A rotating device for axially floating and radially preloading and fixing a rotating body where an inertial element is located

An inertial element and rotating body technology, applied in the field of inertial measurement, can solve the problems of reducing the stability of the rotating body, inability to rotate the modulation technology with errors, and reducing the effective accuracy of the inertial element.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

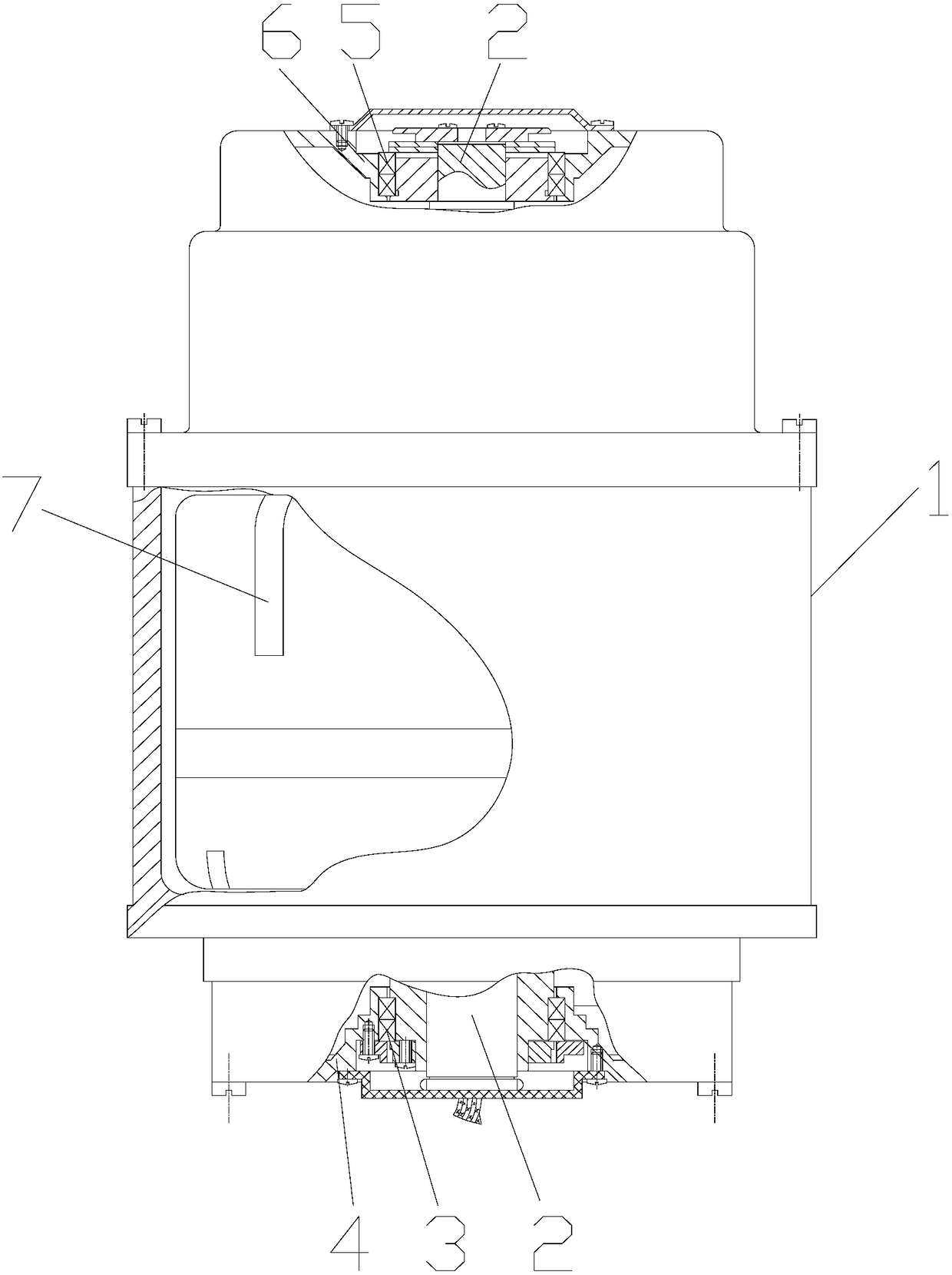

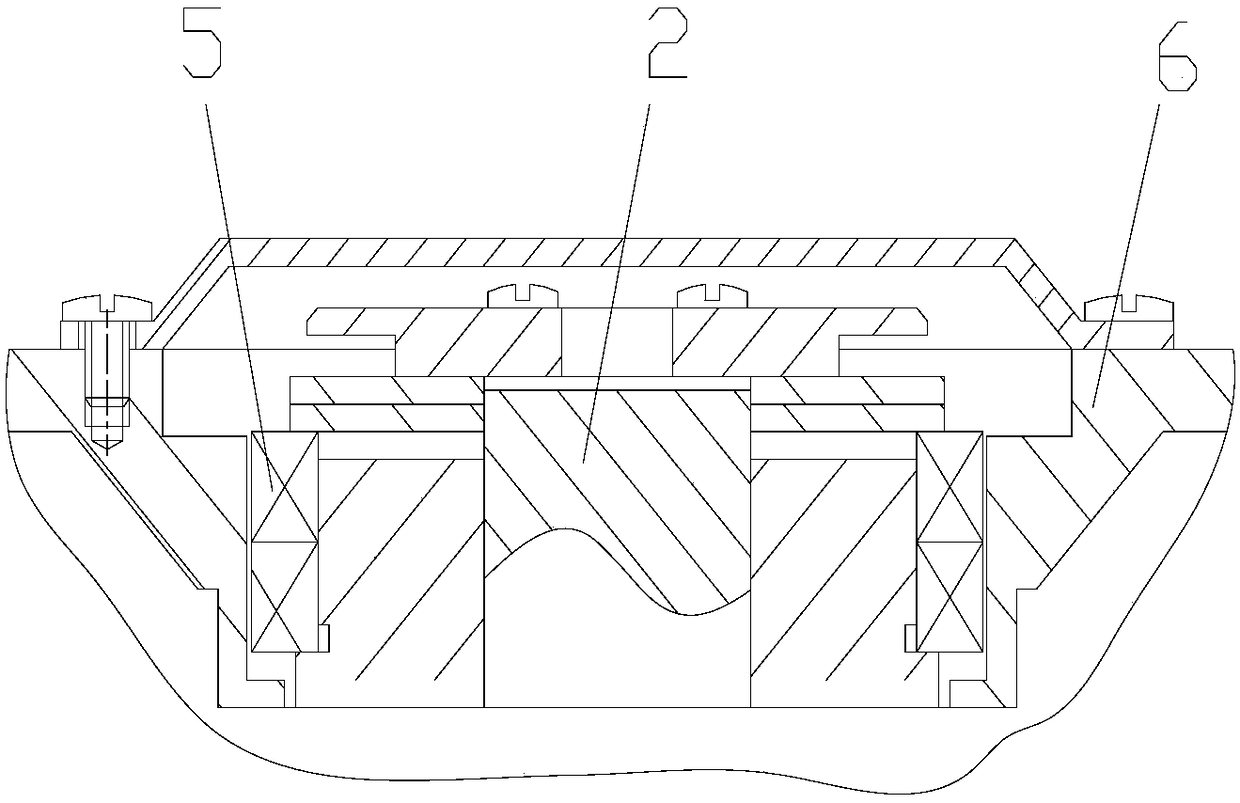

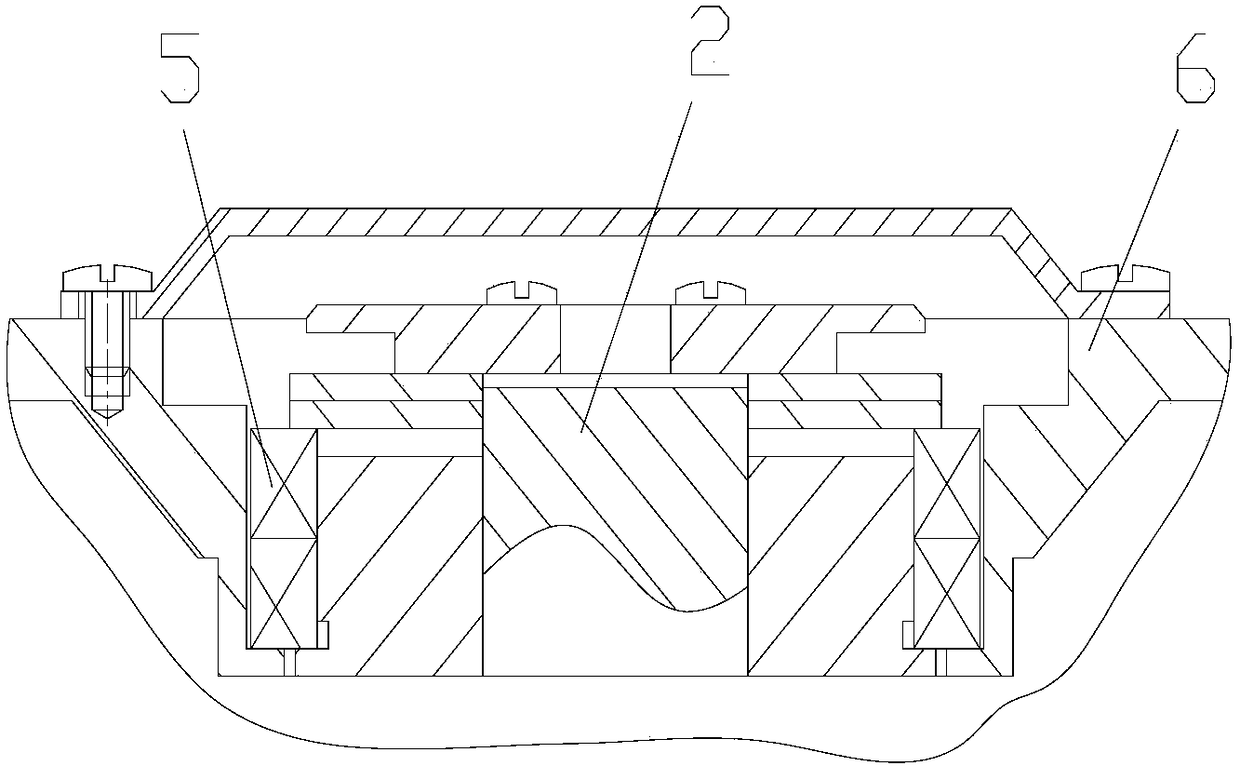

[0016] Attached below Figure 1-4 An embodiment of the present invention is described.

[0017] A device for axially floating, radially pre-tightening and fixing the rotating body where the inertial element is located. It has a non-rotating body 1 and a rotating body 2. The inertial element 7 is installed in the rotating body 2. The lower end of the rotating body 2 is supported by the lower bearing 3 on the On the non-rotating body 1, and the lower bearing 3 is fixed in the lower bearing seat 4, the upper end of the rotating body 2 is supported on the non-rotating body 1 through the upper bearing 5, and when the rotating body 2 is heated or cold, the upper bearing 5 and the upper The bearing seat 6 is floatingly connected, specifically, the outer ring 9 of the upper bearing 5 is in clearance fit with the wall surface of the inner hole of the upper bearing seat 6 , and the upper bearing 5 is fixed on the rotating shaft 8 at the top of the rotating body 2 . At the same time, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com