Vertical-axis wind power generation system working according to double-wind-turbine double-wind-speed power curves

A technology of wind power generation system and power curve, which is applied to wind turbines at right angles to the wind direction, wind turbines, and control of wind turbines, etc., can solve the problems of difficulty in implementation and narrow working wind speed range of wind power generation systems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] specific implementation plan

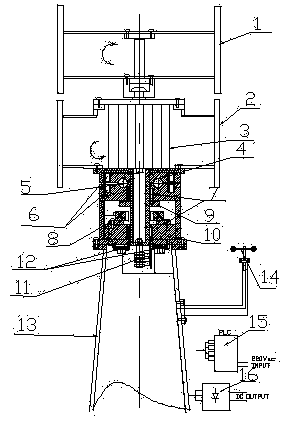

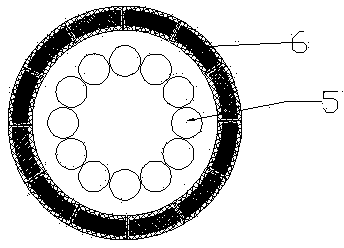

[0016] As shown in the attached figure, when the wind speed sensor (14) detects that the wind speed of the environment where the wind power generation system is located is greater than the predetermined starting wind speed of the fan (for example, the wind speed is 2 m / s), the PLC controller (15) will send The electromagnetic coil in the magnetic levitation device (6) is energized, and the polarity of the opposite magnetic poles in the gap of the magnetic levitation device (6) is the same, generating a repulsive force, so that the rotating body (4) fixed to the generator (3) is in the state of magnetic levitation, and the rotating body (4) There is no vertical contact with the connecting device (10) except for the cylindrical bearing (7) and the slip ring (11), and the resistance moment is very small. The central axis of the generator (3) rotates, and the wind torque of the rotor wind wheel (1) acts on the rotor to reversely rotate around ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com