High-precision silicone rubber extrusion system

A silicone rubber, high-precision technology, applied in the field of silicone rubber extrusion molding, can solve the problems of inability to guarantee consistency, inability to guarantee rubber material, high viscosity, etc., to ensure dimensional stability and consistency, convenient and uniform adjustment, reduce The effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

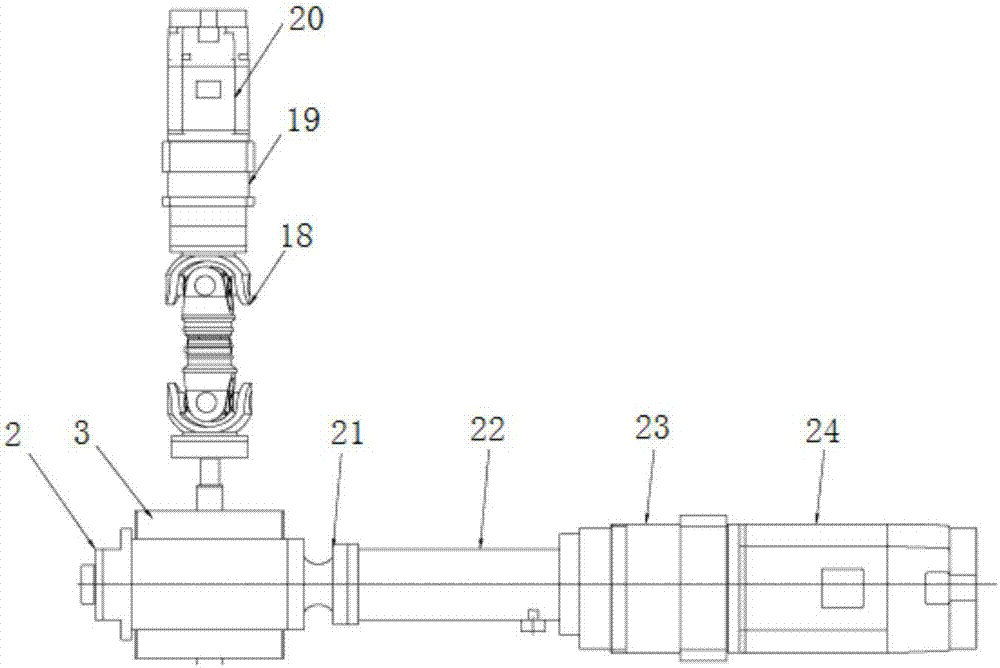

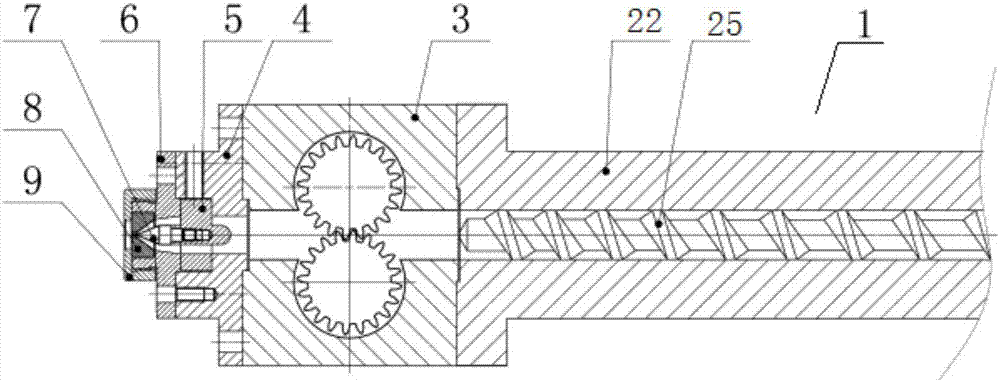

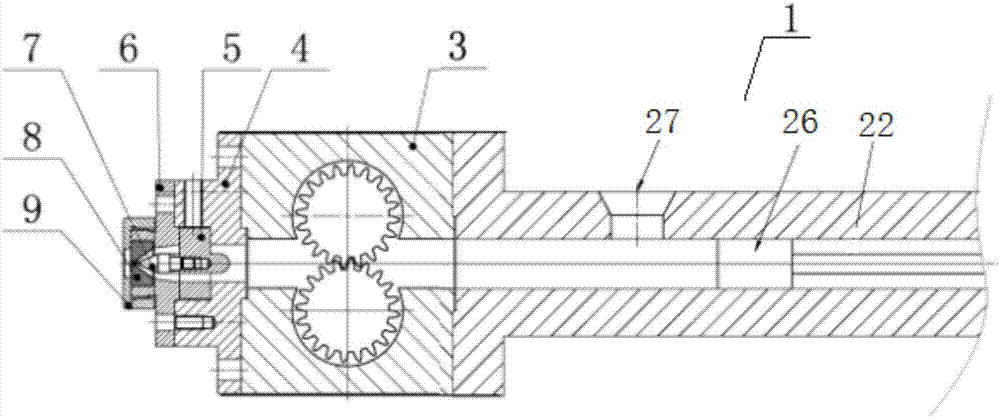

[0019] combined with figure 1 , 2 , 4, 5 describe the first embodiment of the present invention.

[0020] A high-precision silicone rubber extrusion system, including a feed system 1, a gear pump 3 is rigidly connected to the discharge port of the feed system 1, and the feed port of the gear pump 3 is connected to the discharge port of the feed system 1 Corresponding, and sealed with end face hard contact seal; the discharge port of the gear pump 3 is rigidly connected with the extrusion head assembly 2, and the extrusion head assembly 2 includes the adjustment of the rigid hard contact seal connection with the gear pump 3 Seat 4, the stepped inner hole of the adjustment seat 4 is equipped with a split body 5, the center of the outer end surface of the split body 5 is equipped with a core mold 7, and the core mold 7 is provided with a positioning platform to ensure that it is The accuracy of the mounting position on the sub-body 5; the outer end surface of the adjustment sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com