Crowned tooth universal drive shaft

A universal transmission and drum-shaped tooth technology, which is applied in the field of transmission shafts, can solve problems such as poor sealing effect, unreliable lubrication, and complex structure, and achieve the effect of eliminating gaps, preventing lubricating oil leakage, and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

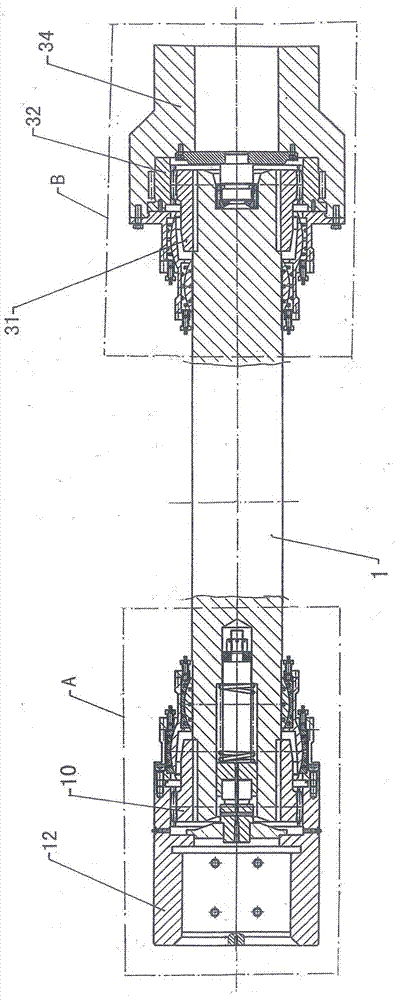

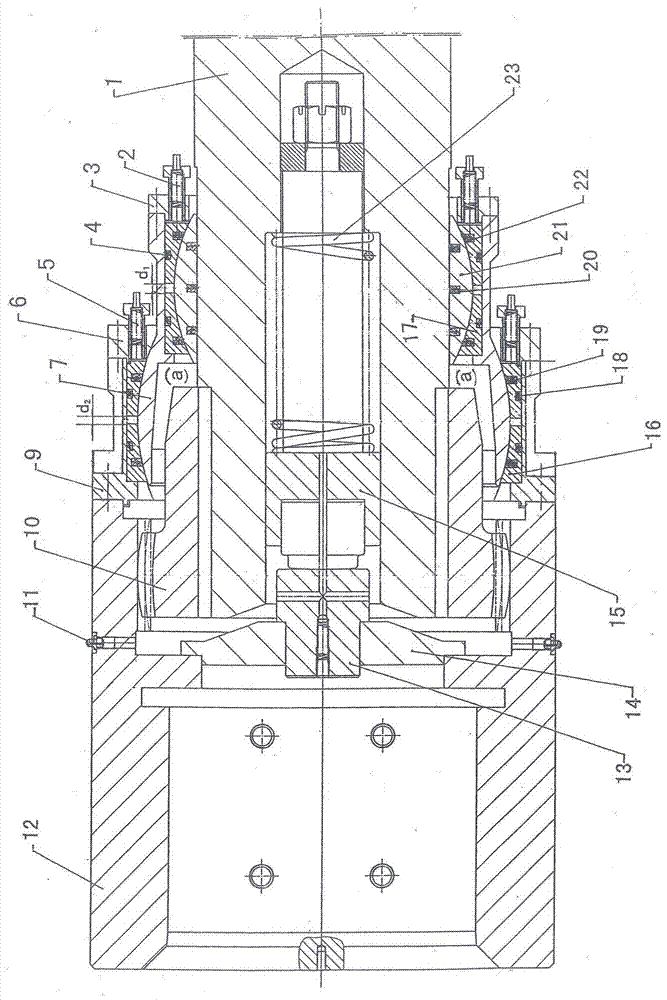

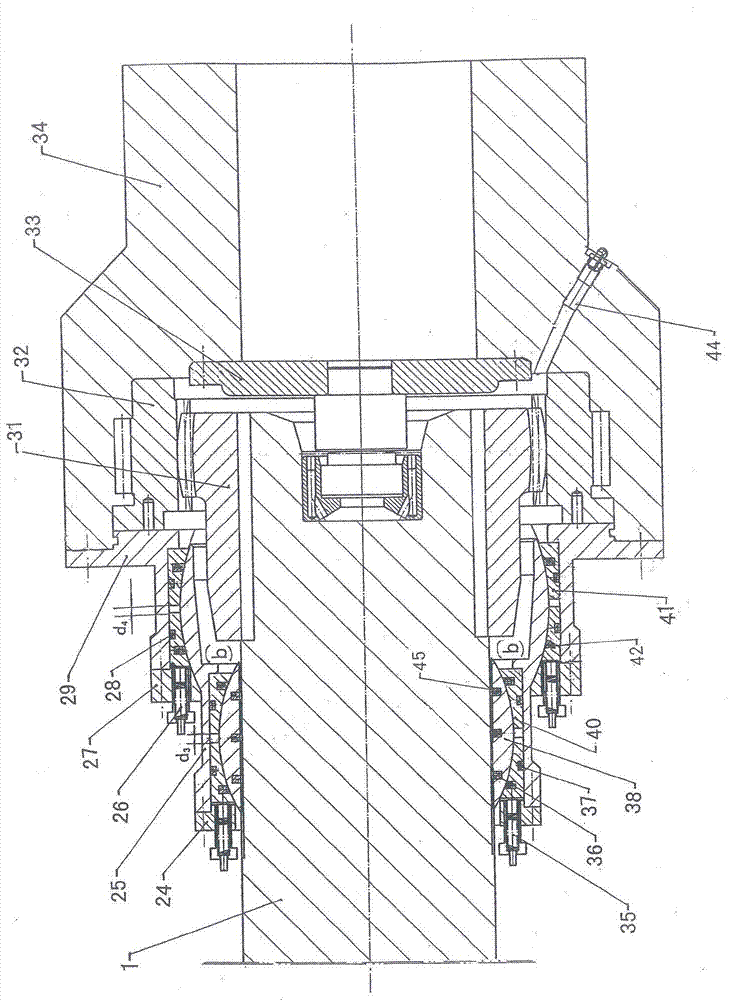

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0023] (As shown in the accompanying drawings) The drum-shaped gear universal transmission shaft of the present invention is mainly designed for the transmission shaft connected with the power part and the roll part of the hot-rolled plate production line or cold-rolled plate production line. It includes shaft body 1, Left first elastic compensator 2, left second elastic compensator 5, right second elastic compensator 35, right second elastic compensator 26, left first pressure ring 3, left second pressure ring 6, left third pressure ring Ring 9, right first pressure ring 24, right second pressure ring 27, right third pressure ring 29, left first sealing ring 4, left second sealing ring 22, left third sealing ring 20, left fourth sealing ring 19. Left fifth sealing ring 18, right first sealing ring 37, right second seali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com