Electromagnetic separation device for treating solid garbage

A solid waste, magnetic separation device technology, applied in solid separation, magnetic separation, combustion methods and other directions, can solve the problems of reducing the reliability and service life of magnetic separation equipment, wasting energy, etc., to extend life and trouble-free working time, Cost reduction and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

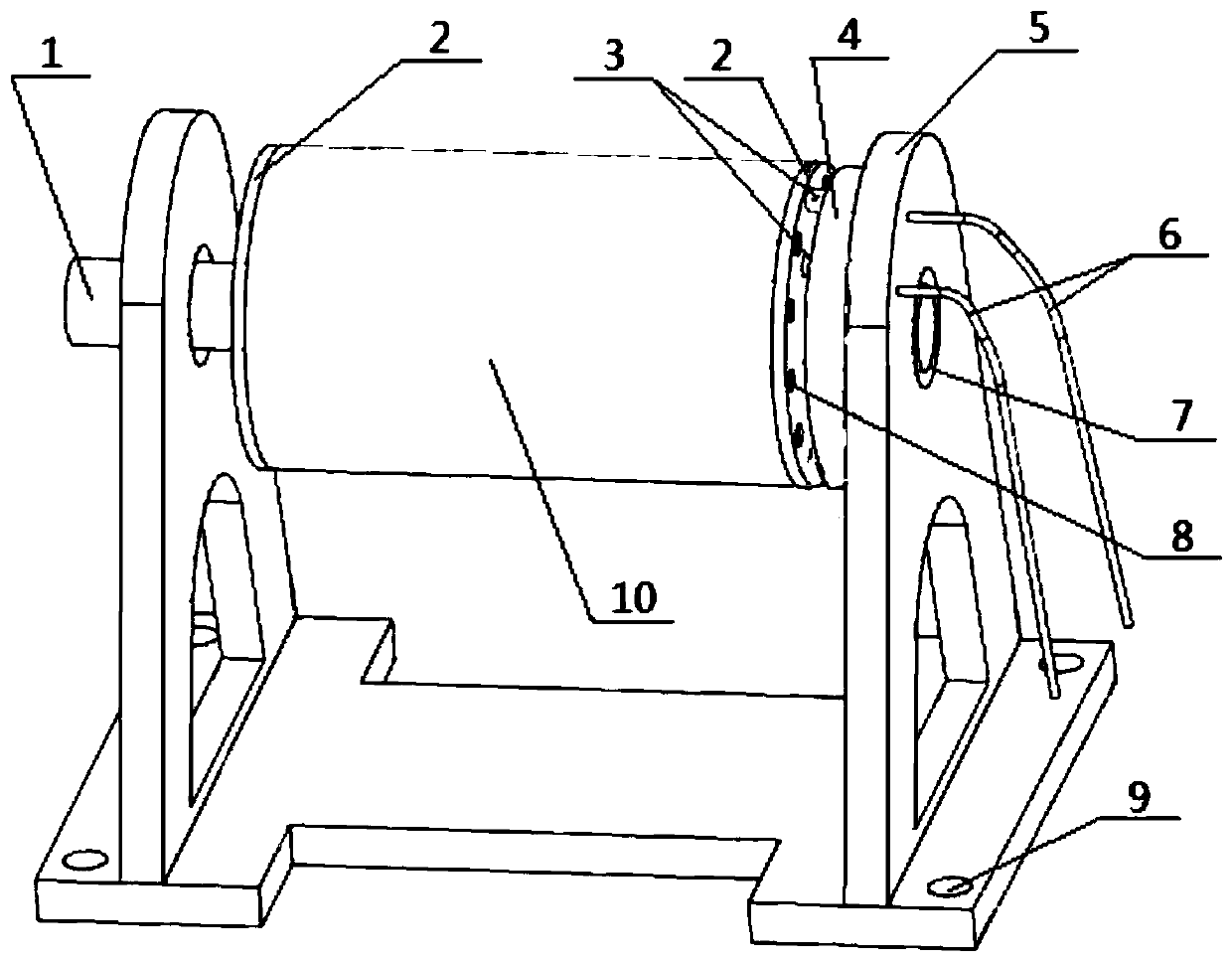

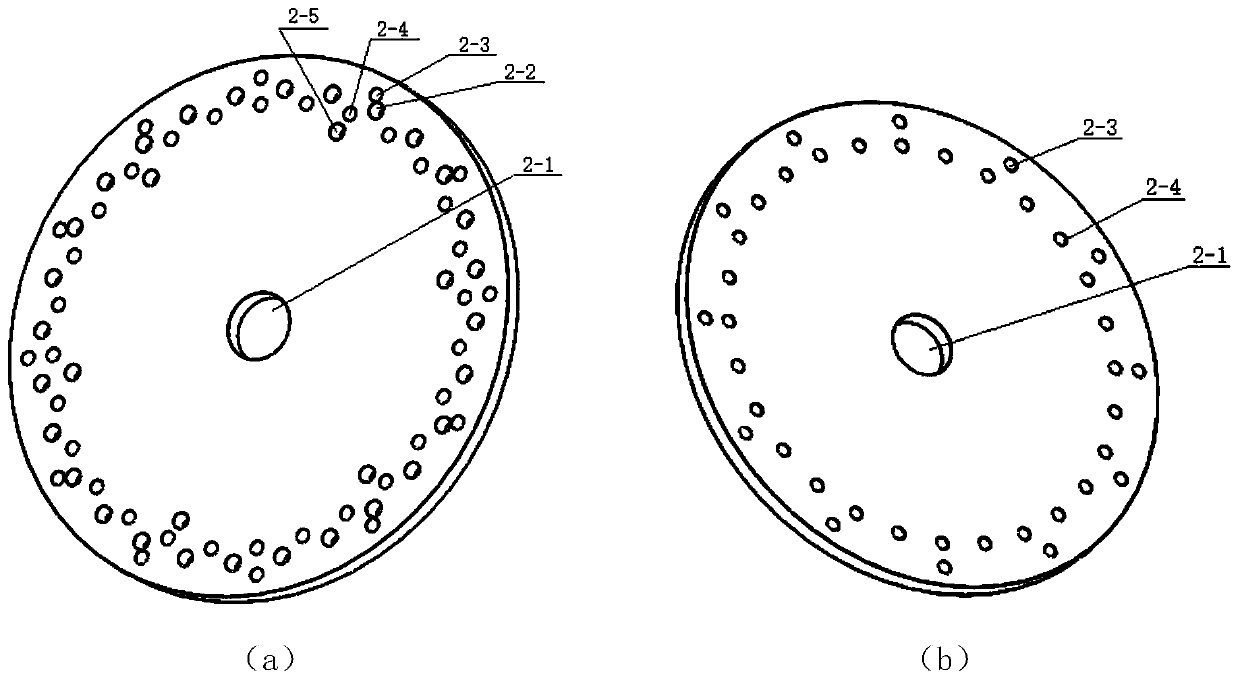

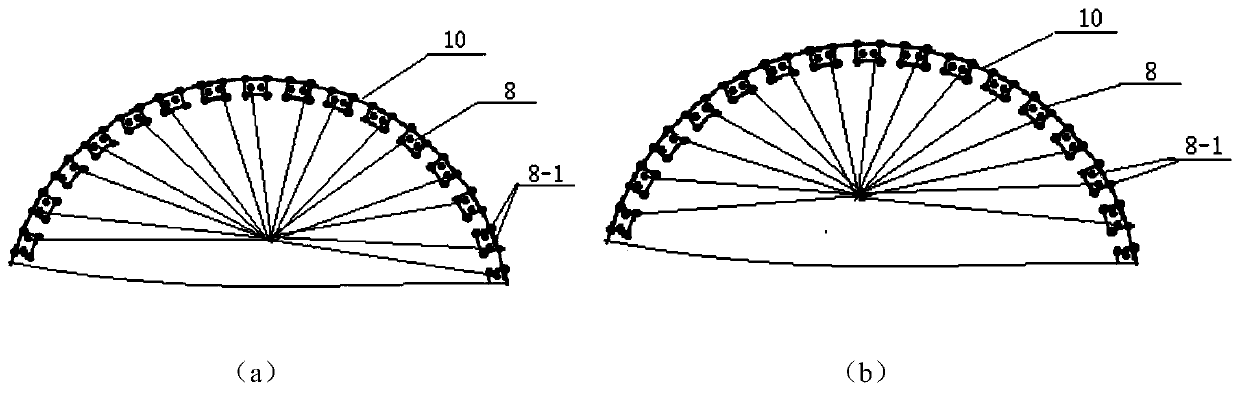

[0024] The structure, principle and working process of the present invention will be further described below in conjunction with the accompanying drawings.

[0025] Figure 1-7 It is a structural schematic diagram of an electromagnetic magnetic separation device for treating solid waste provided by the present invention, including a power input shaft (1), an end plate flange (2), a carbon brush electrode (3), and an electrode supply plate (4) , support (5), magnet assembly (8) and magnetic separation drum (10), etc.; the magnet assembly (8) mainly includes electrode leads (8-1), connecting shaft (8-2), coil (8-3) and iron core (2-4); described magnet assembly (8) is fixed on the connecting shaft (8-2), and the connecting shaft (8-2) at its two ends is respectively connected with the end plate at the two ends of the magnetic separation drum (10) The flange (2) is fixedly connected; the end plate flange (2), the flange shaft mounting hole (2-1), the magnetic separation drum (10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com