Double Piece Hobbing Fixture

A gear hobbing fixture and two-piece technology, applied in gear teeth, gear cutting machines, manufacturing tools, etc., can solve the problems of high labor consumption of workers, low processing efficiency, and insufficient rigidity of the fixture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

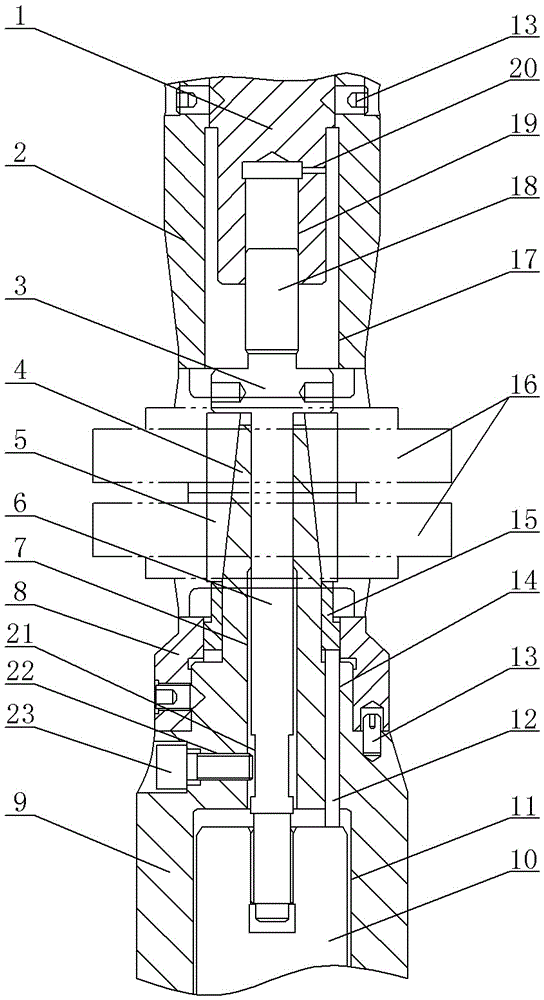

[0020] Below in conjunction with accompanying drawing and embodiment technical solution of the present invention is described in further detail:

[0021] For the convenience of description, the "up" and "down" referred to in the following figure 2 The up and down directions are the same, but it does not limit the structure of the present invention.

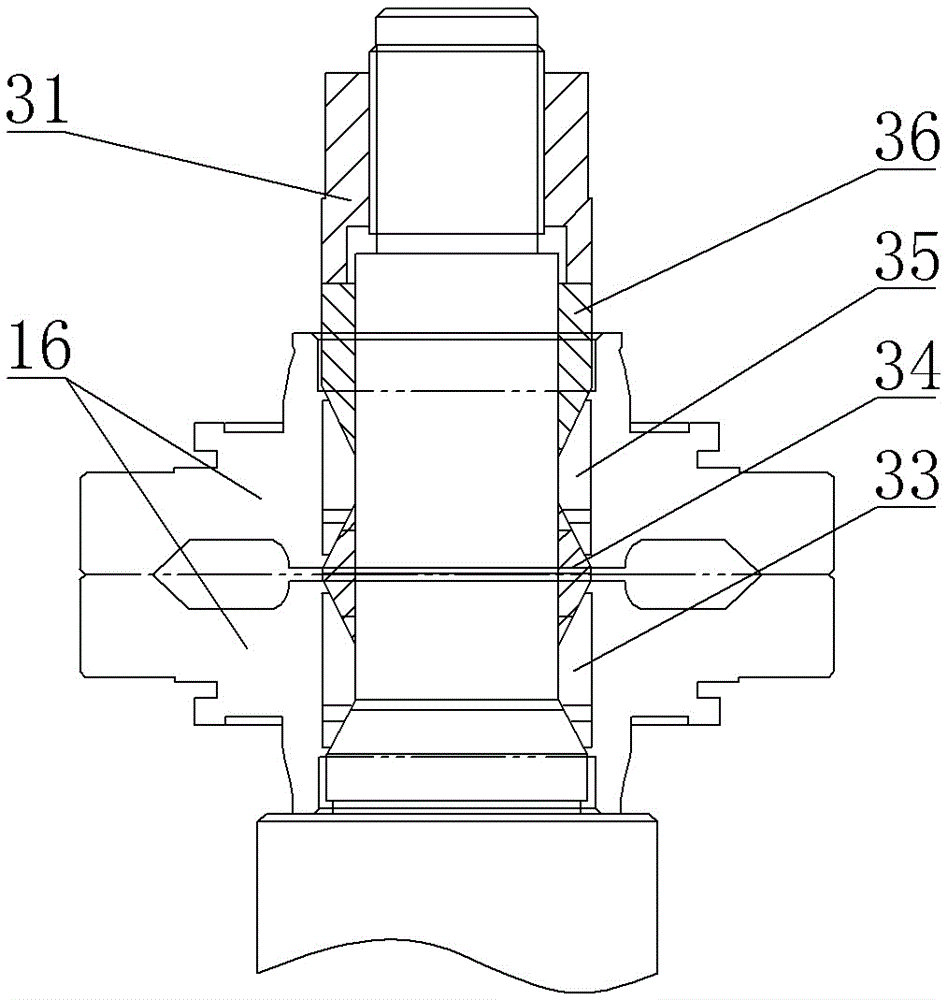

[0022] Such as figure 2 The shown two-piece gear hobbing fixture includes a tapered mandrel, an upper column 1 and a first tie rod 6. The tapered mandrel includes a stepped shaft 9 and a cone 4. The upper end of the stepped shaft 9 is connected to the larger diameter end of the cone 4. And the outer diameters are equal in size, the lower end surface of the tapered mandrel is axially provided with a first through hole 7 and a counterbore 11 for arranging the second pull rod 10, and the centerlines of the first through hole 7 and the counterbore 11 are on the same line; The periphery of the cone 4 is provided with a spring expan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com