Method for determining through-flow upper limit of high-voltage direct-current plastic insulation cable accessory

A cable accessory, high-voltage DC technology, applied in the power field, can solve the problem of lack of in-depth research on the relationship between temperature distribution and current carrying of cable accessories, and achieve the effect of long-term safe and reliable operation and ensure long-term safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings, but the implementation and protection of the present invention are not limited thereto.

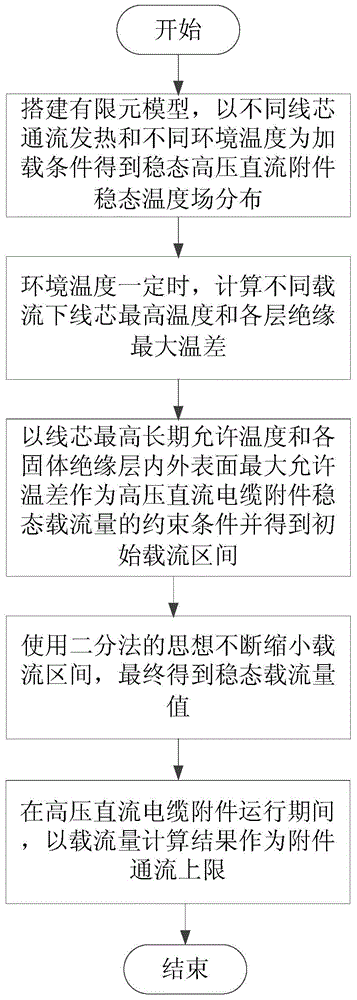

[0030] Such as figure 1 As shown, the method for determining the upper limit of the current flow of high-voltage DC plastic insulated cable accessories in this example includes the following steps:

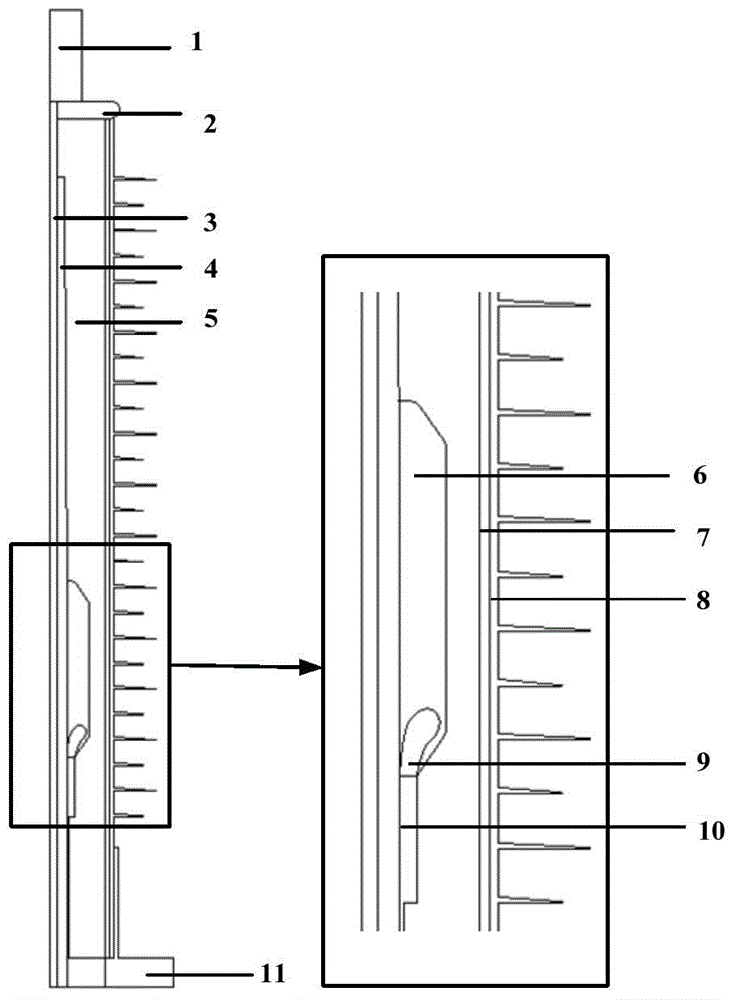

[0031] Step 1. Establish the geometric model of the 160kV high-voltage DC cable terminal according to the structural size of the cable terminal, as shown in the figure figure 2 As shown, it includes terminal 1, shielding cover 2, conductive wire core 3, XLPE insulation 4, silicone oil 5, reinforced insulation 6, epoxy sleeve 7, silicone rubber outer sheath 8, stress cone 9, copper support 10 , flange 11;

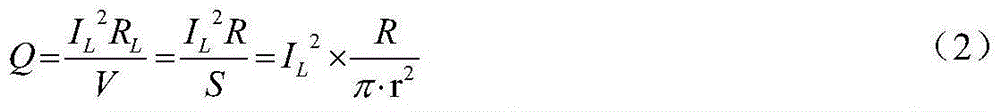

[0032] Step 2, input the material parameters of each component of the cable terminal, divide the grid, and establish the finite element model of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com