Fixing mechanism for brush roller of circuit board grinding machine

A fixing mechanism and plate grinding machine technology, which is applied in the direction of grinding machine tool parts, grinding machines, grinding/polishing equipment, etc., can solve the problem of easy loosening of the fixing mechanism, and achieve the effect of stable operation and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

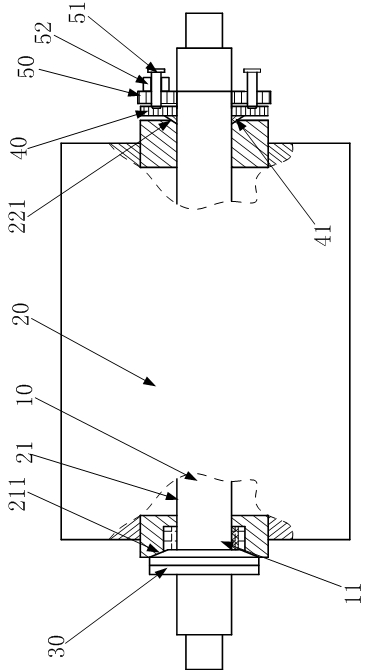

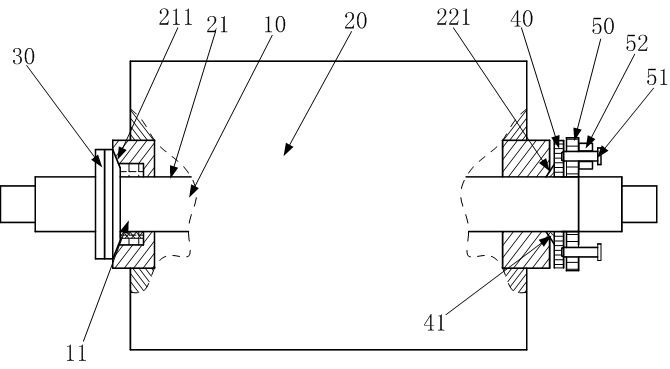

[0007] Specific embodiments of the present invention are described with reference to the above drawings.

[0008] Depend on figure 1 It can be seen from the figure that the fixing mechanism of the brush roller of this circuit board grinder includes a transmission shaft 10, a brush roller 20 sleeved on the transmission shaft 10, the positioning end 11 of the transmission shaft 10 is provided with a positioning cone 30, and the brush roller 20 The positioning end of the middle hole 21 is provided with a first tapered hole 211 that is suitable for the taper of the positioning cone 30, and the fixing mechanism also includes a movable pressure plate 40 that is movably sleeved on the fixed end 12 of the transmission shaft 10 and threaded. The nut pressure plate 50 connected to the fixed end 12 of the transmission shaft 10 , the nut pressure plate 50 presses against the movable pressure plate 40 to compress the brush roller 20 . The traditional brush stick fixing nuts are all thread...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com