Twin tower circulating fluidized bed fume desulfurizing method and device

A circulating fluidized bed and flue gas technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of large power consumption or steam, large volume of desulfurization towers, and increased operating costs, and achieve desulfurization energy. Low consumption, good fluidity and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

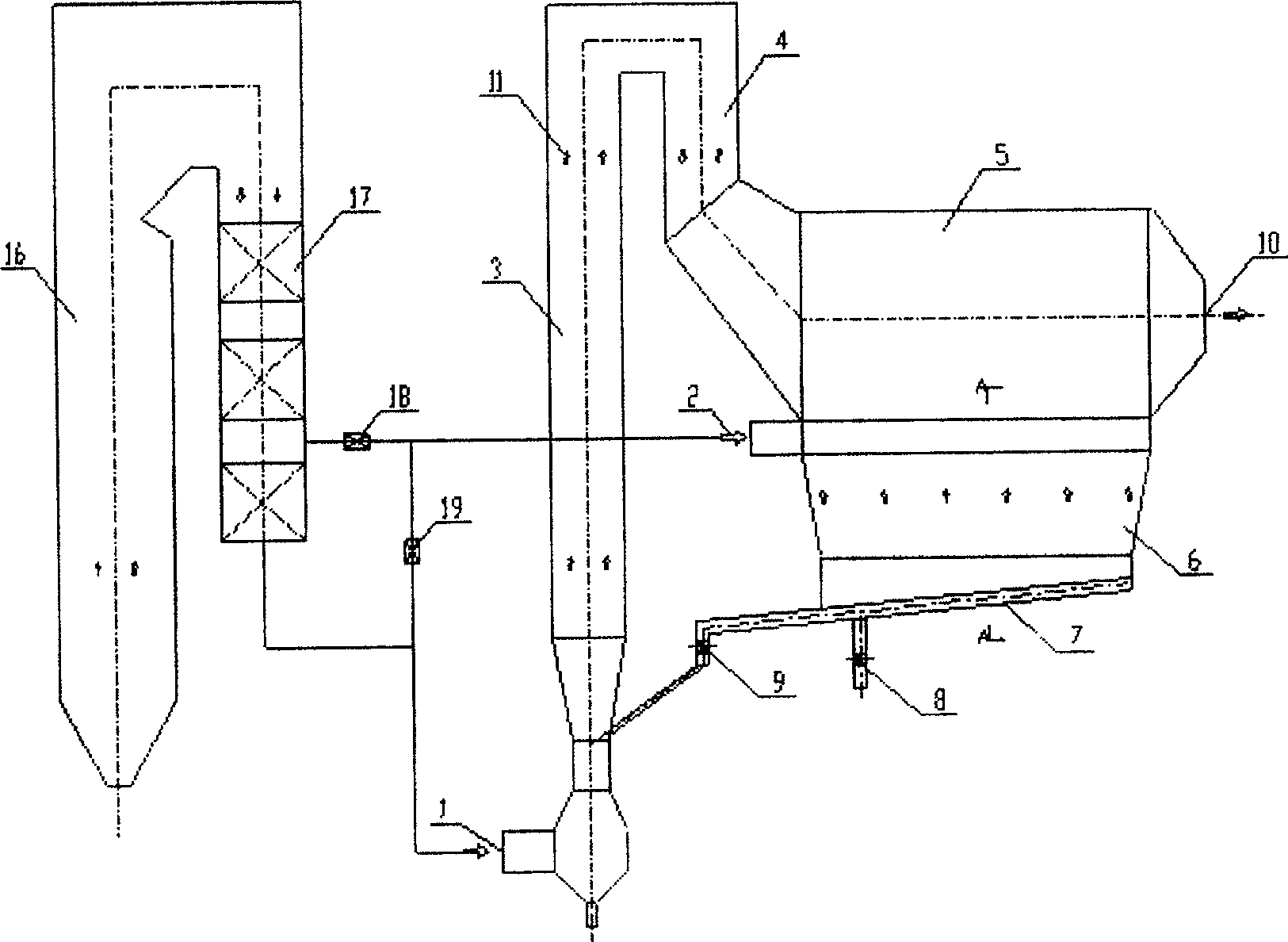

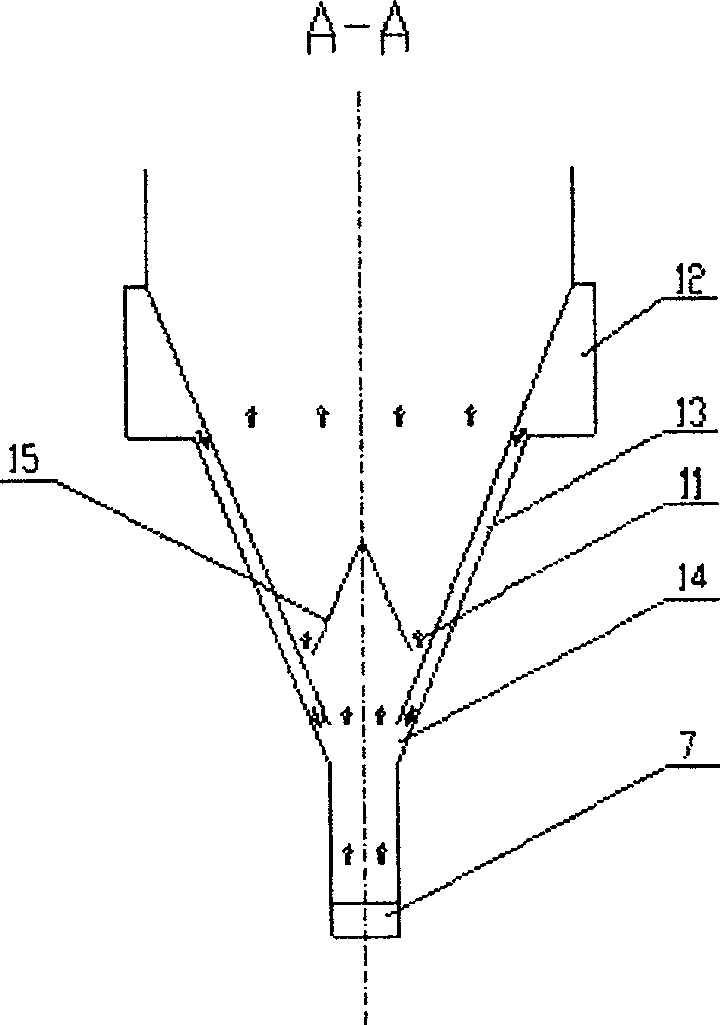

[0010] Depend on figure 1 As shown, the device of the present invention mainly includes a desulfurization reaction main tower 3, a gas-solid separator 5 and an ash hopper 6. The desulfurization reaction main tower 3 is connected with the gas-solid separator 5 by connecting the flue 4, and the gas-solid separator The lower part of 5 is arranged with an ash hopper 6, and the pneumatic chute 7 is arranged at the bottom of the ash hopper 6, and the desulfurization ash outlet 8 and the return device 9 are arranged on the pneumatic chute 7, and the dirty flue gas is divided into two and respectively imported from the flue gas 1 enters the main desulfurization reaction tower and flue gas inlet 2 enters the ash hopper 6 is the desulfurization reaction auxiliary tower. After the dirty flue gas is mixed and reacted with water, desulfurizing agent and circulating materials in the desulfurization reaction main tower, the acid gas in it is effectively removed, and the dirty flue gas enters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com