Sealing device for large bearing

A sealing device and bearing technology, which is applied to bearings, bearing components, shafts and bearings, etc., can solve problems such as increased friction torque, reduced service life of oil seals and mechanical devices, and temperature of oil seal wear systems, so as to reduce frictional heat, Good sealing and dust-proof effect, and the effect of preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

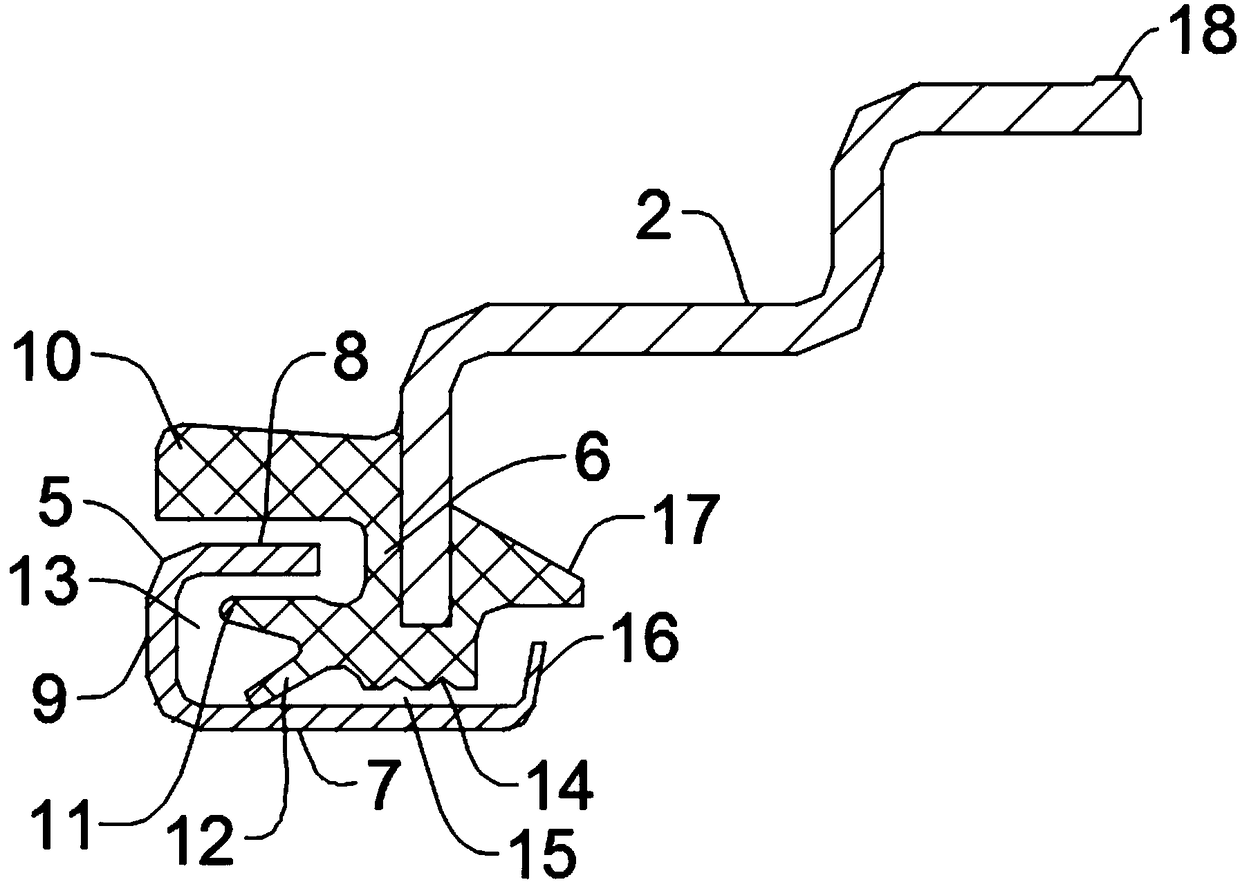

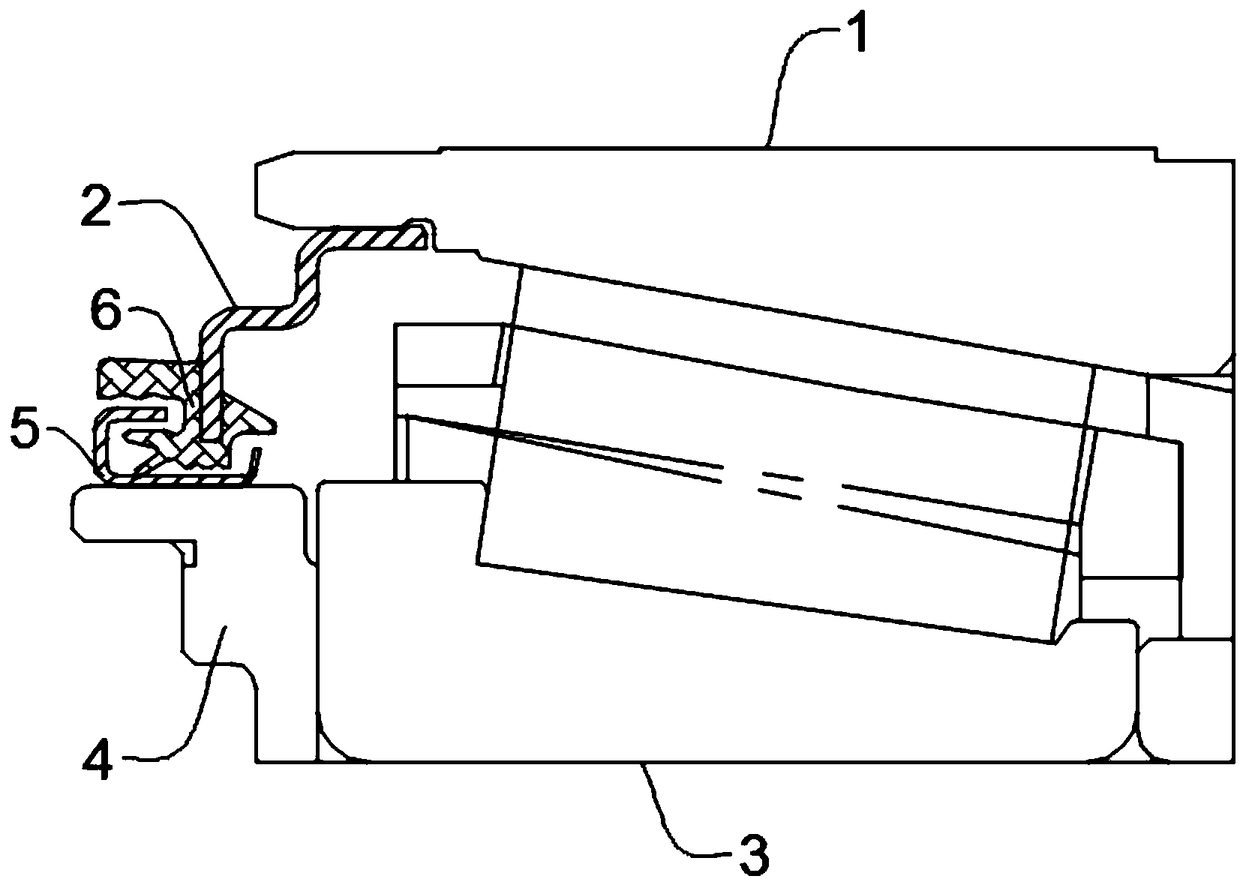

[0027] In one of the examples, as figure 1 , figure 2 As shown, a sealing device for a large bearing includes an outer skeleton 2 fixed on the outer ring 1 of the bearing, an inner skeleton 5 fixed on the sealing seat 4 of the inner ring 3 of the bearing, and an inner skeleton 5 and the outer skeleton 2 arranged between The labyrinth rubber seal 6; the inner skeleton 5 includes an inner skeleton inner ring 7 and an inner skeleton outer ring 8, and the inner skeleton inner ring 7 is fixedly socketed on the outer circumferential surface of the bearing inner ring 3 seal seat 4, The end of the inner frame inner ring 7 that is far away from the bearing inner ring 3 extends outward to form a support ring 9, and the end of the support ring 9 that is far away from the inner frame inner ring 7 extends toward the side close to the bearing inner ring 3 to form the inner frame outer ring 8, and the width of the inner skeleton outer ring 8 is smaller than the width of the inner skeleton ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com