Clamping finger for clamping shaft part

A technology for shaft parts and part clamps, which is applied in the field of clamping fingers for shaft parts, can solve problems such as gaps, parts positioning, and tightness, and achieve the effect of ensuring assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific implementation manner of the patent of the present invention will be described in detail below in conjunction with the technical scheme and accompanying drawings.

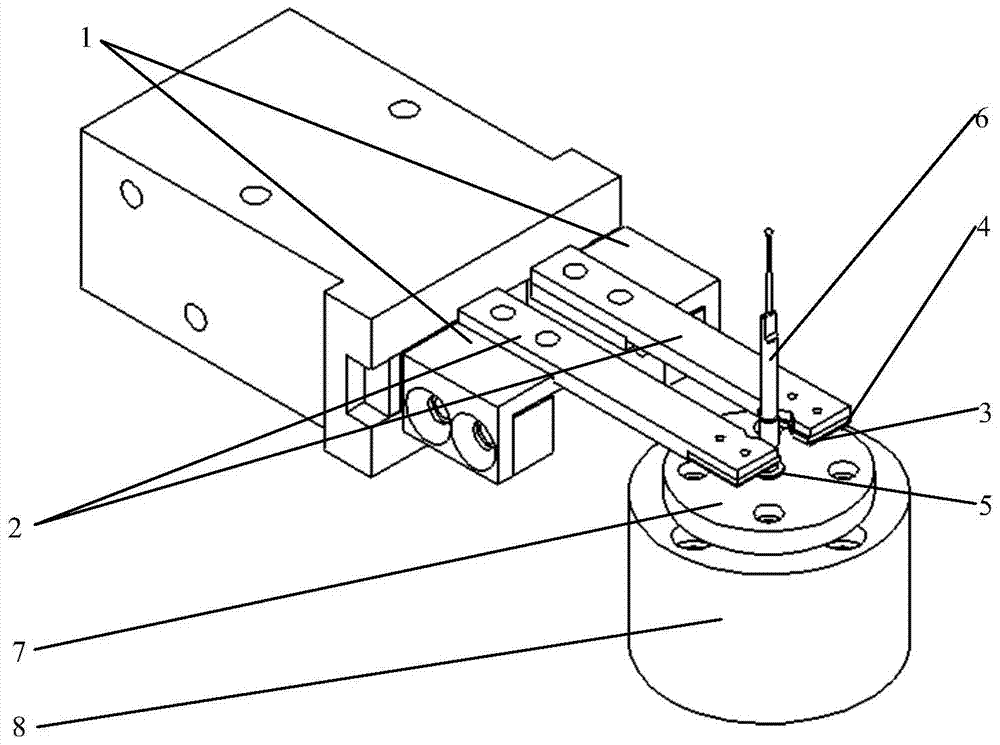

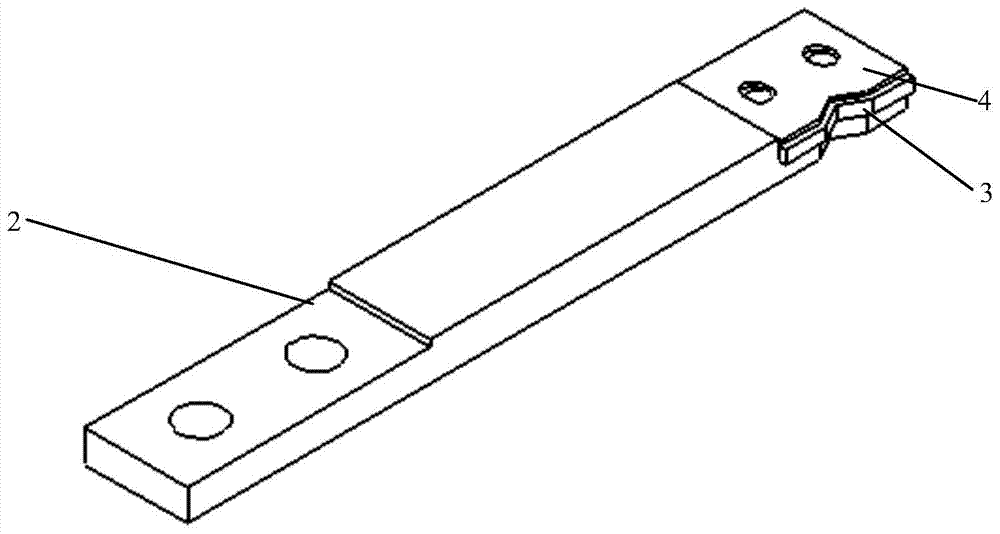

[0011] Such as figure 1 As shown, the opening and closing of the air claw 1 is controlled by the air valve through compressed air. The clamping finger rod 2 is a convex structure. Fix the rubber pad 3 and the sheet 4 in sequence; the V-shaped grooves of the two clamping fingers 2 are opposite to each other for installing the clamped shaft parts 6; V-shaped groove; the rubber pad 3 is wider than the V-shaped groove of the clamp finger bar 2 at the V-shaped groove, and the rubber pad 3 protrudes; the clamped shaft part 6 is fixed on the positioning end face 5, and the positioning end face 5 is located at the center of the positioning disc 7, and the positioning disc 7 is provided with a through hole for fixing with the pressing round table 8; the pressing round table 8 is also provided with a thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com