Plug self-locking connector

A technology for self-locking connectors and connectors, which is applied in the directions of connections, parts of connecting devices, electrical components, etc., can solve the problems of cumbersome operation and achieve the effect of simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

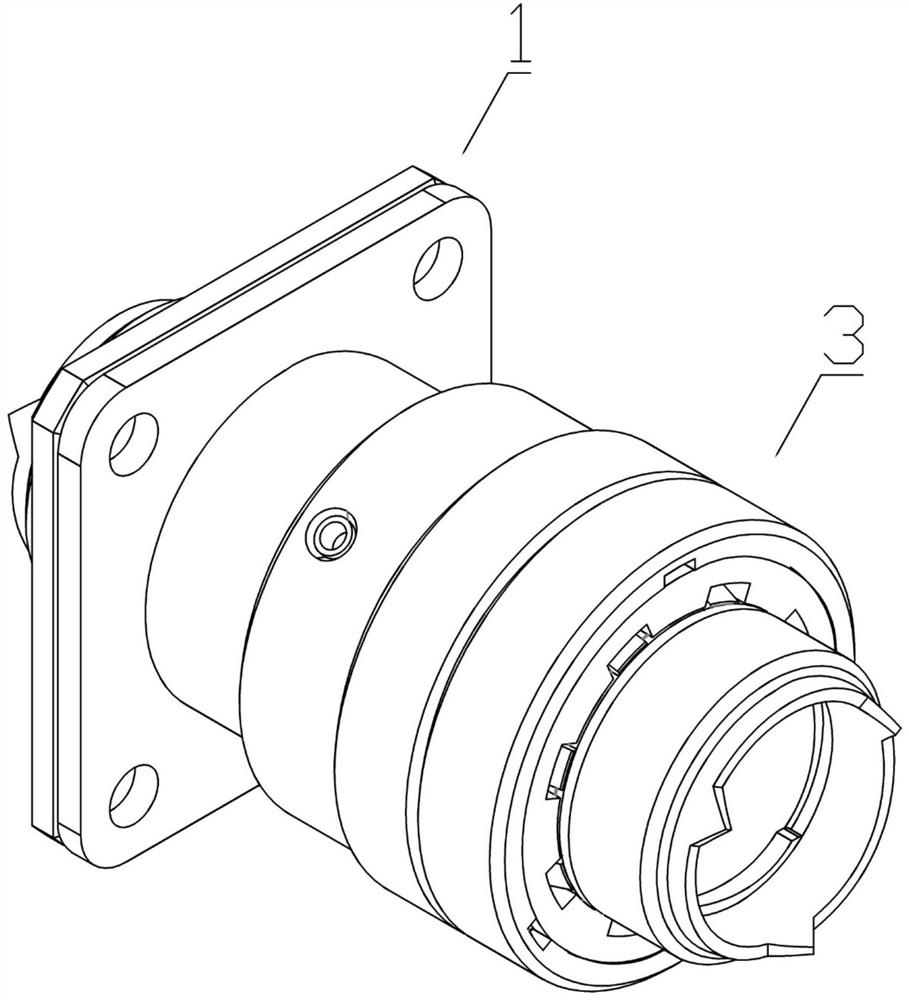

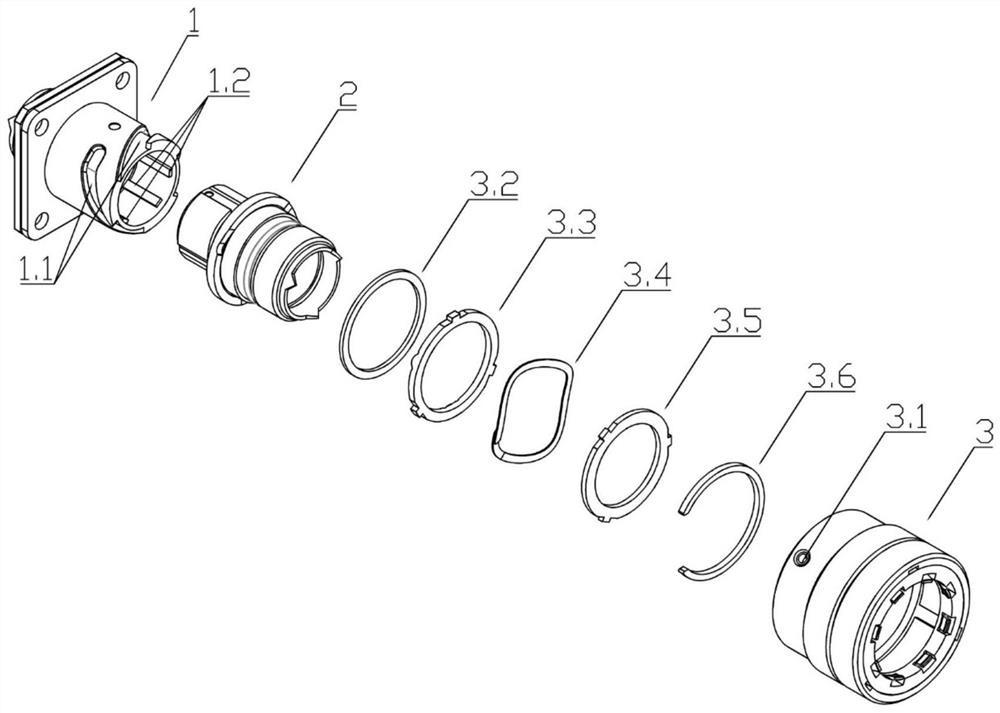

[0041] Such as Figure 1-Figure 11 shown. A plug self-locking connector, including a plug and a socket;

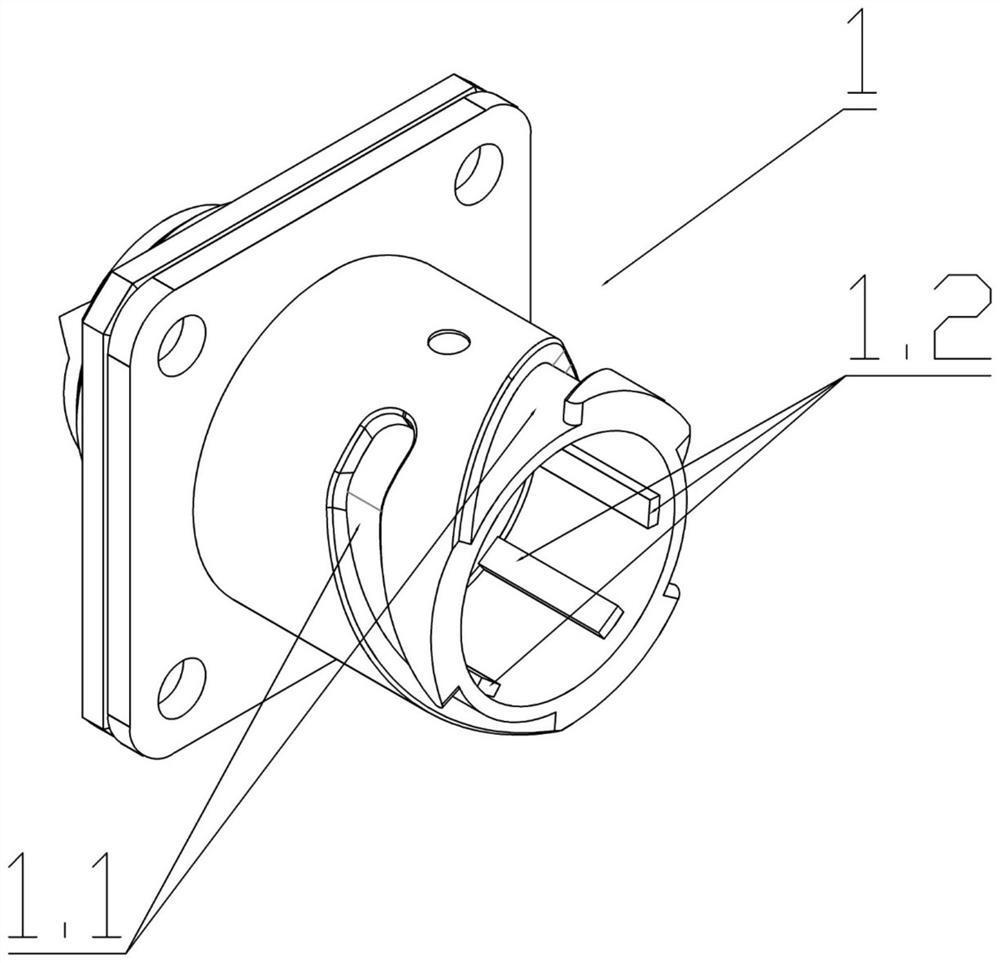

[0042] The socket is a square shell 1. Three curved grooves 1.1 are arranged on the outer wall of the cylinder part where the square disk shell 1 is inserted into the plug, showing a three-curved groove structure. The terminal of the curved groove 1.1 is flat bottom, and the inner wall of the cylinder On the top, there are raised internal splines 1.2, and the internal splines 1.2 are five keys;

[0043] The plug includes a spline housing 2 and a connecting nut 3, the spline housing 2 is in the shape of a hollow shaft, the connecting nut 3 is in a cylindrical shape, and the connecting nut 3 is set outside the spline housing 2;

[0044] The left end of the spline housing 2 is provided with a five-key external keyway, which cooperates with the inner spline 1.2 on the inner wall of the cylinder at the right end of the square housing 1 to form a spline connection. raised dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com