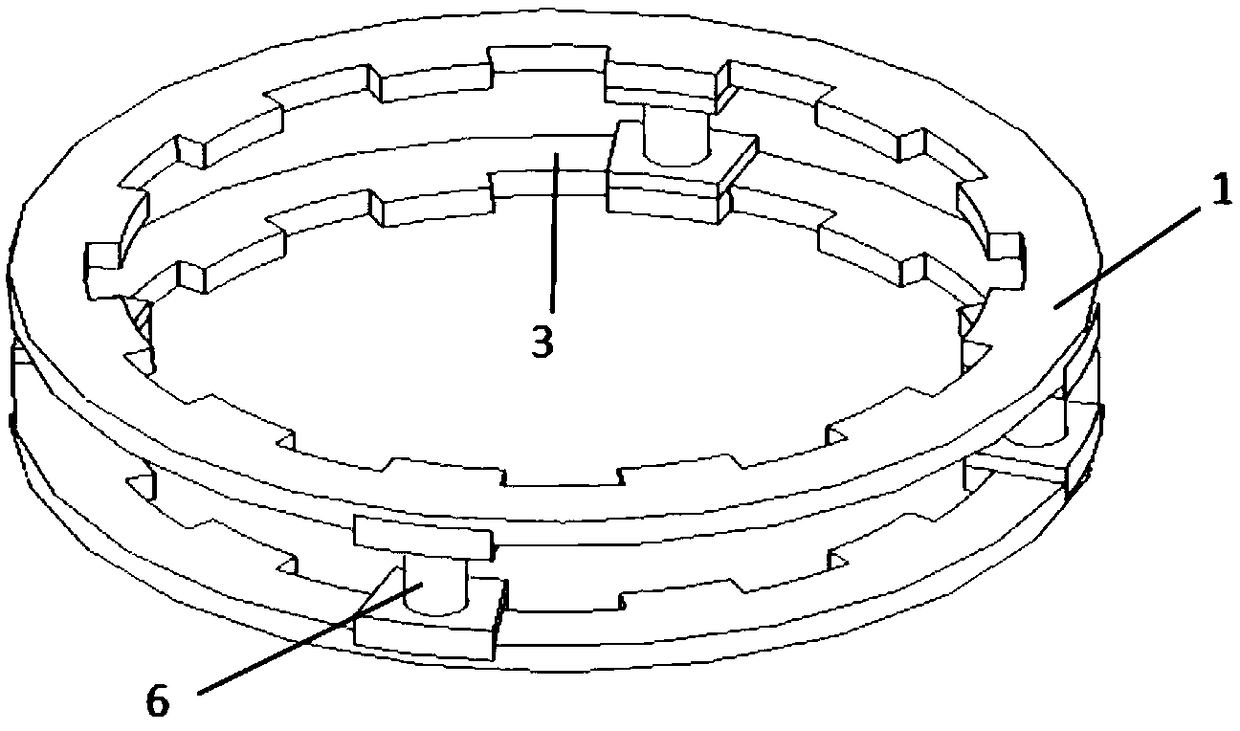

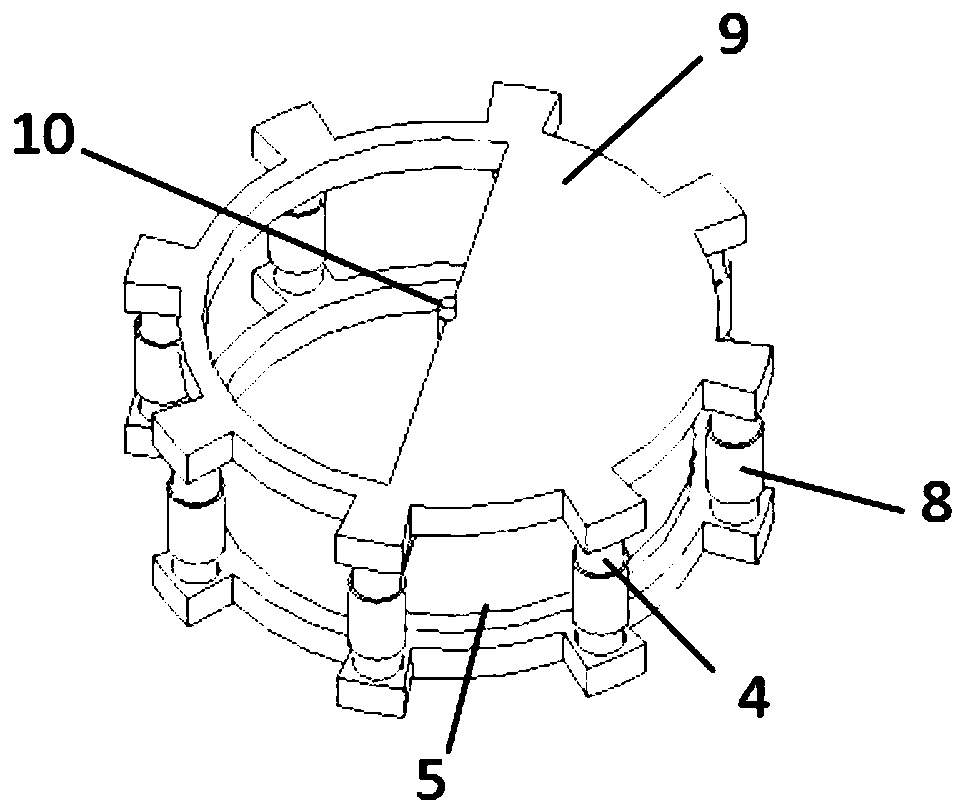

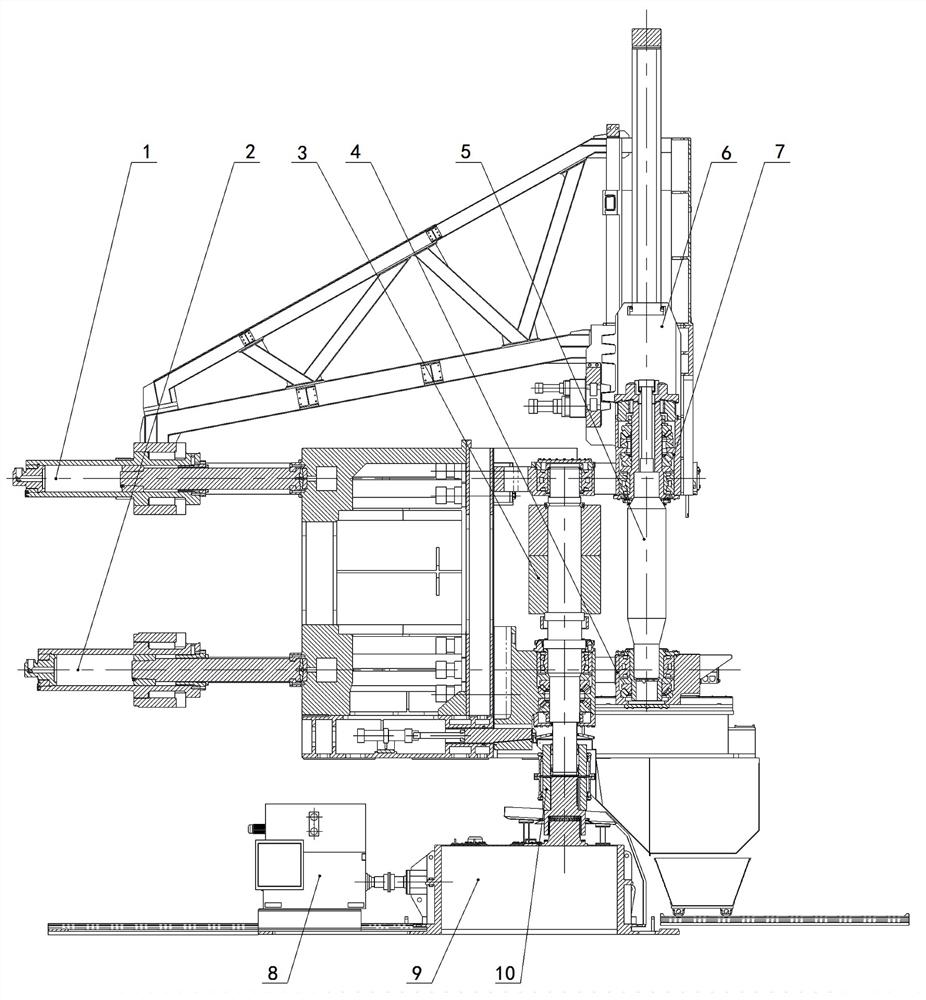

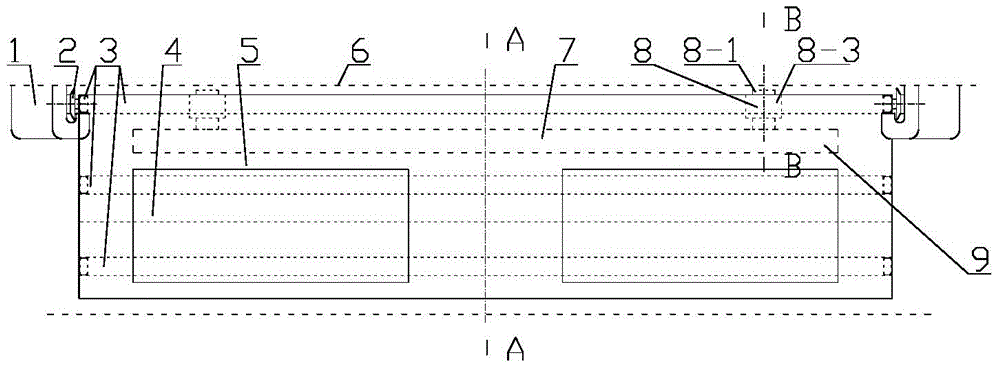

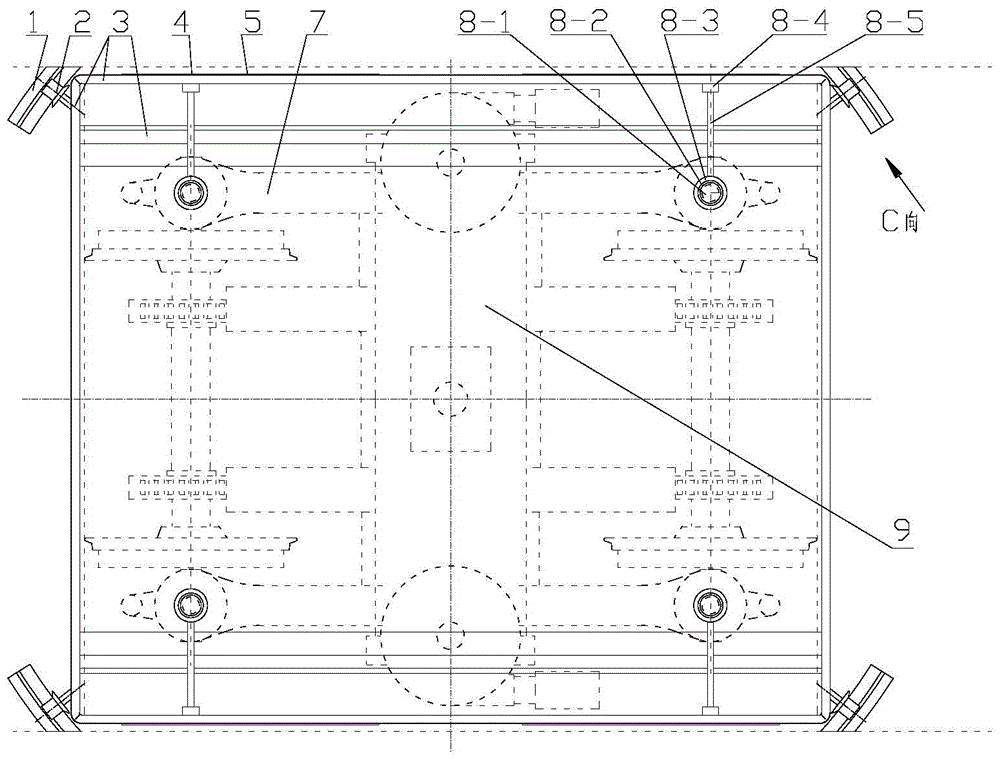

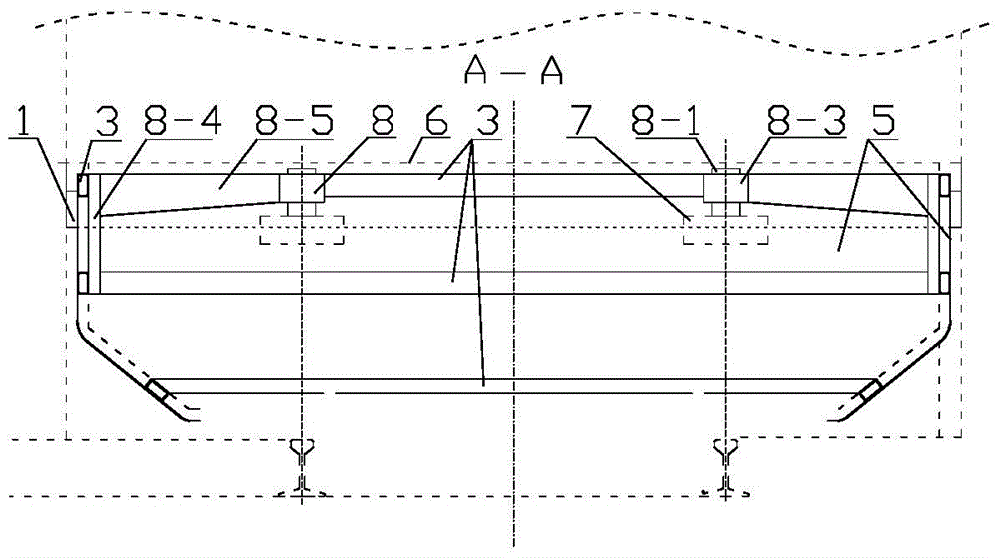

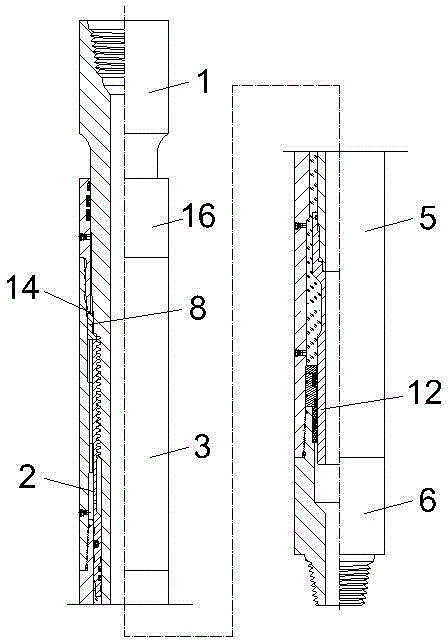

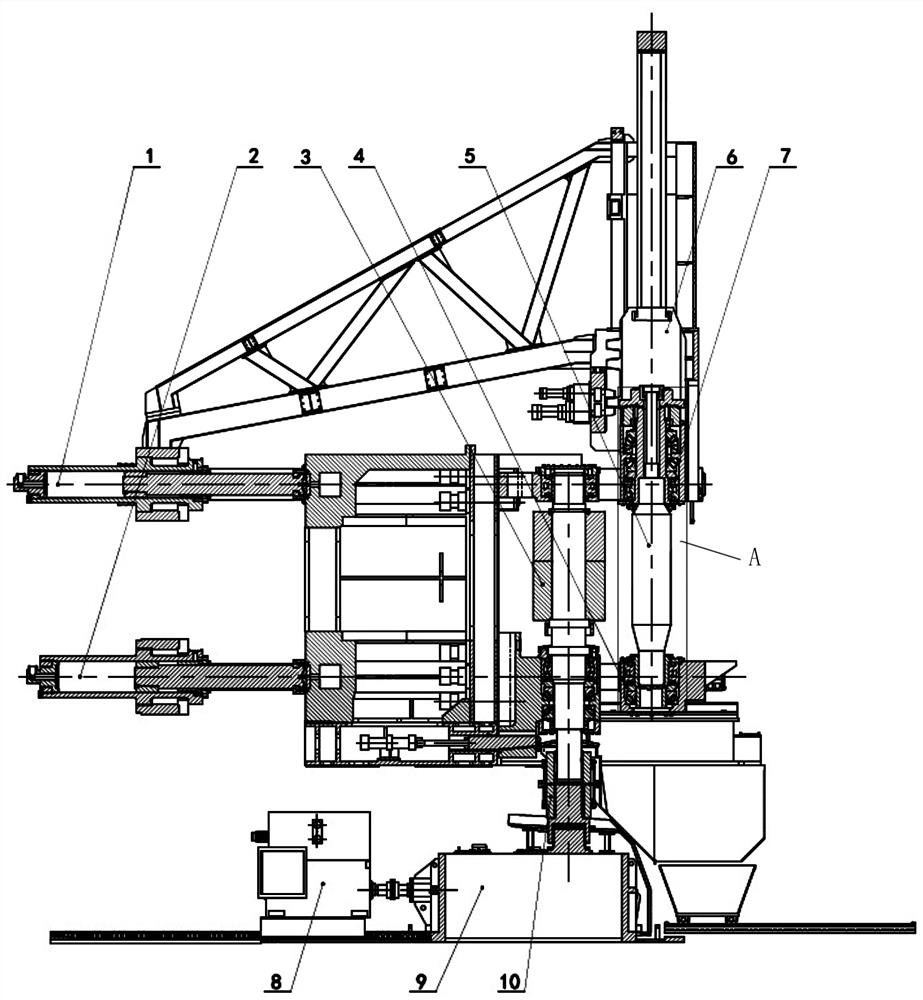

Main mandrel system, ring rolling machine and ring rolling machine radial main mandrel angle adjustment method

ActiveCN112222336BGuaranteed free rotationGuaranteed accurate rollingRollsMetal rolling arrangementsClassical mechanicsEngineering

The invention relates to a main core roll system, a ring rolling machine and a method for adjusting the angle of the radial main core roll of the ring rolling machine, belonging to the field of metal rolling. The main core roll system includes: a main core roll, the main core roll One end of the core roll is connected to the first main core roll slider through the first bearing part, and the other end of the main core roll is connected to the second main core roll slider through the second bearing part; the bearing seat guide device, the bearing The seat guiding device is respectively connected with the first main core roll slider and the second main core roll slider, and the bearing seat guide is used to guide the inclination of the main core roll and carry The radial force and axial force at both ends of the main core roll; the main core roll moving device, the main core roll moving device includes a first independent driving end and a second independent driving end, and the first independent driving end is connected to the The first main core roll slider is connected, and the second independent driving end is connected with the second main core roll slider. It reduces the amount of subsequent processing of large shaped rings.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

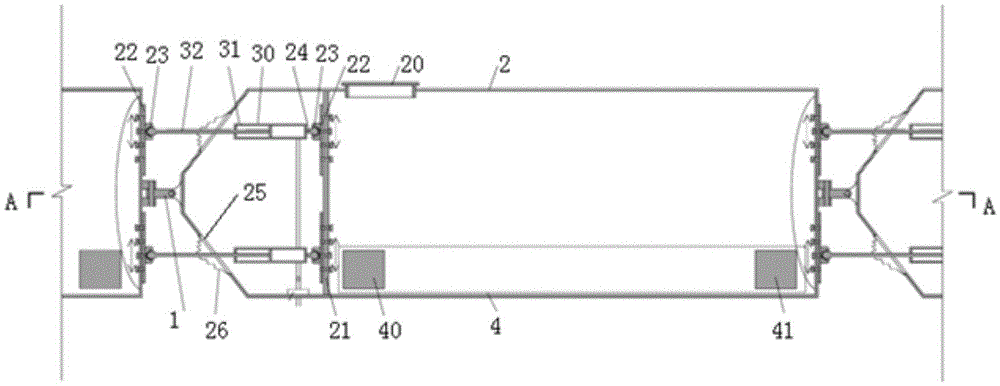

Guiding device for rectification device of train bogie

The invention relates to a train bogie rectifying device and relates to the technical field of train rectifying. The train bogie rectifying device comprises a dome track, dome wheels, a casing frame, an access door, a dome outer casing, a carriage vehicle bottom, a bogie side frame, a guide device, a guide shaft, a guide shaft rubber sleeve, a guide sleeve, a guide sleeve seat, a guide sleeve seat board and a bogie. The train bogie rectifying device is characterized in that the dome outer casing is in a box shape with an upper opening and a lower opening, the dome outer casing is covered outside the bogie, the dome wheels are installed on two sides of the front upper portion and the rear upper portion of the outside covered dome outer casing, the dome outer casing is connected with the dome track through the dome wheels, and the dome track is connected with the carriage vehicle bottom. According to the train bogie rectifying device, on the premise that movement performances of train operation are not changed, air resistance of train operation is reduced, energy consumption is reduced, or train operation speeds are increased; free rotation of the bogie and relative movement of the bogie and a wagon box in an upward and downward direction are guaranteed; radiating during braking is guaranteed; loads are not added to the bogie; and the train bogie rectifying device is convenient to maintain.

Owner:UNIV OF JINAN +1

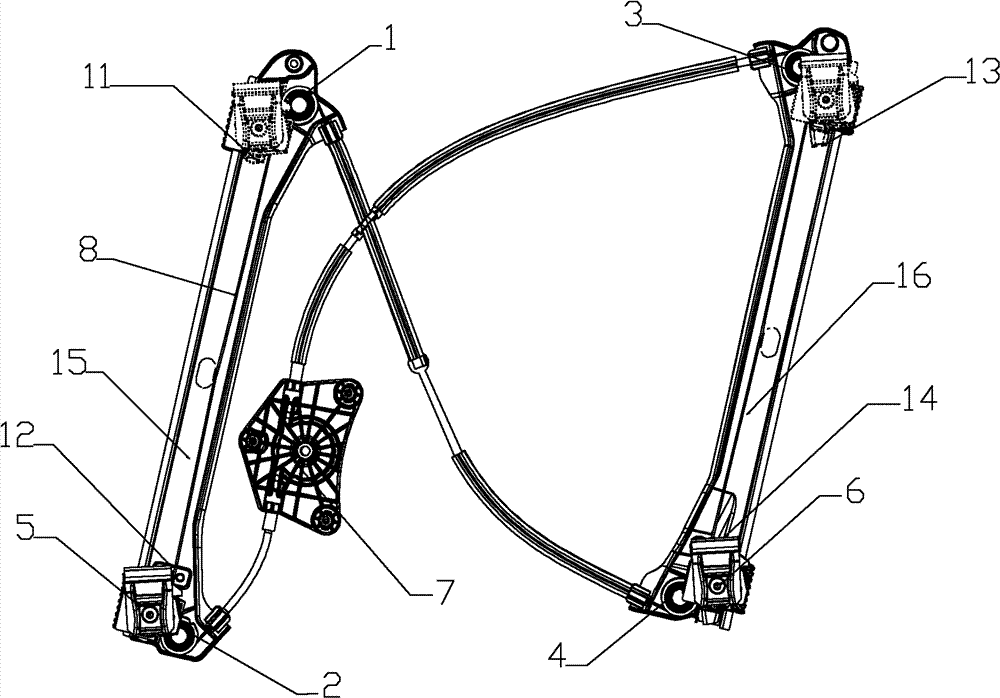

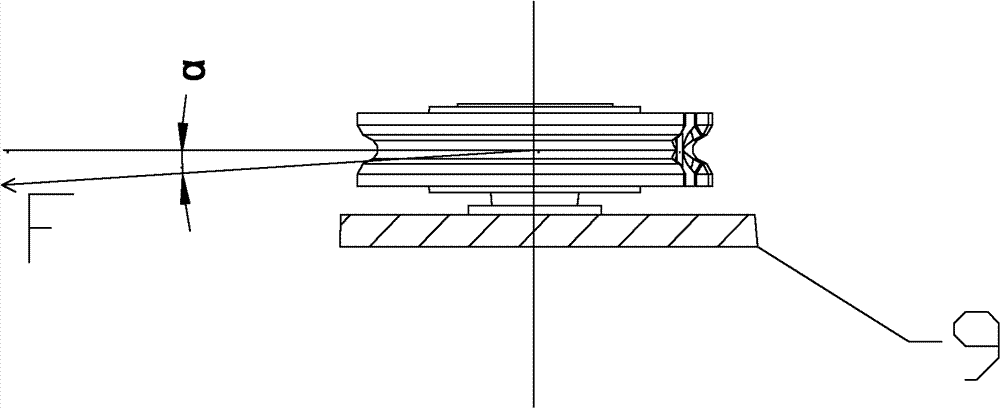

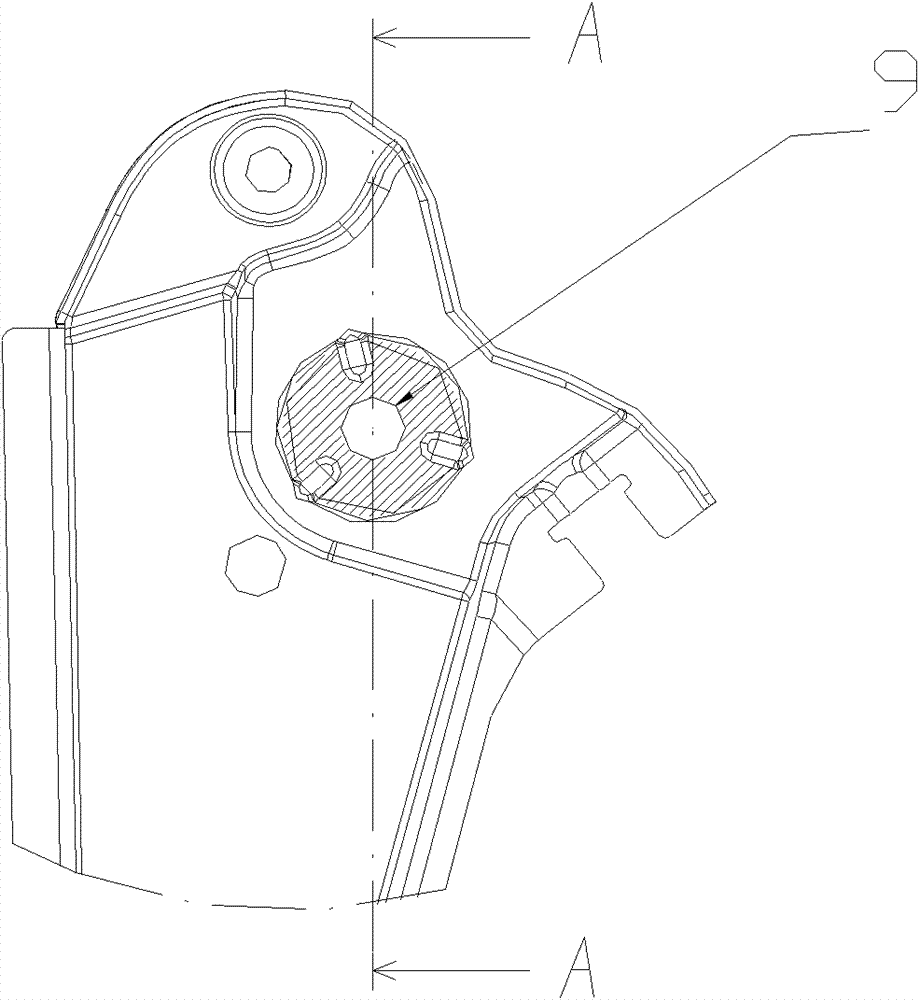

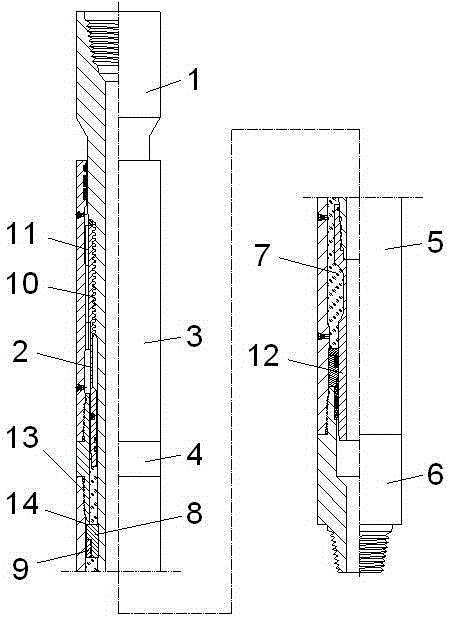

Rope wheel type automobile window lifter

ActiveCN102182379BGuaranteed free rotationReduce bouncePower-operated mechanismAxial pressureEngineering

Owner:SHANGHAI BROSE AUTOMOTIVE COMPONENTS

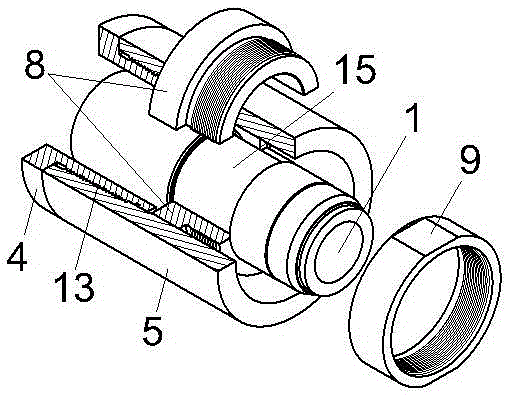

Method for preventing two-way hydraulic shock absorber from withdrawing and shock absorber

ActiveCN103775004BGuaranteed to workGuaranteed free rotationDrilling rodsDrilling casingsFree rotationTorque transmission

The invention discloses a method for preventing a two-way hydraulic shock absorber from buckling and the shock absorber. The method is to set the limit component at the lower end surface of the connecting body in the outer casing of the two-way hydraulic shock absorber; the connecting body and the oil cylinder are connected by torque transmission thread, and the torque transmission thread between the connecting body and the oil cylinder is used to prevent connection. The connection thread between the body and the cylinder is buckled. The invention cancels the easy-release screw connection between the centering outer cylinder and the spline body in the existing two-way hydraulic shock absorber, and moves the limiting surface to between the lower connecting body and the limiting block. The limit block is composed of two half rings, which are directly snapped into the ring groove of the mandrel during installation and fixed with the limit block nut. In order to ensure the free rotation of the limiting block in the annular groove of the mandrel, the relative rotation between the mandrel and the limiting surface of the connecting body is eliminated. At the same time, the connection thread between the connecting body and the oil cylinder is a torque transmission thread, which is always in the state of working torque, so as to ensure that the two-way hydraulic shock absorber will not fall off under the condition of low drilling pressure.

Owner:GUIZHOU GAOFENG GASOLINEEUM MACHINERY

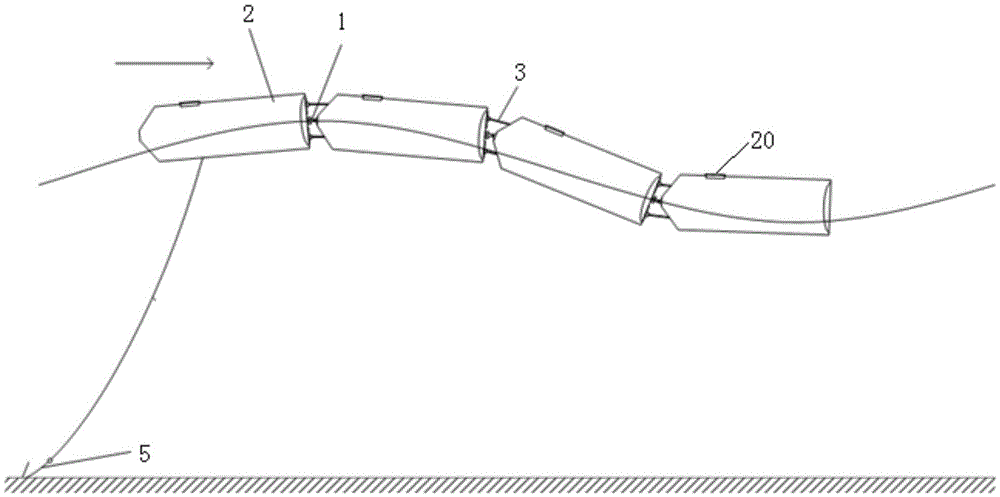

A raft wave pump with adjustable output

InactiveCN104179630BImprove capture abilityLower center of gravityMachines/enginesEngine componentsEngineeringPump wave

The invention relates to an output-adjustable raft type wave pump which comprises wave energy acquisition buoys, hydraulic devices and water inlet and outlet devices. The first wave energy acquisition buoy is anchored on the seabed through an anchor chain. Each wave energy acquisition buoy comprises a rib plate, two vertical slides are tightly connected on each of the front end face of each rib plate and the rear end face of the previous wave energy acquisition buoy, and a rotary part base which is vertically adjustable is arranged on each slide. Each rotary part base on the rib plates is rotationally connected with the bottom end of a cylinder body of the corresponding hydraulic device through a connecting rod, the upper side wall and the lower side wall of the rear end of each cylinder body is provided with a water inlet and a water outlet respectively, and the upper side wall of the front end of each cylinder body is provided with an air hole. A piston rod is inserted in each cylinder body, the rod end of each piston connecting rod horizontally penetrates a through hole formed in the front end face of the corresponding wave energy acquisition buoy and is then rotationally connected with the corresponding rotary part base on the rear end face of the previous wave energy acquisition buoy, and a seal cover is arranged on each through hole. The size of each through hole satisfies the condition that the hydraulic device rotationally connected on each rotary part base and the front end face of the corresponding wave energy acquisition buoy do not interfere with each other when each rotary part base is located at the highest point or the lowest point of the corresponding slide.

Owner:TSINGHUA UNIV

Train bogie rectifying device

The invention relates to a train bogie rectifying device and relates to the technical field of train rectifying. The train bogie rectifying device comprises a dome track, dome wheels, a casing frame, an access door, a dome outer casing, a carriage vehicle bottom, a bogie side frame, a guide device, a guide shaft, a guide shaft rubber sleeve, a guide sleeve, a guide sleeve seat, a guide sleeve seat board and a bogie. The train bogie rectifying device is characterized in that the dome outer casing is in a box shape with an upper opening and a lower opening, the dome outer casing is covered outside the bogie, the dome wheels are installed on two sides of the front upper portion and the rear upper portion of the outside covered dome outer casing, the dome outer casing is connected with the dome track through the dome wheels, and the dome track is connected with the carriage vehicle bottom. According to the train bogie rectifying device, on the premise that movement performances of train operation are not changed, air resistance of train operation is reduced, energy consumption is reduced, or train operation speeds are increased; free rotation of the bogie and relative movement of the bogie and a wagon box in an upward and downward direction are guaranteed; radiating during braking is guaranteed; loads are not added to the bogie; and the train bogie rectifying device is convenient to maintain.

Owner:苗泽旺

Main rolling core roller system, ring rolling mill and ring rolling mill radial main rolling core roller angle adjusting method

ActiveCN112222336AAccurate rollingReduce the amount of processingRollsMetal rolling arrangementsStructural engineeringRolling mill

The invention discloses a main rolling core roller system, a ring rolling mill and a ring rolling mill radial main rolling core roller angle adjusting method, and belongs to the field of metal rolling. The main rolling core roller system comprises a main rolling core roller, a bearing pedestal guide device and a main rolling core roller moving device, wherein one end of the main rolling core roller is connected with a first main rolling core roller sliding block through a first bearing portion, and the other end of the main rolling core roller is connected with a second main rolling core roller sliding block through a second bearing portion; the bearing pedestal guide device is connected with the first main rolling core roller sliding block and the second main rolling core roller sliding block respectively, and the bearing pedestal guide device is used for guiding inclination of the main rolling core roller and bearing radial force and axial force at two ends of the main rolling core roller; and the main rolling core roller moving device comprises a first independent driving end and a second independent driving end, the first independent driving end is connected with the first mainrolling core roller sliding block, and the second independent driving end is connected with the second main rolling core roller sliding block. According to the main rolling core roller system, the ring rolling mill and the ring rolling mill radial main rolling core roller angle adjusting method, the subsequent machining amount of large special-shaped ring pieces is reduced.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

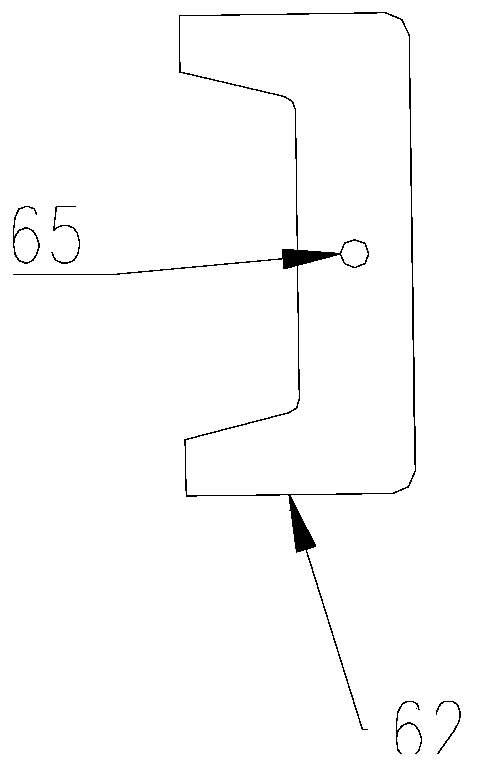

Limiting device for plastic housing

PendingCN108834352AGuaranteed free rotationAvoid the differenceCasings/cabinets/drawers detailsVertical planeEngineering

The invention discloses a limiting device for a plastic housing, and belongs to the field of housing assembly. The limiting device comprises a movable door housing, wherein one end of the movable doorhousing is provided with a plurality of first installation grooves and a plurality of bosses; a movable door top frame, one end of which is provided with a plurality of second installation grooves and a plurality of grooves, wherein the grooves are matched with the bosses, and the movable door top frame can be rotatingly arranged at the upper end of the movable door housing around the length direction of the second installation grooves; and a plurality of link hinges, each of which comprises a first rotating installation block, a second rotating installation block, and a rotating part, wherein two ends of each rotating part are respectively provided with a first installation block and a second installation block, each first installation block is installed in one first installation groove,and each second installation block is installed in one second installation groove. The limiting device is simple and reliable, is low in manufacturing cost, and can guarantee that the external surfaces of two housings are located on the same vertical plane.

Owner:科大智能机器人技术有限公司

On-line test device for dynamic friction performance of paired angular contact ball bearings

ActiveCN109959514BOvercoming Disadvantages of InterferenceGuaranteed free rotationMachine bearings testingBall bearingFriction torque

The invention relates to an on-line test device for dynamic friction performance of paired angular contact ball bearings. It uses the principle of air suspension and combines precision displacement measurement and adjustment technology. Bearing II is loaded in a non-contact axial direction, and the friction torque measuring device proposed by our research group in the patent "A High-speed Miniature Bearing Dynamic Friction Torque Measuring Instrument" (application number: 201610639490.9) measures the friction torque of the tested bearing II, thereby realizing Synchronous online measurement of friction torque, vibration, temperature and wear of a single precision bearing. The outer ring of the accompanying test bearing I of this device is fixed on the base, which not only can limit the rightward movement of the shaft system, but also can be used together with the radial axial air bearing and the non-working surface of the thrust plate when the shaft system is not working statically. To undertake the moment balance of the shaft system through careful counterweighting, so as to protect the non-working surface of the high-precision radial and axial air bearings from long-term contact damage.

Owner:SHANGHAI UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com