Automatic steel pushing and overturning device for profile steel

An automatic and section steel technology, applied in the field of metallurgy, can solve problems such as the inability to achieve effective flipping of rolled pieces, and achieve the effects of promoting the use, improving rolling rhythm, and eliminating collisions between rolled pieces and roller tables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

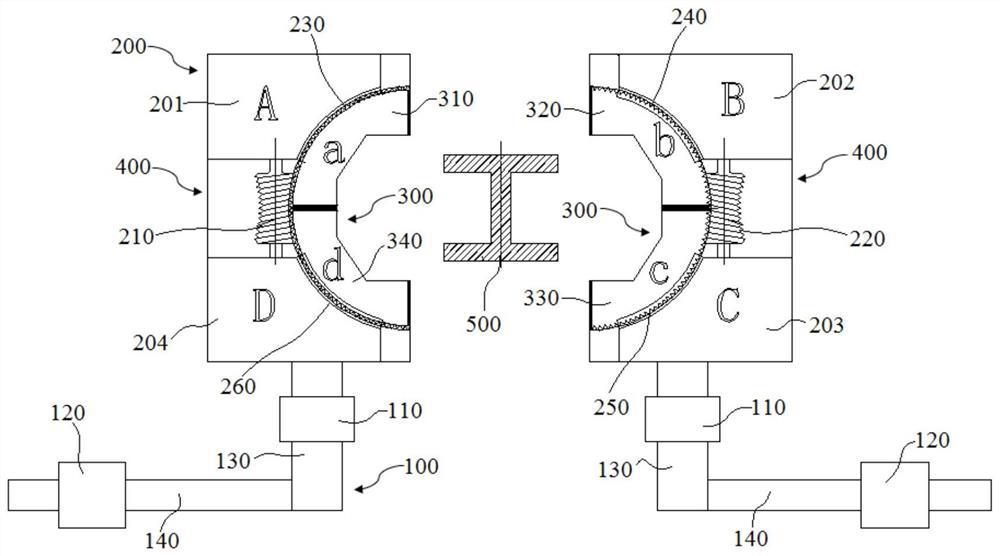

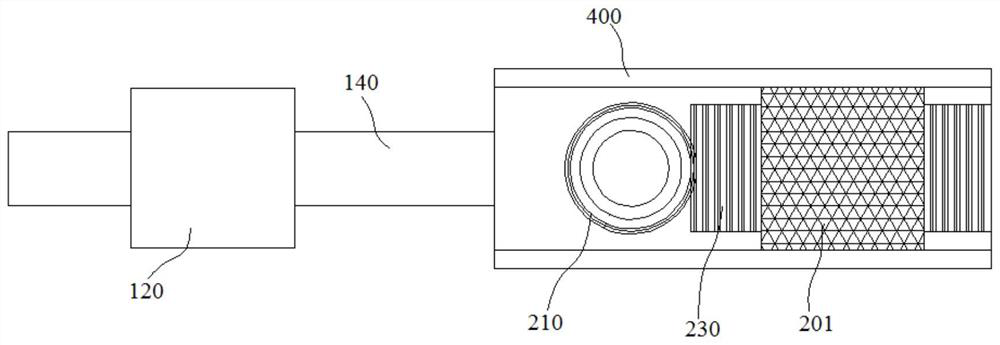

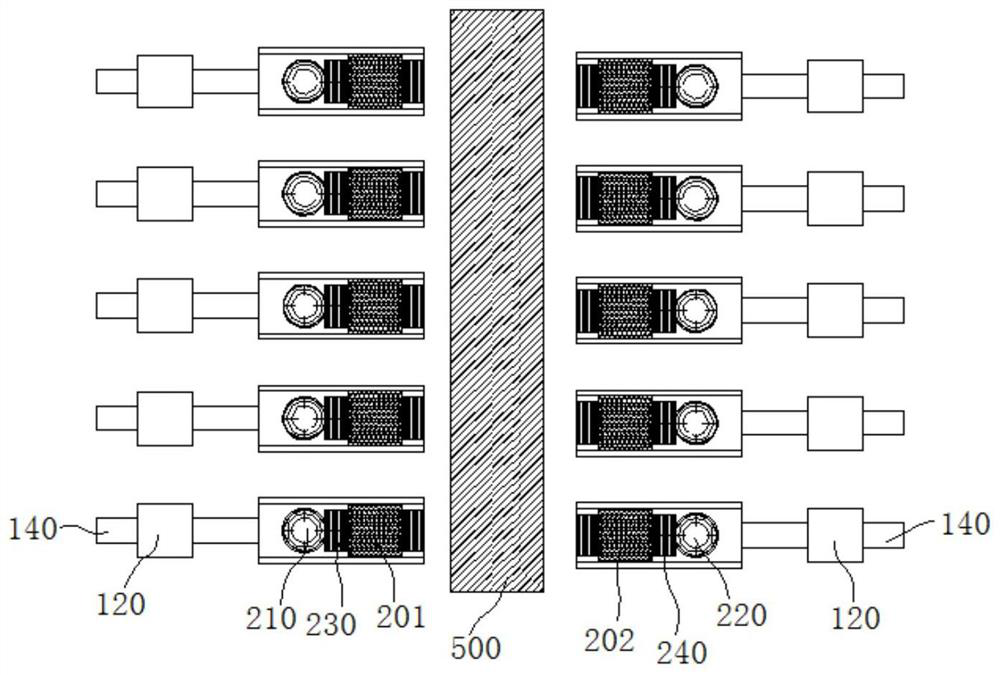

[0048] combine Figure 1-Figure 9 , a kind of automatic steel pushing-turning device for profiled steel of the present embodiment, comprises the left pushing steel-turning steel mechanism and the right pushing steel-turning steel mechanism of horizontal setting, described left pushing steel-turning steel mechanism and right pushing steel - The structure of the steel turning mechanism is the same, and it is distributed symmetrically. The left push steel-turn steel mechanism and the right push steel-turn steel mechanism are located at the same position and height, which is convenient to bite the rolled piece from both sides of the rolled piece, so as to ensure the subsequent pushing The stability of steel and turning steel action, and the left and right symmetrical structure design reduce the size and facilitate storage and use. Such as figure 1 As shown, the left push steel-turning steel mechanism in this embodiment includes a support unit 300 for clamping steel, an execution ...

Embodiment 2

[0054] A kind of section steel of present embodiment is used automatic push steel-turning steel device, and basic structure is identical with embodiment 1, further, as Figure 6 As shown, in this embodiment, the fixing part 270 includes a fixing part 271 connected to the bottom of the rotating gear. The center of the bottom of the fixing part 271 is provided with a push plate, and both sides of the bottom of the fixing part 271 are extended downward with positioning sections for positioning. The bottom of the segment is provided with a positioning protrusion 272 , the two ends of the positioning protrusion 272 in the width direction extend beyond the two ends of the positioning segment, and the pushing steel plate is located between the positioning protrusions 272 on both sides. The positioning projection 272 is used to fix the fixed part 270 and the rotating gear in the gear fixing groove as a whole, and there is a certain gap between the top of the rotating gear and the inner...

Embodiment 3

[0057] A kind of section steel of present embodiment is used automatic push steel-turning steel device, and basic structure is identical with embodiment 1, further, as figure 1 As shown, the displacement unit 100 in this embodiment includes a lifting push rod 130 arranged at the bottom of the execution unit 200, and a lifting hydraulic cylinder 110 is arranged on the lifting pushing rod 130. The lifting hydraulic cylinder 110 is used to control the left pushing steel-turning steel mechanism and The right push steel-turning steel mechanism lifts up and down to adjust the height position of the pushing steel-turning steel device; the bottom side of the lifting push rod 130 is provided with a translation push rod 140, and the translation push rod 140 is provided with a translation hydraulic cylinder 120, and the translation hydraulic cylinder 120 is arranged on the translation push rod 140. Cylinder 120 is used for controlling left push steel-turning steel mechanism and right push...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com