Coring System for Coring While Drilling

A coring and while-drilling technology, which is applied in the direction of undisturbed core extraction, earthwork drilling, wellbore/well components, etc., can solve the problems of high tripping times, poor core quality, interlayer coring and low efficiency of continuous coring and other issues to achieve the effect of improving efficiency and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

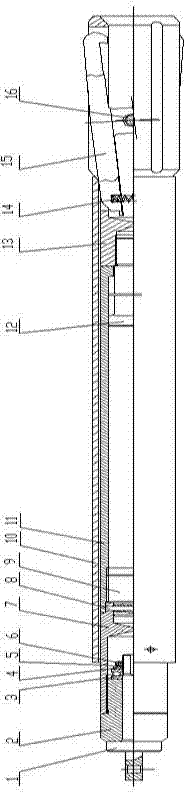

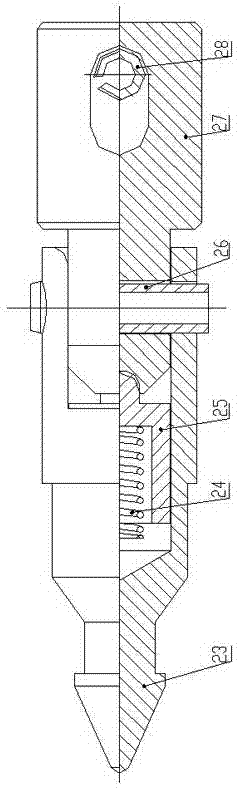

[0044] See attached figure 2 and 7 , the invention discloses a coring system for drilling while drilling. and the adjustment cap; the upper end of the mandrel is fixed in the bearing box through bearings; the lower end of the mandrel is set in the adjustment cap and is threadedly connected with the adjustment cap, and the lower end of the mandrel in the adjustment cap is provided with a single-flow valve seat and a plum blossom baffle and a brake ring, the brake ring is fixed by a pressure cap, and a steel ball is arranged on the single-flow valve seat; the adjustment cap is connected with the elastic locking mechanism.

[0045] In this example, the salvage mechanism and the latching mechanism used are prior art well known to those skilled in the art, and it is sufficient to directly combine the rotating mechanism of this example with the existing fishing mechanism and the latching mechanism.

Embodiment 2

[0047] As a preferred embodiment of the present invention, the present invention also includes that the bearing is placed at the step provided at the upper end of the mandrel, and a half ring is set on the outer side of the bearing close to the upper end of the mandrel, and an axial steel wire retaining ring is set on the half ring . The plum blossom baffle is fixed on the inner step of the lower end of the mandrel by welding, the single-flow valve seat is screwed into the lower end of the mandrel and welded; the pressure cap one is threaded with the mandrel, and the brake ring is connected with the mandrel through the keyway fit , the brake ring is located between the pressure cap and the adjustment cap. The upper end of the adjustment cap is provided with a notch to cooperate with the protrusion on the brake ring. Described bullet card mechanism comprises recovery tube, bullet caliper, bullet card seat, bullet card frame and hanging ring joint, and bullet card mechanism is ...

Embodiment 3

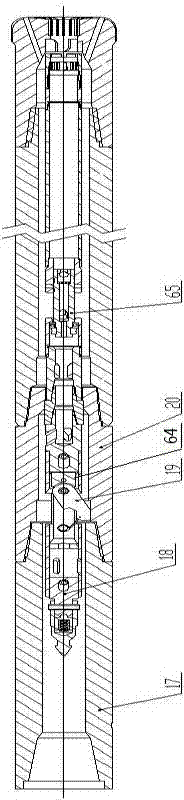

[0055] As the best implementation mode of the present invention, refer to the appended Figure 1-7 , the invention discloses a coring system while drilling:

[0056] 1. Its structure is composed of:

[0057] Refer to the attached Figure 1-7 , which includes a fishing mechanism, a card mechanism, a core bushing rod assembly and a core bushing bit (drilling) or a rotating mechanism (during coring).

[0058] 1. Salvage mechanism:

[0059] The salvage mechanism includes a fishing barrel and a fishing head 41, and the fishing barrel is provided with a lifting ring 1, a card removal sleeve 10, a sleeve 11, a pull rod 12, a fishing hook frame 13 and a fishing hook 15; between the lifting ring 1 and the sleeve 11 There are pressure cap 2, thrust bearing 3, spacer 4, stop washer 5, transition joint 7, safety pin 8 and shear pin joint 9, stop washer 5 is fixed by nut 6, between fishing hook 15 and fishing hook frame 13 Elastic cylindrical pin-16 is arranged between;

[0060] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com