Automobile motor assembly with double rolling bearing structure

A technology of rolling bearings and motor components, which is applied in the direction of electric components, electrical components, electromechanical devices, etc. It can solve the problems of reduced transmission efficiency, damage to the tooth surface of the worm, and warping of the worm shaft, and achieves increased strength, large top diameter, and increased strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

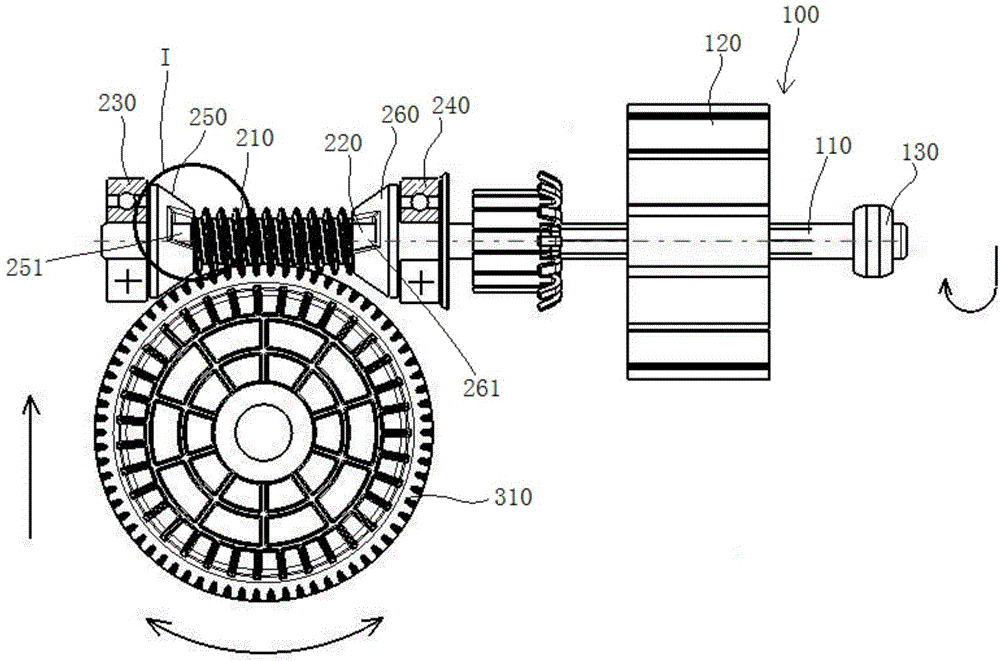

[0027] see figure 1 and figure 2 , the automobile motor assembly with a double rolling bearing mechanism shown in the figure includes: a motor 100, the motor 100 includes a motor output shaft 110 and an electric drive part 120, and the electric drive part 120 drives the output shaft to rotate. One end of the motor output shaft 110 is supported on the motor housing (not shown in the figure) through the oil bearing 130 .

[0028] The automobile motor assembly with a double rolling bearing mechanism also includes a worm 210 , a worm wheel 310 and a reduction body (not shown) for assembling the worm 210 and the worm wheel 310 .

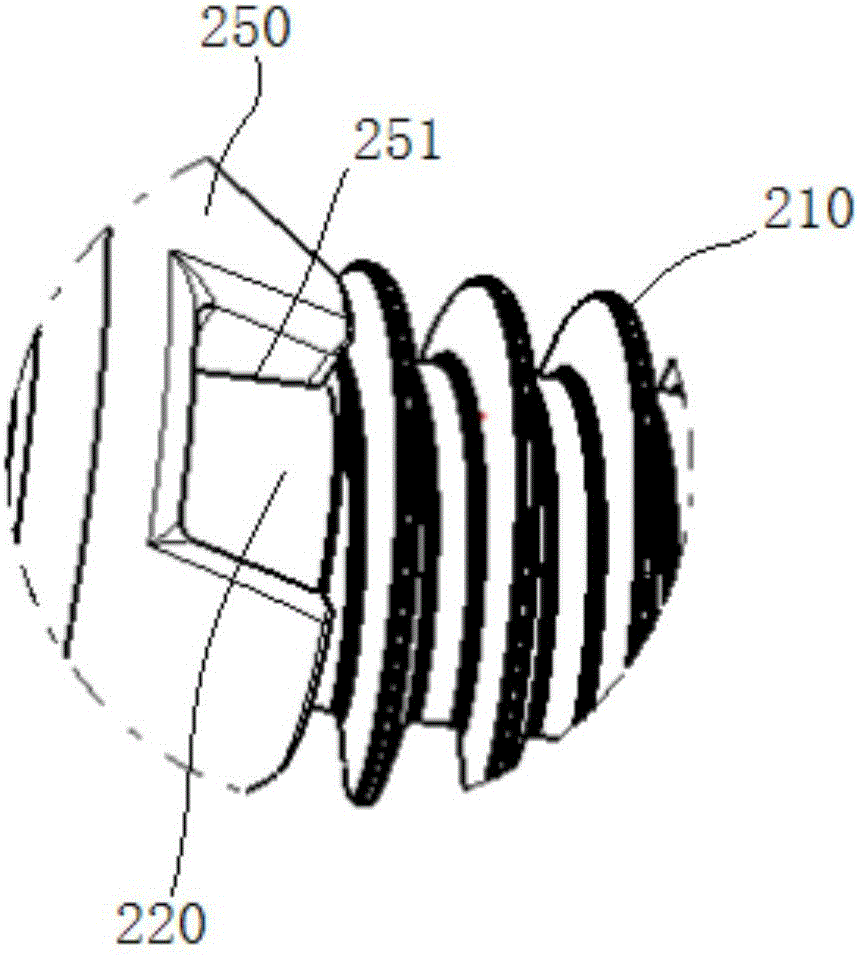

[0029] The worm 210 is installed on the worm end 220 of the output shaft 110 of the motor, and the worm end 220 of the output shaft 110 of the motor is supported in the reduction body through rolling bearings 230 , 240 . On the worm end 220 of the output shaft 110 of the motor, there are also worm elastic positioning taper sleeves 250 , 260 , and each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com