Manual type bearing protection device

A manual technology for protecting bearings, applied in the direction of bearings, shafts, bearings, mechanical equipment, etc., can solve the problems of protecting bearing damage, magnetic bearing system damage, low reliability, etc., achieve stable support, eliminate radial clearance and shaft effect towards the gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

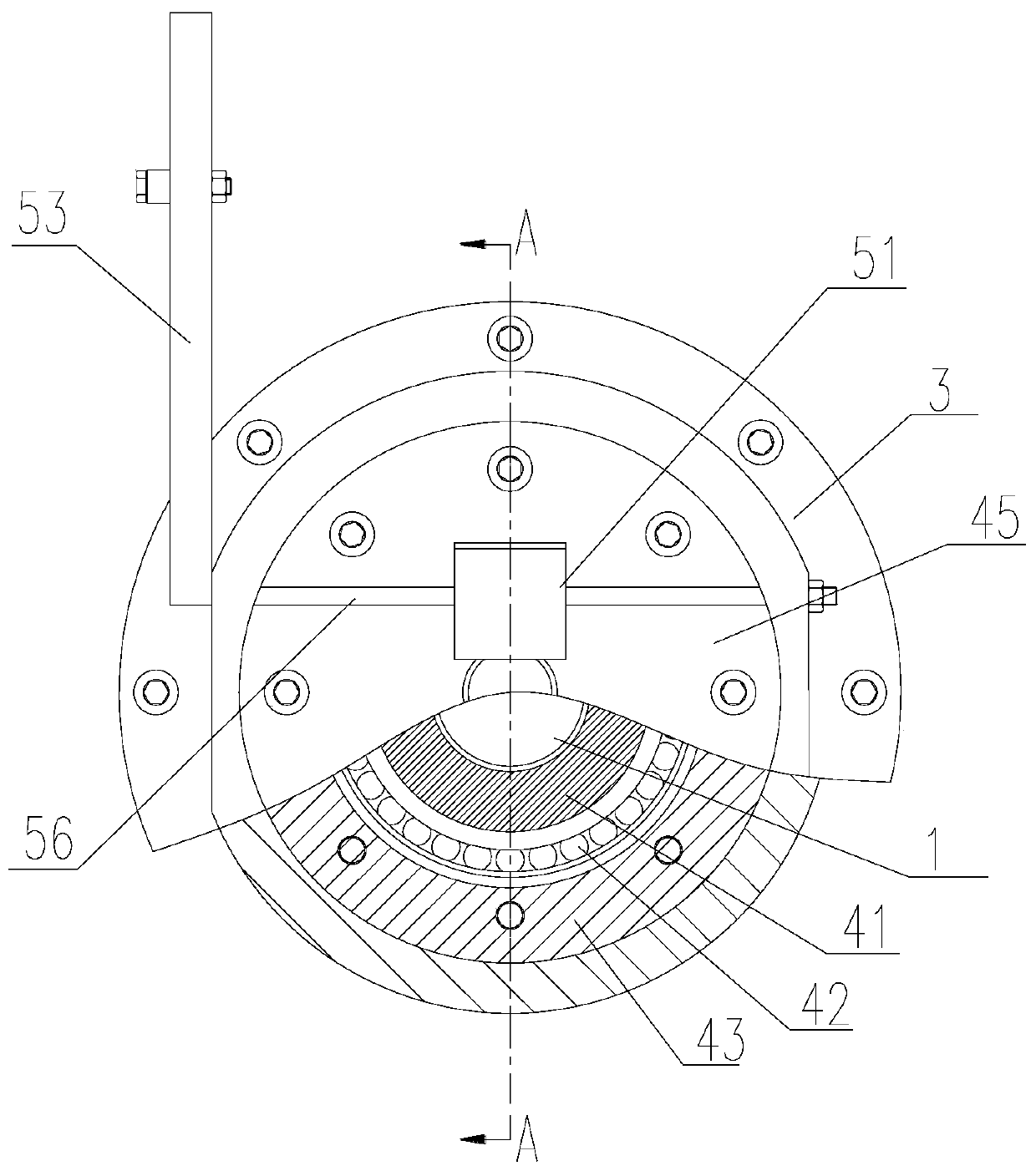

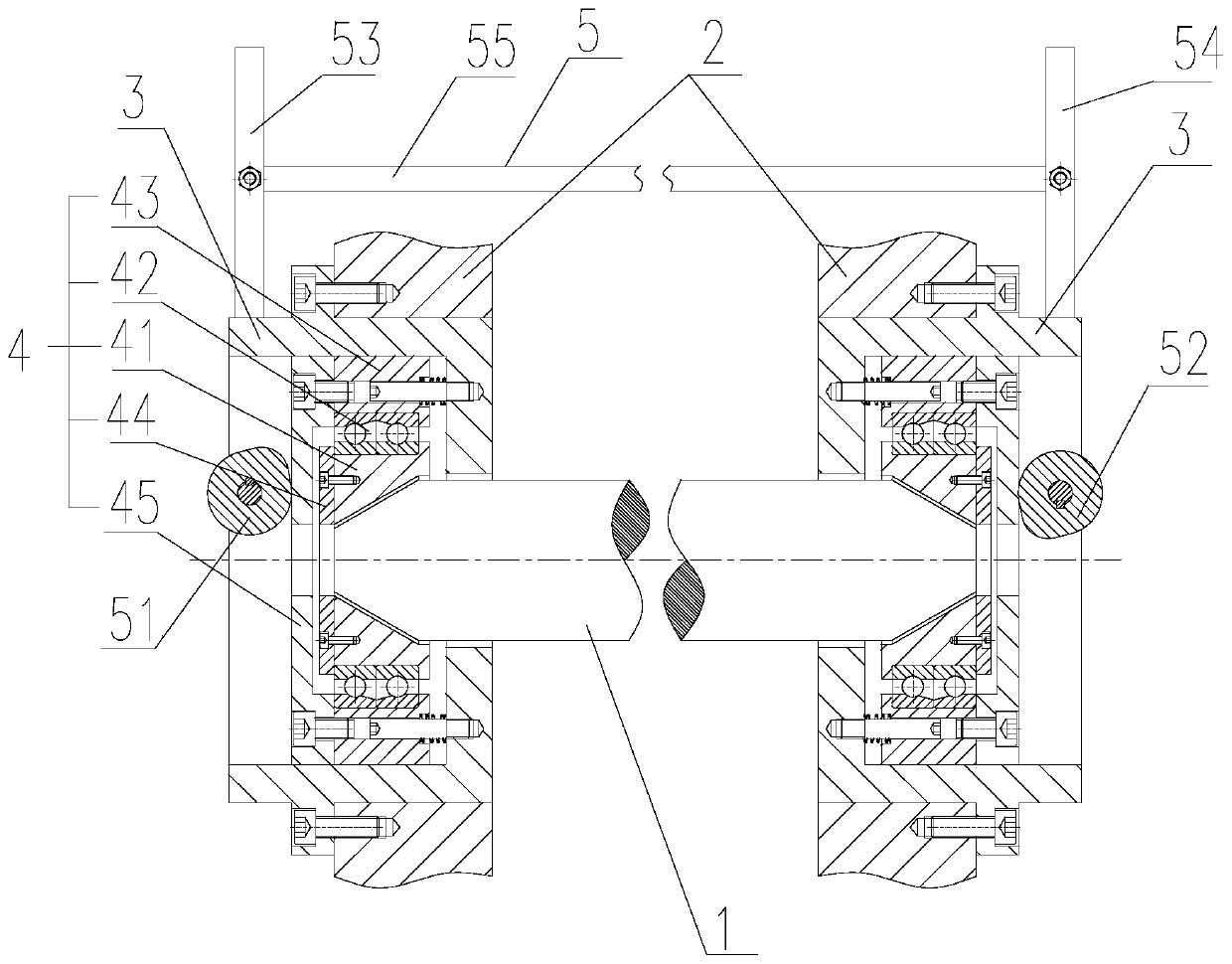

[0024] The content of the present invention will be further described below in conjunction with the accompanying drawings of the specification.

[0025] Such as Figure 1-2 As shown, this embodiment proposes a manual protective bearing device, including: a rotor 1, a bearing seat 3, a protective bearing assembly 4, and a manual drive assembly 5. The two ends of the rotor 1 are in the shape of a truncated cone; there are two bearing seats 3, The protective bearing assembly 4 is fixedly arranged at both ends of the rotor 1. The protective bearing assembly 4 is in two groups, which are respectively arranged in the two bearing housings 3 and can slide along the axis of the bearing housing 3. The protective bearing assembly 4 is provided with the end shape of the rotor 1 Adapted tapered hole; the manual drive assembly 5 drives the protective bearing assembly 4 to approach axially until it contacts the rotor 1. Since the two ends of the rotor 1 are set in the shape of a truncated cone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com