Method for reducing re-contact process energy consumption of catalytic reforming device

A catalytic reforming and recontacting technology, which is applied in the field of petroleum processing, can solve the problems of increasing electricity or steam consumption in ammonia machines, achieve the effects of reducing energy consumption and operating costs, increasing investment, and avoiding high quality and low use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

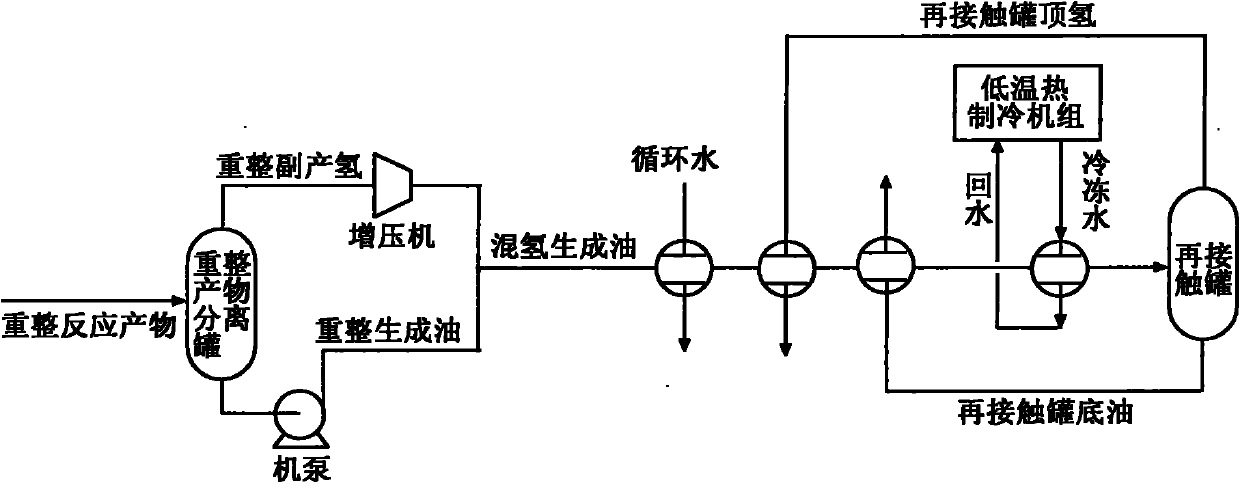

[0027] The technological process of the catalytic reformer recontact process of the present embodiment is as follows figure 2 As shown, compared with the technical process of the catalytic reforming unit reabsorption process of the comparative example, this embodiment has been improved as follows:

[0028] (1) Increase the low-temperature thermal refrigeration system

[0029] 53.9t / h of hot water at 95°C generated by low-temperature heat is passed through a set of newly added refrigeration units to generate 129.4t / h of chilled water at 5°C, and the temperature of hot water leaving the refrigeration unit is about 80°C.

[0030] (2) Improvement of heat transfer process

[0031] In the follow-up process of heat exchange between the hydrogen-mixed oil and the re-contact tank bottom oil, a hydrogen-mixed oil-chilled water heat exchanger is added. The heat exchange process is as follows: the 129.4t / h, 5°C chilled water generated in (1) passes through the newly added hydrogen-mixe...

Embodiment 2

[0038] The technological process of the catalytic reformer recontact process of the present embodiment is as follows figure 2 As shown, compared with the technical process of the catalytic reforming unit reabsorption process of the comparative example, this embodiment has been improved as follows:

[0039] (1) Increase the low-temperature thermal refrigeration system

[0040] 49.8t / h of 90°C hot water generated by low-temperature heat is passed through a new refrigeration unit to generate 79.6t / h of 10°C chilled water, and the temperature of the hot water leaving the refrigeration unit is about 80°C.

[0041] (2) Improvement of heat transfer process

[0042] In the follow-up process of heat exchange between the hydrogen-mixed oil and the re-contact tank bottom oil, a hydrogen-mixed oil-chilled water heat exchanger is added. The heat exchange process is as follows: the 79.6t / h, 10°C chilled water generated in (1) passes through the newly added hydrogen-mixed oil-chilled wate...

Embodiment 3

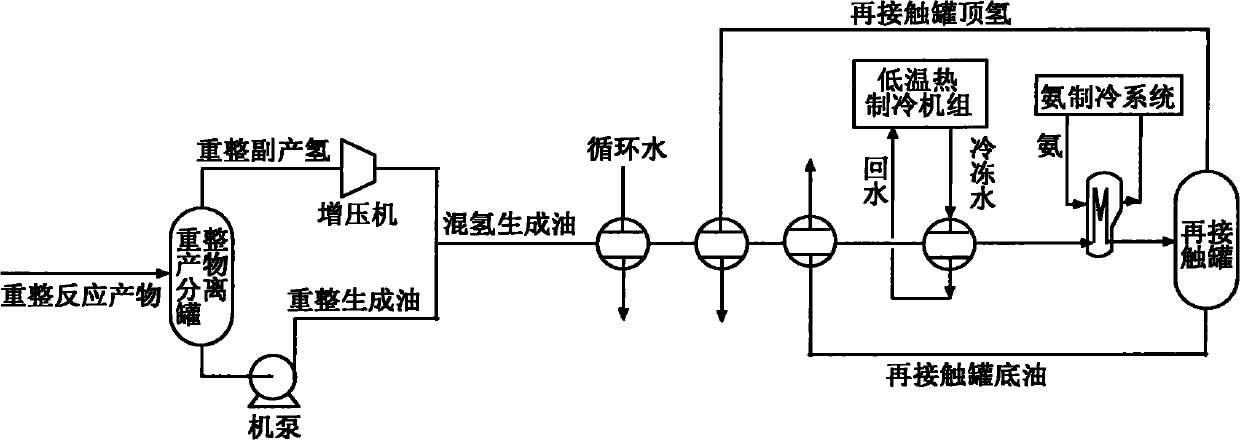

[0049] The technological process of the catalytic reformer recontacting system of the present embodiment is as follows image 3 As shown, the difference between this embodiment and embodiment 1 is the improvement of the heat exchange process, which is as follows:

[0050] (1) Changes in the load of the low-temperature thermal refrigeration system

[0051] 55.63t / h of 95°C hot water generated by low-temperature heat passes through a refrigeration unit to produce 133.52t / h of 5°C chilled water, and the temperature of the hot water leaving the refrigeration unit is 80°C.

[0052] (2) Cancellation of ammonia cooling reforming oil and gas process

[0053] After the hydrogen-mixed oil is cooled to 12°C by chilled water, it directly enters the recontact tank for gas-liquid balance. Cancel the process of cooling it to 0°C through the ammonia cooling system.

[0054] (3) Improvement of heat transfer process

[0055] After being cooled by circulating water, the 40°C hydrogen-mixed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com