A steam mixing system for realizing denitration and warming and its adjustment method

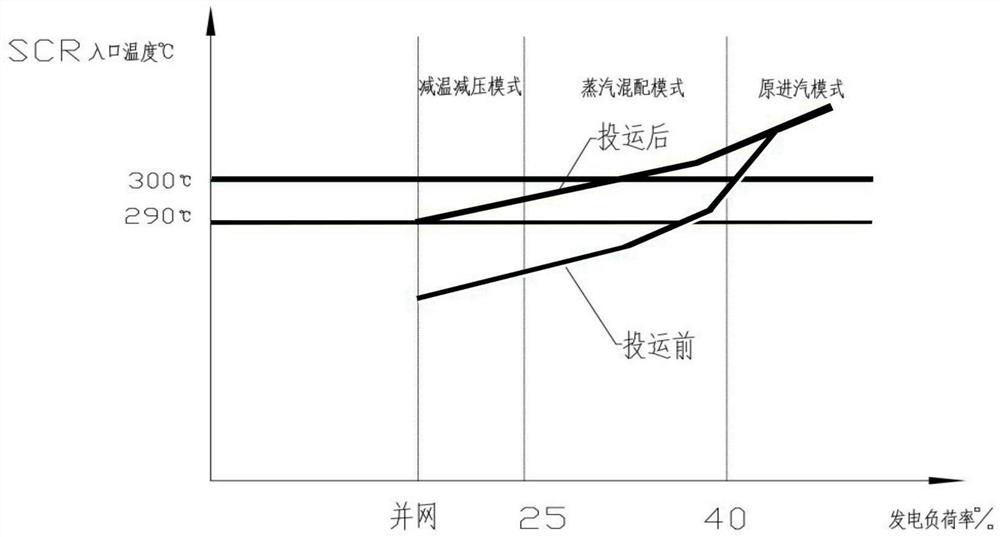

An adjustment method and steam technology, applied in the field of flue gas denitration treatment, can solve the problems of poor load adaptability, high investment cost, easy jamming of the baffle door, etc., and achieve strong ability to adapt to load changes, reduce heat absorption, and improve heating efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, not to limit the present invention.

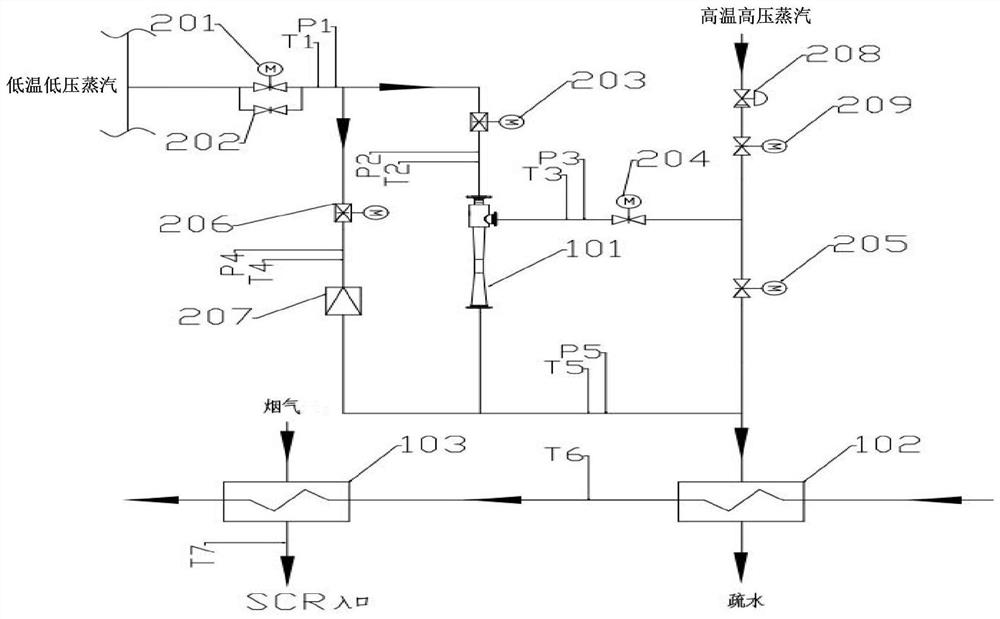

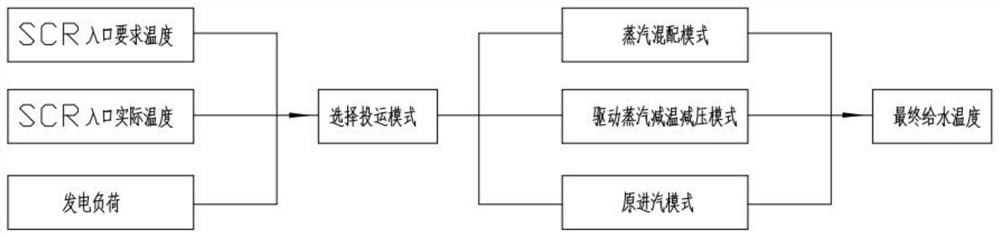

[0035] The invention discloses a steam mixing system for denitrification and temperature raising, such as figure 1 As shown, it includes a driving steam isolation unit, a steam mixing device 101, a high-pressure heater 102 and an economizer 103 connected in sequence through a steam pipeline. The steam pipeline is provided with a pressure and temperature detection device, and the steam pipeline inlet and The low-temperature and low-pressure steam pipelines are connected, the high-pressure heater 102 is connected with high-temperature and high-pressure steam pipelines, the injection port of the steam mixing device 101 is connected with the high-temperature and high-pressure steam pipeline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com