Lurking type composite solid lubrication cutting tooth component of coal cutter and lurking type composite solid lubrication cutting tooth component method

A technology of solid lubrication and solid lubricant, which is applied in the direction of cutting machinery, etc., can solve the problems of short service life, wear between the pick and the pick sleeve, the pick sleeve and the pick seat, etc., so as to prolong the service life and uniform Abrasion, the effect of saving manufacturing resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

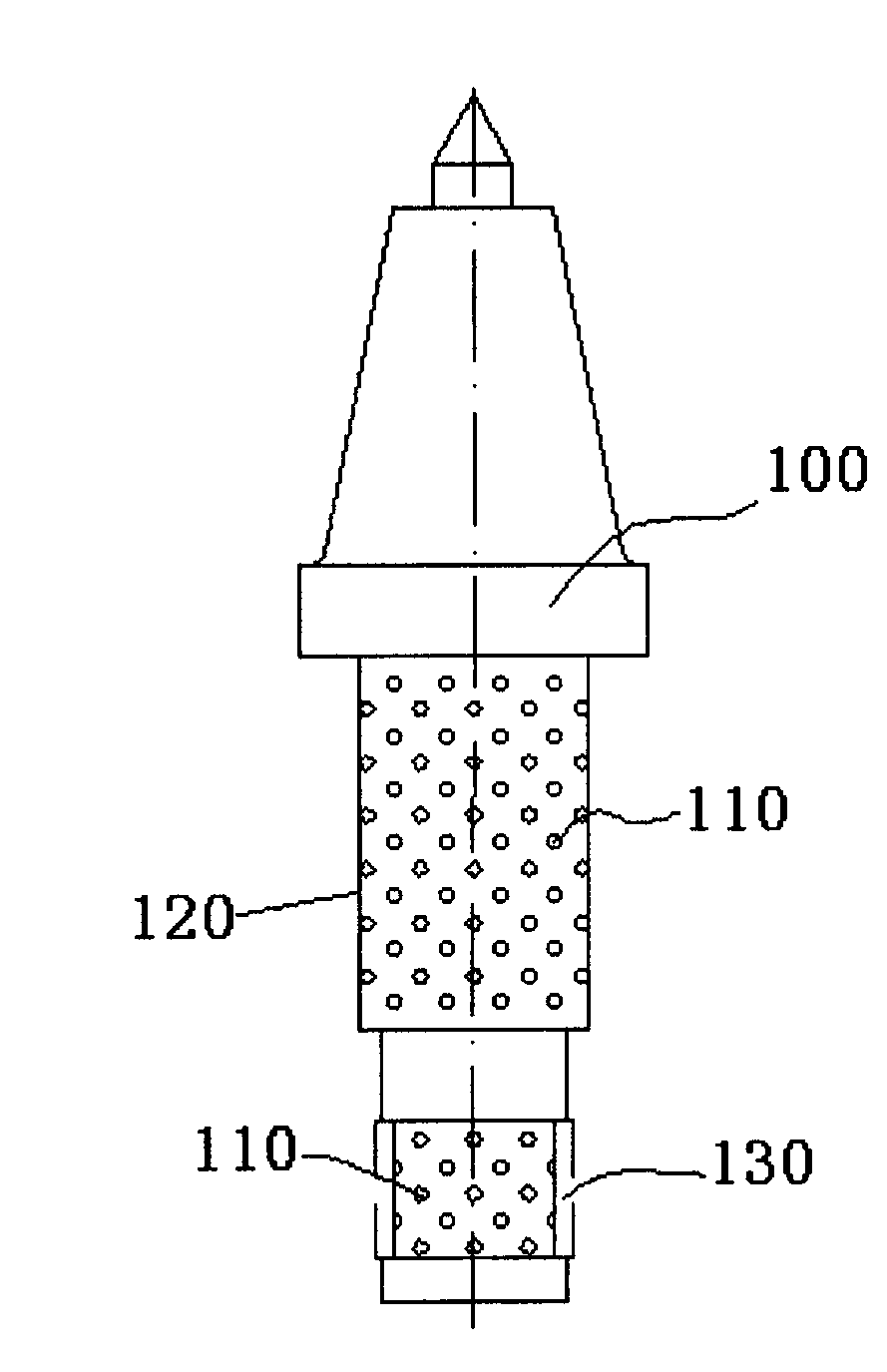

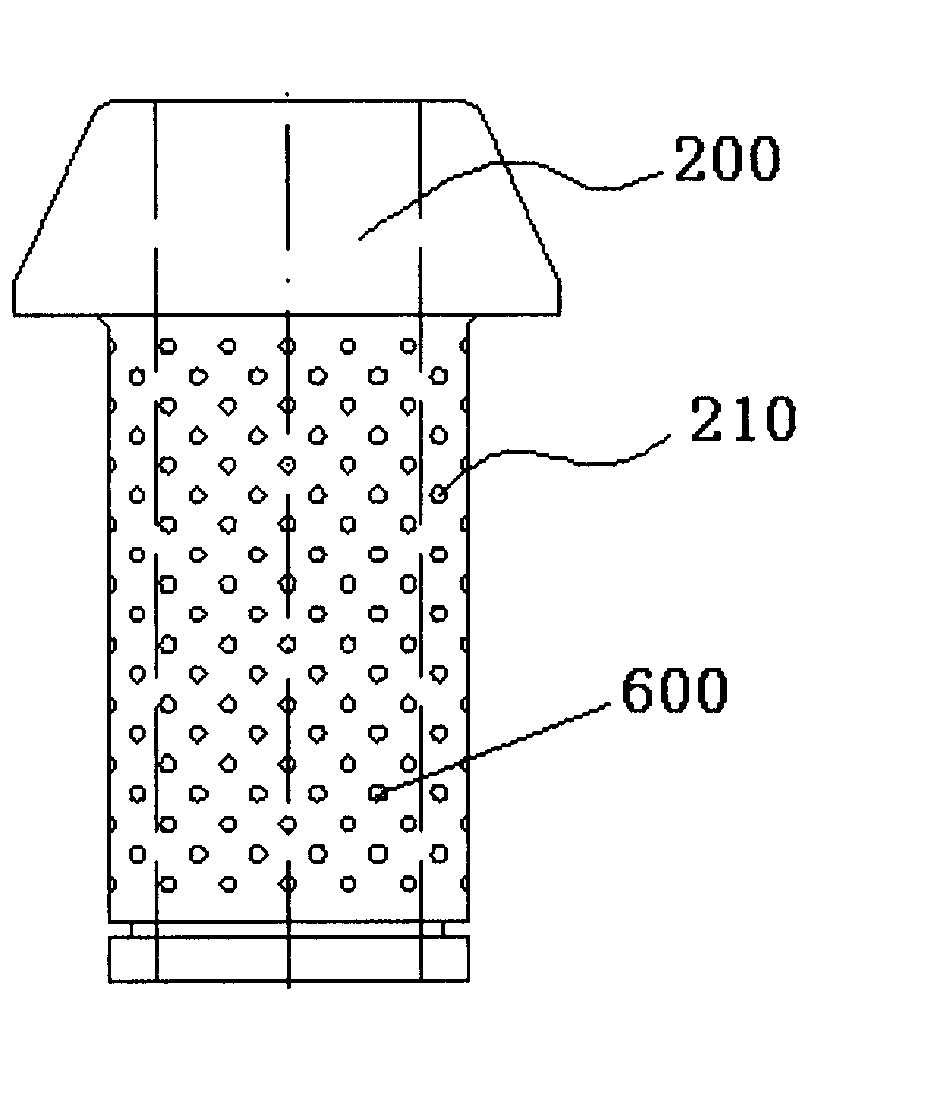

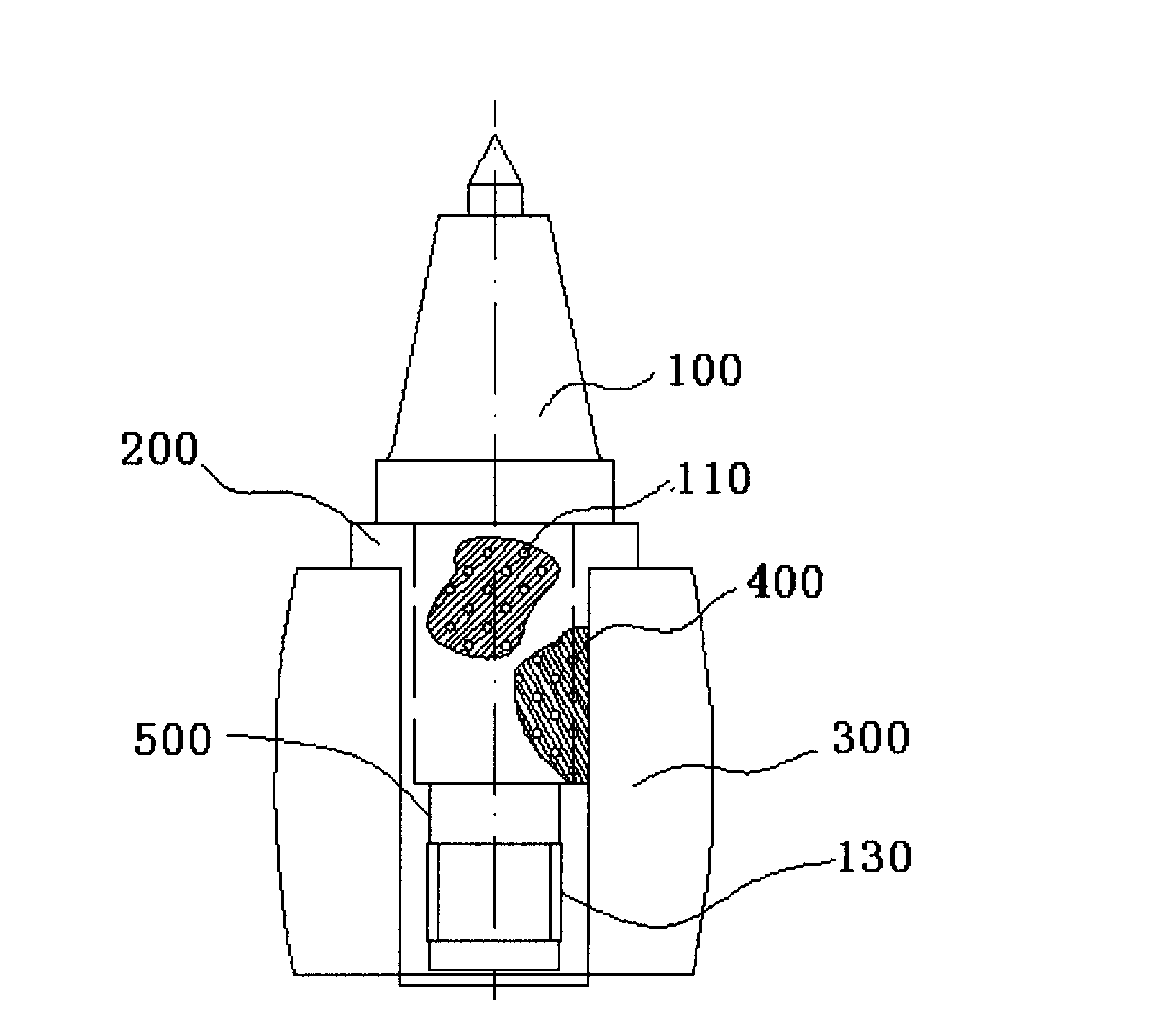

[0023] Example 1: see figure 1 , figure 2 , image 3 , a shearer latent composite solid lubricating pick assembly, including pick 100, pick sleeve 200, pick seat 300, the upper end of pick 100 is a conical body, and the lower end is composed of a columnar body to form pick shank 120, The lower end of the tooth shank 120 is sleeved with a tension sleeve 130 separated by a circumferential groove; the pick sleeve 200 is sleeved on the pick shank 120, the pick sleeve 200 is seated in the pick seat 300, the pick 100, the pick The sleeve 200 and the pick seat 300 form a coaxial body with clearance, the outer walls of the pick handle 120 and the tensioning sleeve 130, and the outer wall of the pick sleeve 200 are respectively processed with an inner lurking pit 110 and an outer lurking pit 210, the inner lurking pit 110 and the outer lurking pit The pits 210 are evenly spaced pits 600 (see figure 1 , figure 2 ), processed around the shank face of the pick.

[0024] The steps o...

Embodiment 2

[0031] Example 2: see figure 1 , figure 2 , image 3 , a shearer latent composite solid lubricating pick assembly, including pick 100, pick sleeve 200, pick seat 300, the upper end of pick 100 is a conical body, and the lower end is composed of a columnar body to form pick shank 120, The lower end of the shank 120 is sleeved with a tension sleeve 130 separated by a circumferential groove; the pick sleeve 200 is sleeved on the end of the pick shank 120 of the pick 100, the pick sleeve 200 is seated in the pick seat 300, and the pick 100. The pick sleeve 200 and the pick seat 300 form a coaxial body with clearance, the outer wall of the pick handle 120 and the tension sleeve 130, and the outer wall of the pick sleeve 200 are respectively machined with an inner lurking pit 110 and an outer lurking pit 210, and the inner lurking pit 110 and outer lurking pits 210 are array hole groups 400 (see image 3 ), the array hole group 400 is processed around the shank face of the pick....

Embodiment 3

[0039] Example 3: see figure 1 , figure 2 , image 3 , a shearer latent composite solid lubricating pick assembly, including pick 100, pick sleeve 200, pick seat 300, the upper end of pick 100 is a conical body, and the lower end is composed of a columnar body to form pick shank 120, The lower end of the shank 120 is sleeved with a tension sleeve 130 separated by a circumferential groove; the pick sleeve 200 is sleeved on the end of the pick shank 120 of the pick 100, the pick sleeve 200 is seated in the pick seat 300, and the pick 100. The pick sleeve 200 and the pick seat 300 form a coaxial body with clearance, the outer wall of the pick handle 120 and the tension sleeve 130, and the outer wall of the pick sleeve 200 are respectively machined with an inner lurking pit 110 and an outer lurking pit 210, and the inner lurking pit 110 And the outer lurking pit 210 or the threaded groove.

[0040] The steps of thread groove processing and assembly of the pick 100, the pick sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com