Double-rocker transmission mechanism applicable to movable control surface of aerial vehicle

A technology of transmission mechanism and aircraft, which is applied in the directions of aircraft transmission, aircraft power transmission, and aircraft power devices, etc., can solve the problems of exposed high and low temperature environment, affect the performance of the motor, no layout space, etc., and achieve high connection rigidity of the mechanism. The effect of mechanism movement reliability and high transmission precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

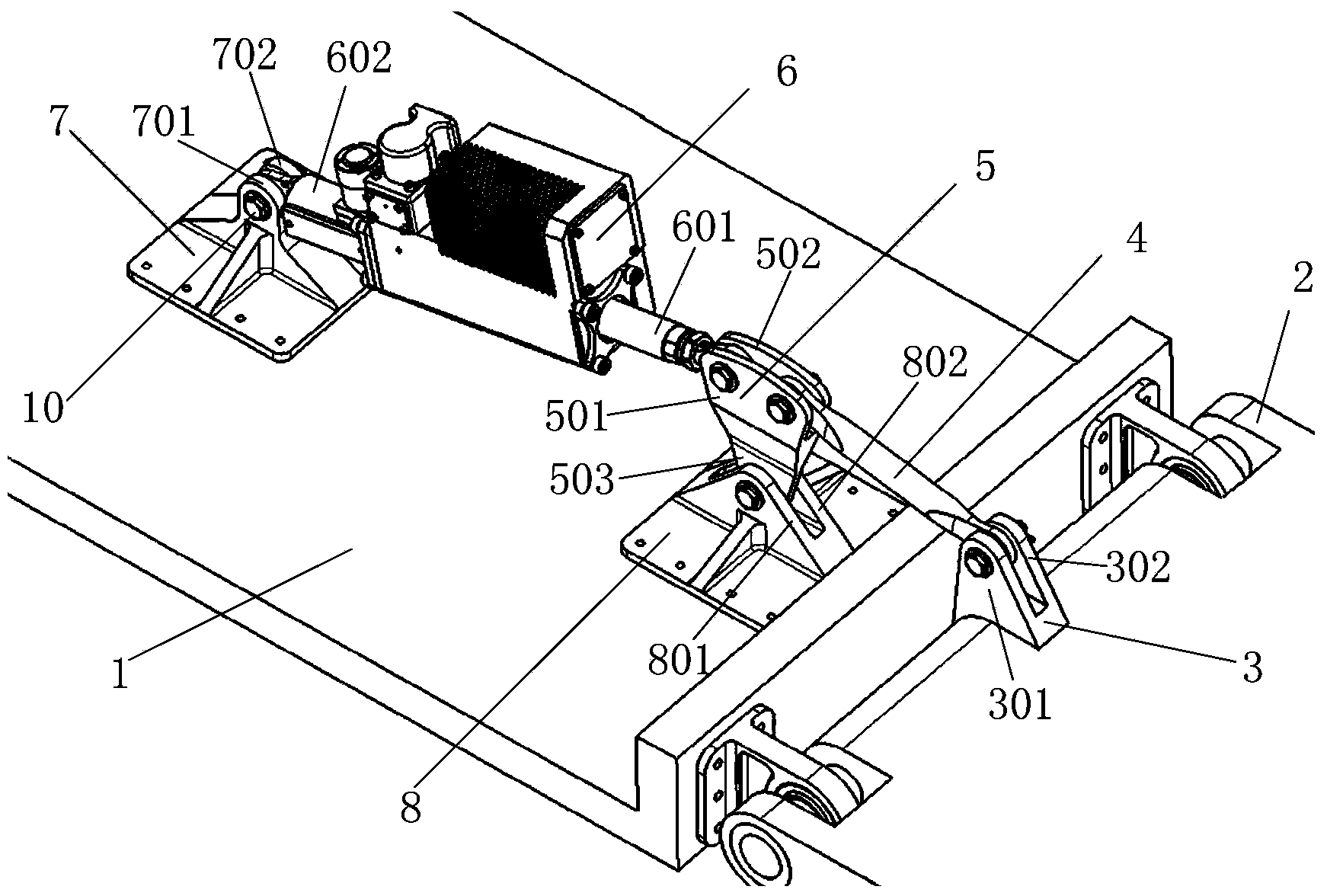

[0014] The double rocker arm transmission mechanism according to the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

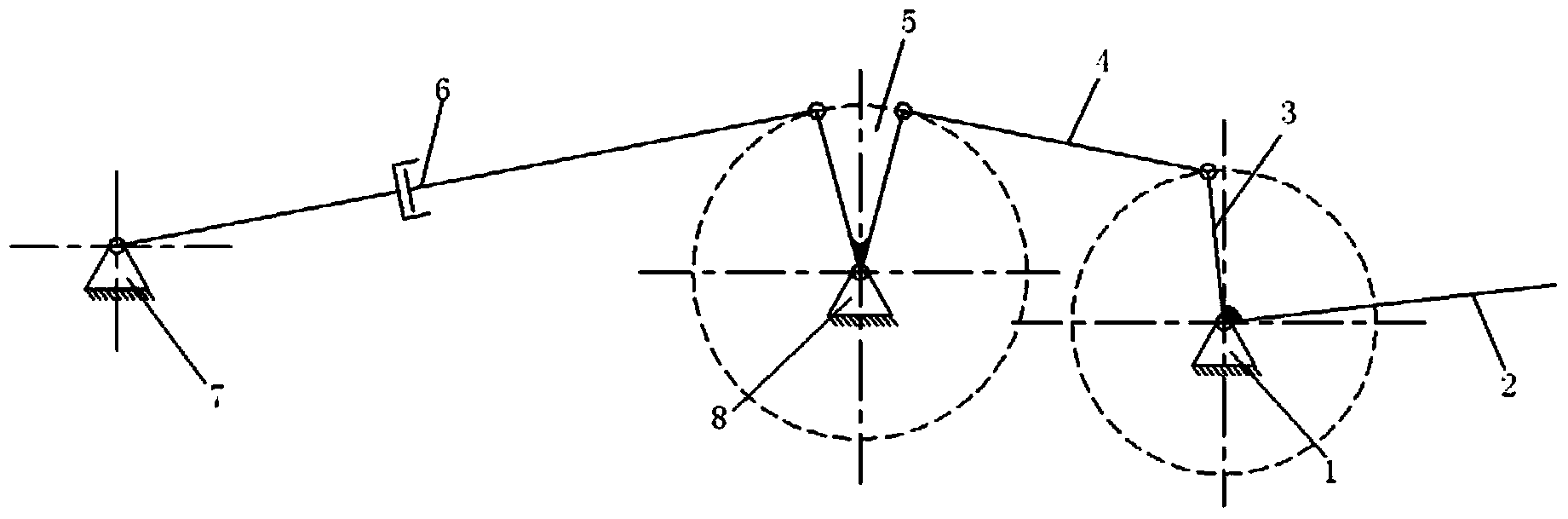

[0015] figure 1 It is a structural schematic diagram of the double rocker arm transmission mechanism of the present invention, as figure 1 As shown, in the double rocker arm transmission mechanism, the movable rudder surface 2 is rotatably connected to the aircraft body 1, and can swing around the rotation point between it and the aircraft body 1 by means of the double rocker arm transmission mechanism. action.

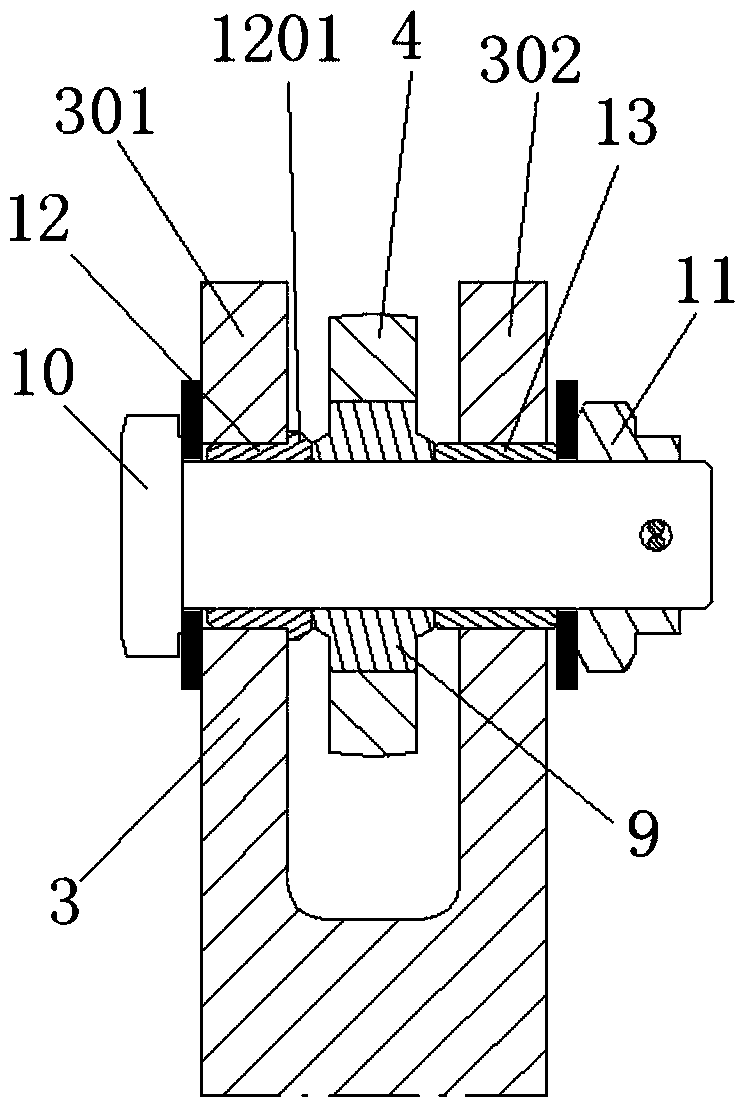

[0016] As shown in the figure, the double rocker arm transmission mechanism of the present invention includes a rocker arm 3 , a connecting rod 4 , an auxiliary rocker arm 5 , a linear servo actuator 6 , a first base 7 , and a second base 8 . Wherein, the rocker arm 3 is fixedly installed on the movable rudder surface 2 , and the first base 7 and the second base 8 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com