Flue gas SCR denitration efficiency-improving system and method

A denitrification efficiency and denitrification technology, which is applied in the field of flue gas SCR denitrification efficiency improvement system, can solve the problems of high operating cost, increased flue gas resistance, and high investment cost of SCR denitrification system, so as to reduce catalyst loading, investment and operation Cost, effect of high denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with specific embodiment the present invention is described in further detail, described is explanation of the present invention rather than limitation.

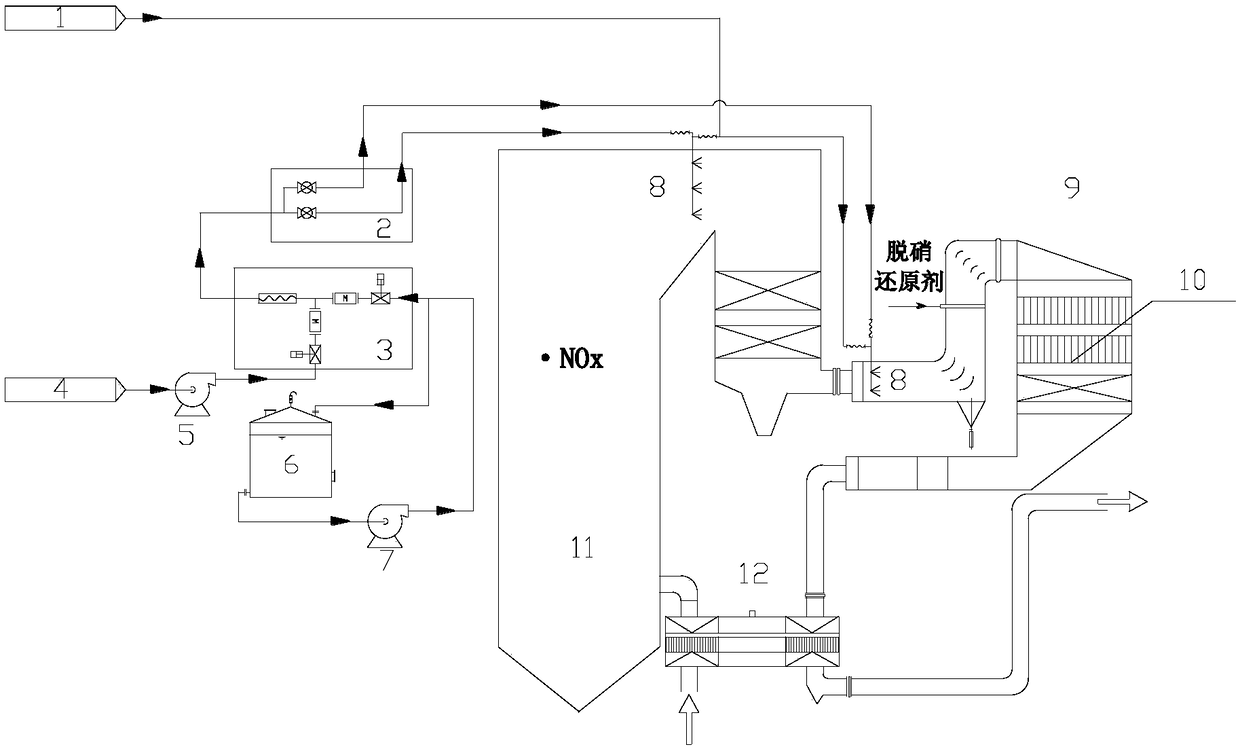

[0032] A flue gas SCR denitrification efficiency improvement system of the present invention comprises high-pressure air 1, distribution module 2, metering and dilution module 3, dilution desalted water tank 4, dilution water pump 5, oxidant tank 6, oxidant pump 7, nozzle system 8;

[0033] The oxidant stored in the oxidant tank 6 is pressurized by the oxidant pump 7 and then sent to the metering and dilution module 3. The oxidant output flow is adjusted according to the oxidant injection amount calculated by the process system, and then mixed with the diluted desalted water tank 4 and the dilution water pump 5. The mixed diluted desalted water is sent to the selected position before the SCR denitrification through the distribution module 2, and is sprayed into the flue through the nozzle system 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com