Heat pump type crude oil heating system

A heating system and heat pump technology, applied in heat recovery systems, heat pumps, energy-saving heating/cooling, etc., can solve the problems of unused oil field waste heat resources, inflexible load regulation, and serious environmental pollution, etc., and achieve reduction in combustion volume, The effect of long equipment life cycle and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

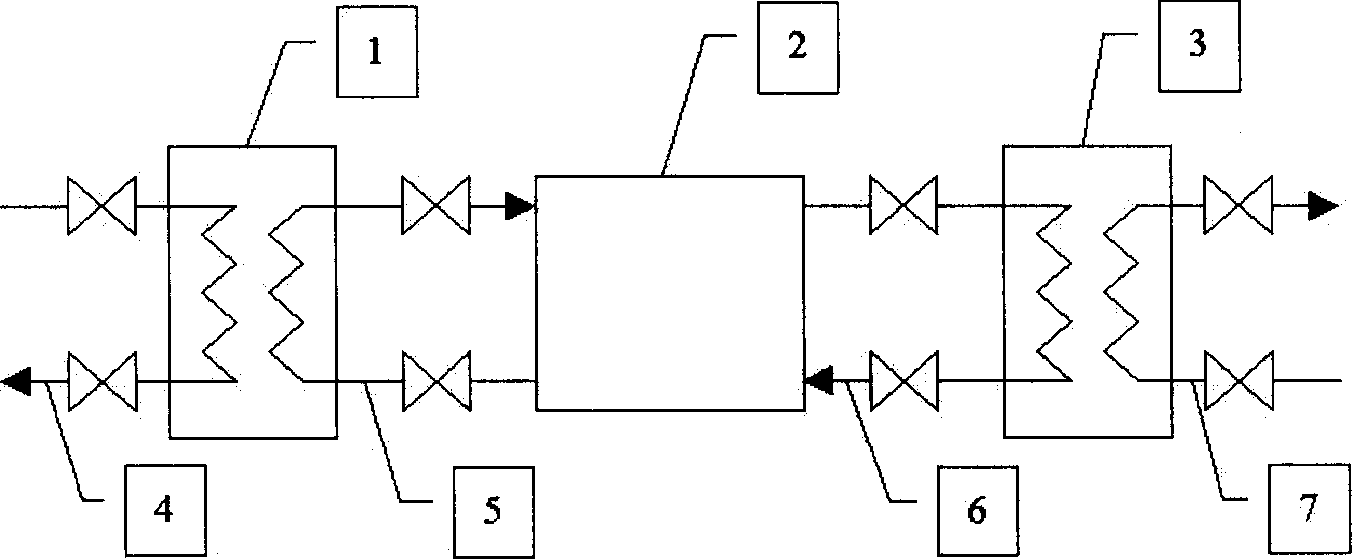

[0033] figure 1 It is the process flow diagram of the first embodiment of the heat pump crude oil heating system of the present invention

[0034] The heat pump crude oil heating system of the present invention includes a water / water heat exchange device 1, an absorption heat pump unit 2, a crude oil / water heat exchange device 3, a residual hot water pipeline 4, a medium-temperature clean water circulation pipeline 5, a high-temperature clean water circulation pipeline 6, and a crude oil pipeline 7.

[0035] The oilfield sewage or geothermal water with a temperature of 25-80°C in the waste water pipeline 4 passes through the water / water heat exchange device 1, exchanges heat with the medium-temperature circulating water, and transfers part of the heat to the medium-temperature circulating water, and the medium-temperature circulating water passes through the medium-temperature circulating water. The clean water circulating water pipeline 5 enters the absorption heat pump unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com