Web adhesive foot for wind turbine blade, wind turbine blade and forming method thereof

A wind power blade and molding method technology, applied in the field of web bonding feet, can solve problems such as difficult control of bonding structural adhesives, and achieve the effects of ensuring dimensional consistency, versatility, and process simplicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

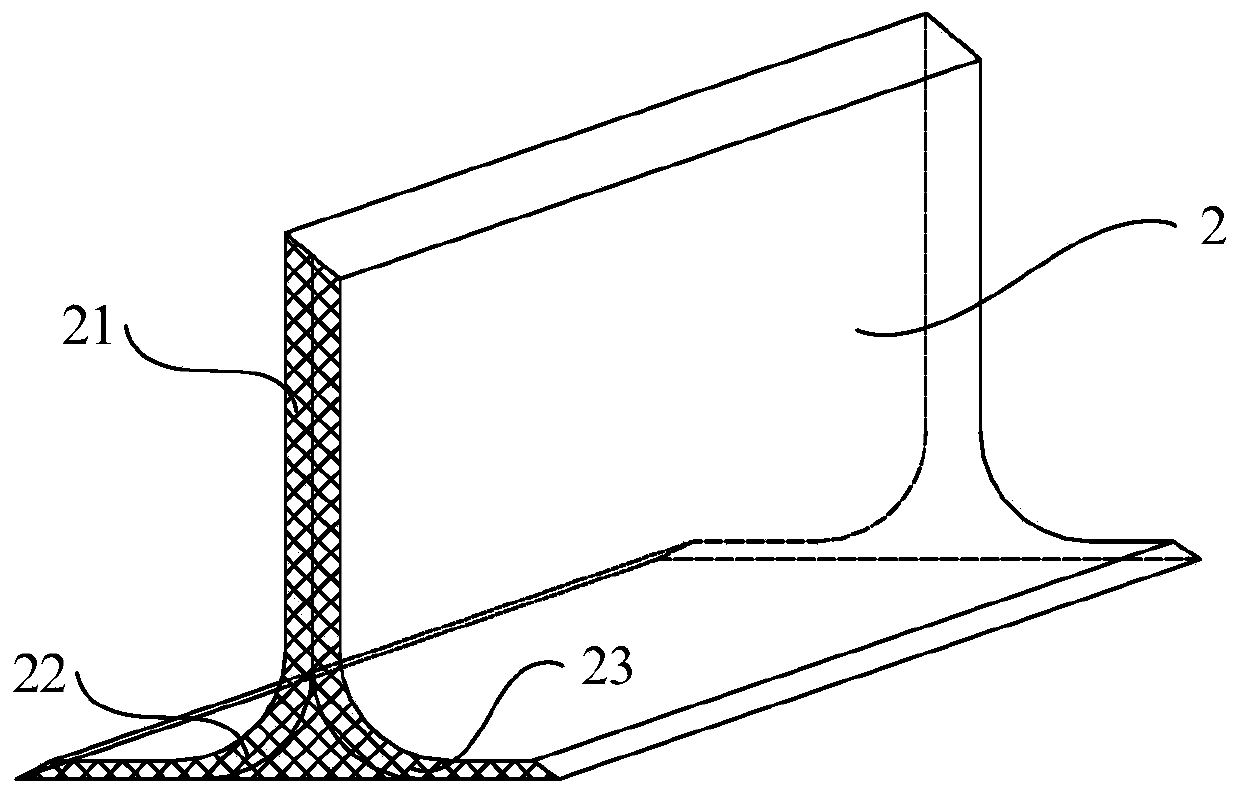

[0044] Such as image 3 As shown, the longitudinal section of the web bonding foot 2 of the present invention is an inverted "T" shape, including a main body 21 and an outer extension 22 and an inner extension 23 connected to the main body 21 .

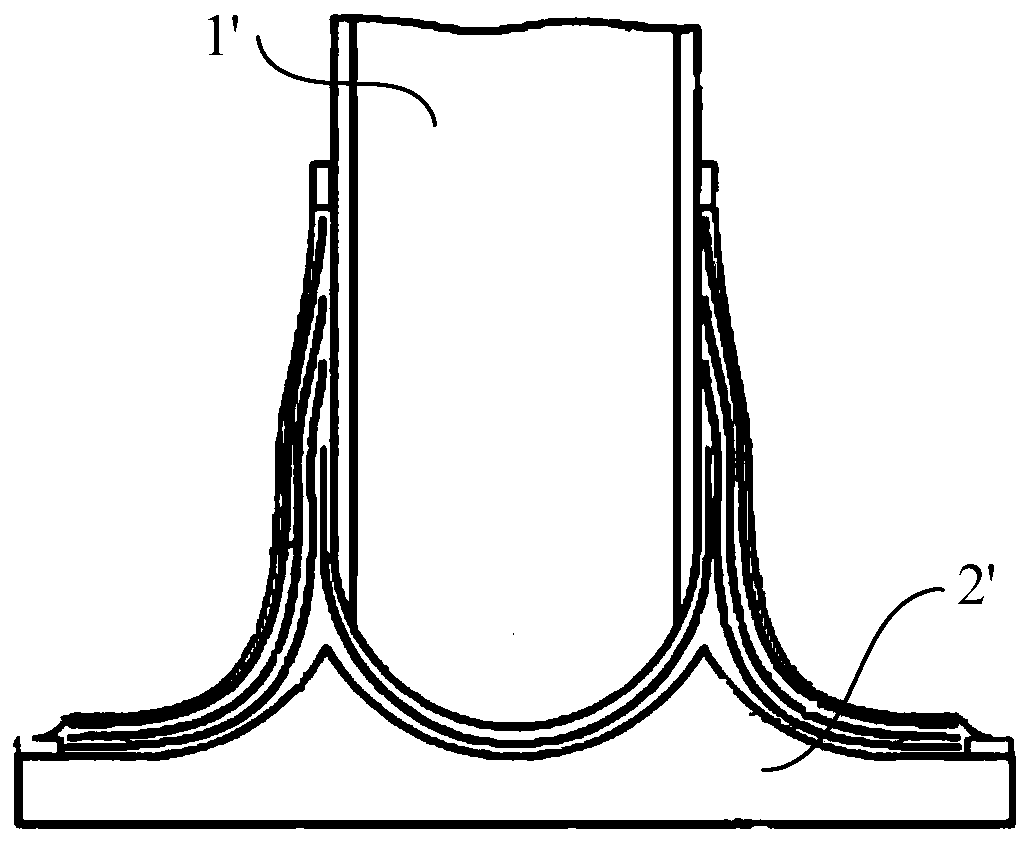

[0045] Such as Figure 2-Figure 4 As shown, the present invention provides a wind power blade, which includes a web plate structure 1, and also includes two web bonding feet 2 connected to the web plate structure 1, and the web plate structure 1 is inserted into the two web bonding feet 2; wherein the longitudinal section of each web bonding foot 2 is an inverted "T" shape, including a main body 21 and an outer extension 22 and an inner extension 23 connected with the main body 21 .

[0046] The invention provides a method for forming a wind power blade, which specifically includes the following steps:

[0047] S1, making the web plate structure 1 through the web mold;

[0048] S2, making the web bonding foot 2, making the web bond...

Embodiment 2

[0055] Such as Figure 5 , Figure 6As shown, the steps of this embodiment are basically the same as those of Embodiment 1, the difference being that step S4 is the following steps: Insert the web plate 1 between the two web bonding feet 2, and glue the two webs together The connecting pin 2 and the web plate structure 1 are poured with resin 5 to form the whole web, lay the web plate structure 1 flat, and lay 2- Three layers of glass fiber cloth 6, two web bonding feet 2 are laid, and clamping tools 7 are used at intervals in the length direction of the web plate structure 1, so that the web bonding feet 2 and the web plate structure 1 are fixed, Vacuumize the laying vacuum system, pour the resin 5 between the web bonding foot 2 and the web plate structure 1 through vacuum infusion, and heat and cure; step S5 is the following steps: pass the whole web and the main shell 3 through the structure Glue 4 bonding, forms blade. As an alternative, other adhesives can also be used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com