LRM photoelectric radio frequency integrated connector compatible with VPX standard

A technology of radio frequency integration and connectors, which is applied in the direction of connection, two-part connection devices, parts of connection devices, etc. It can solve problems such as connector deformation, heavy weight, and connector mating asynchronously, so as to prevent mating difficulties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

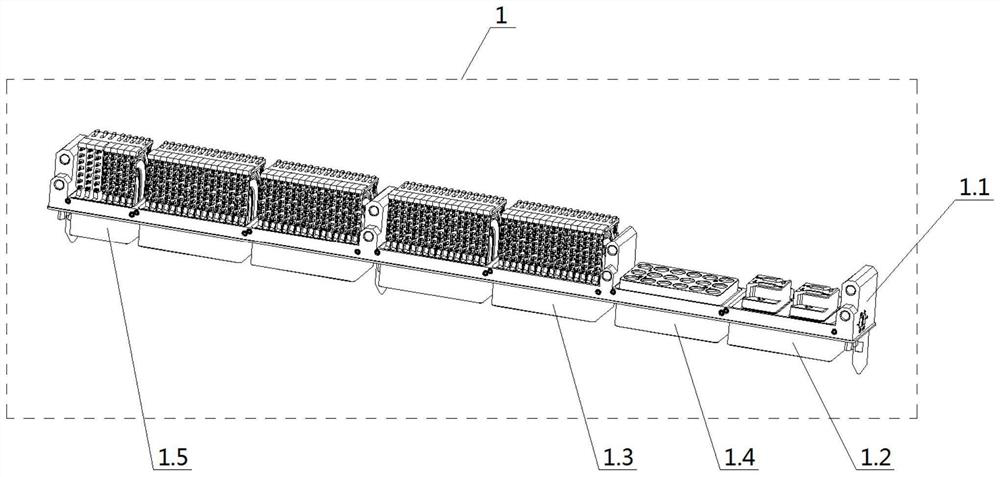

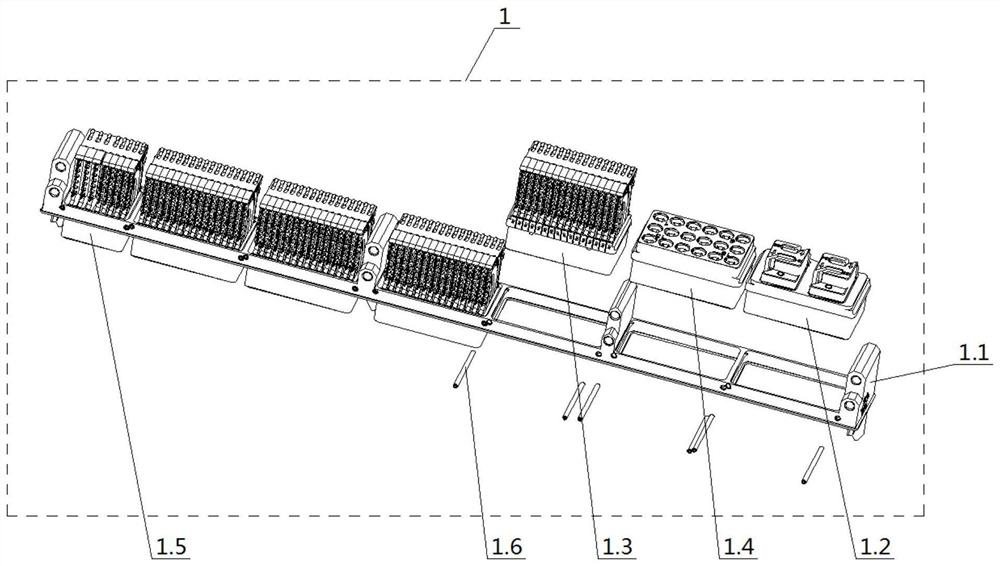

[0067] An LRM photoelectric radio-frequency integrated connector compatible with the VPX standard, comprising a plug 1 and a socket 2; the plug 1 includes a plug housing 1.1, on which an optical fiber plug module 1.2, several high-speed plug modules 1.3, a radio frequency plug module Group 1.4, hybrid plug module 1.5; the socket 2 includes a socket housing 2.1, on which an optical fiber socket module 2.2, a number of high-speed socket modules 2.3, a radio frequency socket module 2.4, and a hybrid socket module 2.5 are fixed; The plug 1 and the socket 2 are mated together to form an LRM photoelectric radio frequency integrated connector compatible with the VPX standard;

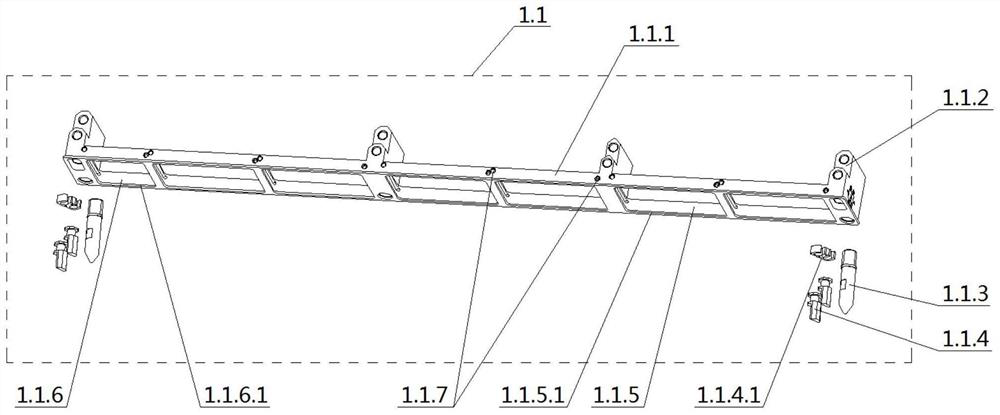

[0068] The plug housing 1.1 includes a plug housing body 1.1.1, which is in the shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com