Patents

Literature

39results about How to "Flexible operation adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

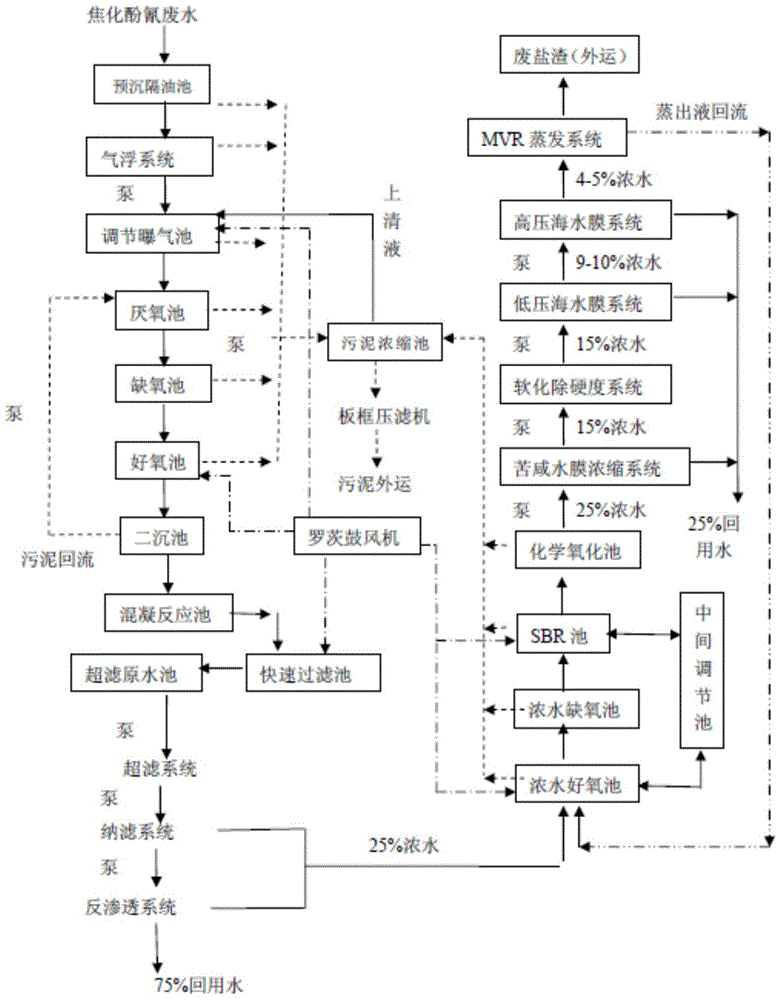

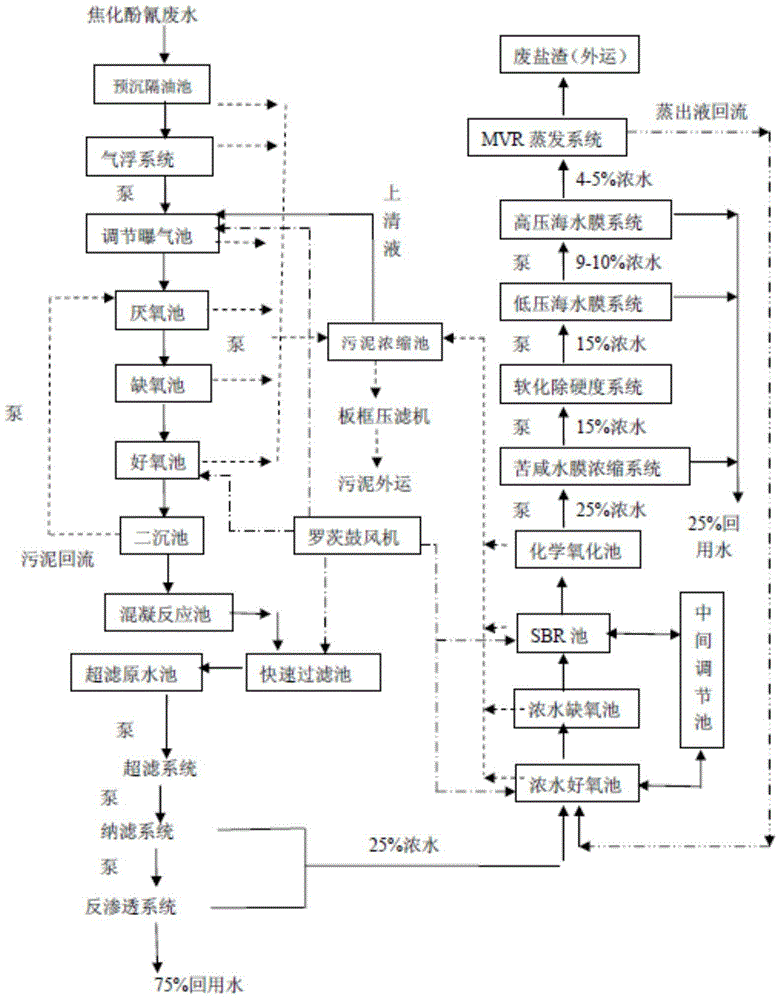

Treating and recycling zero-emission technology and equipment for coking phenol-cyanogen wastewater

ActiveCN104803548AGuaranteed stable operationStrong load impact resistanceMultistage water/sewage treatmentSeawaterZero emission

The invention discloses a treating and recycling zero-emission technology for coking phenol-cyanogen wastewater. According to the treating and recycling zero-emission technology, a pre-sedimentation oil separating tank, an air floating system, an adjusting aeration tank, an anaerobic tank, an anoxic tank, an aerobic tank, a secondary sedimentation tank, a coagulating reaction tank, a quick filtering tank, an ultrafiltration raw water tank, an ultrafiltration system, a nanofiltration system, a reverse osmosis system, a concentrated water aerobic tank, a concentrated water anoxic tank, an SBR tank, a chemical oxidation tank, a bitter water film concentrating system, a softening rigidity removing system, a low-pressure sea-water film system, a high-pressure sea-water film system, an MVR evaporating system, a sludge thickening tank, a press filter and a Roots blower are adopted for technological treatment. The invention further discloses treating and recycling zero-emission equipment for coking phenol-cyanogen wastewater. The treating and recycling zero-emission technology and equipment are high in treatment efficiency and low in cost, and have the advantages that zero emission of sewage can be realized.

Owner:ZHEJIANG BEROOT ENVIRONMENTAL PROTECTION TECH CO LTD

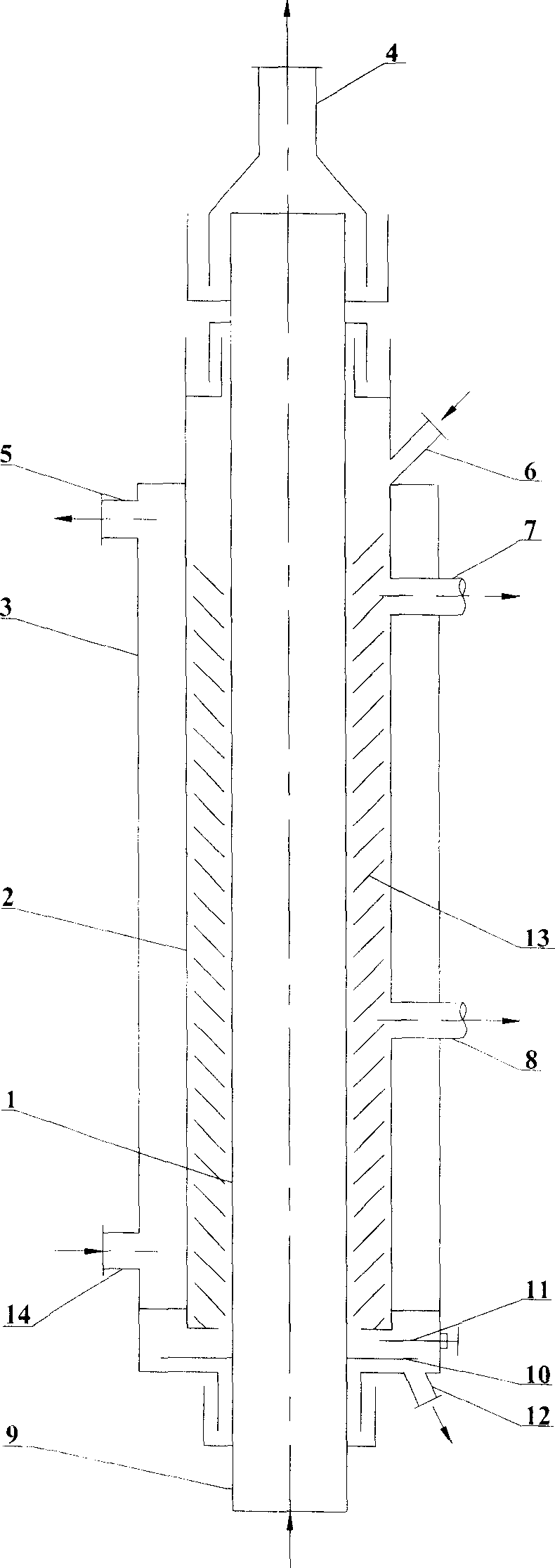

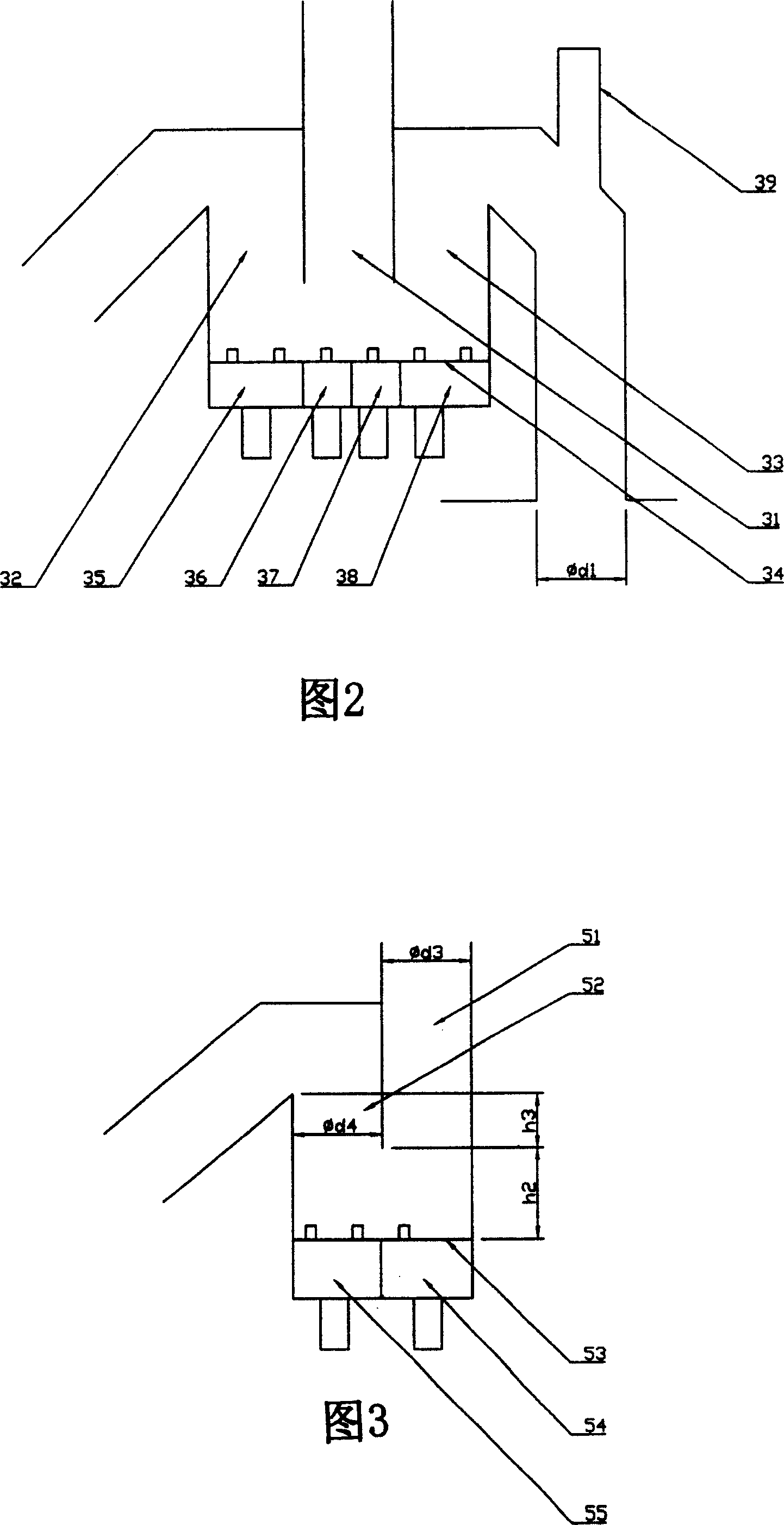

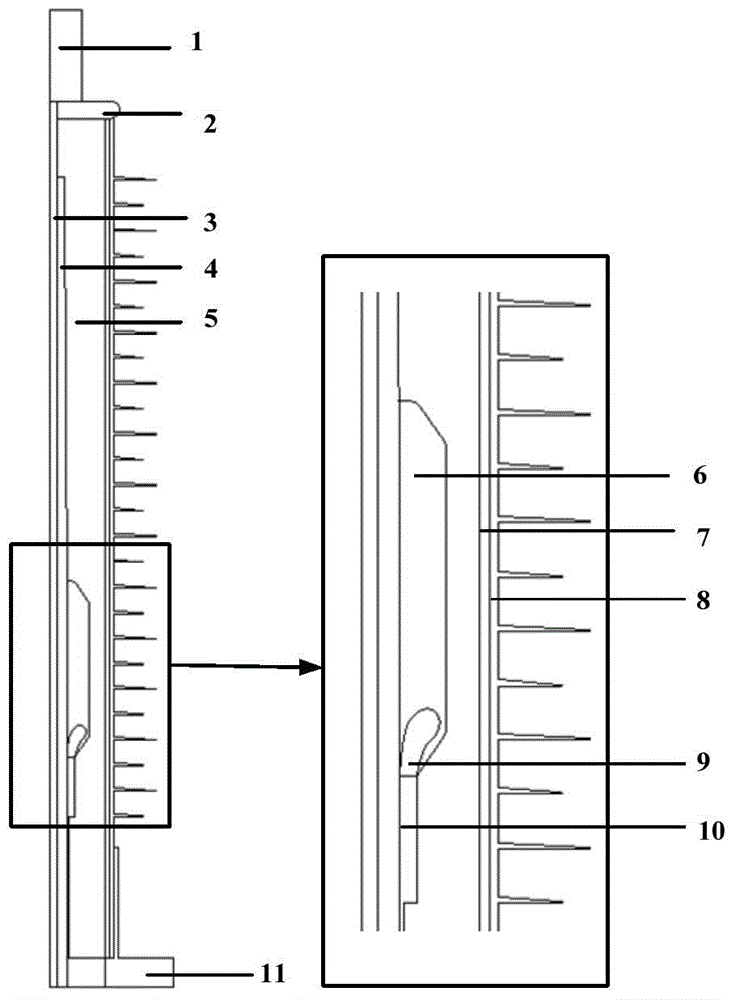

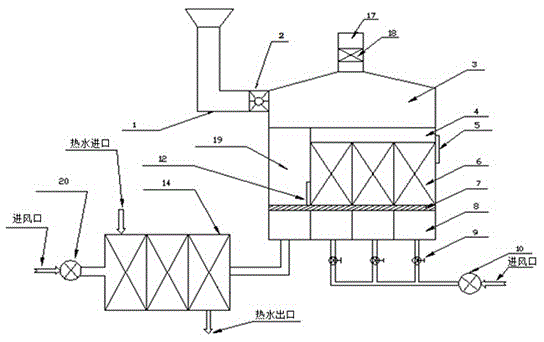

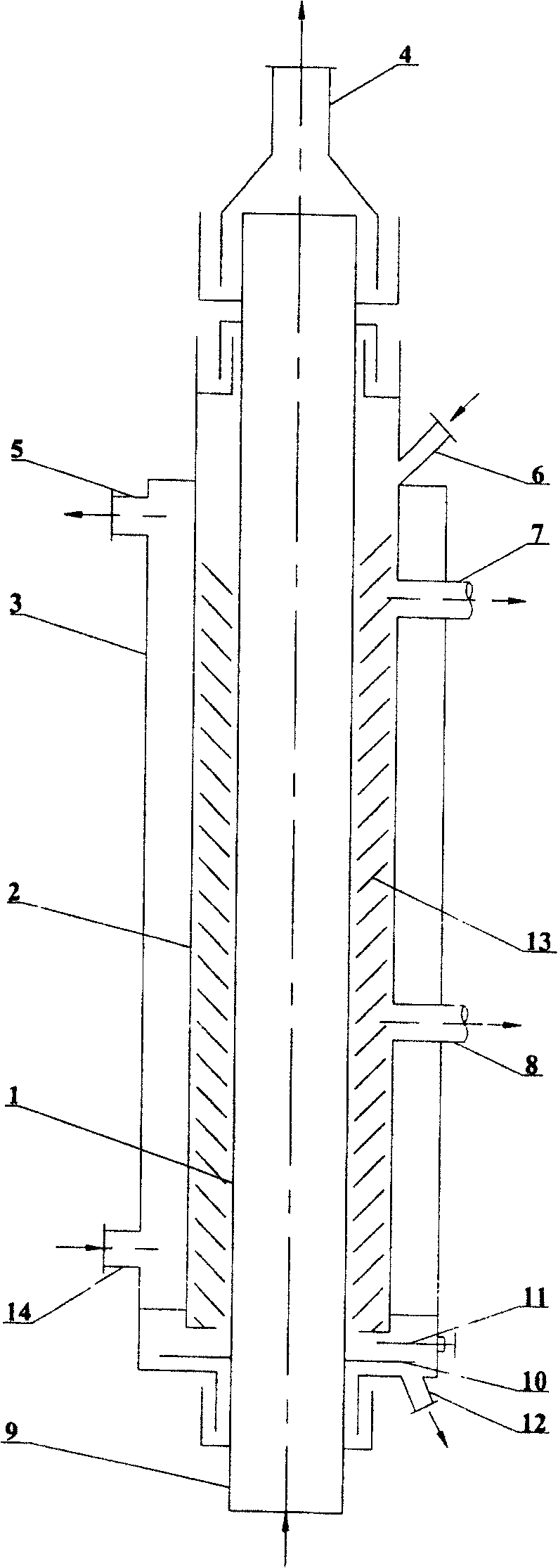

Low temperature distillation method and device for high volatile component weak viscosity coal

InactiveCN1865398AEvenly heatedAvoid stickingLiquid hydrocarbon mixture productionSpecial form destructive distillationWater vaporTar

The invention discloses a low-temperature retorting method of high-volatile flux fine particle, which is characterized by the following: the method adopts vertical pipe with inner, middle and outer concentric casing to move two sides of outer heat retort furnace, which produces char coal, gas and tar; the needed energy of retorting is provided by fine grain coal in the middle casing ring-shaped space from inner and outer casing high-temperature gas, which proceeds drying and charring steps; the steam and char volatile product are guided out of upper segment steam and lower segment char hole separately; the char coal falls in the char furnace chassis discharger, which is discharged from outlet.

Owner:FUZHOU UNIV

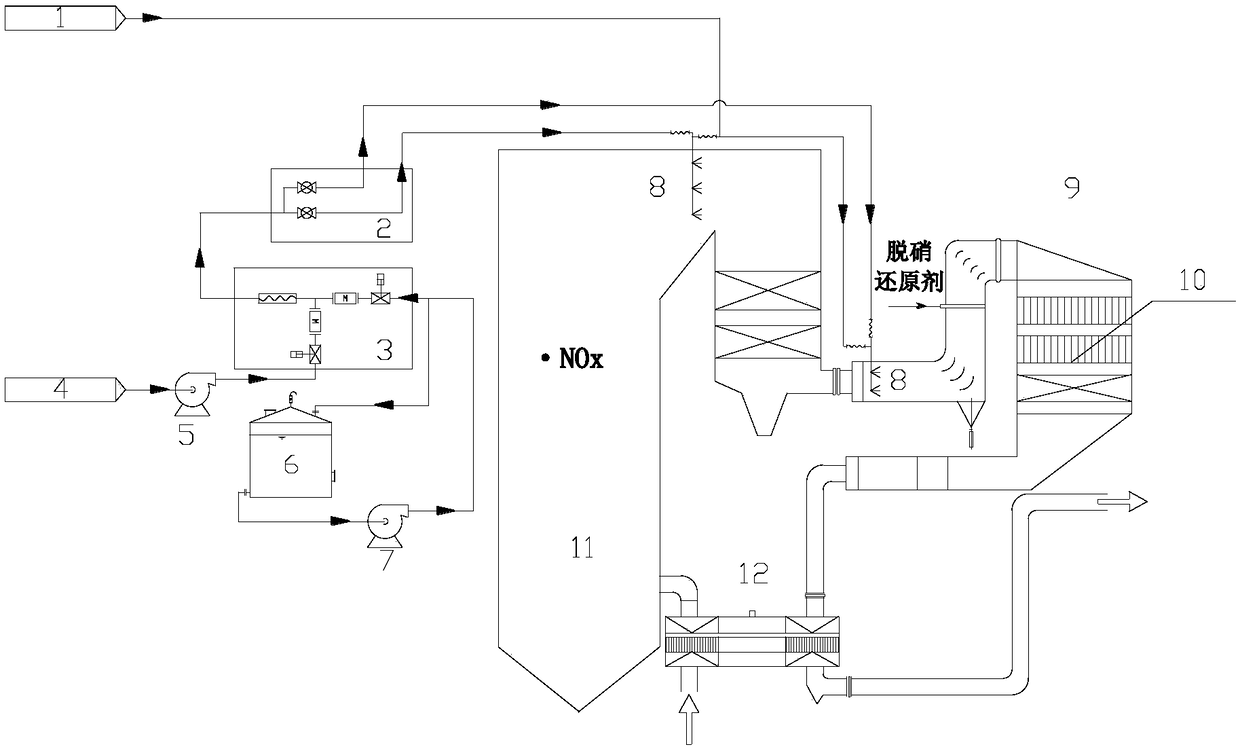

Flue gas SCR denitration efficiency-improving system and method

PendingCN108404653ASpeed up the denitrification reaction rateImprove denitrification efficiencyGas treatmentDispersed particle separationFlueSpray nozzle

The invention provides a flue gas SCR denitration efficiency-improving system and method. The method includes: spraying an oxidant into a flue between a boiler hearth outlet and a SCR denitration catalyst to partly oxidize NO in flue gas into NO2; enabling NO2 to enter a SCR denitration system to contact with a denitration catalyst to be in quick SCR denitration reaction at the present of NH3. SCRdenitration reaction velocity is accelerated, and denitration efficiency of an original SCR denitration system is improved. The system comprises an oxidant injection system and a SCR catalytic reducing denitration system, the oxidant injection system comprises an oxidant tank, an oxidant pump, a metering module, a dilution system, a distribution module and a nozzle system, and the SCR catalytic reducing denitration system comprises a SCR denitration reaction tower connected on a boiler flue gas outlet and a catalyst arranged in the SCR denitration reaction tower. The method and the system canimprove denitration efficiency of existing flue gas SCR denitration systems and are suitable for flue gas SCR denitration systems of many industries.

Owner:XIAN THERMAL POWER RES INST CO LTD

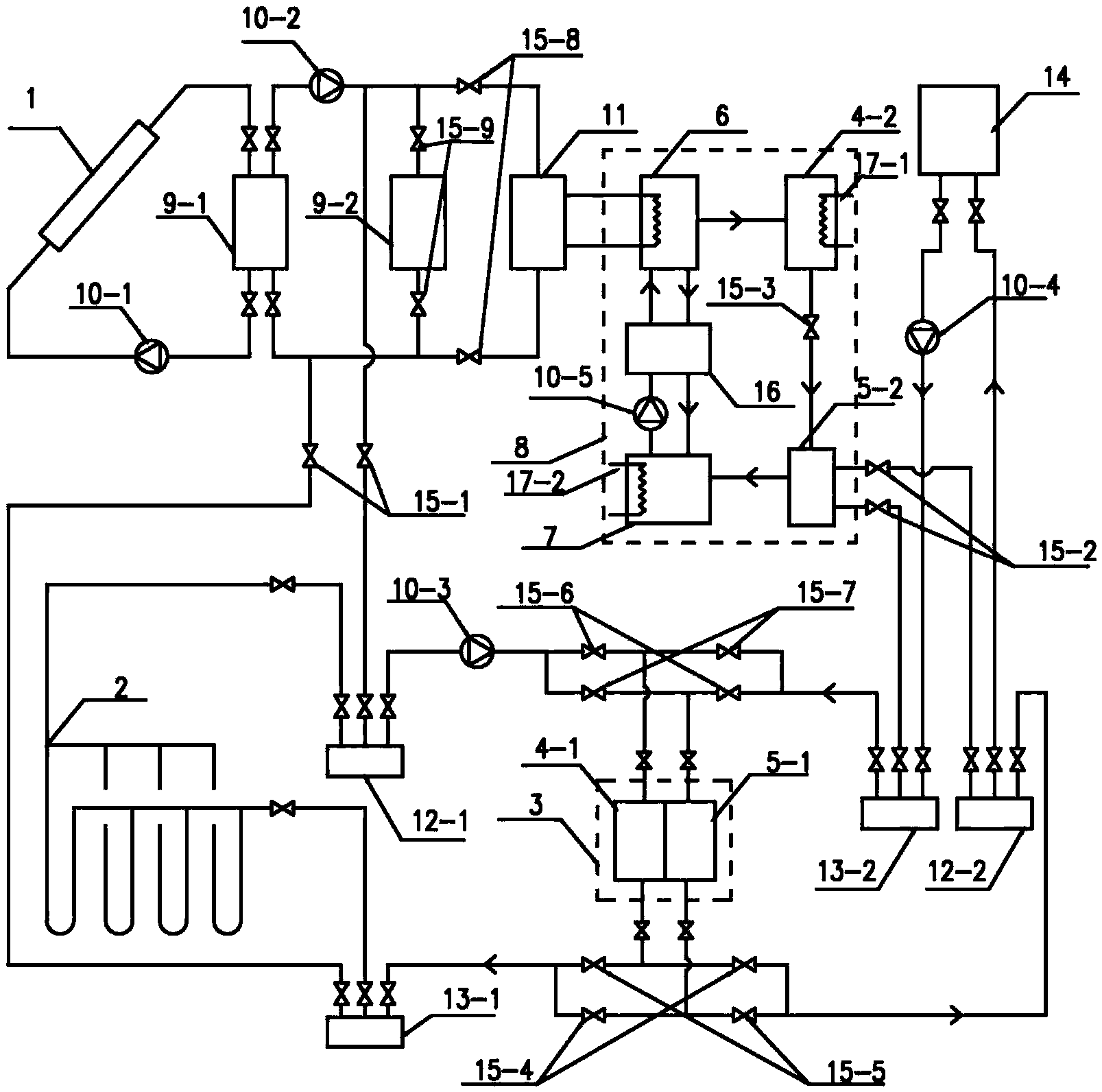

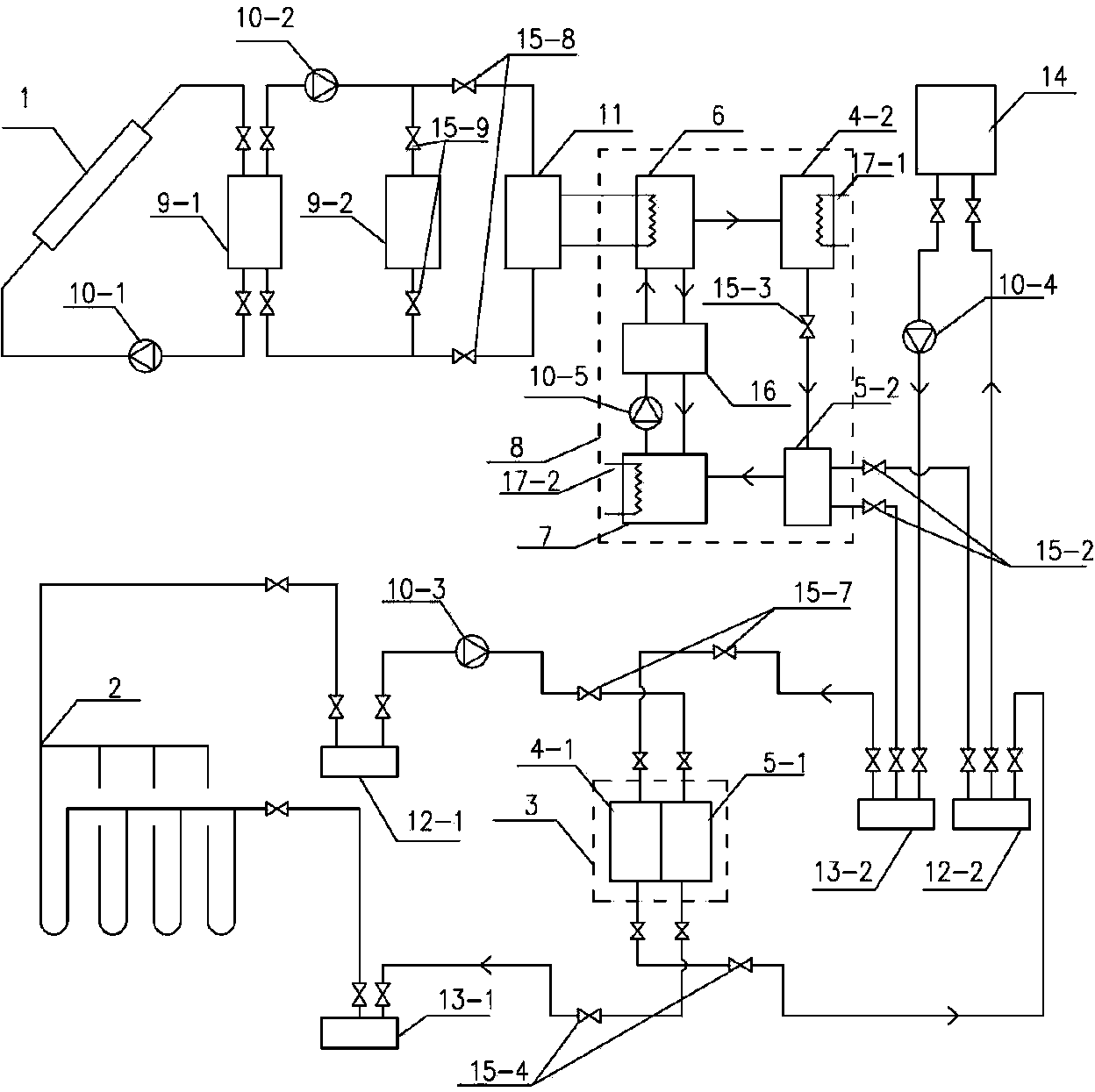

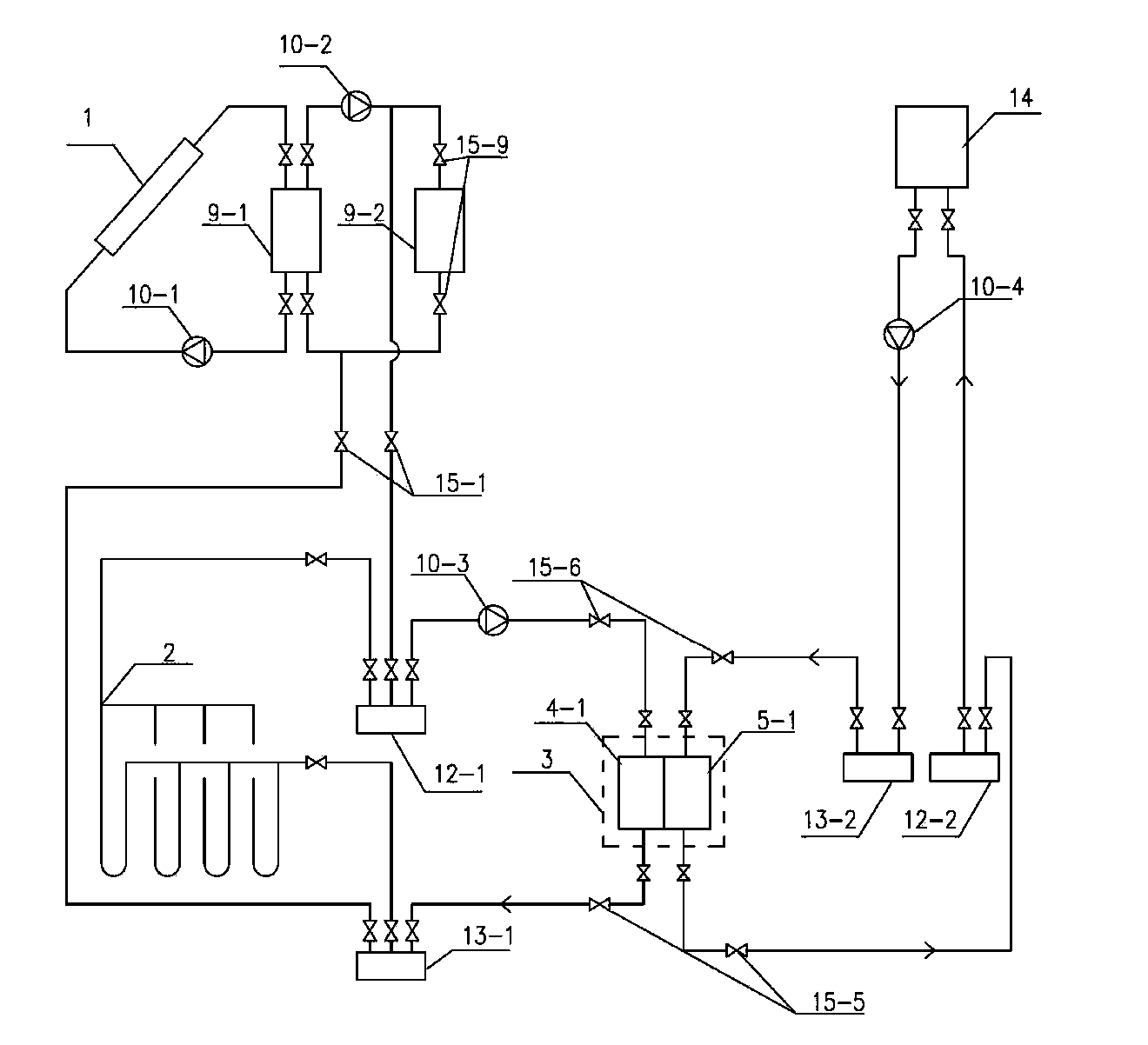

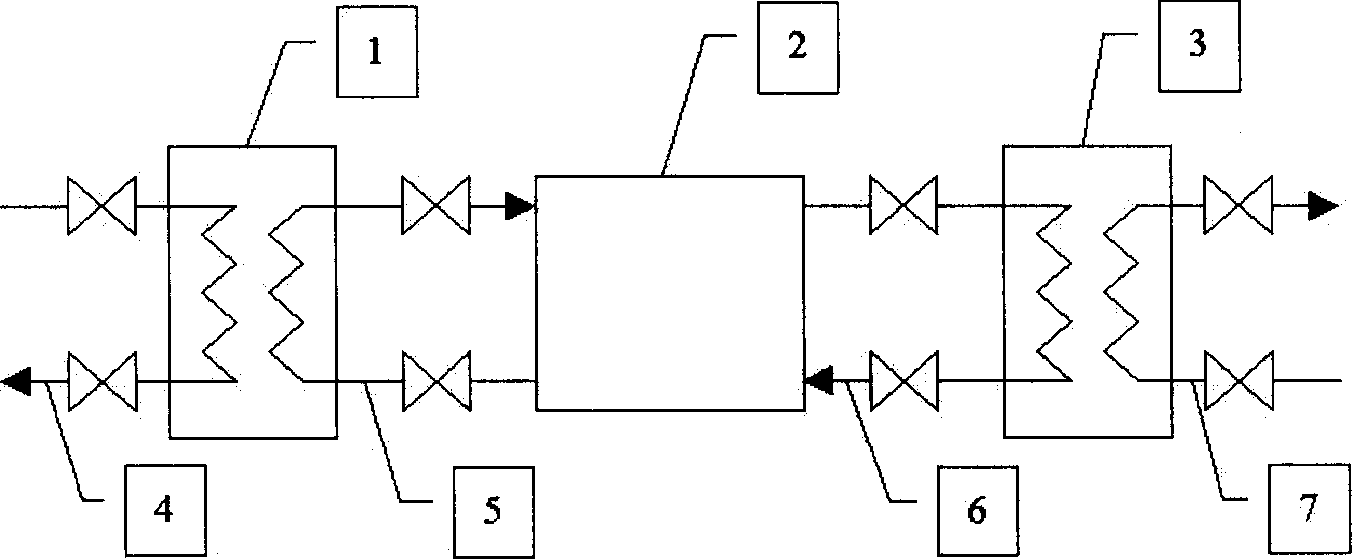

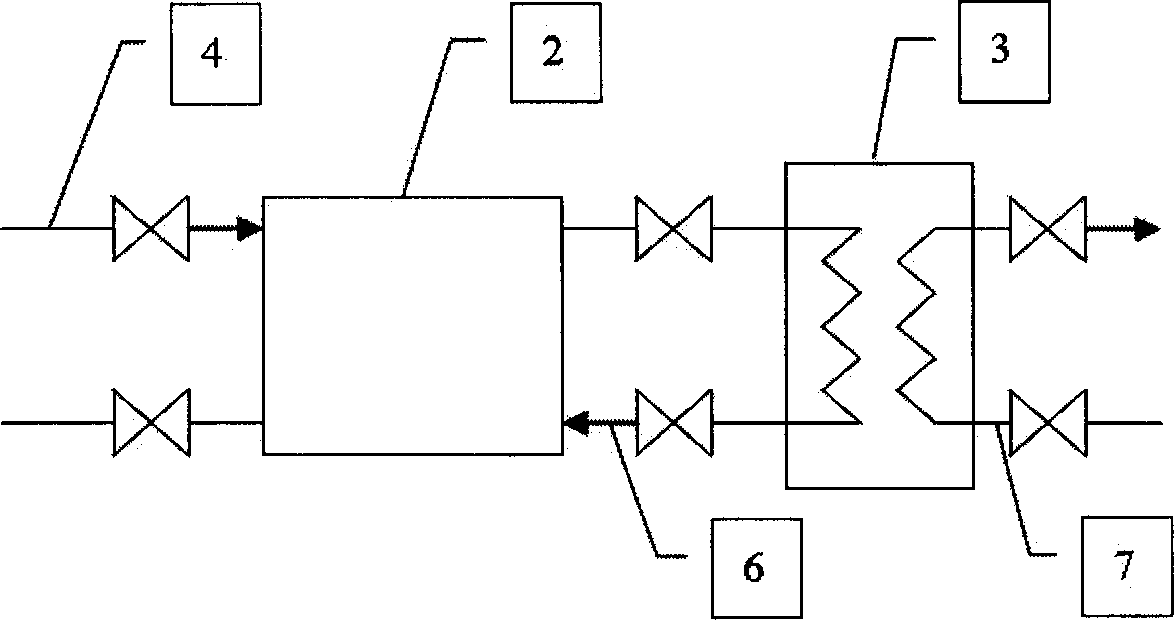

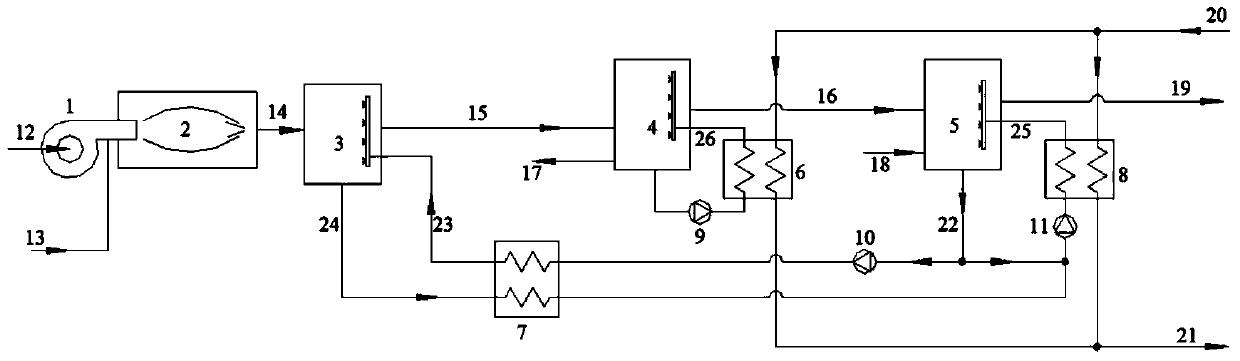

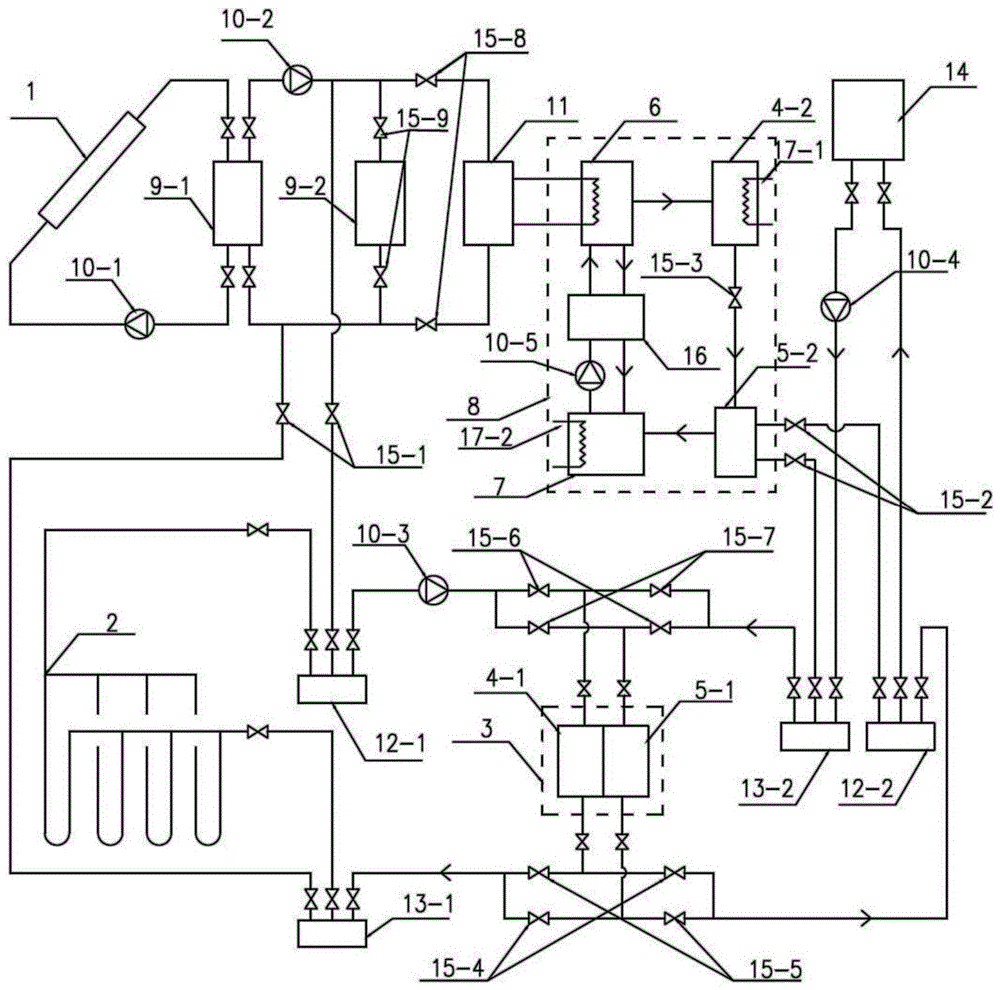

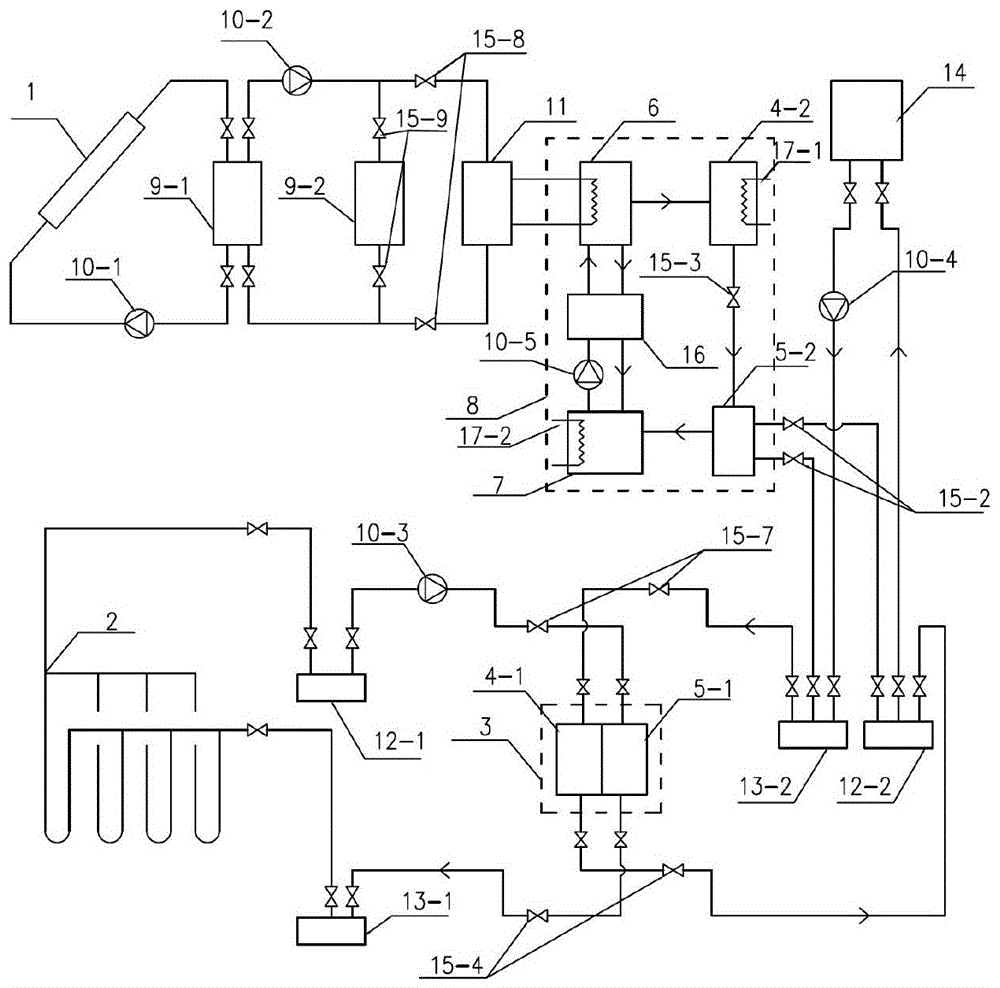

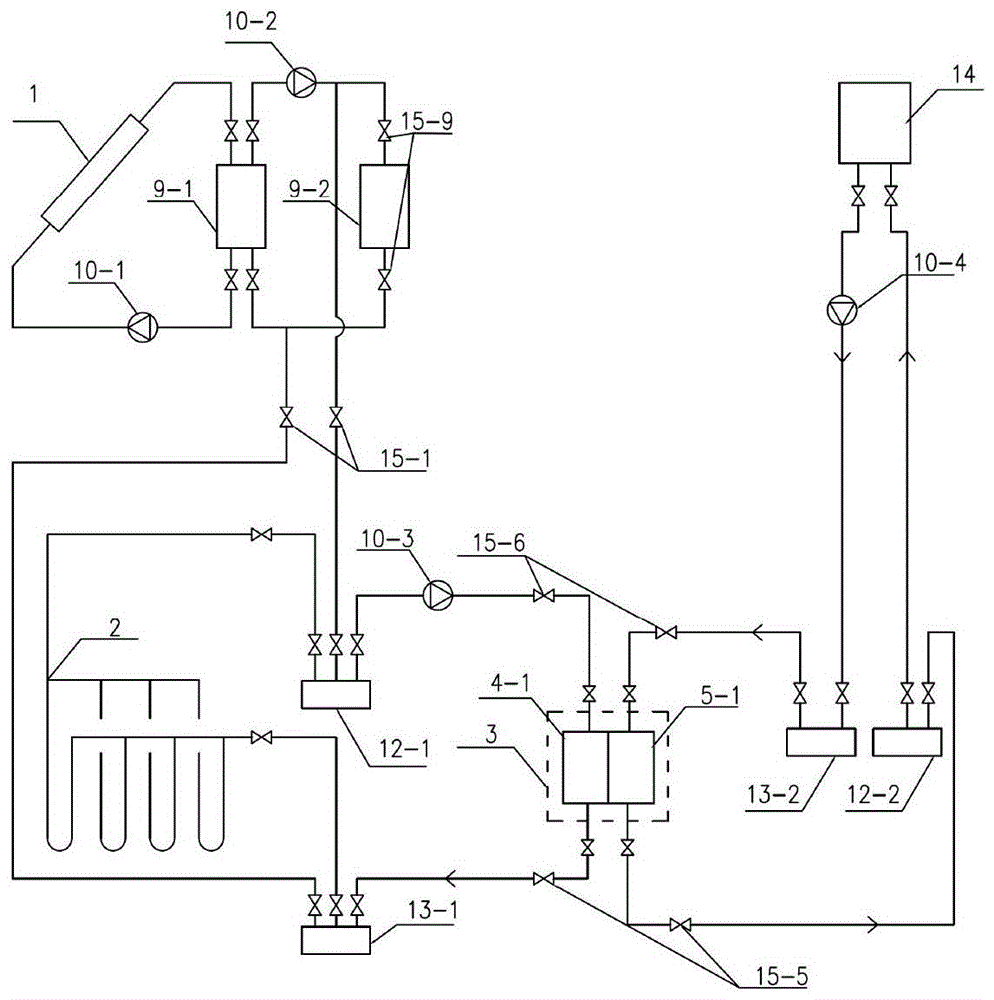

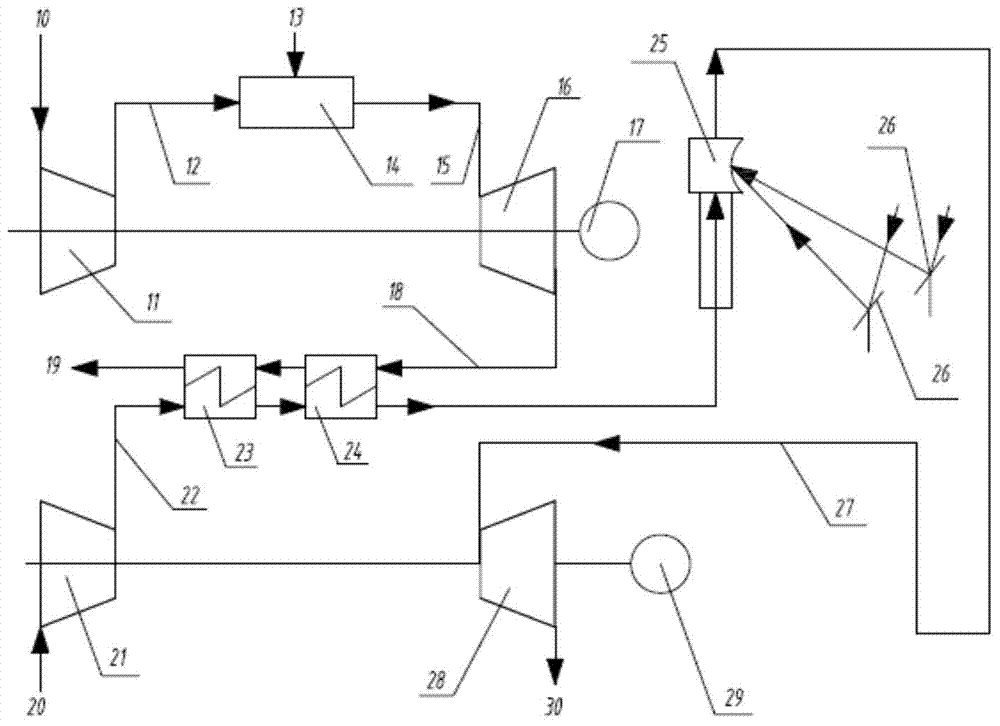

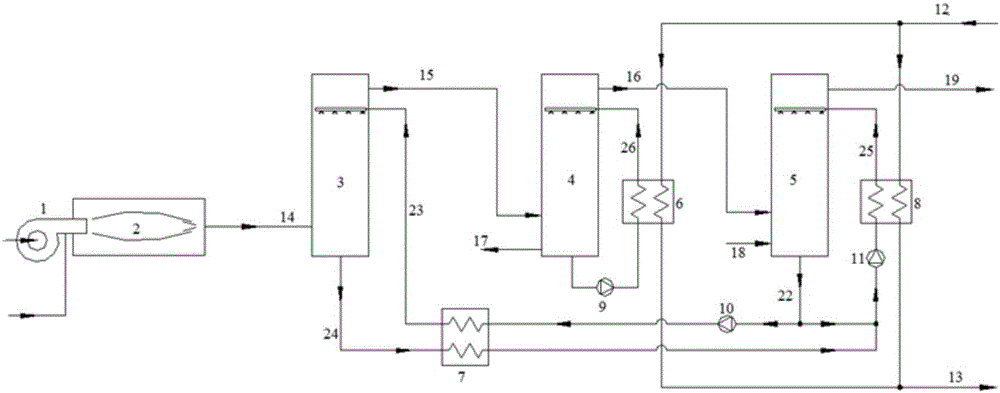

Heat exchange system in combined operation of solar energy and geothermal energy

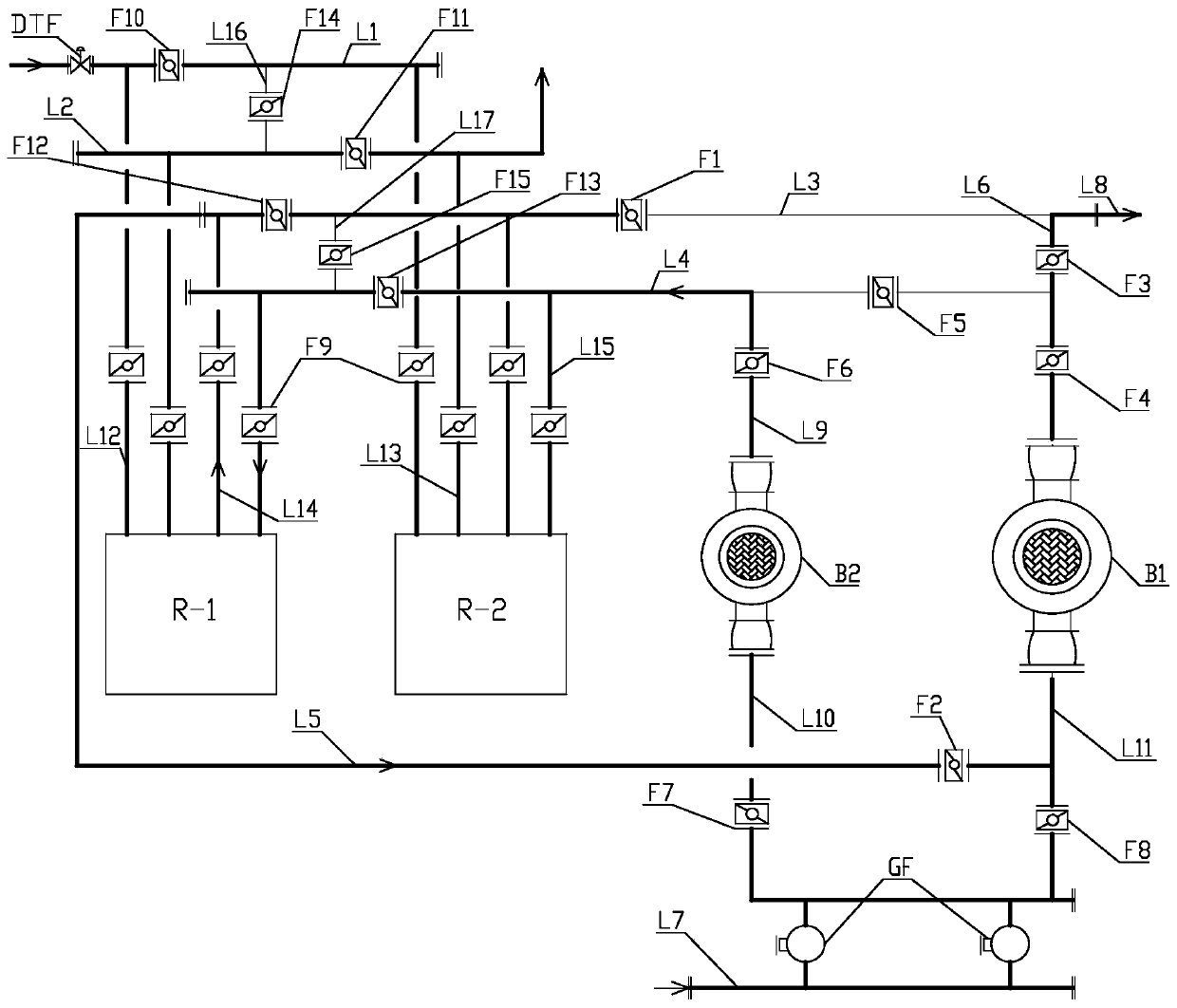

ActiveCN103900287ATroubleshoot Thermal ImbalancesFlexible operation adjustmentHeat pumpsClimate change adaptationEngineeringHeat pump

The invention discloses a heat exchange system in combined operation of solar energy and geothermal energy. The heat exchange system comprises a solar heat collector, a buried pipe heat exchanger, a heat pump unit, an absorbing type refrigerating unit, a user end, a plurality of hot water tanks, a plurality of water pumps, a plurality of connection pipes and a plurality of valves, wherein the solar heat collector is communicated with a first hot water tank, the first hot water tank is connected with a second water tank and an auxiliary heater via a second water pump so as to form a loop, the buried pipe heat exchanger is communicated with the heat pump unit, the heat pump unit is connected with the buried pipe heat exchanger and the first hot water tank via a third water pump so as to form a loop, the user end is connected with the heat pump unit and the absorbing type refrigerating unit via a fourth water pump so as to form a loop. The heat exchange system in combined operation of the solar energy and the geothermal energy has the advantages that unbalance problem of soil heat is effectively solved, cooling in summer, heating in winter and supplying of domestic hot water for all year around for buildings are achieved on the basis that the solar energy and the geothermal energy are utilized efficiently, and the heat exchange system is flexible to operate and adjust and diversified in functions.

Owner:SOUTHEAST UNIV

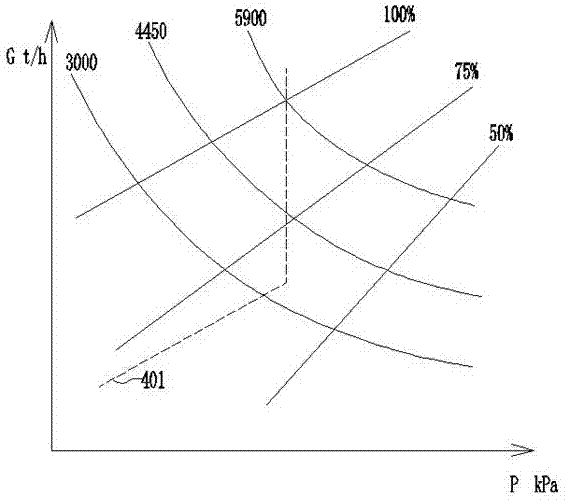

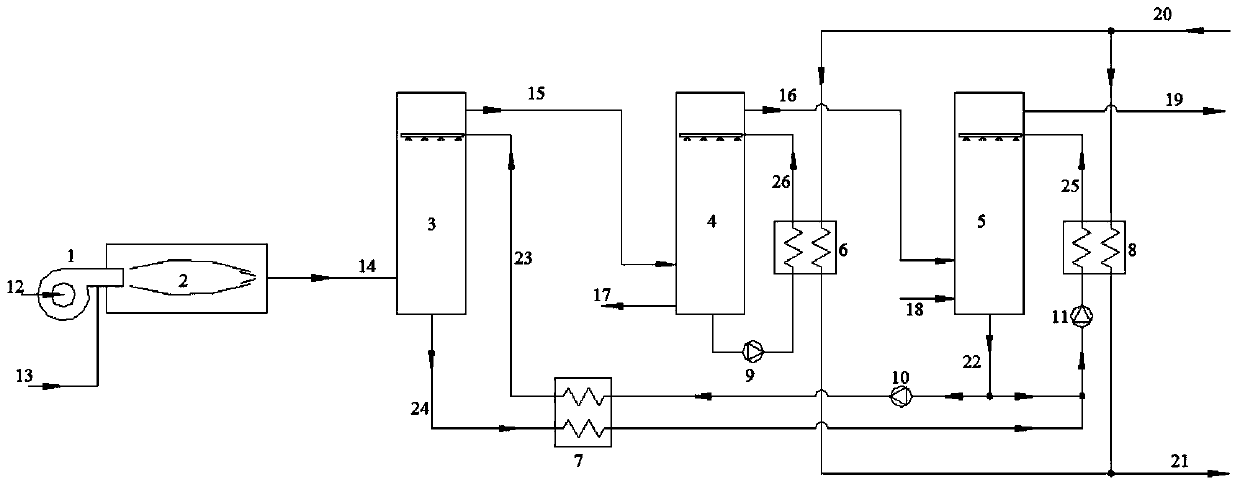

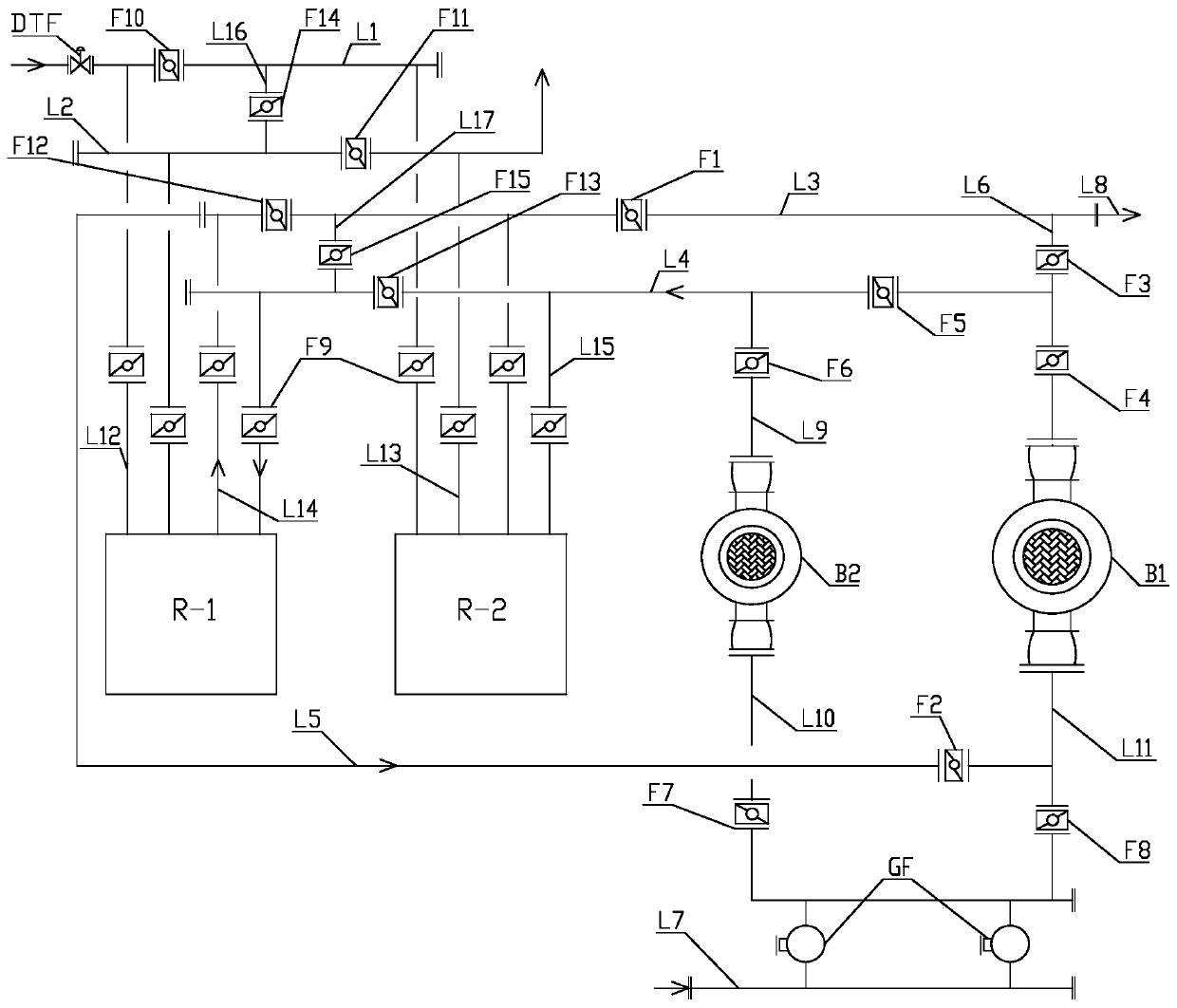

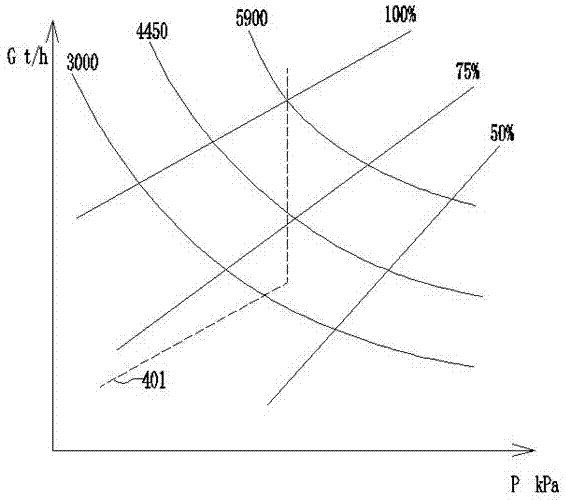

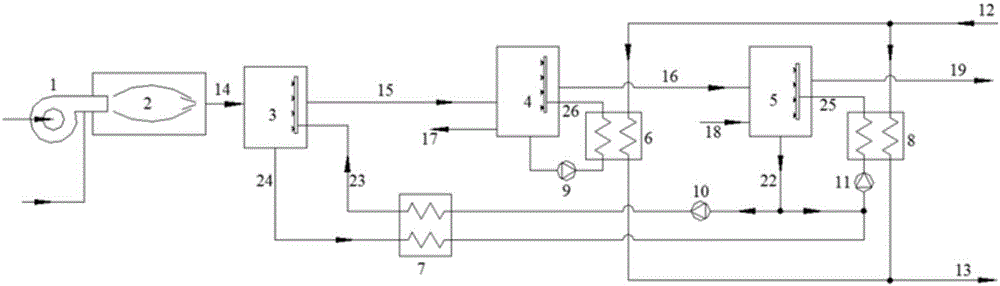

Adjusting method of steam compressor in application system of upgrading and heat supplying of exhausted steam of thermal power generating unit steam turbine

ActiveCN106930792AOperation impactImprove thermal efficiencyLighting and heating apparatusSteam regenerationElectricityGas compressor

The invention provides a configuration and adjusting method of a steam compressor in an application system of upgrading and heat supplying of exhausted steam of a thermal power generating unit steam turbine. The system comprises a steam compressor driving small steam turbine, two levels of steam compressors, two levels of thermal-system heaters, a lubricating oil system, a gland seal system, valves and pipe fittings, wherein the valves and the pipe fittings are used for connecting the steam compressor driving small steam turbine, the two levels of steam compressors, the two levels of thermal-system heaters, the lubricating oil system and the gland seal system. By adoption of the system, low-pressure and low-temperature exhausted steam of the steam turbine is compressed through the steam compressor by using little driving steam, the pressure and the temperature of the steam are increased so that the steam can serve as a heat source to heat heat-supply network circulating water for heat supply, and therefore, the purpose that the exhausted steam of the steam turbine is used is achieved. According to the changing characteristics of the heat supply quantity and the water supply parameters, and the steam compressor efficiency operating characteristics, the adjusting method is used for adjusting the rotary speed of the small steam turbine and the opening of an inlet baffle of the steam compressor to achieve adjustment of the compressed steam flow quantity and the outlet pressure. By adoption of the technology, adaptability to the heat supply condition is wide, and heat utilizing efficiency is high. Heat supply efficiency is not influenced by the generating unit electrical load and heat load.

Owner:北京源深能源科技有限责任公司

Heat pump type crude oil heating system

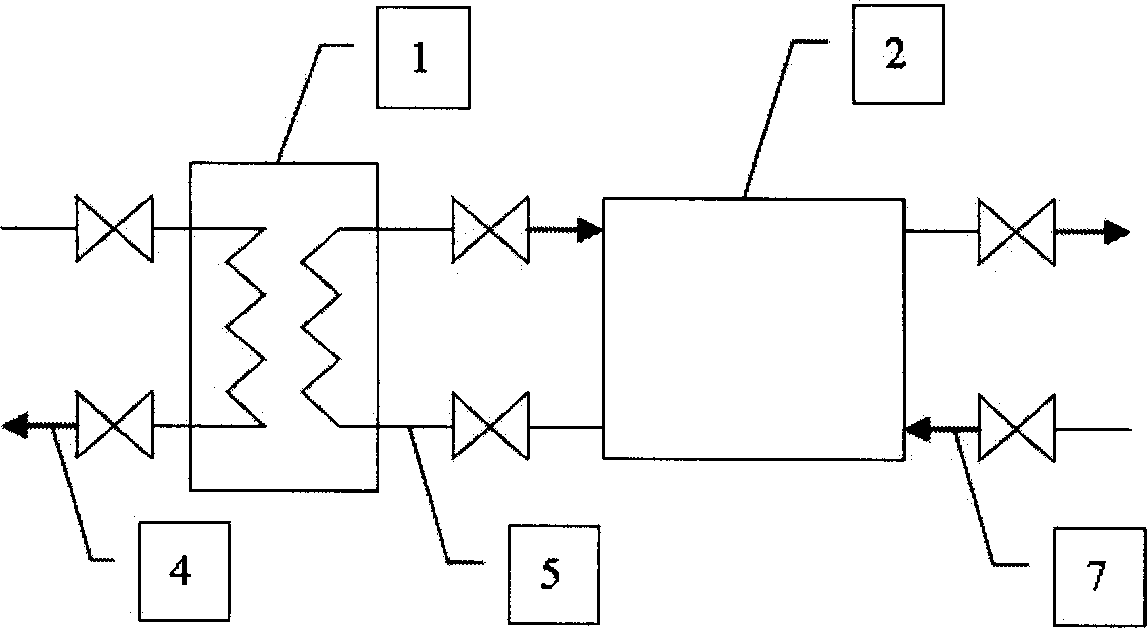

InactiveCN1412505AReduce consumptionLow costHeat pumpsHeat recovery systemsDirect combustionProcess engineering

The crude oil heating system is a system utilizing absorption heat pump system (steam type, hot water type, direct combustion type) to recover oil field sewage or geothermal water or heat quantity ofsolar energy to heat crude oil, and is characterized by that the waste hot water pipeline is connected with input end of absorption heat pump unit directly or by means of at least a water / water heat exchanger device, and the crude oil pipeline is connected with output end of absorption heat pump unit directly or by means of at least a crude oil / water heat-exchanger device.

Owner:BEIJING PEITEMU SCI & TECH DEV

Flue gas waste heat recovery unit

ActiveCN104180523AIncrease discharge temperatureReduce consumptionStorage heatersAir heatersWaste heat recovery unitFlue gas

The invention relates to a flue gas waste heat recovery unit which comprises a flue gas unit, a generator unit, a condenser unit, an absorber unit, a water return pipe and a water supply pipe. The flue gas unit is sequentially connected with the generator unit, the condenser unit and the absorber unit to form a flue gas heat exchanging path; the outlet of the generator unit is connected with the inlet of a solution-to-solution heat exchanger, the outlet of the absorber unit is divided into two paths: one path is merged with the outlet of the solution-to-solution heat exchanger to be connected with the inlet of a solution-to-water heat exchanger through a solution spray pump, the outlet of the solution-to-water heat exchanger is connected with a solution spray mechanism in the absorber unit, the other path is connected with the inlet of a solution-to-solution heat exchanger through a solution circulating pump, and the outlet of the solution-to-solution heat exchanger is connected with a dilute solution spray mechanism through the generator unit so as to form a solution heat exchanging and circulating loop; the outlet of the condenser unit is connected with the inlet of a water-to-water heat exchanger through a condense water spray pump, the outlet of the water-to-water heat exchanger is connected with a condense water spray mechanism through the condenser unit to form a condense water heat exchanging and circulating loop; the water return pipe is connected with a water-to-water heat exchanger unit and the inlet of a solution-to-water heat exchanger, and the water supply pipe is connected with the water-to-water heat exchanger and the inlet of the solution-to-water heat exchanger.

Owner:TSINGHUA UNIV +1

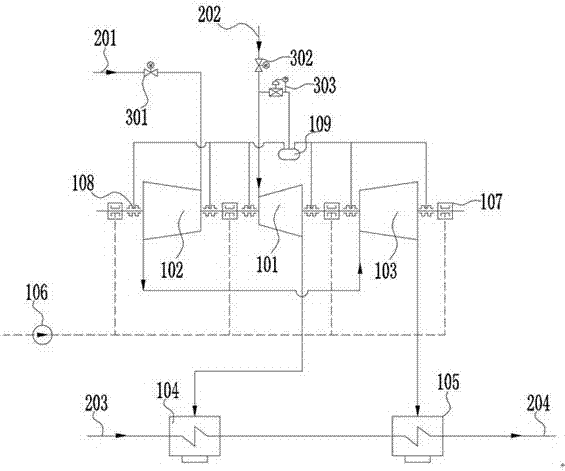

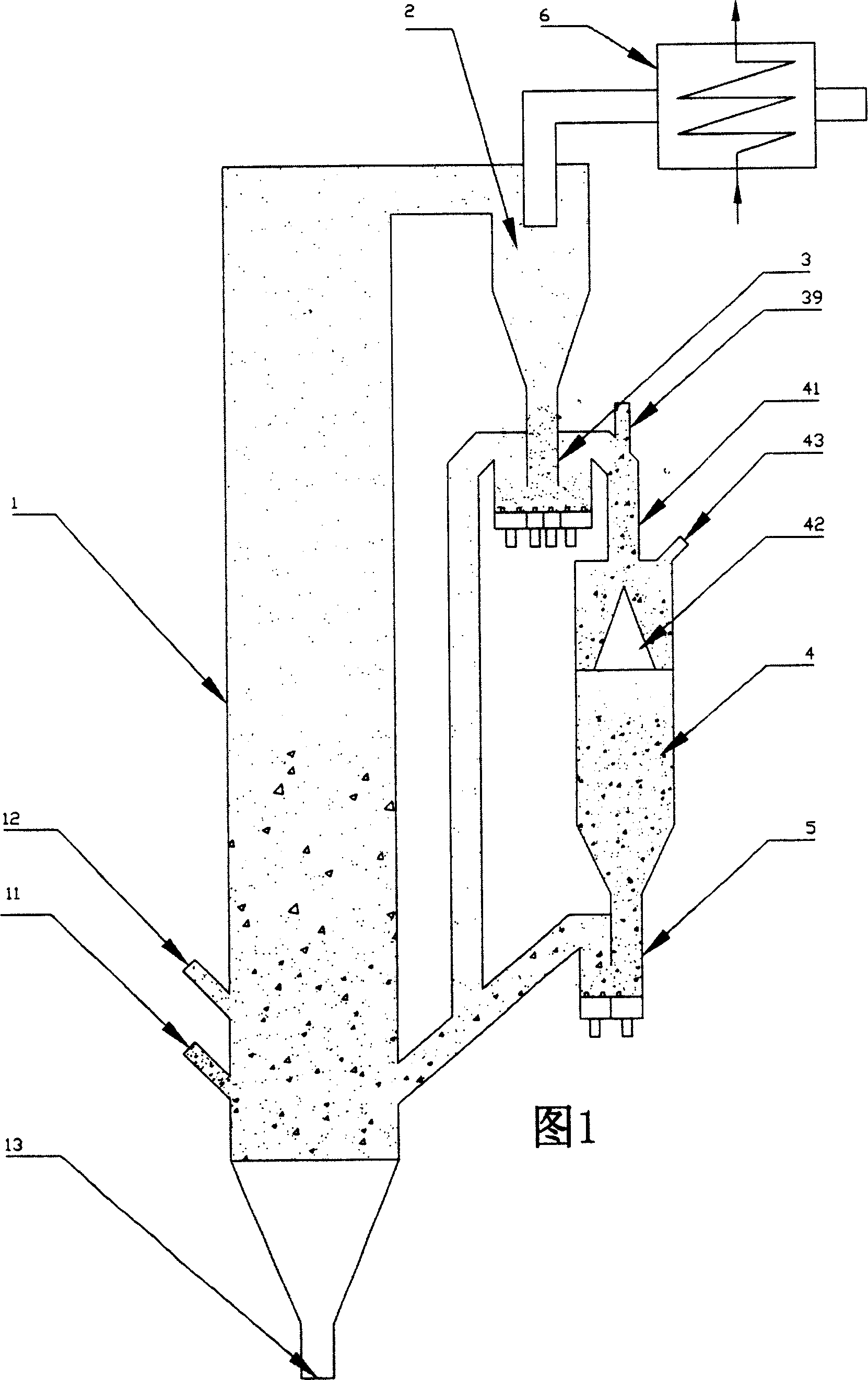

Method for producing both gas and steam, and boiler of circulating fluid bed with pyrolysis vaporizer

InactiveCN1318796CReduce solid impuritiesReduce tar contentFluidized bed combustionSolid fuel combustionCombustion chamberEngineering

The present invention relates to a gas-steam joint production method and circulating fluidized-bed boiler. It includes the following portions: fluidized-bed combustion chamber, cyclone separator, hot ash distributor, pyrolysis gasification chamber, heat exchanger and differential bed material-retuning device. Said invention also provides its concrete technological process, it can be used as steam boiler, and can implement gas-steam joint production.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI +1

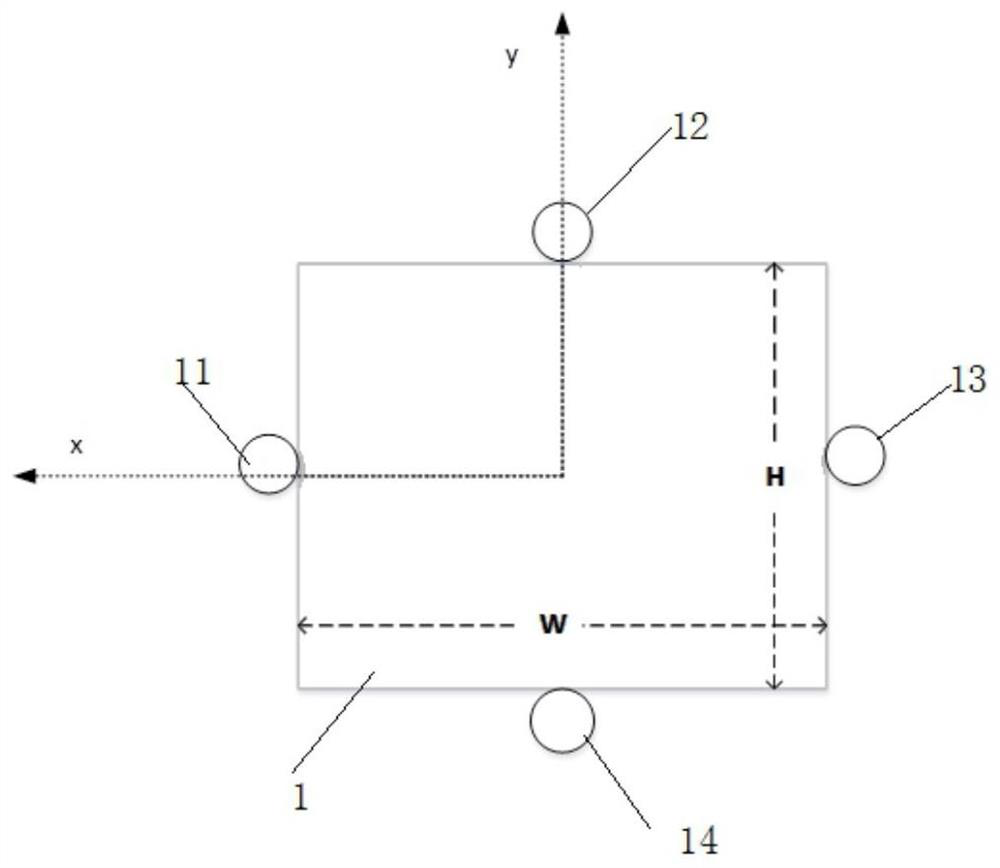

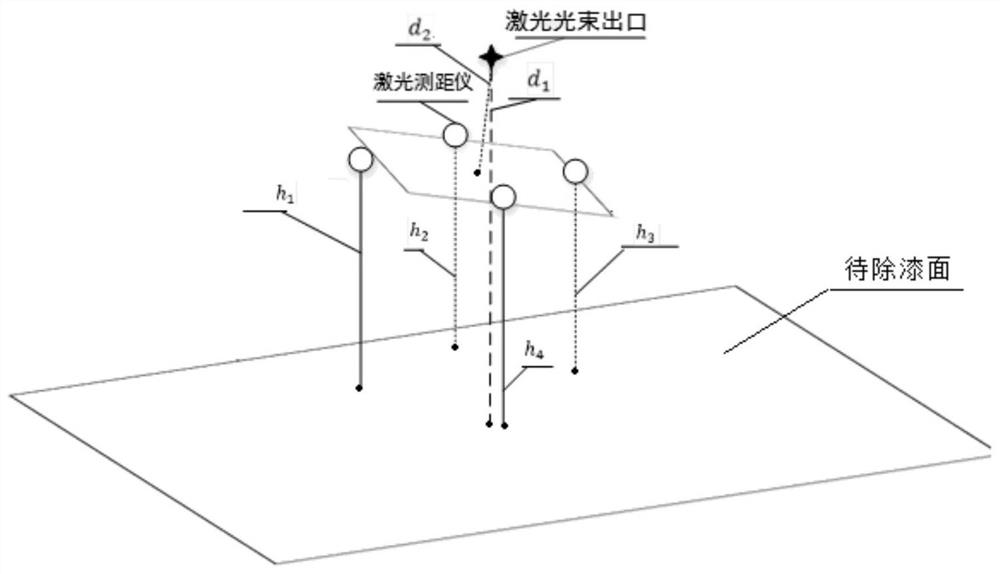

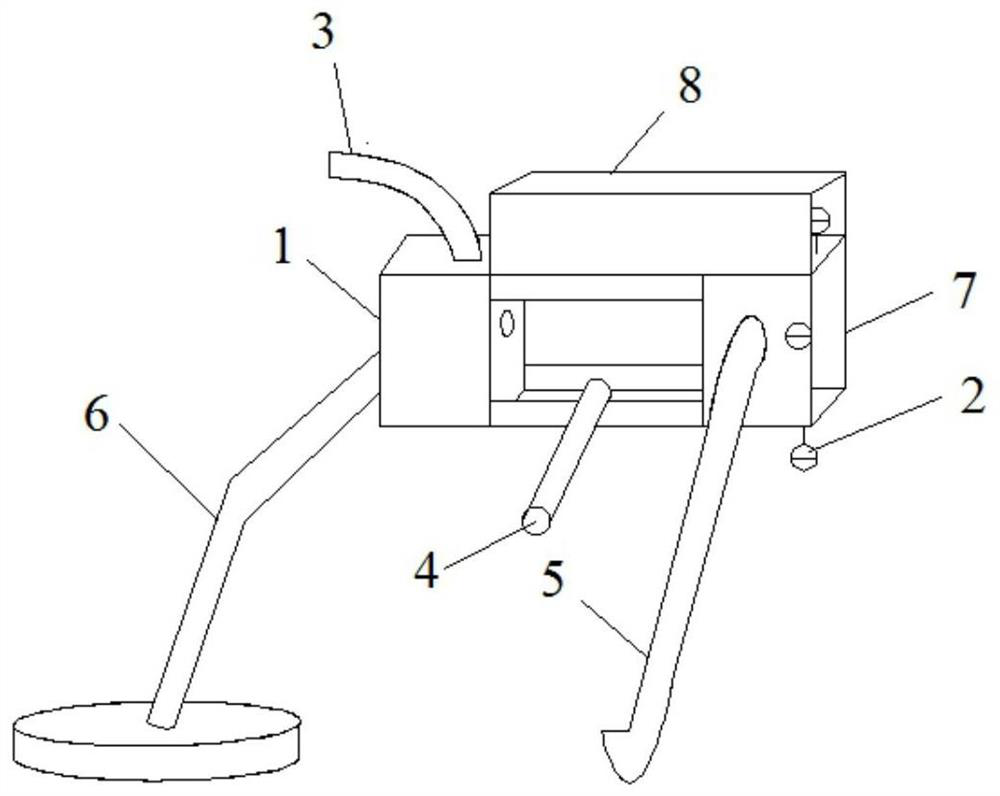

Mechanical arm posture self-adaptive adjusting method for laser paint removal

ActiveCN112916515ARealize position compensationGuaranteed parallelCleaning processes and apparatusLaser rangingRotational axis

The invention discloses a mechanical arm posture self-adaptive adjusting method for laser paint removal. The mechanical arm posture self-adaptive adjusting method comprises the steps that S1, the initial position and the working range of a mechanical arm are determined; a height parameter, an anti-shaking parameter and a mechanical arm rotating shaft angle offset threshold value of the mechanical arm are set; S2, according to the working range set in the step S1, the starting and stopping time of a laser signal is set, and when the laser signal is started, automatic paint removal is conducted through automatic laser emitting; and S3, in the paint removing process of the step S2, a controller of the mechanical arm calculates the offsets in the z-axis direction of the mechanical arm and the w-axis direction and the p-axis direction of the rotating shaft of the mechanical arm according to the real-time measurement information of each laser range finder, the height and width of a laser output device, the height parameter, the anti-shaking parameter and the angle offset threshold parameter, so that the mechanical arm automatically conducts offset compensation. The problem that according to an existing laser cleaning device, the laser output device cannot be automatically adjusted to be parallel to the surface of to-be-machined equipment, and the cleaning effect is affected is solved.

Owner:西安唐人电子科技有限公司

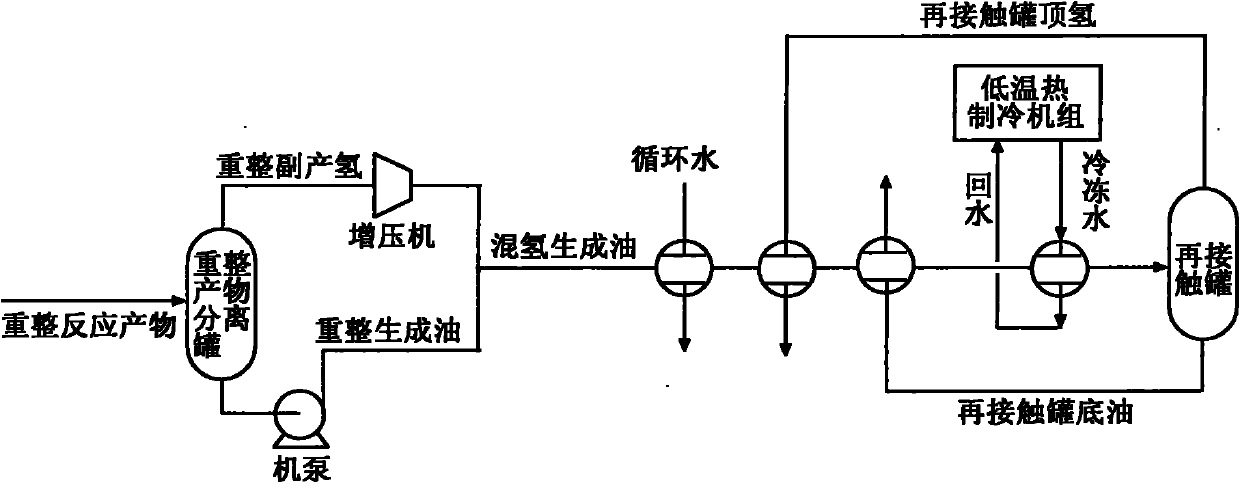

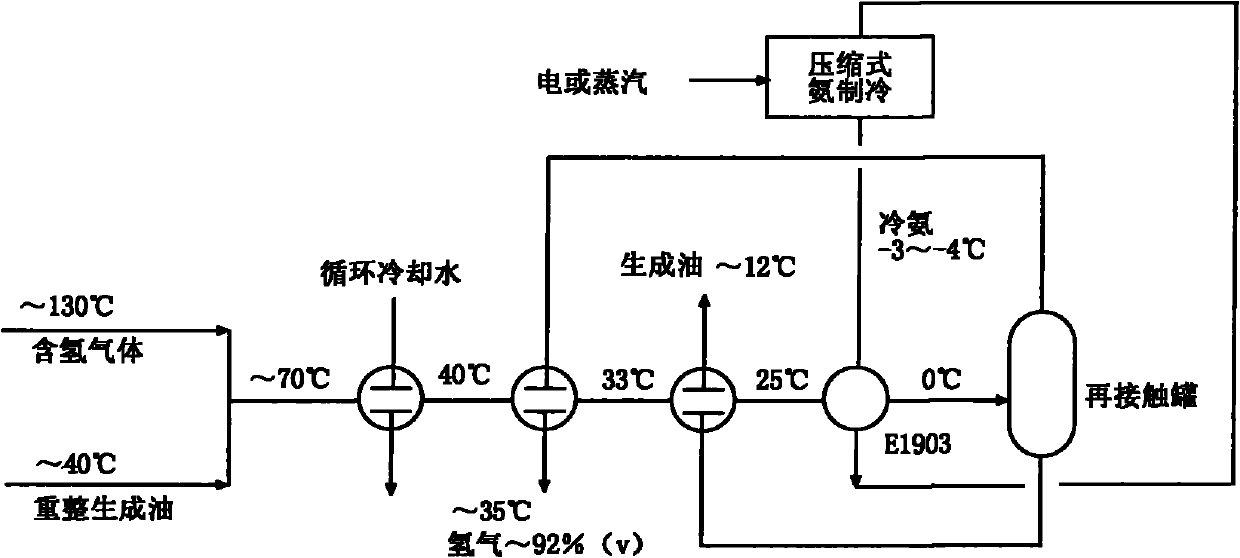

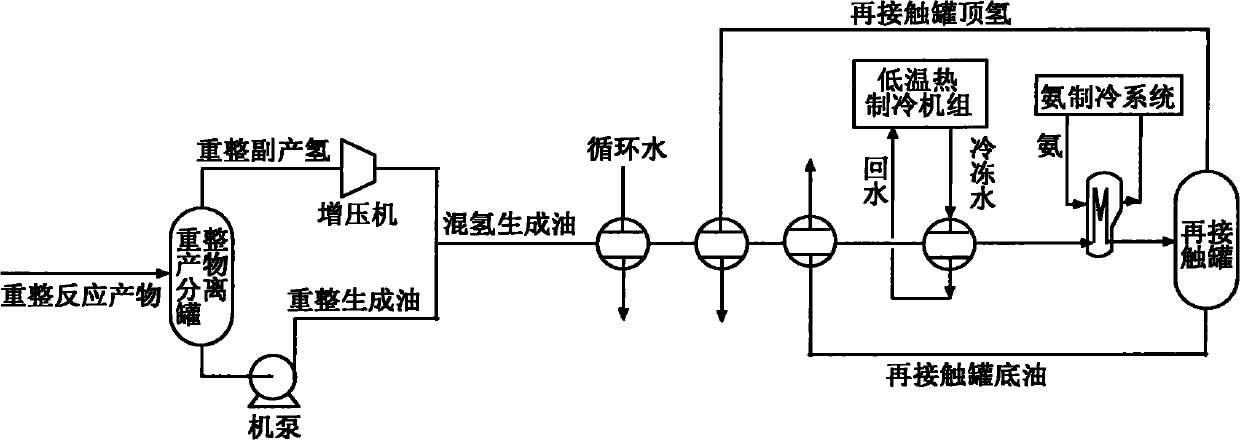

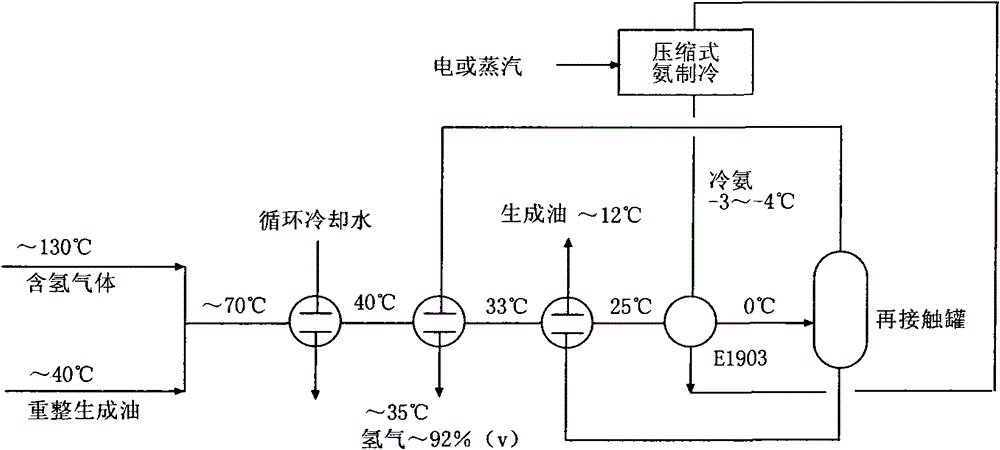

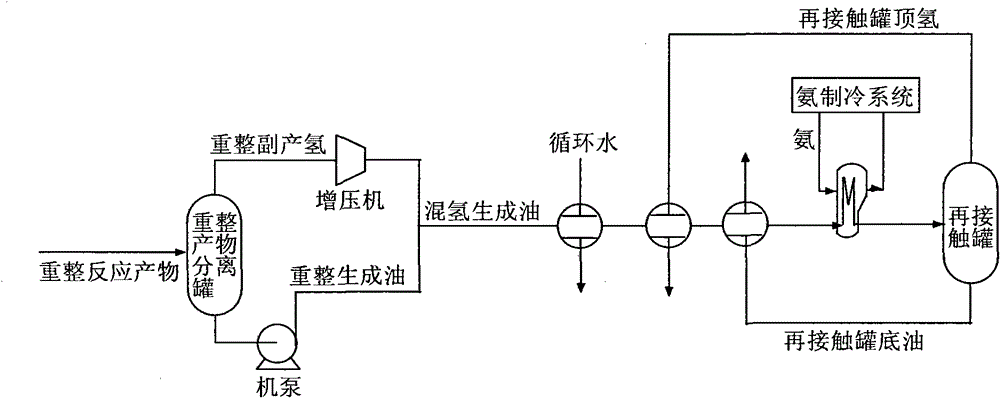

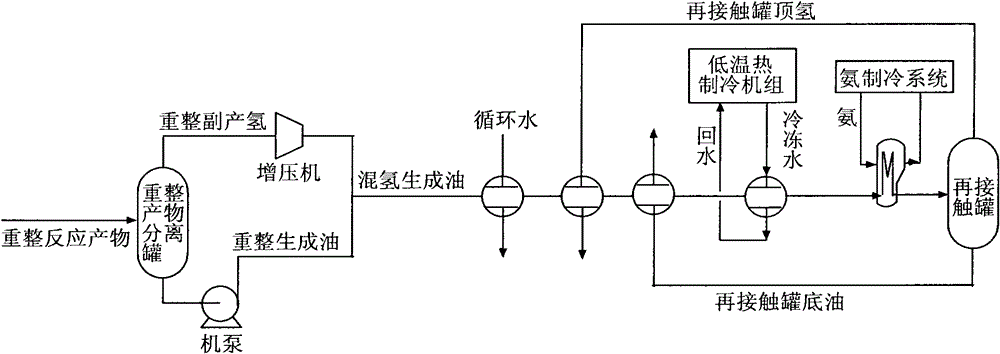

Method for reducing re-contact process energy consumption of catalytic reforming device

ActiveCN101818075AReduce electricity or steam consumptionReduce consumptionCatalytic naphtha reformingCatalytic reformingEconomic benefits

The invention discloses a method for reducing re-contact process energy consumption of a catalytic reforming device. The method comprises the following steps of: cooling hydrogen-mixing generated oil through circulating water heat exchange, re-contacting tank top hydrogen-containing gas heat exchange, re-contacting tank bottom oil heat exchange, chilled water heat exchange and ammonia-cooling heat exchange in turn, and then delivering the cooled hydrogen-mixing generated oil to a re-contact tank to perform gas-liquid balancing separation, wherein the chilled water of 5 to 10 DEG C is producedby delivering the hot water of 90 to 95 DEG C generated by low-temperature waste heat of a refinery to a refrigerating unit. The method can reduce the load of the ammonia-cooling hydrogen-mixing generated oil or cancel the ammonia-cooling hydrogen-mixing generated oil, and shut down an ammonia refrigerating system. The method can obviously reduce the energy consumption of a re-contact system of the catalytic reforming device, and meanwhile the concentration of the hydrogen concentrated by the re-contact system can meet the production requirement. Moreover, the increment of a low-temperature heat refrigerating system can find an ideal way for the utilization of low-temperature heat. In the whole process, the flow reformation is simple and feasible, and the economic benefit is obvious.

Owner:SOUTH CHINA UNIV OF TECH

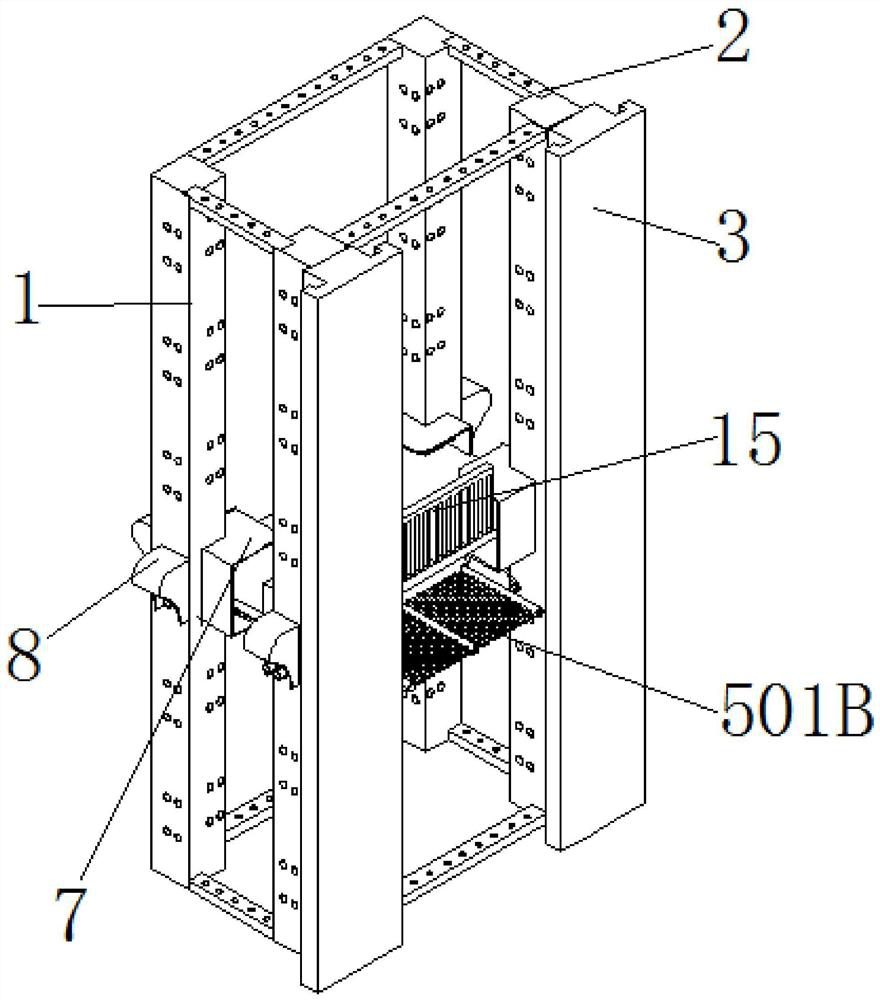

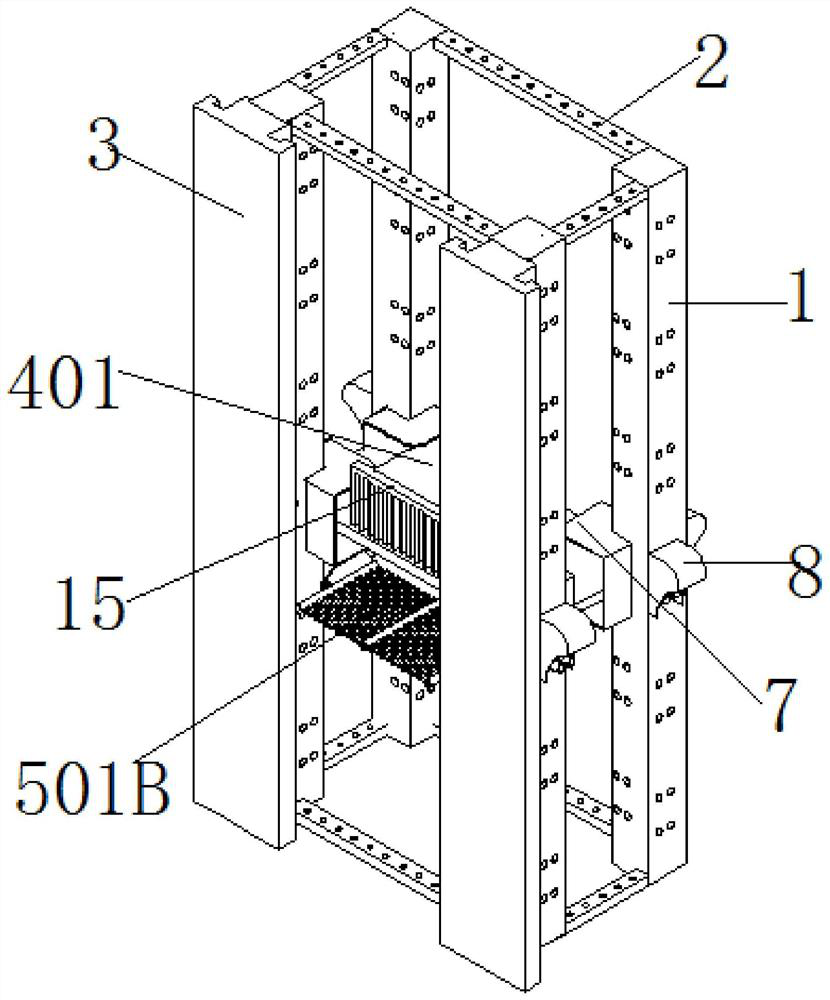

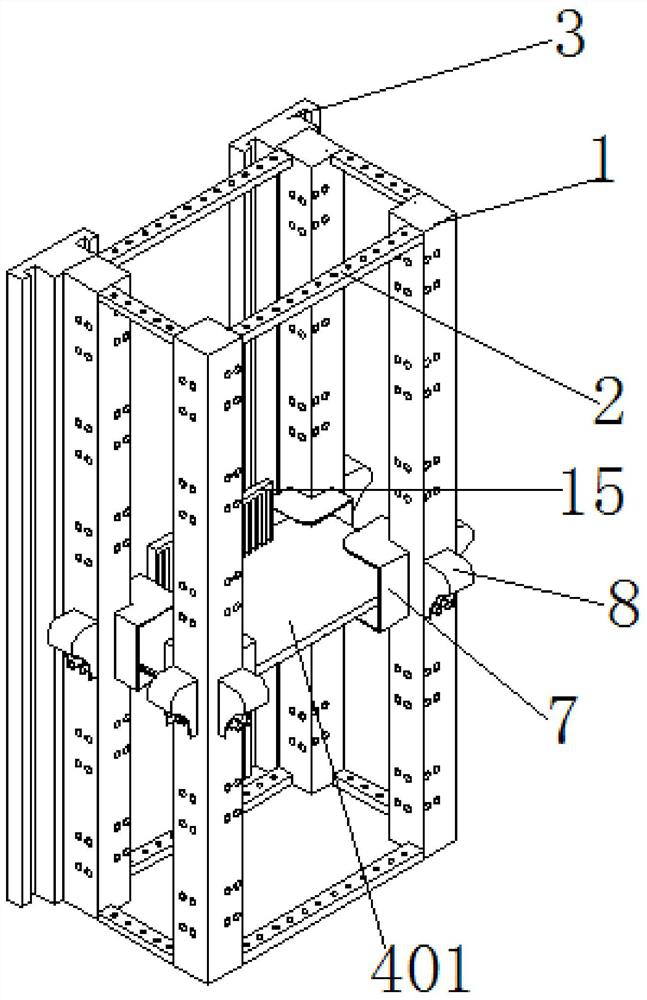

Convenient-to-adjust climbing frame for construction industry

ActiveCN112267661AImprove construction safetyAvoid smashingScaffold connectionsScaffold accessoriesFoot boardsMechanical engineering

The invention provides a convenient-to-adjust climbing frame for the construction industry, and belongs to the technical field of construction engineering. The convenient-to-adjust climbing frame comprises vertical beams, cross beams and guide rails, and further comprises a movable pedal assembly and a falling object bearing assembly, wherein the height of a pedal is flexibly adjusted among the multiple vertical beams, and thus the mounting height of the pedal is adjusted. By arranging a bearing net plate, fallen tools can be borne, the tools are prevented from injuring operators below, and the construction safety of the climbing frame is improved; the bearing net plate is rotatably connected with a fixing shaft and is borne by a movable hook, and thus the bearing net plate can be movablyconnected with the pedal; and the movable hook is detached from a bearing-supporting shaft, the bearing net plate and the movable hook freely droop under the action of gravity, and the bearing net plate and the movable hook are both located under the pedal so that the bearing net plate can be prevented from colliding with a protruding area on a wall in the lifting process of the climbing frame, and smooth climbing of the climbing frame is guaranteed.

Owner:厦门安科科技有限公司

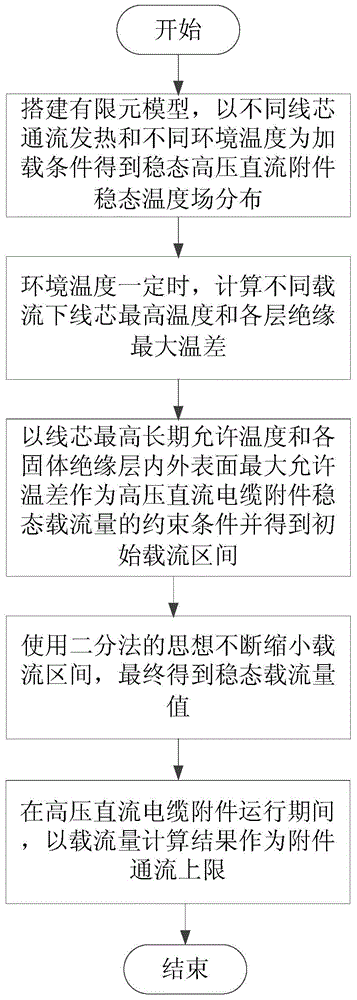

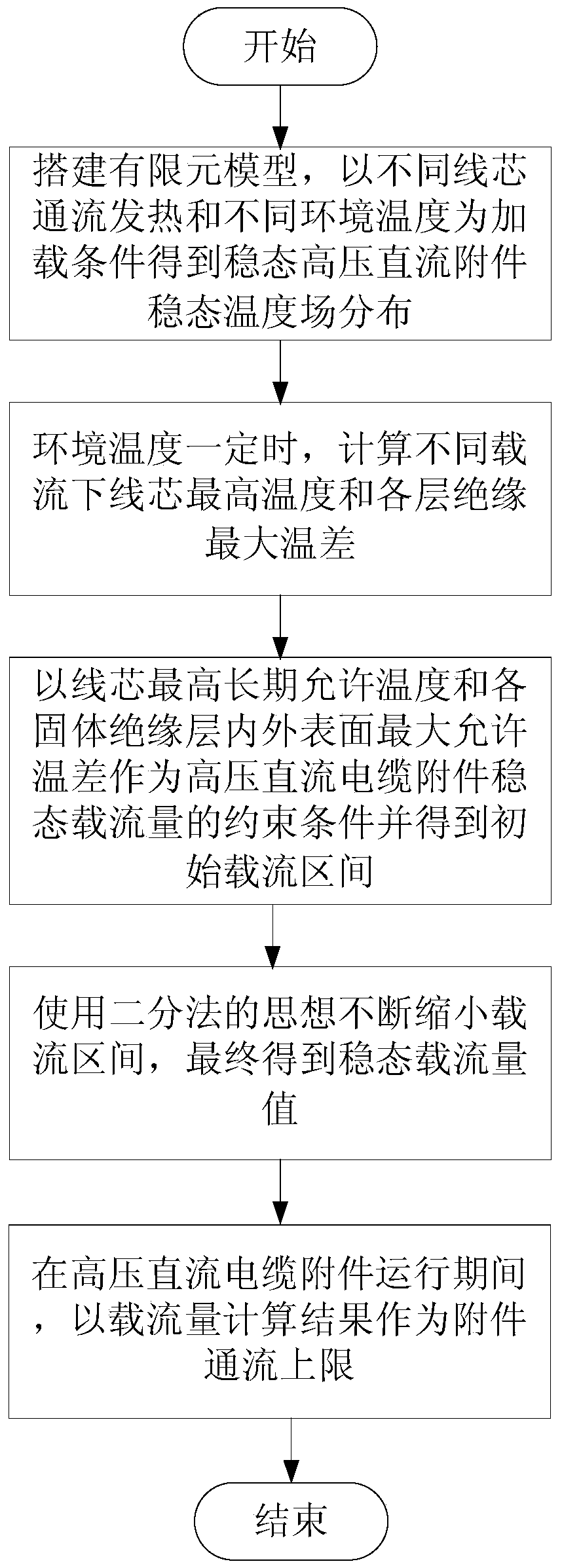

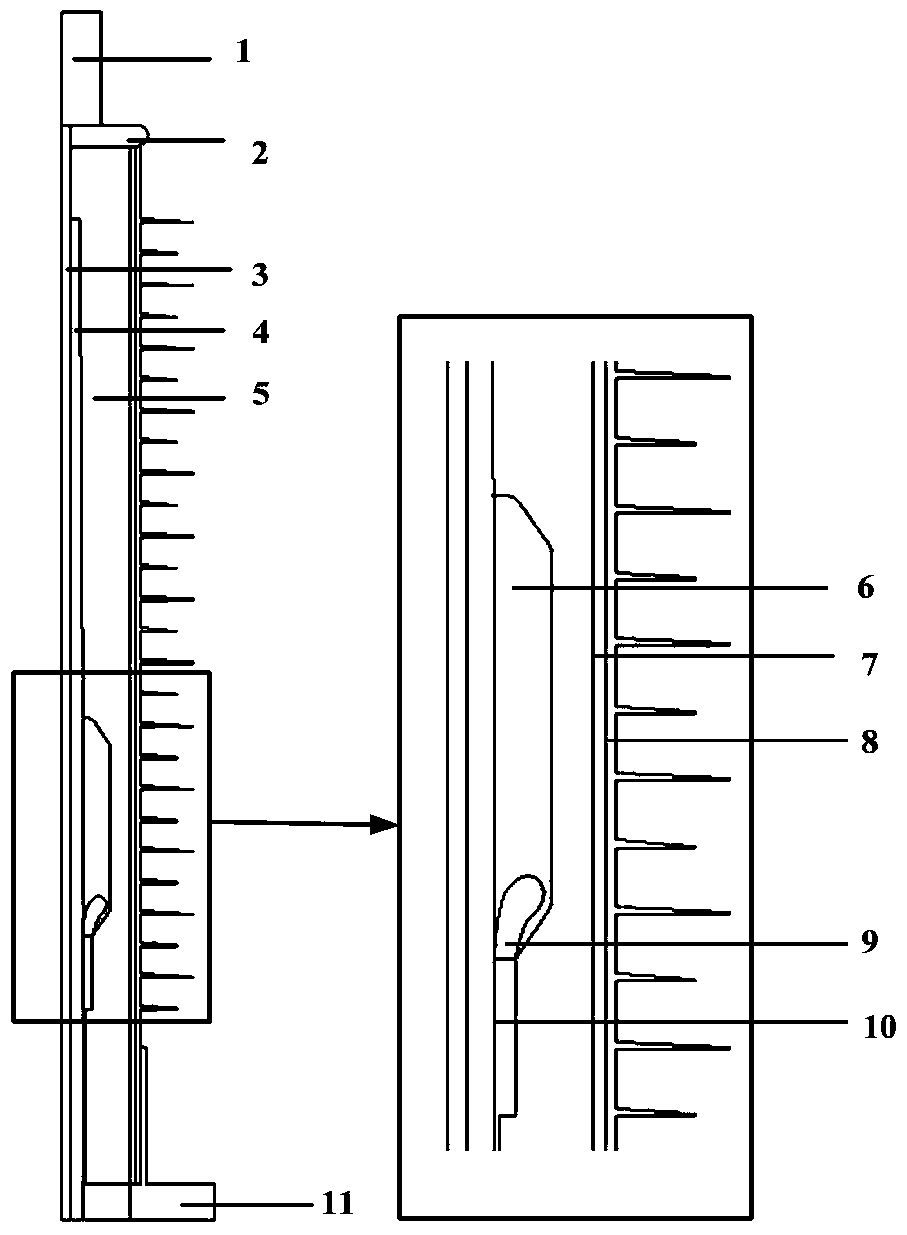

Method for determining through-flow upper limit of high-voltage direct-current plastic insulation cable accessory

ActiveCN105044489AMeet the requirements of insulation characteristicsMake full use of transmission capacityElectrical testingElement modelHigh-voltage direct current

The invention discloses a method for determining through-flow upper limit of high-voltage direct-current plastic insulation cable accessory. The method comprises following steps: building a finite element model; calculating the highest temperature of a wire core under different load currents and the maximal temperature difference allowed by the exterior surface inside each solid insulation layer; taking the highest long-term allowable temperature of the wire core and the maximum allowable temperature difference between inside and outside surfaces of each solid insulation layer as restricting conditions for the steady load flow of high voltage direct current cable attachment to get an initial current loading section; using the ideas of dichotomy to continuously narrow the current loading section and finally obtaining the steady load flow of high voltage direct current cable attachment. During the operation of high voltage direct current cable attachment, taking the calculated result of load carrying capacity as the through-flow upper limit of the attachment. In the invention, both the highest long-term allowable temperature of the wire core and the maximum allowable temperature difference between inside and outside surfaces of each solid insulation layer are taken as two restricting conditions, which meets the insulation characteristics of high voltage direct current cable attachment. With the method, it is possible to flexibly adjust the load carrying capacity of the attachment in accordance to exterior environment. The method makes full use of the transmission capacity of an electric cable line, therefore, increasing the utilization efficiency of an electric cable.

Owner:SOUTH CHINA UNIV OF TECH +1

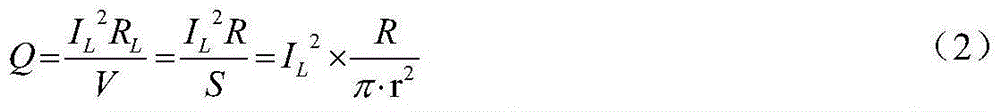

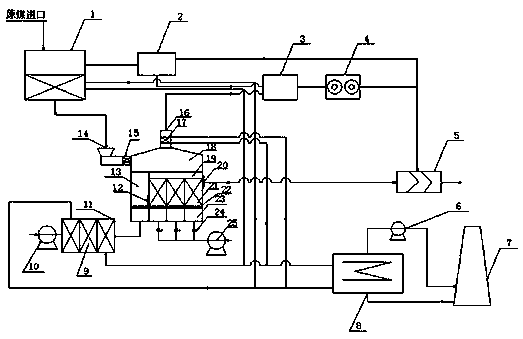

Clean and efficient gradient screening internal thermal fluidized bed coal moisture control process

InactiveCN105733635AWide adaptability to humidityReliable operation regulationCoke ovensScreening proceduresHeat carrier

The invention discloses a clean and efficient gradient screening internal thermal fluidized bed coal moisture control process.An internal thermal fluidized bed dryer serves as a main device; in the coal moisture control procedure, a coal particle diameter gradient screening procedure, a selective smashing procedure and a coal fly ash recovering and pelleting procedure are included; step-by-step screening of coal particle diameters is realized in the mode of mechanical screening through a low-temperature variable speed fluidized bed, orderly control over coal particle smashing and drying and coal dust is ensured, repeated processing of coal materials is reduced, and energy is reasonably input in the technological process.Air with strong moisture carrying capacity and high-temperature hot water with high thermal capacity are selected as a fluidizing medium and a heat transfer medium respectively according to the physical properties of the air and the high-temperature hot water.Compared with a traditional fluidized bed coal moisture control process, the functions of a heat carrier, a moisture carrier and the fluidizing medium in the coal moisture control process are separated, flexible control and precise processing can be achieved in terms of control and regulation, and the process is particularly suitable for moisture control over dryness of high-humidity coal materials.

Owner:WUXI YIEN TECH

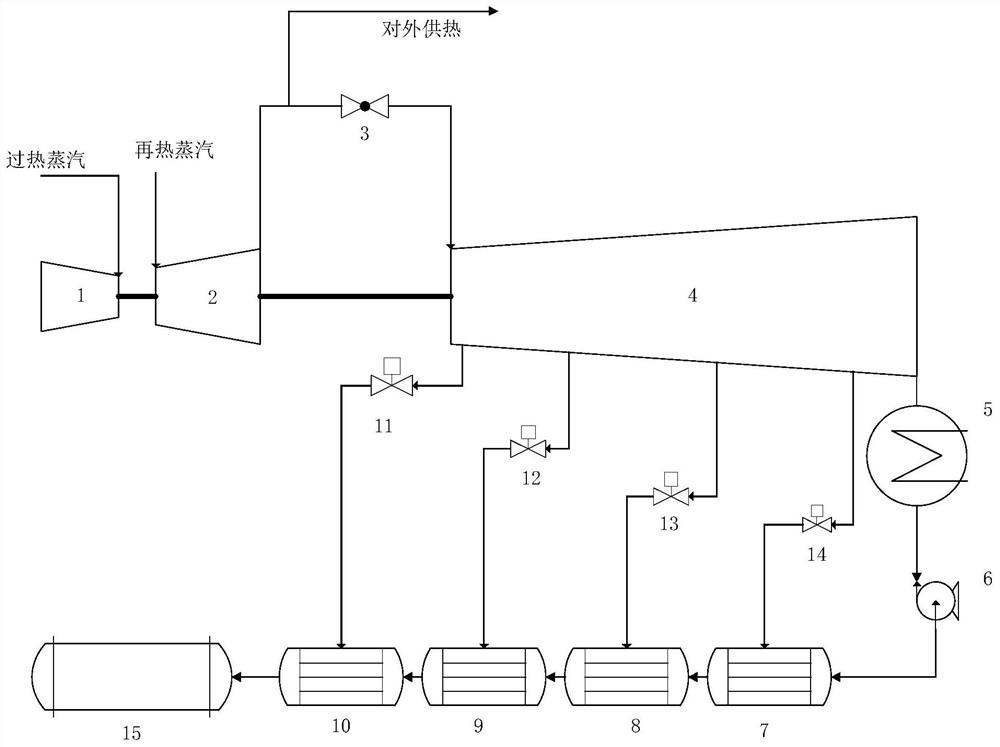

Comprehensive frequency modulation system and method for coupling heat supply and low-pressure steam extraction

InactiveCN113006891AImprove load responsivenessEasy to adjustLighting and heating apparatusSteam useProcess engineeringDeaerator

The invention discloses a comprehensive frequency modulation system and method for coupling heat supply and low-pressure steam extraction. The comprehensive frequency modulation system comprises a steam turbine high-pressure cylinder, a steam turbine medium-pressure cylinder and a steam turbine low-pressure cylinder; the steam inlet of the steam turbine high-pressure cylinder is boiler superheated steam; the steam inlet of the steam turbine medium-pressure cylinder is boiler reheated steam; the steam inlet of the steam turbine low-pressure cylinder is part of the steam exhaust of the steam turbine medium-pressure cylinder; and the steam exhaust of the steam turbine low-pressure cylinder enters a deaerator through a low-pressure heater set. According to the comprehensive frequency modulation system and method, the load response capacity of a heat supply unit can be greatly improved; a heat supply regulating valve is arranged on a heat supply steam extraction pipeline, and a low-pressure steam extraction regulating valve is arranged on each stage of low-pressure steam extraction pipeline; and during operation regulation, the heat supply regulating valve and the low-pressure steam extraction regulating valves are adopted to simultaneously regulate the amount of steam entering the low-pressure cylinder and the steam extraction amount of the low-pressure heater, and meanwhile, the method of changing the operation frequency of condensed water is adopted to realize rapid regulation of the flow of the condensed water so as to realize the rapid response function of the load.

Owner:XIAN THERMAL POWER RES INST CO LTD +1

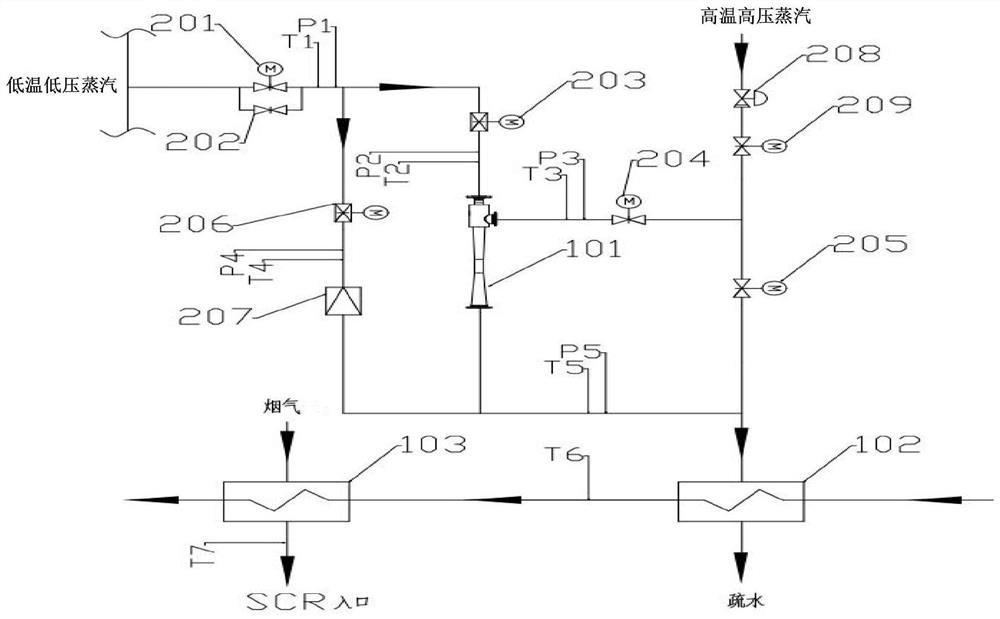

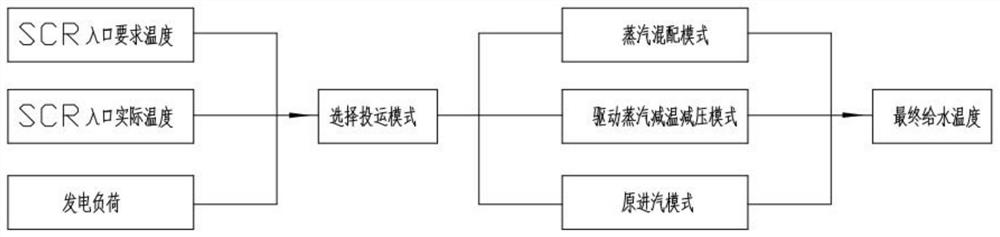

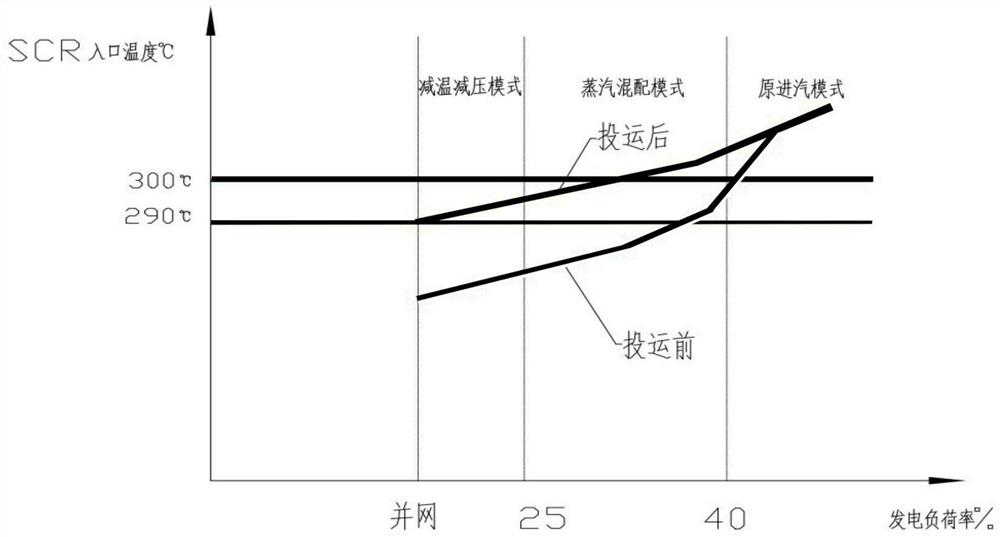

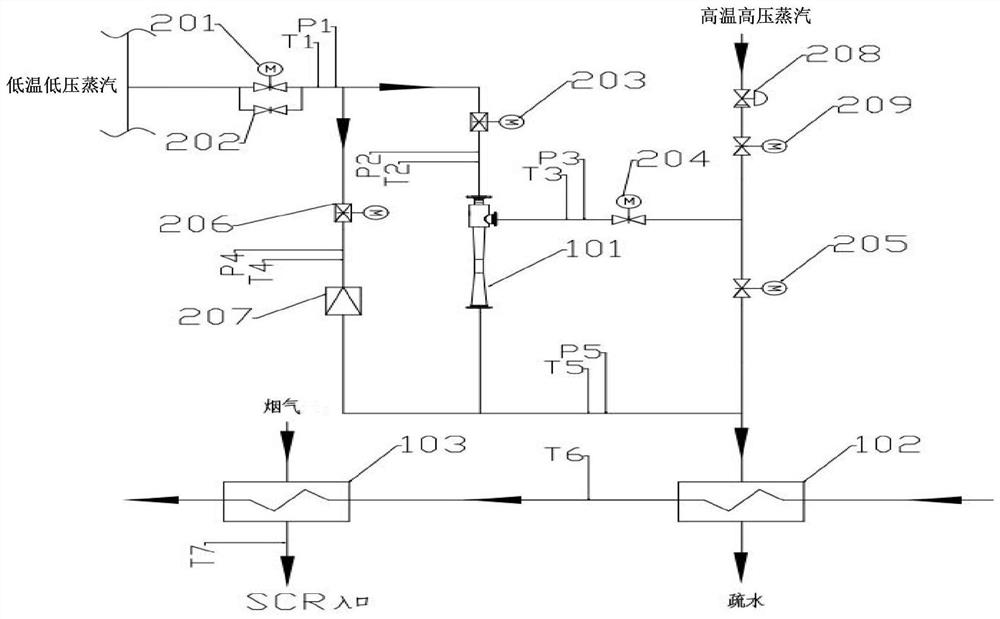

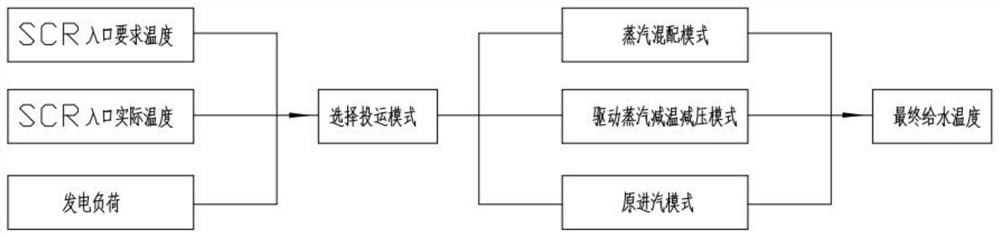

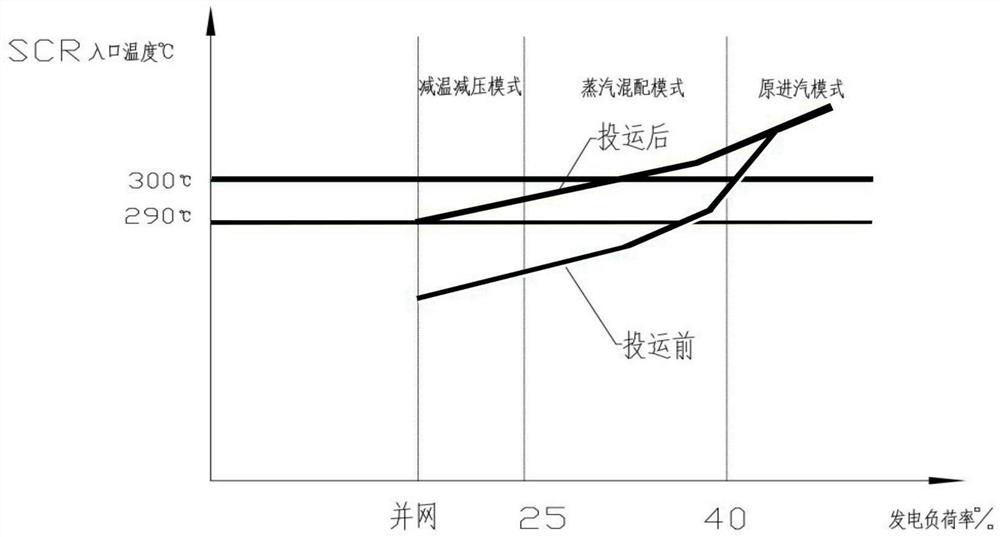

Steam mixing system for realizing denitration temperature rise and adjusting method of steam mixing system

ActiveCN113405086AReduce heat absorptionIncrease temperatureSuperheating controlEmission preventionThermodynamicsFlue gas

The invention discloses a steam mixing system for realizing denitration temperature rise and an adjusting method of the steam mixing system. The steam mixing system comprises a driving steam isolation unit, a steam mixing device, a high-pressure heater and an economizer which are sequentially connected through a steam pipeline, the steam pipeline is provided with a pressure and temperature detection device, an inlet of the steam pipeline is connected with a low-temperature and low-pressure steam pipeline, the high-pressure heater is connected with a high-temperature and high-pressure steam pipeline, an injection opening of the steam mixing device is connected with the high-temperature and high-pressure steam pipeline through a steam pipeline, the steam mixing device is connected with a driving steam adjusting unit in parallel, feed water passes through the high-pressure heater and then is heated by the economizer to flow out, and boiler flue gas passes through the economizer and then enters a denitration system (SCR). According to the system and the method, the peak regulation capacity and the unit operation flexibility of a thermal power enterprise unit are improved, denitration full-load section adjustment can be realized, the load change adaptability is high, and the system and the method are suitable for the technical field of flue gas denitration treatment.

Owner:北京天瑞泰达电力工程有限公司

A zero-discharge process and equipment for coking phenol cyanide wastewater treatment and reuse

ActiveCN104803548BOxygen works wellGuaranteed uptimeMultistage water/sewage treatmentSludgeHigh pressure

The invention discloses a treating and recycling zero-emission technology for coking phenol-cyanogen wastewater. According to the treating and recycling zero-emission technology, a pre-sedimentation oil separating tank, an air floating system, an adjusting aeration tank, an anaerobic tank, an anoxic tank, an aerobic tank, a secondary sedimentation tank, a coagulating reaction tank, a quick filtering tank, an ultrafiltration raw water tank, an ultrafiltration system, a nanofiltration system, a reverse osmosis system, a concentrated water aerobic tank, a concentrated water anoxic tank, an SBR tank, a chemical oxidation tank, a bitter water film concentrating system, a softening rigidity removing system, a low-pressure sea-water film system, a high-pressure sea-water film system, an MVR evaporating system, a sludge thickening tank, a press filter and a Roots blower are adopted for technological treatment. The invention further discloses treating and recycling zero-emission equipment for coking phenol-cyanogen wastewater. The treating and recycling zero-emission technology and equipment are high in treatment efficiency and low in cost, and have the advantages that zero emission of sewage can be realized.

Owner:ZHEJIANG BEROOT ENVIRONMENTAL PROTECTION TECH CO LTD

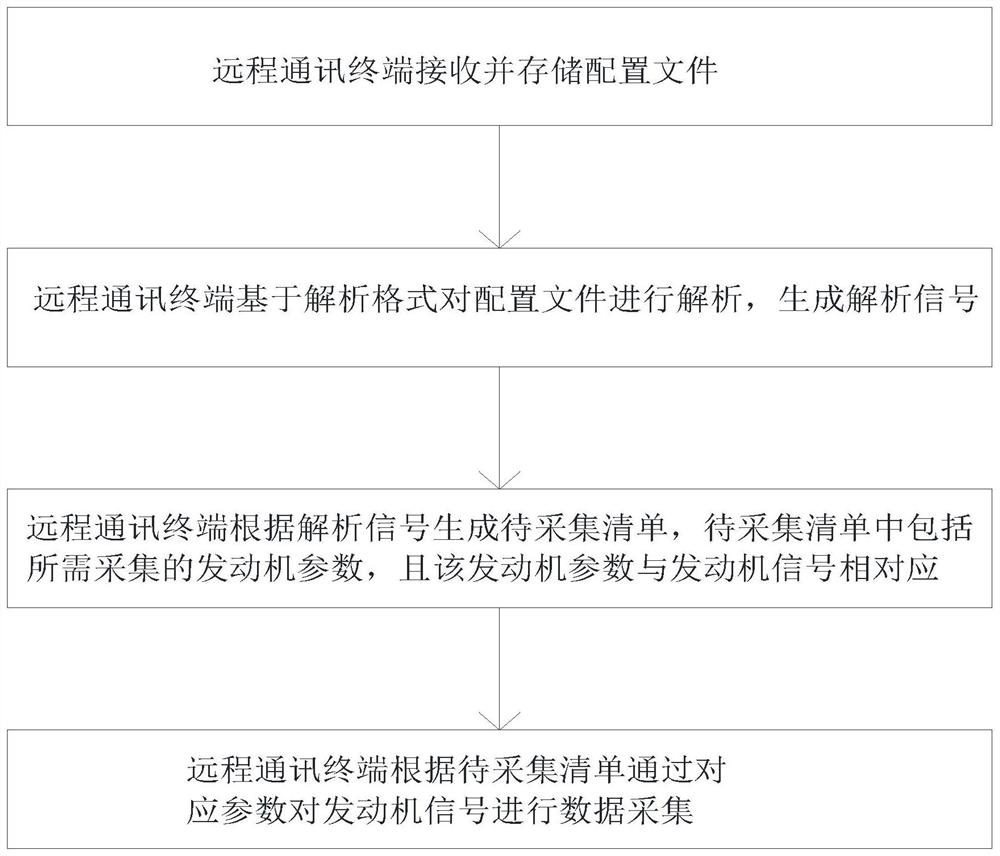

Remote communication terminal data acquisition method based on configuration file

PendingCN113709226AFlexible operation adjustmentFast iterationTelemetry/telecontrol selection arrangementsTransmissionData acquisitionAnalytic signal

The invention discloses a remote communication terminal data acquisition method based on a configuration file. The method comprises the following steps: 1, the configuration file is received and stored by a remote communication terminal; 2, the remote communication terminal analyzes the configuration file based on the analysis format to generate an analysis signal; 3, the remote communication terminal generates a to-be-collected list according to the analysis signal, the to-be-collected list comprises engine parameters needing to be collected, and the engine parameters correspond to the engine signals; and 4, the remote communication terminal carries out data acquisition on the engine through the corresponding engine parameters according to the list to be acquired. According to the invention, the configuration file is used as a target carrier of the engine signal, so that various engine signal acquisition under different protocols is compatible.

Owner:上海新动力汽车科技股份有限公司

Combined heat exchange system for solar and geothermal energy

ActiveCN103900287BTroubleshoot Thermal ImbalancesFlexible operation adjustmentHeat pumpsEnergy efficient heating/coolingEngineeringHeat pump

The invention discloses a heat exchange system in combined operation of solar energy and geothermal energy. The heat exchange system comprises a solar heat collector, a buried pipe heat exchanger, a heat pump unit, an absorbing type refrigerating unit, a user end, a plurality of hot water tanks, a plurality of water pumps, a plurality of connection pipes and a plurality of valves, wherein the solar heat collector is communicated with a first hot water tank, the first hot water tank is connected with a second water tank and an auxiliary heater via a second water pump so as to form a loop, the buried pipe heat exchanger is communicated with the heat pump unit, the heat pump unit is connected with the buried pipe heat exchanger and the first hot water tank via a third water pump so as to form a loop, the user end is connected with the heat pump unit and the absorbing type refrigerating unit via a fourth water pump so as to form a loop. The heat exchange system in combined operation of the solar energy and the geothermal energy has the advantages that unbalance problem of soil heat is effectively solved, cooling in summer, heating in winter and supplying of domestic hot water for all year around for buildings are achieved on the basis that the solar energy and the geothermal energy are utilized efficiently, and the heat exchange system is flexible to operate and adjust and diversified in functions.

Owner:SOUTHEAST UNIV

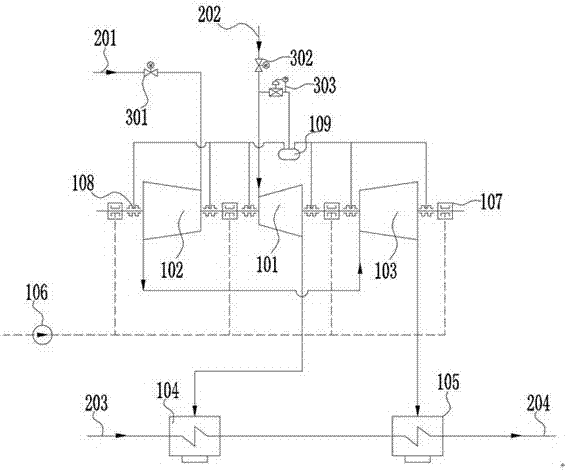

Device for coking coal stage drying step humidify regulating process

ActiveCN105647557AGuaranteed installation and maintenanceGuarantee normal productionDrying solid materials with heatCoke ovensAir preheaterProcess engineering

The invention discloses a device for a coking coal stage drying step humidify regulating process. The device comprises a first-stage humidify regulating process loop and a second-stage humidify regulating process loop, wherein the first-stage humidify regulating process loop comprises a first-stage fluidization air chamber (19), an air preheater (14) and a first fluidization fan (20), wherein no coiled pipe heating module is arranged in the first-stage fluidization air chamber (19), and a layer of bed materials with the thickness being 500 to 600mm is arranged at the bottom; the second-stage humidify regulating process loop comprises a second-stage fluidization air chamber (6) and a second fluidization fan (10); the second-stage fluidization air chamber (6) mainly consists of a plurality of humidify regulating modules; a coiled pipe heater is arranged in each humidify regulating module. The device has the advantages that the stage drying step humidify regulation is realized through two stages of humidify regulating process loops, so that the device has wide coal humidify applicability; the coal dust generation and elutriation can be orderly controlled; energy can be fed in a step way according to the technological process; the system operation regulation is reliable and flexible; the energy saving performance is high.

Owner:WUXI YIEN TECH

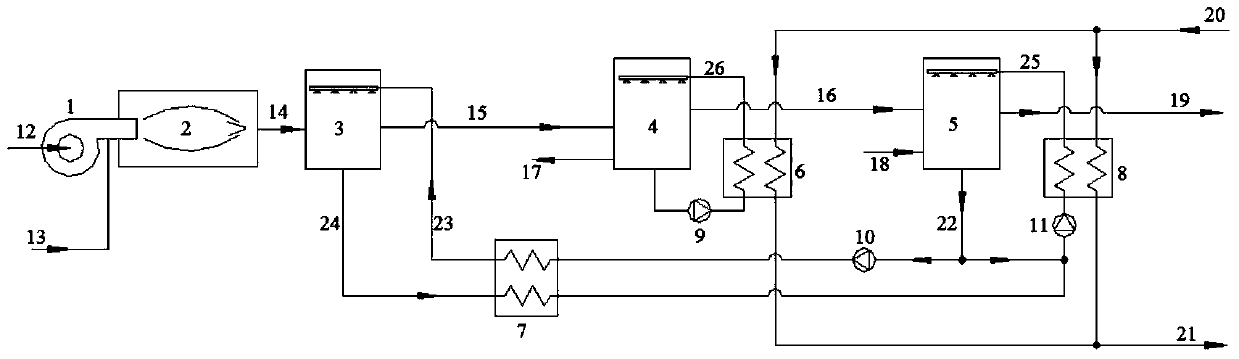

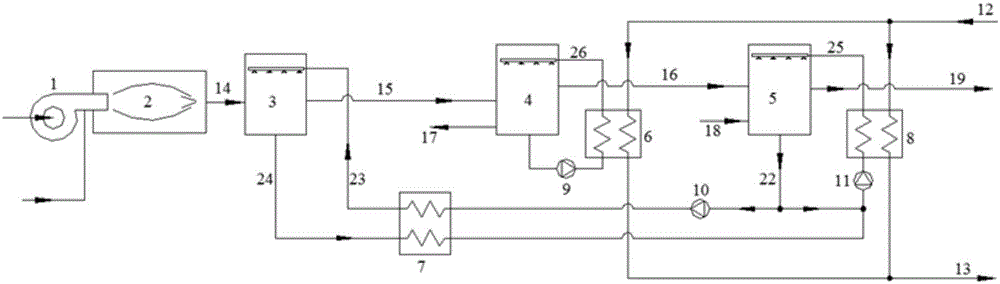

Britten combined cycle power generation device with solar energy heating

ActiveCN104847499AFlexible operation adjustmentReduce water consumptionFrom solar energyGas turbine plantsProcess engineeringThermal energy

The invention relates to a Britten combined cycle power generation device with solar energy heating. The device adopts an operation method in which top Britten cycle and bottom Britten cycle are combined; the flue gas of relatively high temperature exhausted from the gas turbine in the top Britten cycle is used as the heat source of the bottom Britten cycle; the bottom cycle adopts air as the working medium for recycling the waste heat of the high-temperature flue gas exhausted from the gas turbine; the working medium is then heated through the cavity type receiver of a solar energy heat gathering device and used for bottom Britten cycle power generation. According to the device, the thermal energy generated from fuel combustion is reasonably utilized; meanwhile, the heat of the solar energy is effectively utilized and the purposes of saving energy and reducing energy consumption are realized and the device is particularly suitable for drought areas to use.

Owner:STATE GRID CORP OF CHINA +3

Method for reducing re-contact process energy consumption of catalytic reforming device

ActiveCN101818075BReduce electricity or steam consumptionReduce consumptionCatalytic naphtha reformingCatalytic reformingEconomic benefits

The invention discloses a method for reducing re-contact process energy consumption of a catalytic reforming device. The method comprises the following steps of: cooling hydrogen-mixing generated oil through circulating water heat exchange, re-contacting tank top hydrogen-containing gas heat exchange, re-contacting tank bottom oil heat exchange, chilled water heat exchange and ammonia-cooling heat exchange in turn, and then delivering the cooled hydrogen-mixing generated oil to a re-contact tank to perform gas-liquid balancing separation, wherein the chilled water of 5 to 10 DEG C is producedby delivering the hot water of 90 to 95 DEG C generated by low-temperature waste heat of a refinery to a refrigerating unit. The method can reduce the load of the ammonia-cooling hydrogen-mixing generated oil or cancel the ammonia-cooling hydrogen-mixing generated oil, and shut down an ammonia refrigerating system. The method can obviously reduce the energy consumption of a re-contact system of the catalytic reforming device, and meanwhile the concentration of the hydrogen concentrated by the re-contact system can meet the production requirement. Moreover, the increment of a low-temperature heat refrigerating system can find an ideal way for the utilization of low-temperature heat. In the whole process, the flow reformation is simple and feasible, and the economic benefit is obvious.

Owner:SOUTH CHINA UNIV OF TECH

Clean and efficient cascade screening coal humidity control process with built-in thermal fluidized bed

InactiveCN105733635BWide adaptability to humidityReliable operation regulationCoke ovensHeat carrierHigh humidity

The invention discloses a clean and efficient gradient screening internal thermal fluidized bed coal moisture control process.An internal thermal fluidized bed dryer serves as a main device; in the coal moisture control procedure, a coal particle diameter gradient screening procedure, a selective smashing procedure and a coal fly ash recovering and pelleting procedure are included; step-by-step screening of coal particle diameters is realized in the mode of mechanical screening through a low-temperature variable speed fluidized bed, orderly control over coal particle smashing and drying and coal dust is ensured, repeated processing of coal materials is reduced, and energy is reasonably input in the technological process.Air with strong moisture carrying capacity and high-temperature hot water with high thermal capacity are selected as a fluidizing medium and a heat transfer medium respectively according to the physical properties of the air and the high-temperature hot water.Compared with a traditional fluidized bed coal moisture control process, the functions of a heat carrier, a moisture carrier and the fluidizing medium in the coal moisture control process are separated, flexible control and precise processing can be achieved in terms of control and regulation, and the process is particularly suitable for moisture control over dryness of high-humidity coal materials.

Owner:WUXI YIEN TECH

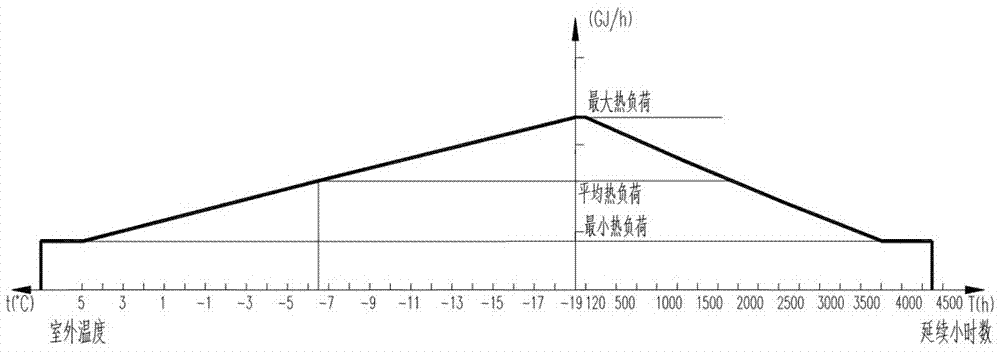

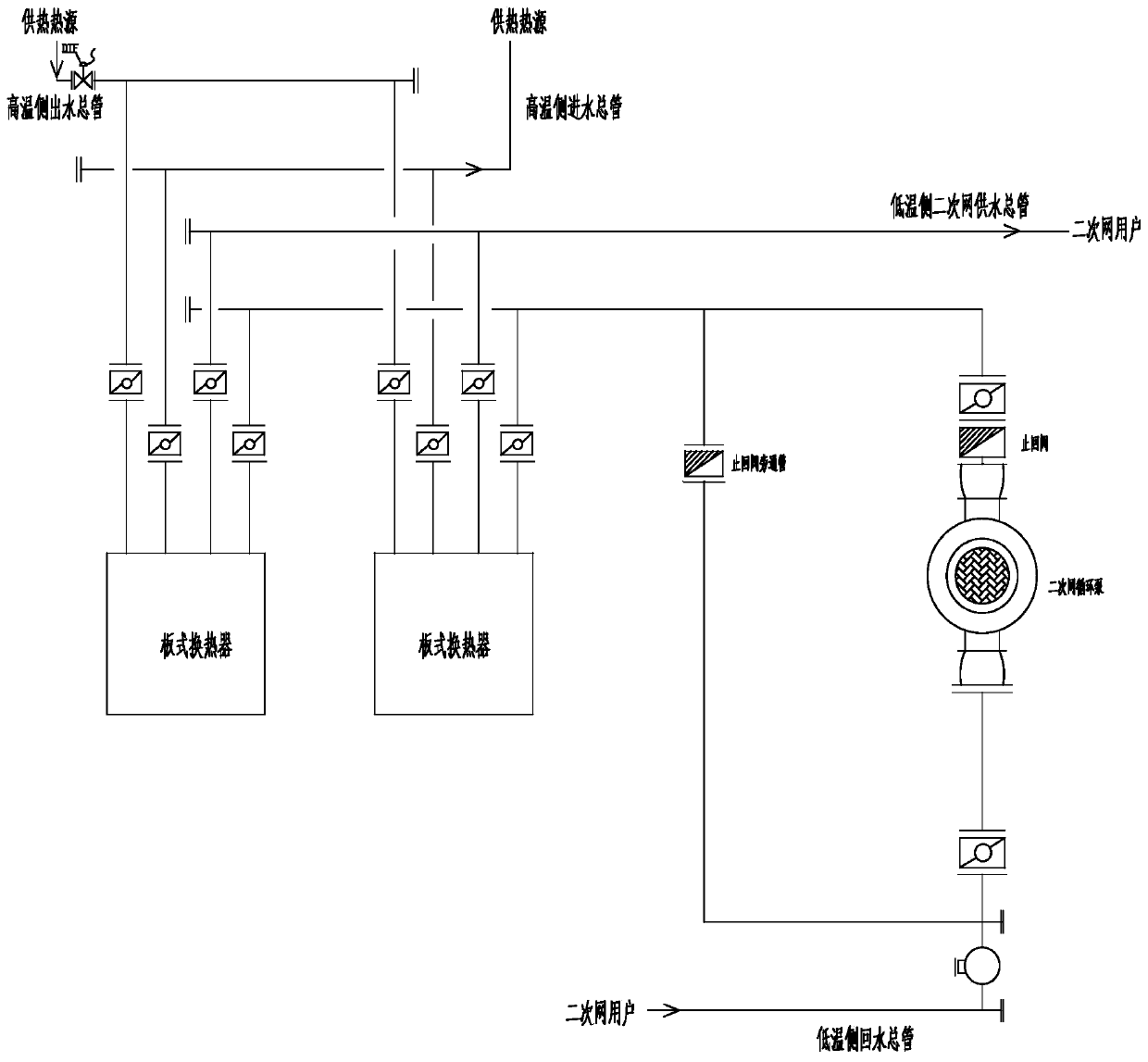

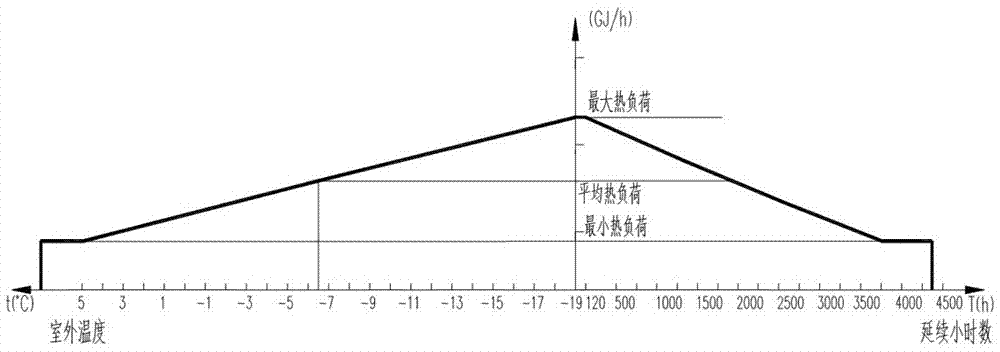

Heat supply unit energy-saving retrofit system and energy-saving operation control method thereof

PendingCN111380100AFlexible operation adjustmentReduce operating energy consumptionLighting and heating apparatusSpace heating and ventilation detailsCirculator pumpProcess engineering

The invention discloses a heat supply unit energy-saving retrofit system and an energy-saving operation control method thereof. The heat supply unit energy-saving retrofit system includes a high temperature side water inlet main pipe, a high temperature side water outlet main pipe, a low temperature side water outlet main pipe, a low temperature side water inlet main pipe, a secondary network circulating pump, a heat exchange circulating pump, a secondary network backwater main pipe, a secondary network water supply main pipe, a heat exchange module, a low temperature side water outlet bypasspipe which communicates a low temperature side water outlet of the heat exchange module with a water suction port of the secondary network circulating pump, a low temperature side water inlet and outlet water bypass pipe which communicates a water outlet of the secondary network circulating pump with the low temperature side water outlet main pipe and a shutoff valve arranged on a corresponding pipeline. According to the heat supply unit energy-saving retrofit system and the energy-saving operation control method thereof, on the basis of a traditional typical central heat supply unit, a new heat supply system structure and an operation mode are formed by retaining the secondary network circulating pump, increasing the heat exchange circulating pump and associated pipelines and valves thereof, and removing a check valve on the water outlet side of a check bypass pipe and the secondary network circulating pump, the operation and regulation are more flexible, and the operation energy consumption is significantly reduced.

Owner:内蒙古思铂睿特节能科技有限公司 +1

A steam mixing system for realizing denitration and warming and its adjustment method

ActiveCN113405086BReduce heat absorptionIncrease temperatureSuperheating controlEmission preventionThermodynamicsFlue gas

The invention discloses a steam mixing system for realizing denitrification and temperature raising and its adjustment method, which comprises a driving steam isolation unit, a steam mixing device, a high-pressure heater and an economizer sequentially connected through a steam pipeline. The road is equipped with a pressure and temperature detection device. The inlet of the steam pipeline is connected to a low-temperature and low-pressure steam pipeline. The high-pressure heater is connected to a high-temperature and high-pressure steam pipeline. The mixing device is connected in parallel with a driving steam regulating unit. The feed water passes through the high-pressure heater and flows out after being heated by the economizer. The boiler flue gas enters the denitrification system (SCR) denitrification system after passing through the economizer. And unit operation flexibility, can realize denitrification full load section adjustment, strong ability to adapt to load changes, suitable for flue gas denitrification treatment technology field.

Owner:北京天瑞泰达电力工程有限公司

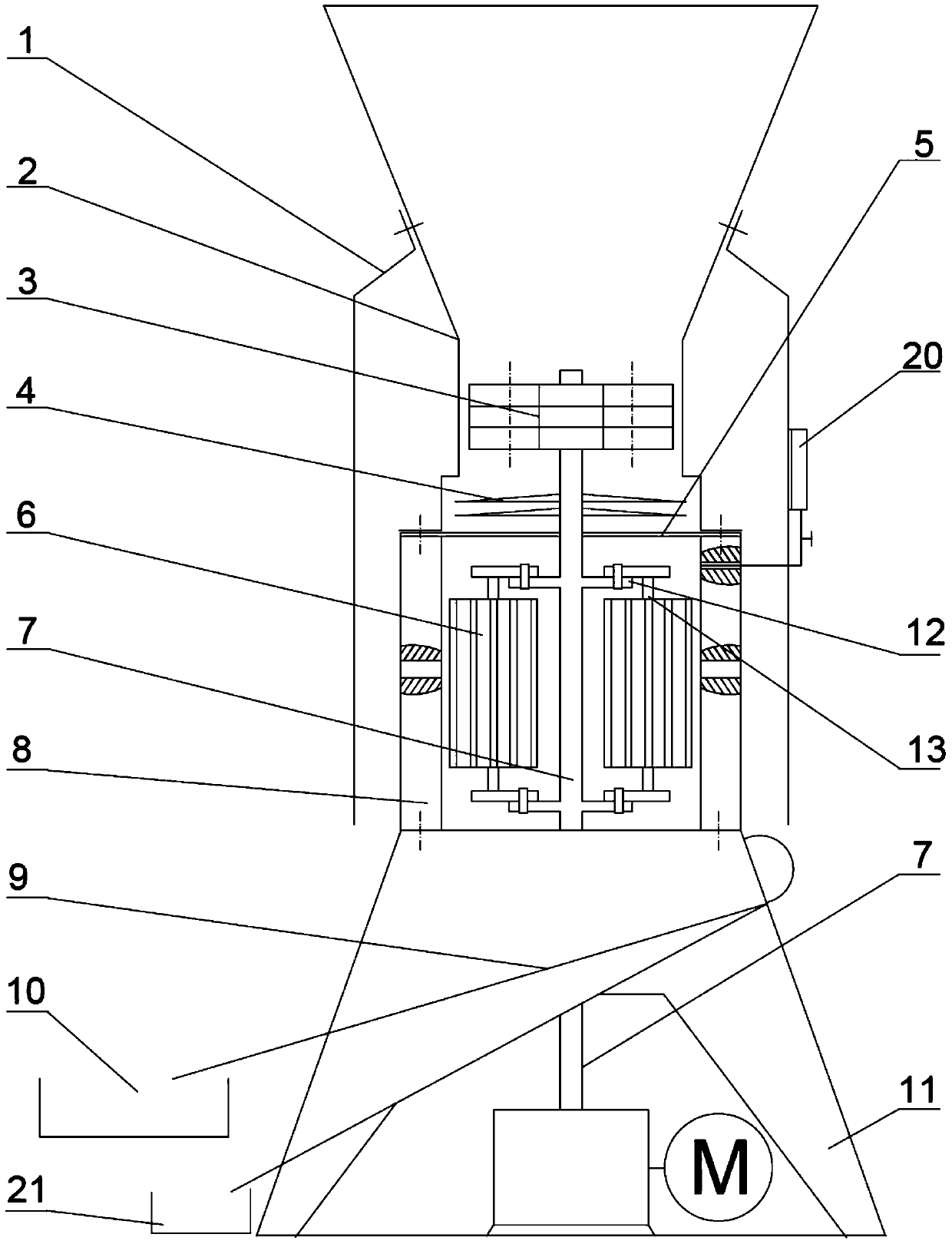

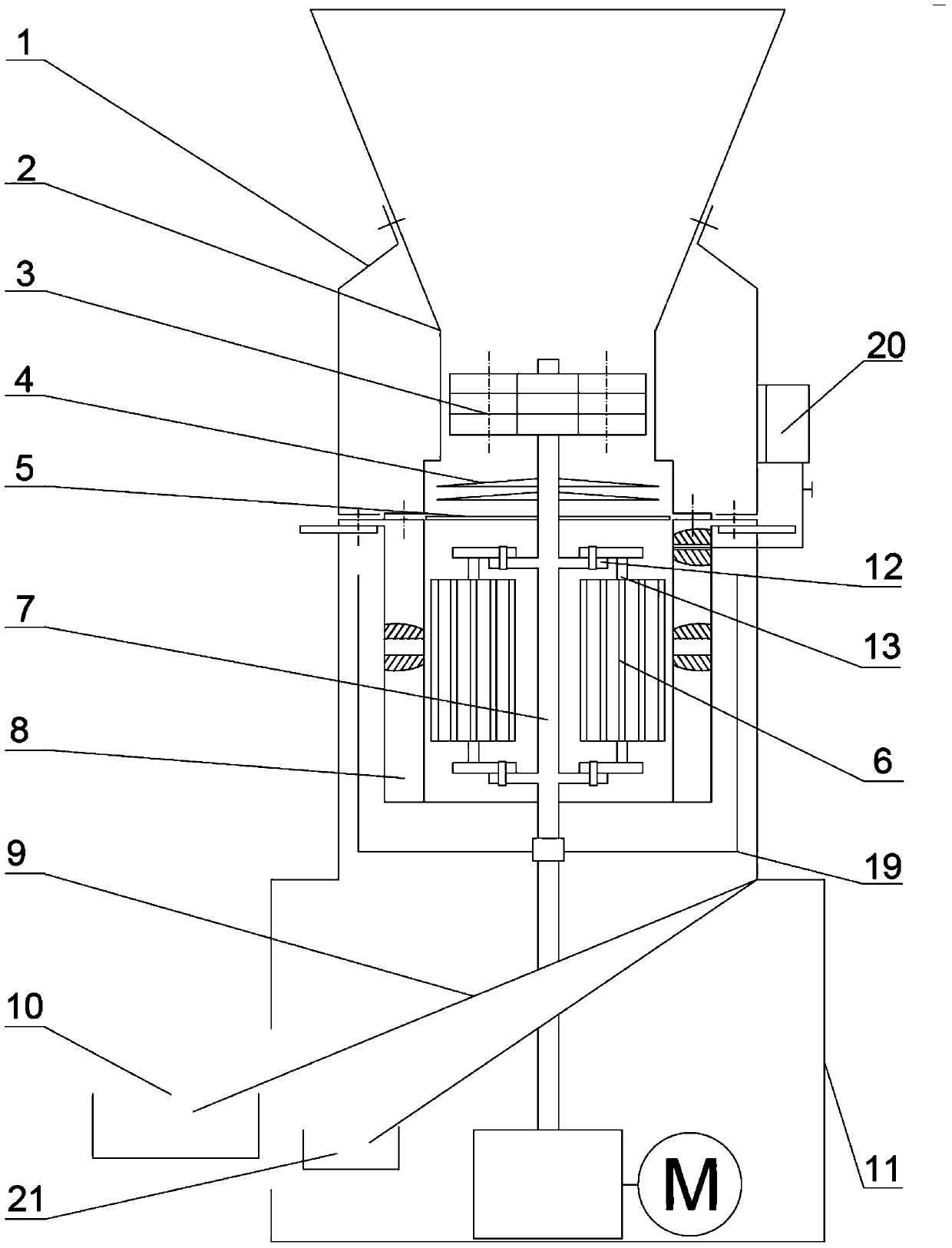

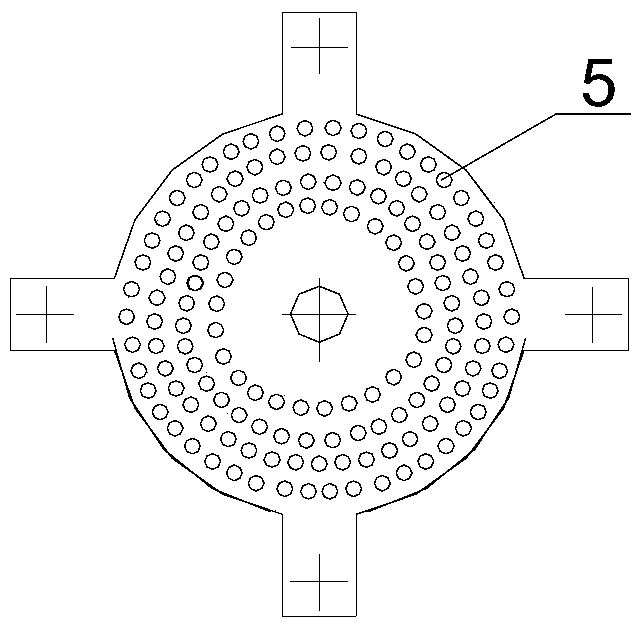

A vertical coaxial biomass crushing and forming integrated device

ActiveCN105413585BLower requirementImprove preprocessing efficiencyBiofuelsSolid fuelsFuel gasificationVolumetric Mass Density

The invention relates to a vertical coaxial biomass crushing and molding integrated device, which includes a biomass feeding hopper, a crushing unit, a molding rotor system, a molding ring mold, a molding particle cooler, a powder collecting plate, a molding particle collector, a powder Collector and unit base. The interaction of crushing equipment and rotors and ring molds is used for biomass processing and molding, effectively combining crushing and molding units to reduce the requirements for biomass raw materials, greatly improving the bulk density and energy density of biomass, and improving the system. Efficiency, stability and reliability, reducing floor space and reducing investment costs; using the heat generated by the mechanical friction of the crushing and forming device and the moisture in the biomass to promote the formation of biomass and improve the mechanical strength of the formed particles and durability; suitable for a wide range of raw materials, shaped particles can be directly used for combustion gasification, or mixed with coal combustion gasification, can be stored for a long time, suitable for industrial and civil fields.

Owner:代建军 +1

Adjustment method of steam compressor in thermal power unit steam turbine waste steam stripping heat application system

ActiveCN106930792BOperation impactImprove thermal efficiencyLighting and heating apparatusSteam regenerationElectricityPipe fitting

The invention provides a configuration and adjusting method of a steam compressor in an application system of upgrading and heat supplying of exhausted steam of a thermal power generating unit steam turbine. The system comprises a steam compressor driving small steam turbine, two levels of steam compressors, two levels of thermal-system heaters, a lubricating oil system, a gland seal system, valves and pipe fittings, wherein the valves and the pipe fittings are used for connecting the steam compressor driving small steam turbine, the two levels of steam compressors, the two levels of thermal-system heaters, the lubricating oil system and the gland seal system. By adoption of the system, low-pressure and low-temperature exhausted steam of the steam turbine is compressed through the steam compressor by using little driving steam, the pressure and the temperature of the steam are increased so that the steam can serve as a heat source to heat heat-supply network circulating water for heat supply, and therefore, the purpose that the exhausted steam of the steam turbine is used is achieved. According to the changing characteristics of the heat supply quantity and the water supply parameters, and the steam compressor efficiency operating characteristics, the adjusting method is used for adjusting the rotary speed of the small steam turbine and the opening of an inlet baffle of the steam compressor to achieve adjustment of the compressed steam flow quantity and the outlet pressure. By adoption of the technology, adaptability to the heat supply condition is wide, and heat utilizing efficiency is high. Heat supply efficiency is not influenced by the generating unit electrical load and heat load.

Owner:北京源深能源科技有限责任公司

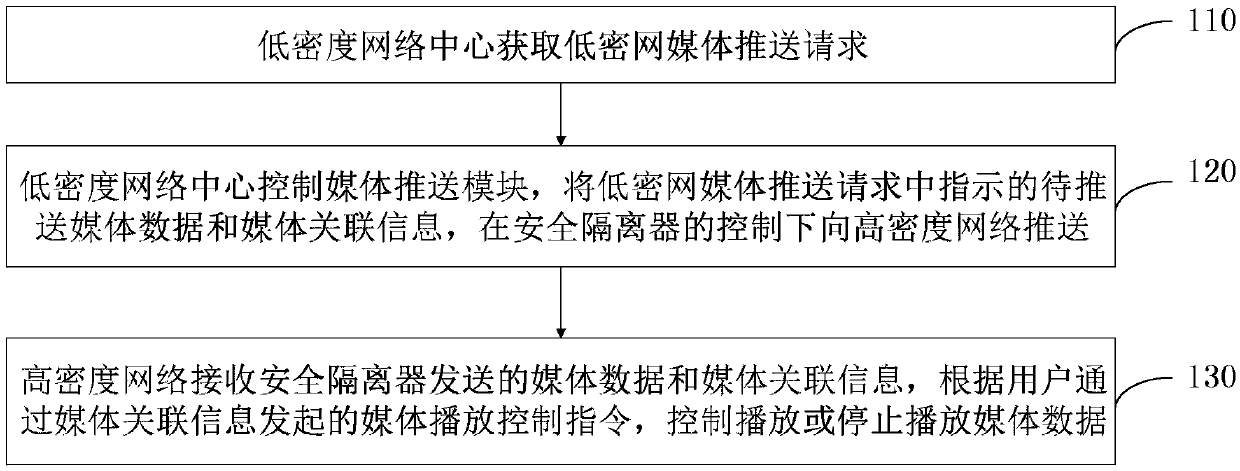

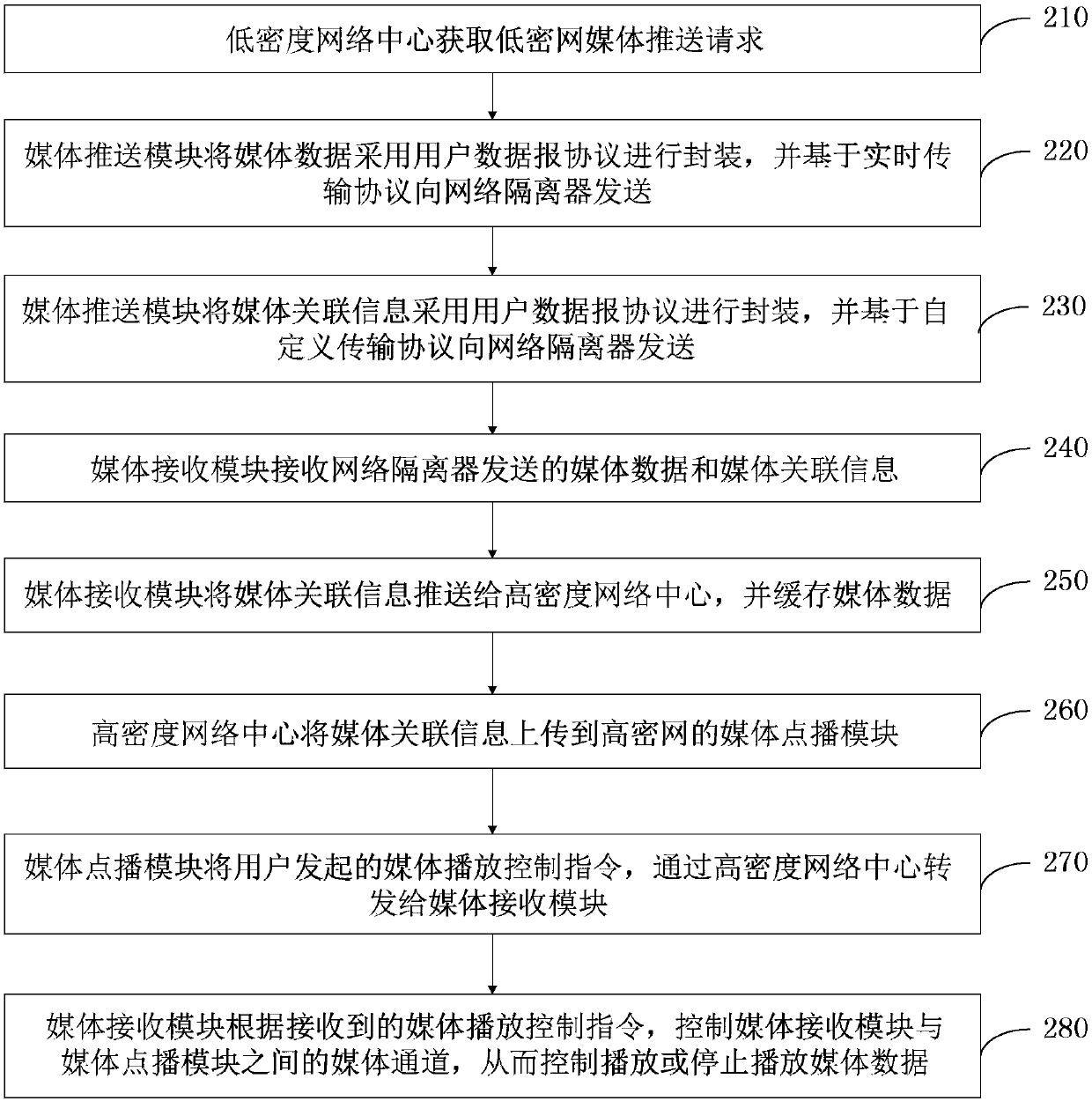

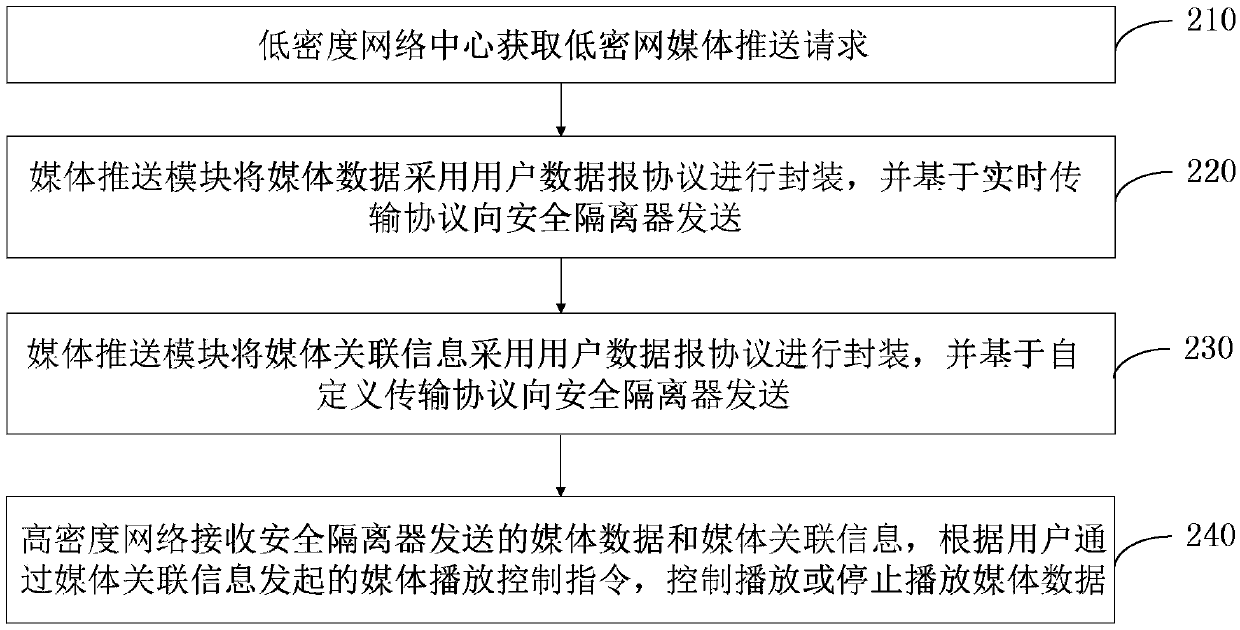

Media transmission method and system between high and low density networks

ActiveCN109660829AReduce transport limitationsHigh expansion costSelective content distributionHigh densityComputer module

The embodiment of the invention discloses a media transmission method and system between high and low density networks. The method comprises the following steps: a low density network center obtains amedia push request; the low density network center controls a media push module to push to-be-pushed media data and media association information indicated in a low density network media push requestto a high density network under the control of a security isolator; and the high density network receives the media data and the media association information sent by the security isolator, and controls to play or stop playing the media data according to a media playing control instruction initiated by a user through the media association information. By adoption of the technical scheme of the embodiment of the invention, the limitation of media stream transmission between the high and low density networks can be reduced.

Owner:KYLAND TECH CO LTD +1

A flue gas waste heat recovery device

ActiveCN104180523BIncrease discharge temperatureReduce consumptionStorage heatersAir heatersWaste heat recovery unitPlate heat exchanger

The invention relates to a flue gas waste heat recovery unit which comprises a flue gas unit, a generator unit, a condenser unit, an absorber unit, a water return pipe and a water supply pipe. The flue gas unit is sequentially connected with the generator unit, the condenser unit and the absorber unit to form a flue gas heat exchanging path; the outlet of the generator unit is connected with the inlet of a solution-to-solution heat exchanger, the outlet of the absorber unit is divided into two paths: one path is merged with the outlet of the solution-to-solution heat exchanger to be connected with the inlet of a solution-to-water heat exchanger through a solution spray pump, the outlet of the solution-to-water heat exchanger is connected with a solution spray mechanism in the absorber unit, the other path is connected with the inlet of a solution-to-solution heat exchanger through a solution circulating pump, and the outlet of the solution-to-solution heat exchanger is connected with a dilute solution spray mechanism through the generator unit so as to form a solution heat exchanging and circulating loop; the outlet of the condenser unit is connected with the inlet of a water-to-water heat exchanger through a condense water spray pump, the outlet of the water-to-water heat exchanger is connected with a condense water spray mechanism through the condenser unit to form a condense water heat exchanging and circulating loop; the water return pipe is connected with a water-to-water heat exchanger unit and the inlet of a solution-to-water heat exchanger, and the water supply pipe is connected with the water-to-water heat exchanger and the inlet of the solution-to-water heat exchanger.

Owner:TSINGHUA UNIV +1

Method for Determining the Upper Limit of Flow of High-Voltage DC Plastic Insulated Cable Accessories

ActiveCN105044489BMeet the requirements of insulation characteristicsMake full use of transmission capacityElectrical testingInsulation layerElement model

The present invention discloses a high -voltage DC plastic insulating cable attachment to the upper limit of the annex. This method includes steps: build a finite element model; calculate the maximum temperature difference between the maximum temperature and the maximum temperature difference between the insulation of different layers; The maximum allowable temperature difference between the inner and outer surfaces of each solid insulating layer is used as the constraint condition of the steady-state current-carrying capacity of the HVDC cable accessories, and the initial current-carrying interval is obtained; the idea of dichotomy is used to continuously reduce the current-carrying interval, and finally the steady-state ampacity of the HVDC cable accessories is obtained ; During the operation of the high -voltage DC cable, the load calculation results are used as the access limit of the attachment. The present invention simultaneously considers the two constraint conditions of the maximum long-term allowable temperature of the conductive wire core and the maximum allowable temperature difference between the inner and outer surfaces of each solid insulating layer, and conforms to the insulation characteristics of the high-voltage DC cable accessories; it can flexibly adjust the carrying capacity of the accessories according to changes in the external environment, and make full use of The transmission capacity of the power cable line is improved, and the utilization rate of the cable is improved.

Owner:SOUTH CHINA UNIV OF TECH +1

Low temperature distillation method and device for high volatile component weak viscosity coal

InactiveCN100445348CEvenly heatedAvoid stickingLiquid hydrocarbon mixture productionSpecial form destructive distillationTarProcess engineering

The invention discloses a low-temperature retorting method of high-volatile flux fine particle, which is characterized by the following: the method adopts vertical pipe with inner, middle and outer concentric casing to move two sides of outer heat retort furnace, which produces char coal, gas and tar; the needed energy of retorting is provided by fine grain coal in the middle casing ring-shaped space from inner and outer casing high-temperature gas, which proceeds drying and charring steps; the steam and char volatile product are guided out of upper segment steam and lower segment char hole separately; the char coal falls in the char furnace chassis discharger, which is discharged from outlet.

Owner:FUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com