Small size single stage single water suction ring vacuum pump

A water-absorbing ring and vacuum pump technology, which is applied to pumps, pump components, non-variable pumps, etc., can solve the problems of incomplete concentricity of the pump shaft and large footprint, and achieve floor space saving, small footprint, and The effect of preventing water from entering the bearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

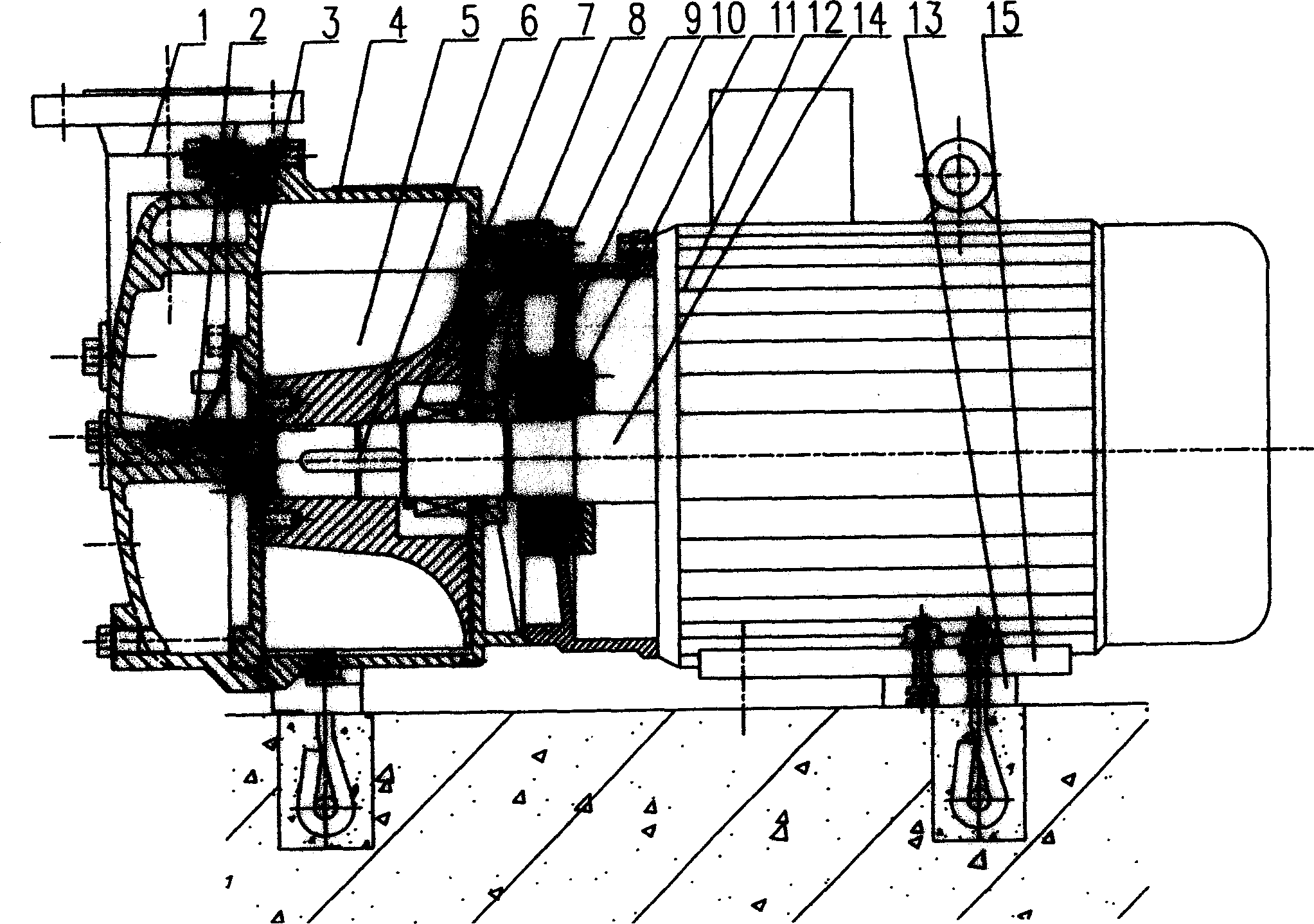

[0019] see figure 1 , The motor of the present invention adopts a Y2 type extended shaft motor, and the motor main shaft adopts a stainless steel shaft. The motor 12, the bearing bracket 9 and the pump body 4 are fixedly connected together with bolts, the pump body 4 and the pump cover 1 are fixedly connected by bolts, the bearing bracket 9 is equipped with a bearing 11, and the bearing 11 is matched on the motor main shaft 14 and is located in the pump There is a lip-type oil seal 10 at the joint between the bearing bracket 9 on the right side of the body 4 and the motor shaft 14 to prevent water from entering the bearing due to shaft seal leakage; the impeller 5 in the pump body is directly shrunk on the motor shaft and keyed, and the There is also a mechanical seal 8 on the motor shaft 14, the mechanical seal adopts a rubber bellows seal, and the mechanical seal retaining ring 7 is positioned by a key, the motor frame 15 at the bottom of the motor 12 has a bottom corner hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com