Clamping head of blanking machine

A blanking machine and machine clip technology, which is applied to the accessories of tool clips, turning equipment, automatic/semi-automatic lathes, etc., can solve the problems affecting the machining accuracy of the workpiece, achieve the effect of novel structure and ensure dimensional consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

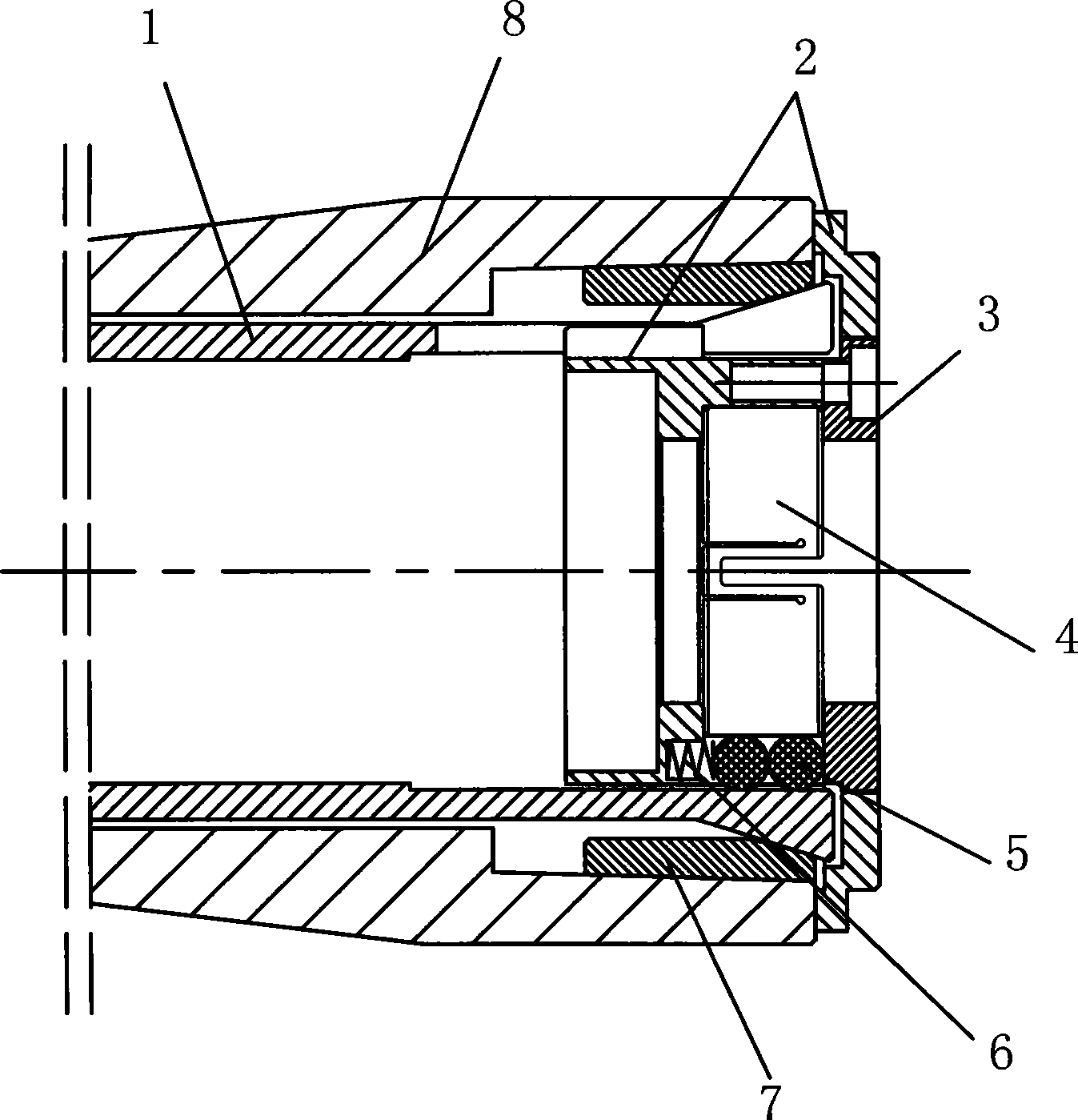

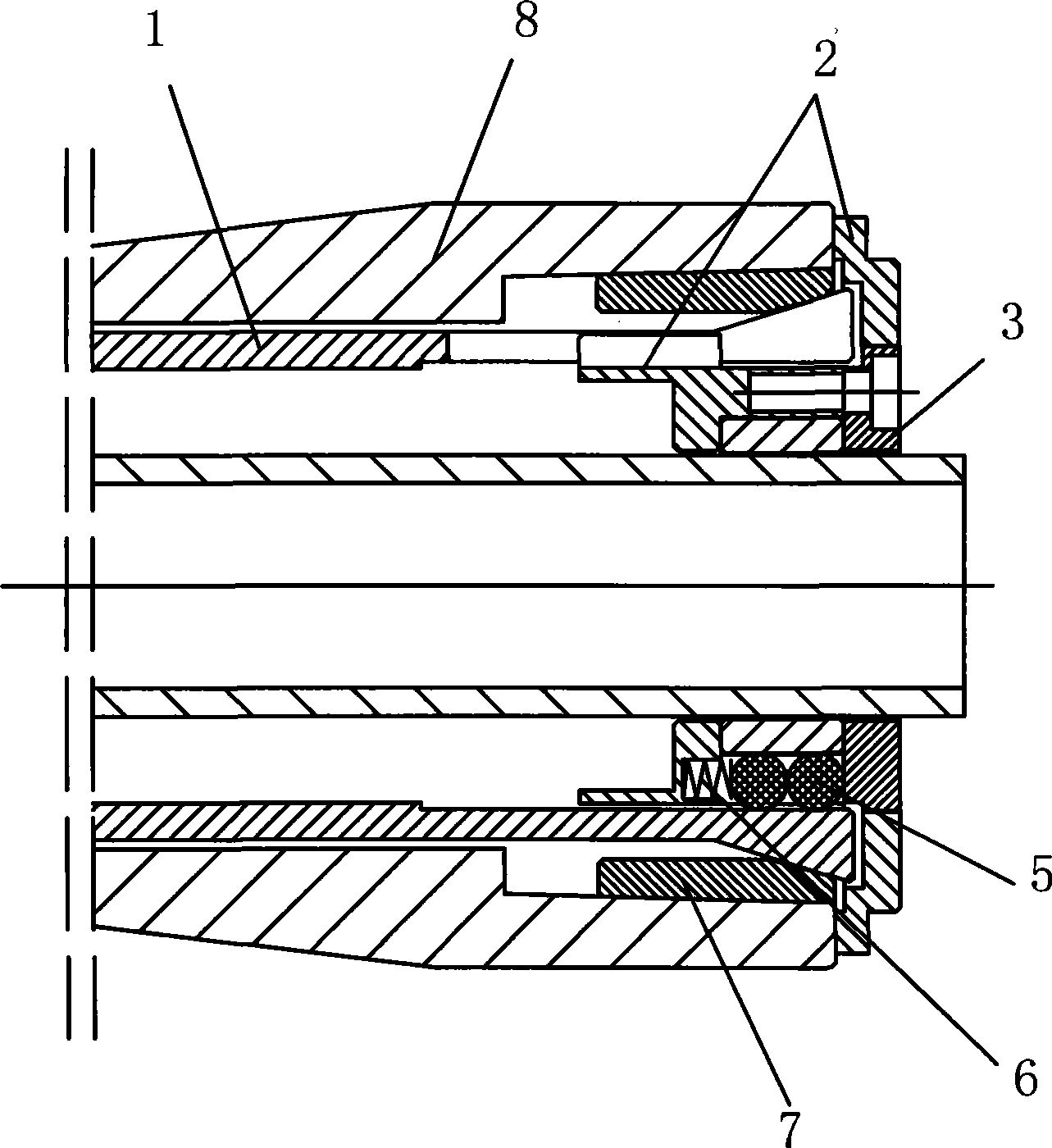

[0016] See Figure 1 ~ Figure 3 , The chuck of the blanking machine is mainly composed of a spring chuck 1, a movable component 5, a clamping sleeve 4, and the like.

[0017] The outer side of the left end of the collet 1 is provided with a taper, the taper is provided with an outer locking sleeve 7, the outer locking sleeve 7 is installed on the main shaft 8, and the inner side of the collet 1 is provided with a clamping sleeve 2, One end of the clamping sleeve 2 protrudes from the collet 1 .

[0018] The clamping sleeve 2 is provided with a plurality of rolling grooves, the elastic component and the movable component 5 are movably arranged in the rolling grooves, and the inner side of the movable component 5 is provided with a clamping sleeve 4 .

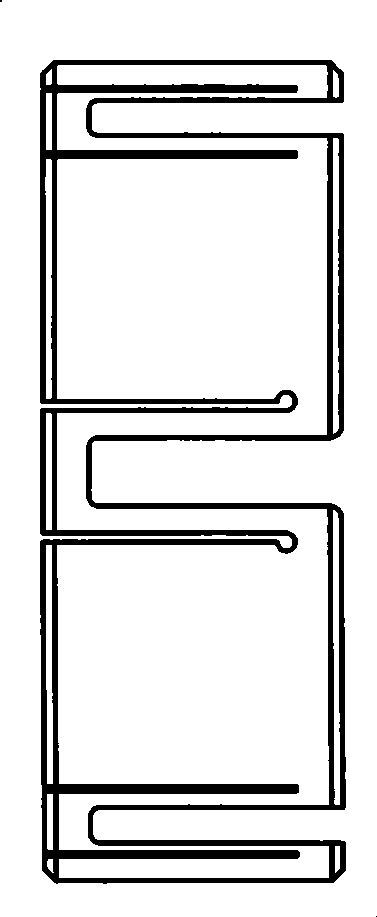

[0019] Preferably, the tightening sleeve 4 is provided with long grooves in opposite direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com