Adjustment method of steam compressor in thermal power unit steam turbine waste steam stripping heat application system

A technology of steam compressor and application system, which is applied in the direction of heating system, steam engine device, space heating and ventilation details, etc. It can solve the problems of poor energy saving effect, high quality of heating steam, complicated operation and maintenance, etc., and achieve high thermal efficiency , Improve energy utilization rate, flexible operation adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

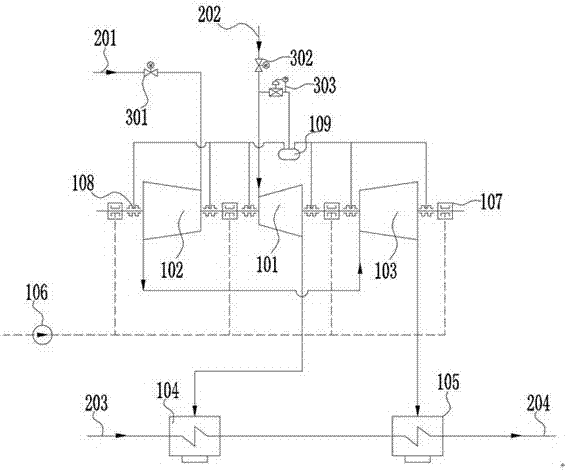

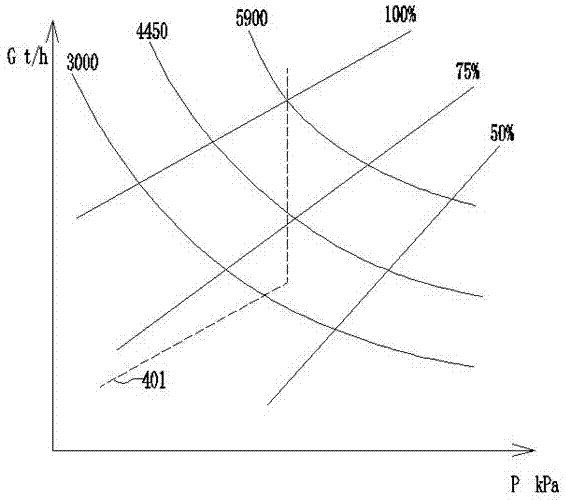

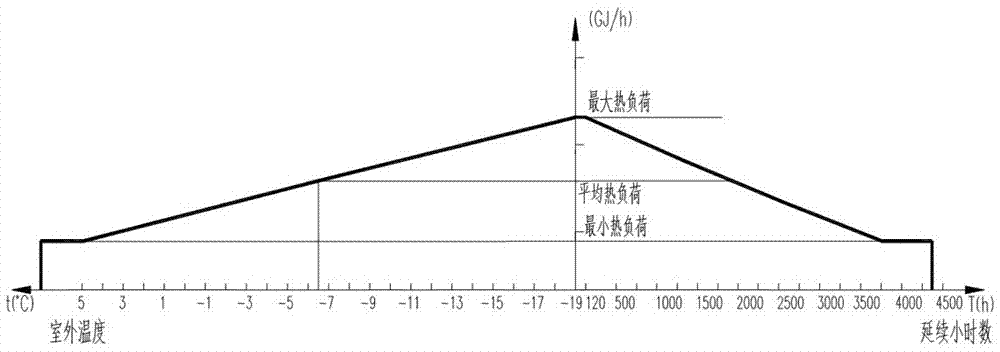

[0050] Next, the attached Figure 1-3 The present invention is further described:

[0051] In order to solve the above-mentioned problems in the prior art, the present invention provides a method for adjusting a steam compressor in an application system for heat supply of a steam turbine of a thermal power unit, wherein the system mainly includes a steam compressor driving a small steam turbine (101 ), the first stage of steam compressor (102), the second stage of steam compressor (103), the first stage heat network heater (104), the second stage heat network heater (105), lubricating oil pump (106), Radial support tilting pad sliding bearing (107), shaft seal (108), shaft seal steam supply header (109), steam turbine exhaust steam (201), small steam turbine driving steam (202), heating network circulating water return water ( 203), heating network circulating water supply (204), steam turbine exhaust steam shut-off valve (301), small steam turbine driven steam shut-off valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com