Rope wheel type automobile window lifter

A window-swinger and rope wheel type technology, which is applied in the field of auto parts, can solve problems such as wire rope coming out, and achieve the effects of reducing internal friction, reducing abnormal noise, and reducing the probability of wire rope jumping out.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

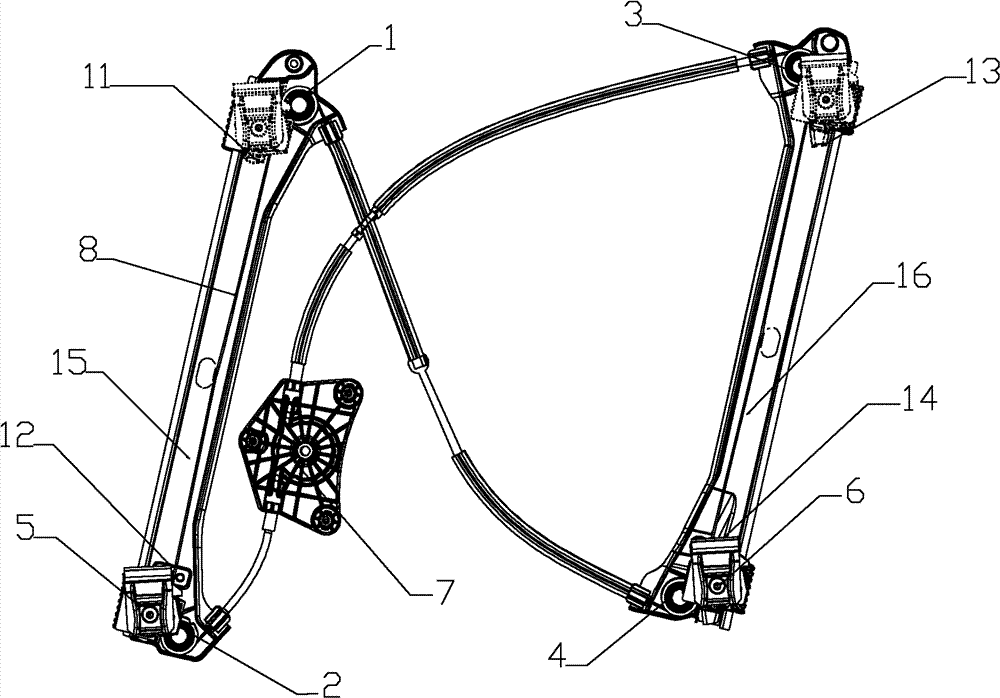

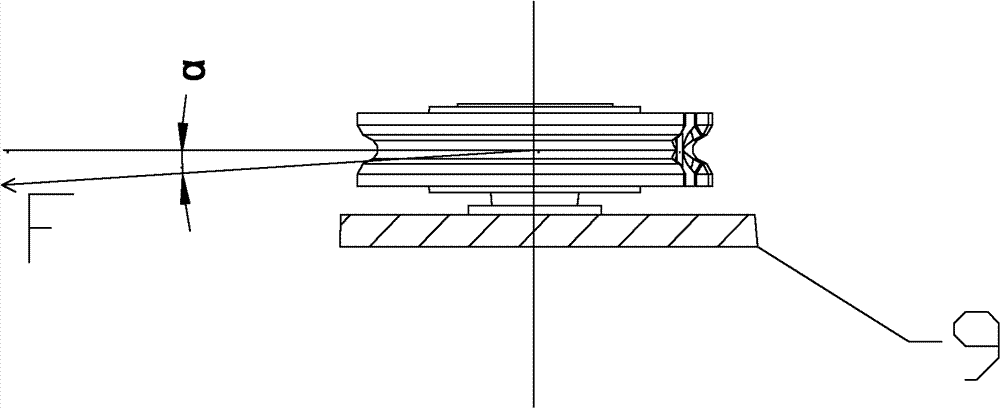

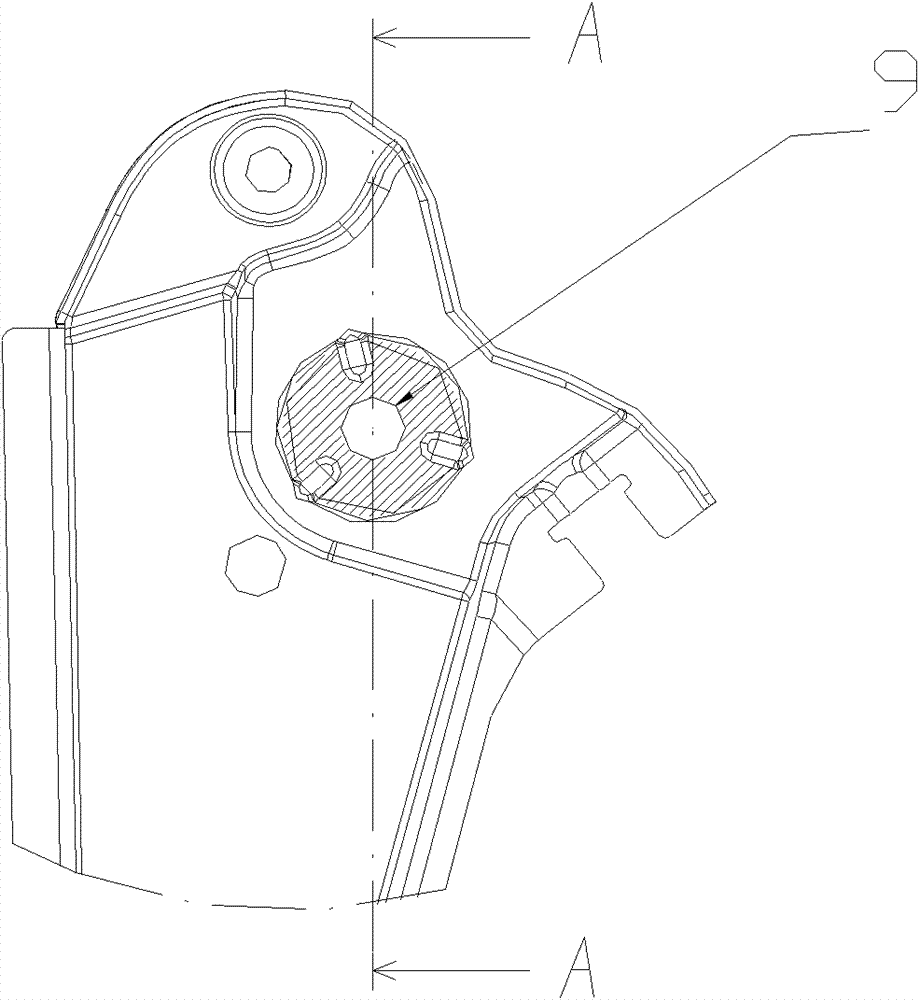

[0019] like figure 1 As shown, it is a structural schematic diagram of a double-track rope-wheel type car window shaker that can be used for the front window of a car. Driven by the drive motor 7, the steel wire rope 8 goes around the first pulley 1, the second pulley 2, the third pulley 3 and the fourth pulley. The pulley 4 drives the first slider 5 to move between the first top dead center 11 and the first bottom dead center 12, and the second slider 6 moves between the second top dead center 13 and the second bottom dead center 14. The resulting cambered surface of the guide rail forms the first bonding point 15 and the second bonding point 16 of the steel wire rope 8 and the guide rail. combine figure 2 , 3 And 4, the double-track rope wheel type automobile window shaker of the present invention, the angle α of the supporting assembly surface of the guide rail pulley of the window shaker and the wire rope outlet direction F is given by the formula:

[0020] OK, among...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com