Patents

Literature

32results about How to "Reduce total space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

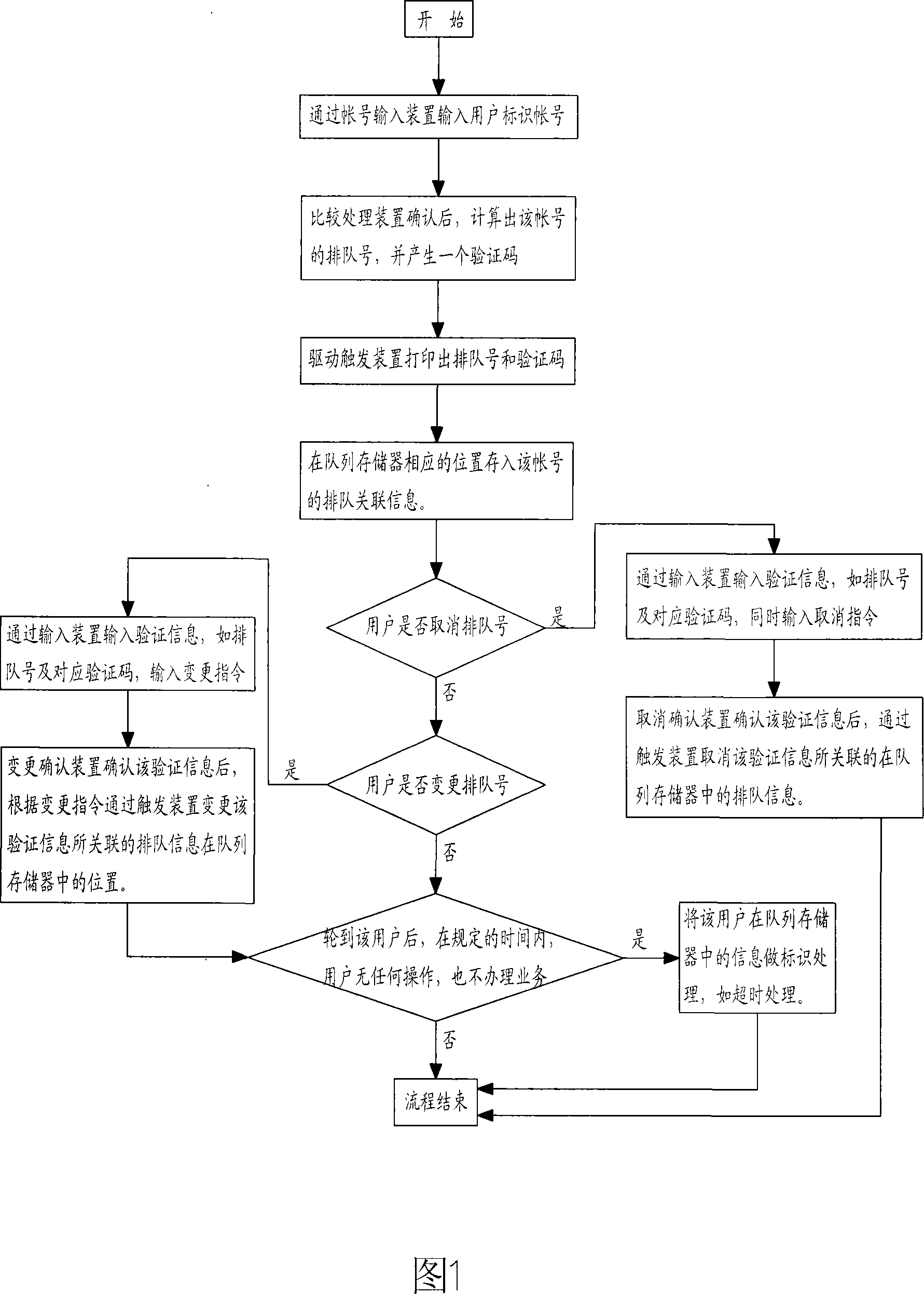

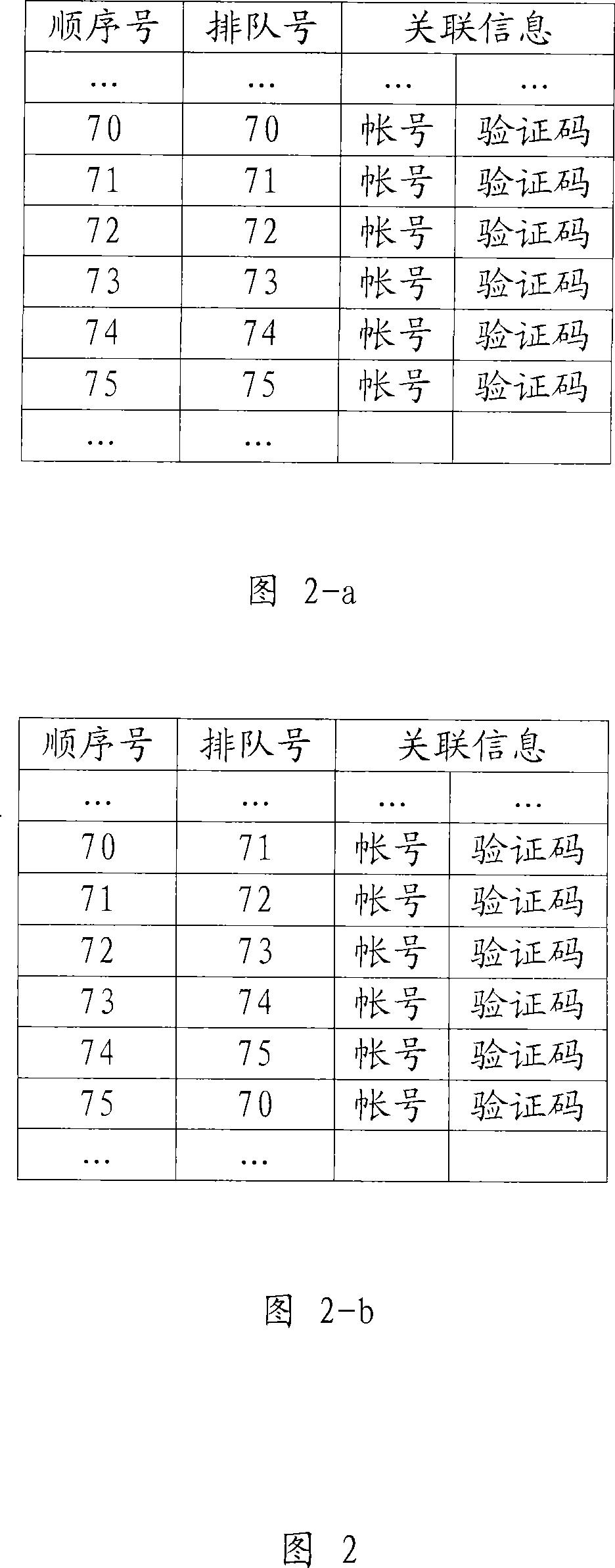

Queuing method

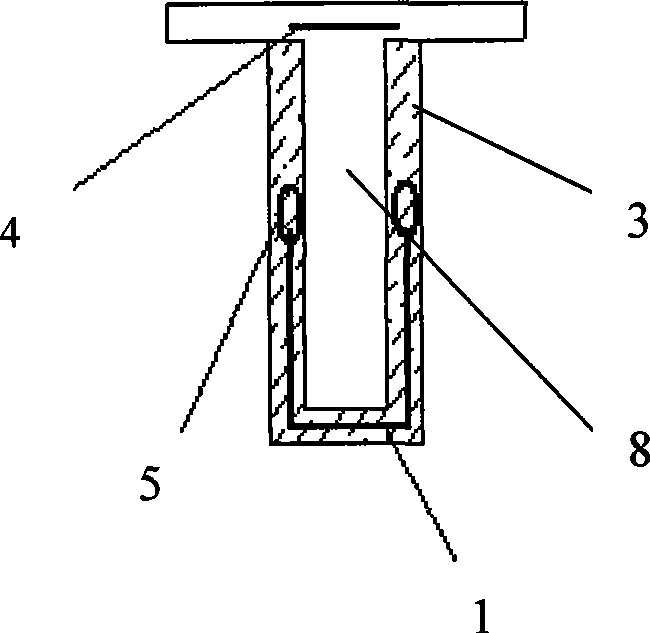

InactiveCN101241613APrevent number takingReduce total spaceFinanceChecking apparatusUser needsComputer science

The present invention relates to a time register, especially a queuing method, which is used in various location needing queuing such as hospital, bank etc. The invention has advantages in that a queuing method is provides, a marking accounts according with user's identity or operation identity is used as basis to acquire queuing number, each user needing queuing number obtains a severe limited queuing number, so a maliciousness or mischievous acquiring number can be avoided, and the queuing efficiency can be increased greatly. In addition, the invention also provides a method for canceling and changing queuing number, thus the queuing user can cancel or change queuing number according with need, and can further reduce dead number generated by subjective reason or objective reason of the queuing user.

Owner:郑志豪

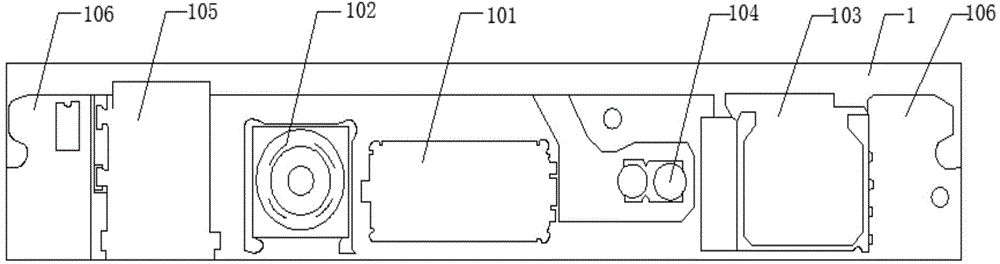

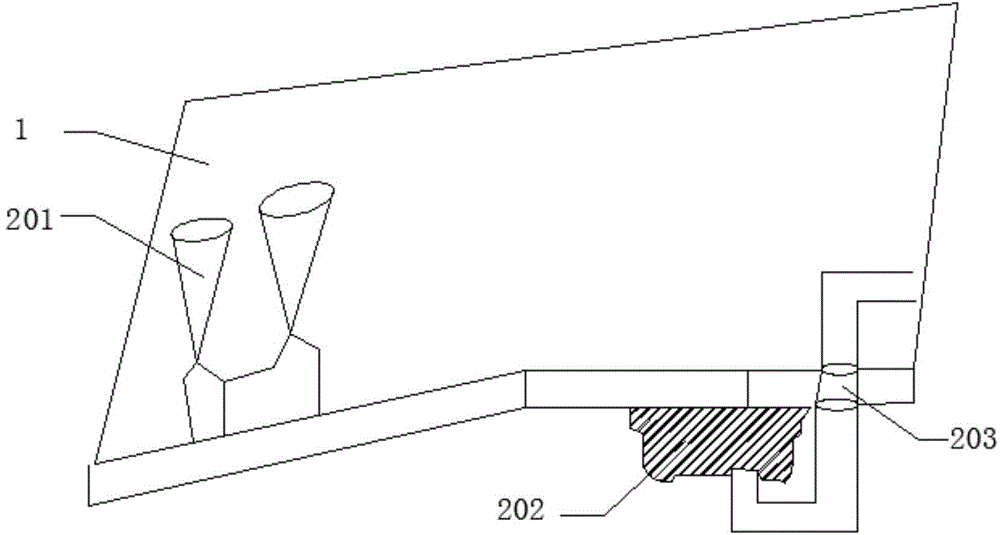

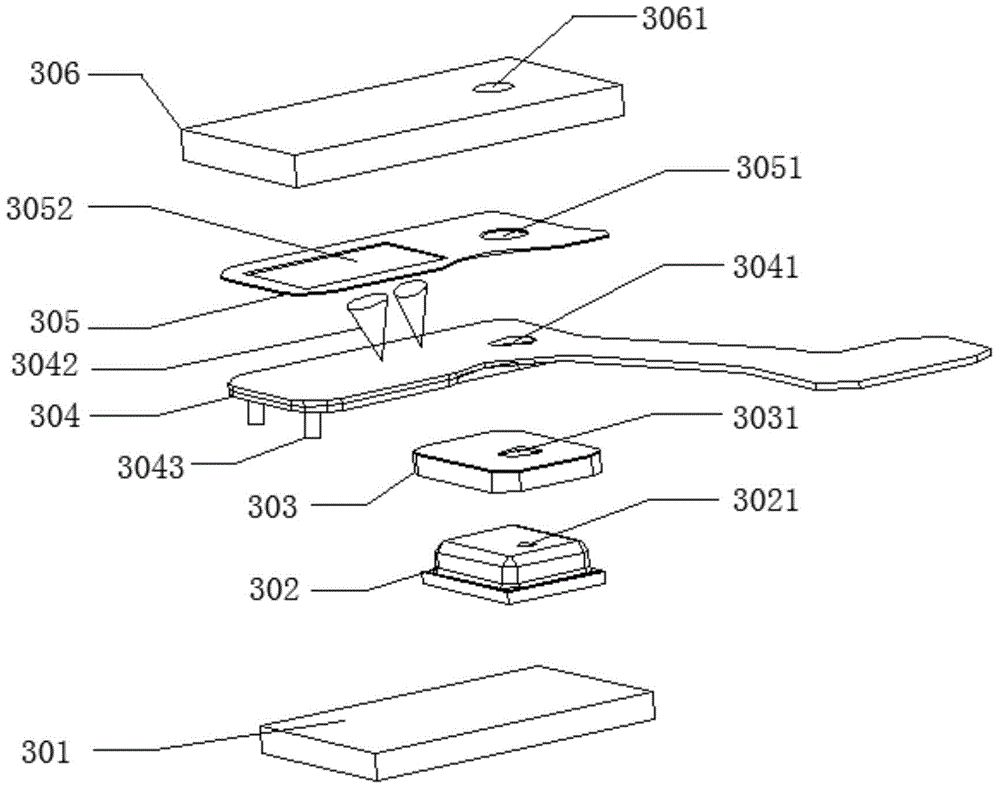

Internal space-optimized mobile phone

ActiveCN104821972AIncrease profitSimplified sound cavity seal channelTelephone set constructionsLight sensingEngineering

The embodiment of the invention discloses an internal space-optimized mobile phone. The internal space-optimized mobile phone includes a printed circuit board (PCB), an auxiliary microphone (MIC), sealing foam, an flexible printed circuit (FPC), an adhesive layer and a shell, wherein the auxiliary MIC is arranged at the front surface of the PCB and is provided with a first sound incoming hole, the sealing foam is arranged at the front surface of the auxiliary MIC and is provided with a second sound incoming hole which is corresponding to the first sound incoming hole, the FPC is arranged at the upper side of the auxiliary MIC through the sealing foam and is provided with a third sound incoming hole and a light sensing device, the adhesive layer is provided with a fourth sound incoming hole which is aligned with the third incoming hole, and the back surface of the FPC is bonded on the shell through the adhesive layer. According to the internal space-optimized mobile phone, the utilization rate of the internal space of the mobile phone is increased, and a cavity sealing channel of the auxiliary MIC of the mobile phone can be simplified.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

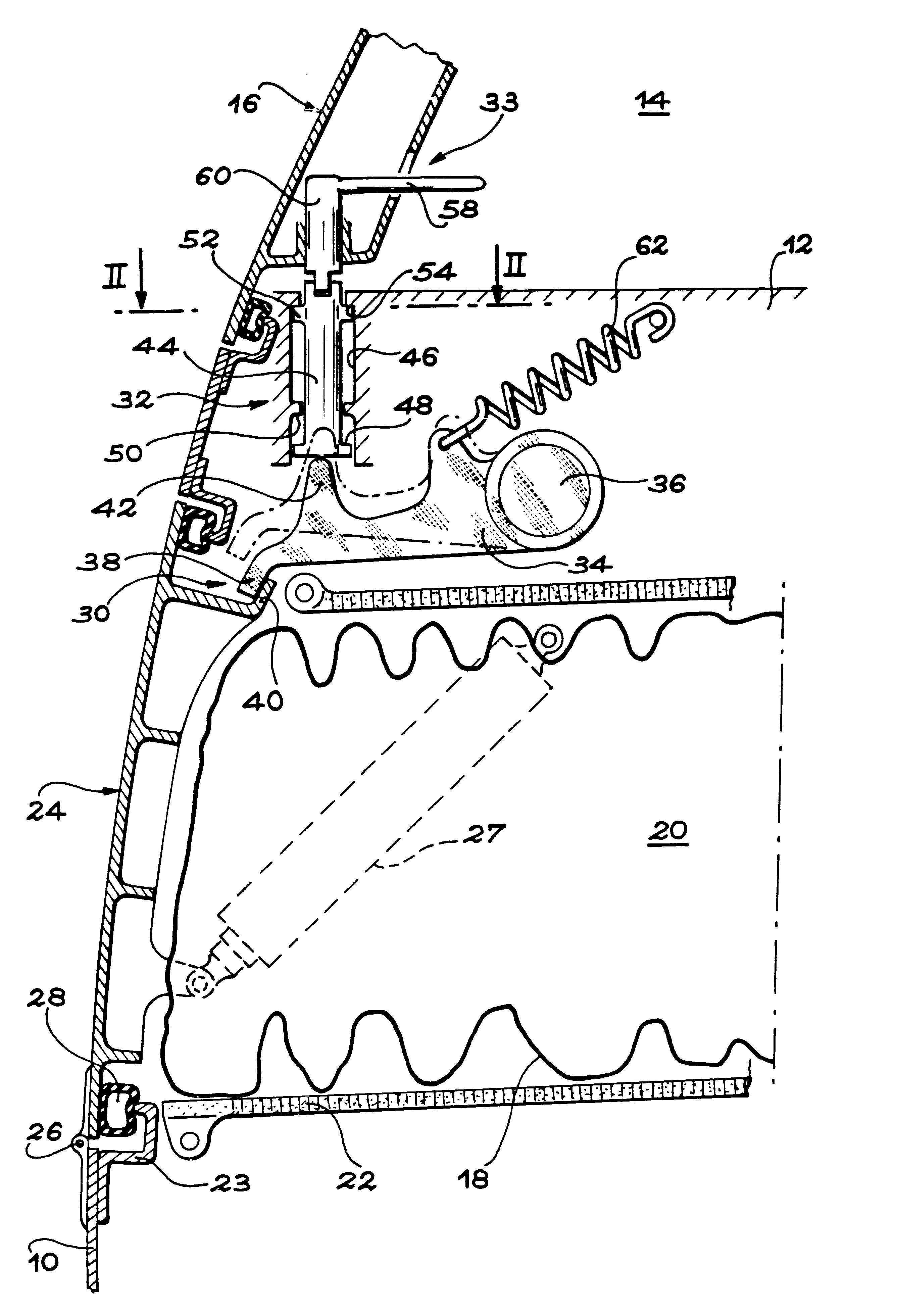

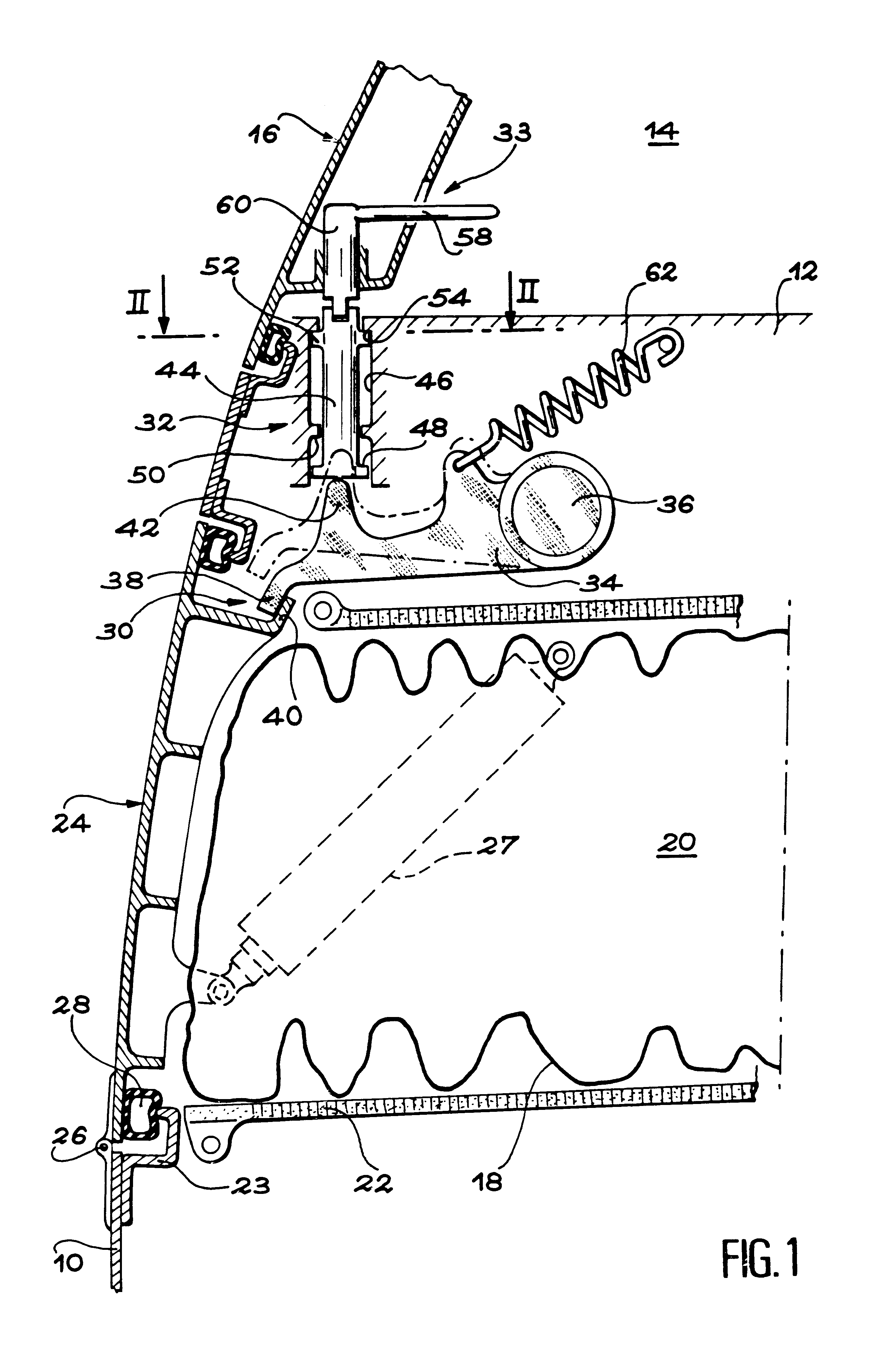

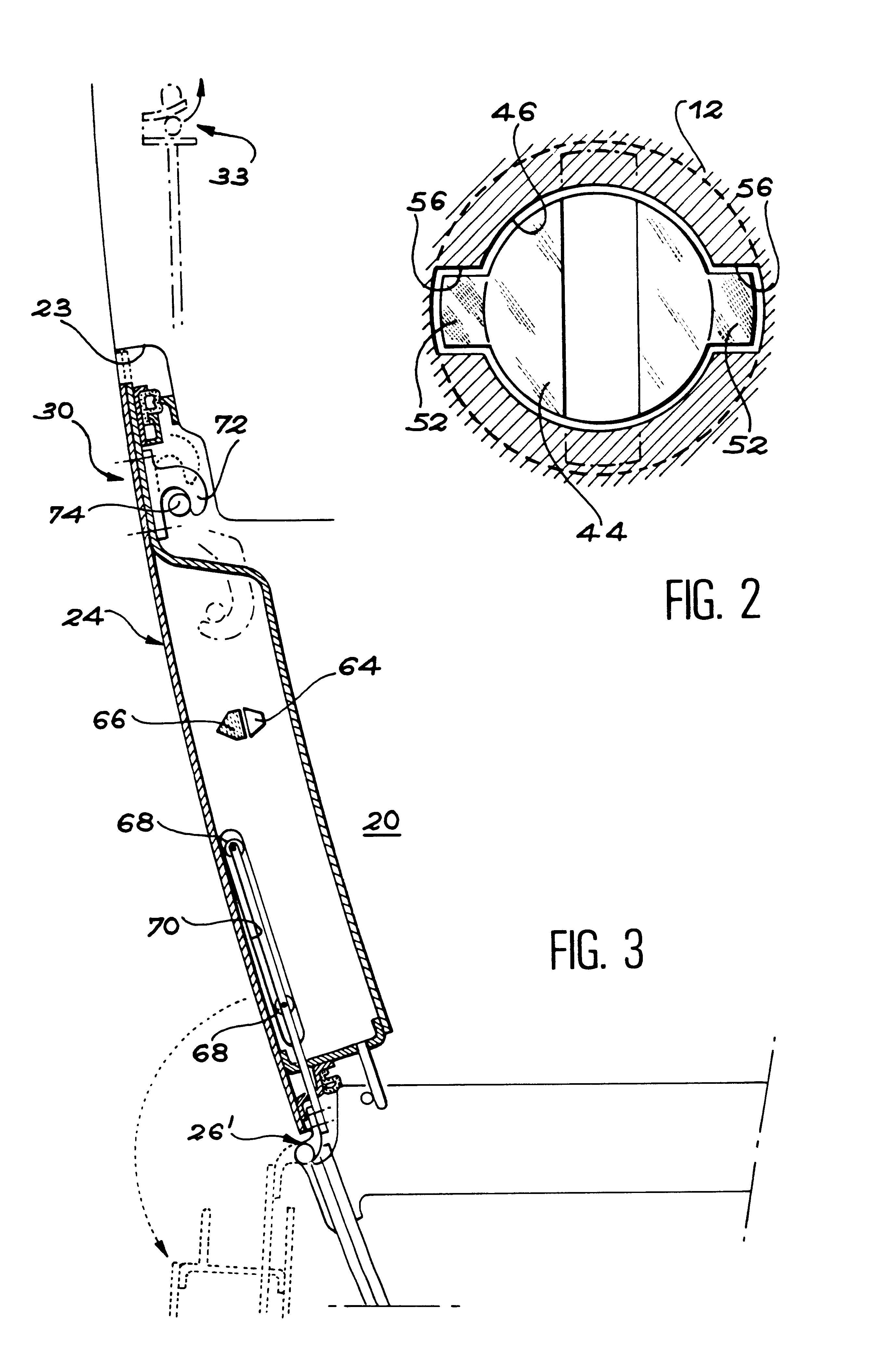

Fast evacuation device for aircraft

InactiveUS6761337B2Reduce excess spaceSimplify doorAircraft ejection meansAircraft controlNacelleFlight vehicle

Fast evacuation device for an aircraft.An inflatable slide (18) is placed in a housing (20) close to an access door (16) to a cabin (14) of an aircraft. More precisely, the housing (20) is located in a pressurised area of the aircraft but outside the wall delimiting the cabin (14). Thus, there is no constraint for delimiting the housing (20) on the inside of the aircraft. On the outside, the housing (20) is closed by a hatch (24) capable of resisting the pressure. A lock (30) normally keeps the hatch (24) fixed in the closed position. A mechanism (32) connects this lock (30) to the door (16) when the slide arming system (33) is armed. Opening the door (16) then unlocks the hatch (24) that is then opened due to inflation of the slide (18).

Owner:AIRBUS OPERATIONS (SAS)

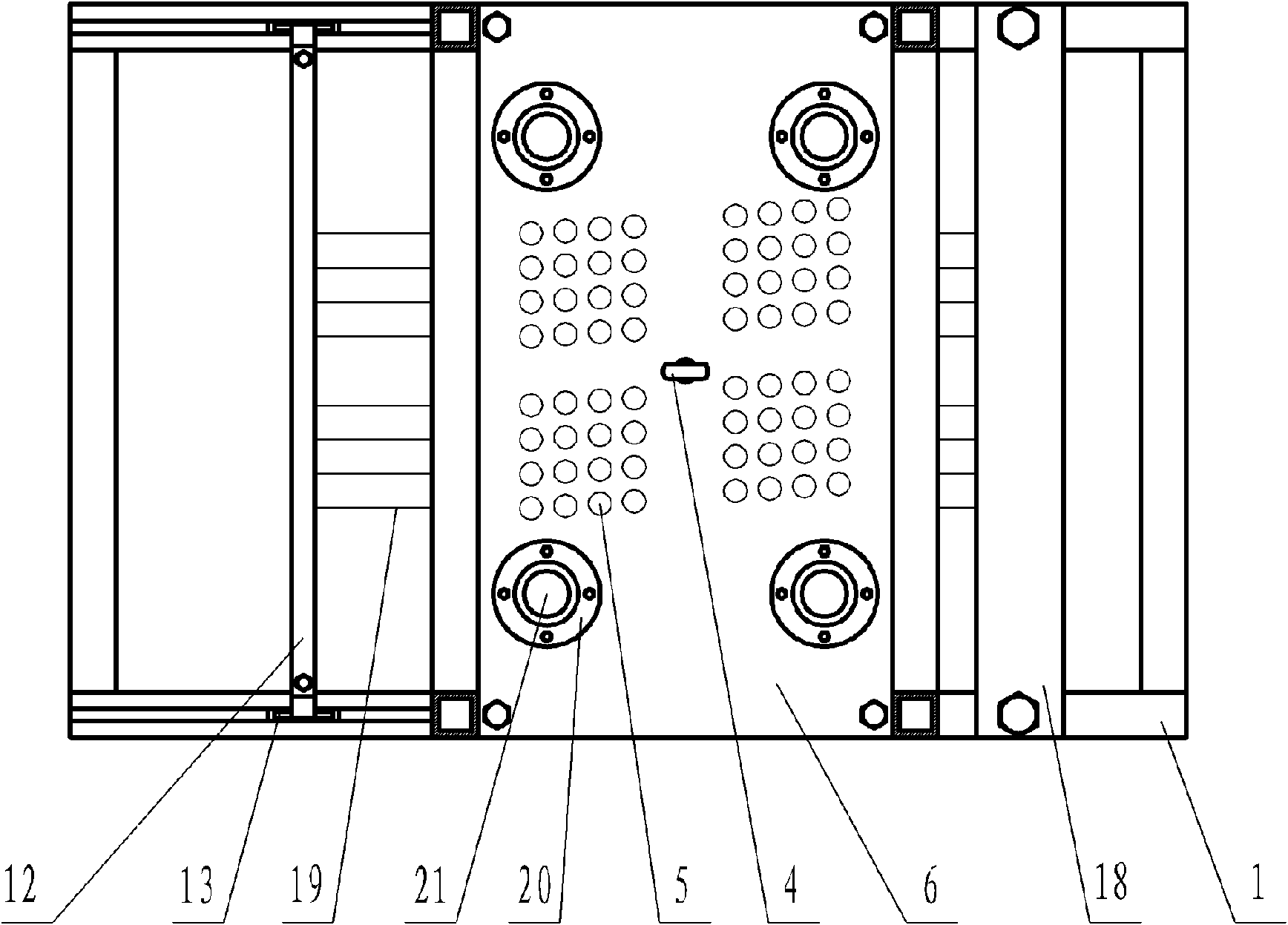

LRM photoelectric radio frequency integrated connector compatible with VPX standard

ActiveCN111969376AEliminate radial playEliminate axial playIncorrect coupling preventionTwo-part coupling devicesRadio frequencyMechanical engineering

The invention provides an LRM photoelectric radio frequency integrated connector compatible with VPX standard. The LRM photoelectric radio frequency integrated connector comprises a plug and a socket,wherein the plug comprises a plug shell provided with an optical fiber plug module, a plurality of high-speed plug modules, a radio frequency plug module and a mixed plug module, the socket comprisesa socket shell fixedly provided with an optical fiber socket module, a plurality of high-speed socket modules, a radio frequency socket module and a mixed socket module, and the plug and the socket are matched and inserted to form the LRM photoelectric radio frequency integrated connector compatible with the VPX standard. According to the invention, different types of connectors meeting the VPX standard requirements are integrated on the same connector shell, and through structural optimization design, the connector has the advantages of being small in occupied total space, light in weight, highly uniform in connector installation height and accurate in connector relative position, the reliability of signal transmission between components or systems meeting the VPX standard is guaranteed,and the increasingly complex and precise signal connection requirements between hardware components and systems compatible with the VPX standard are met.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

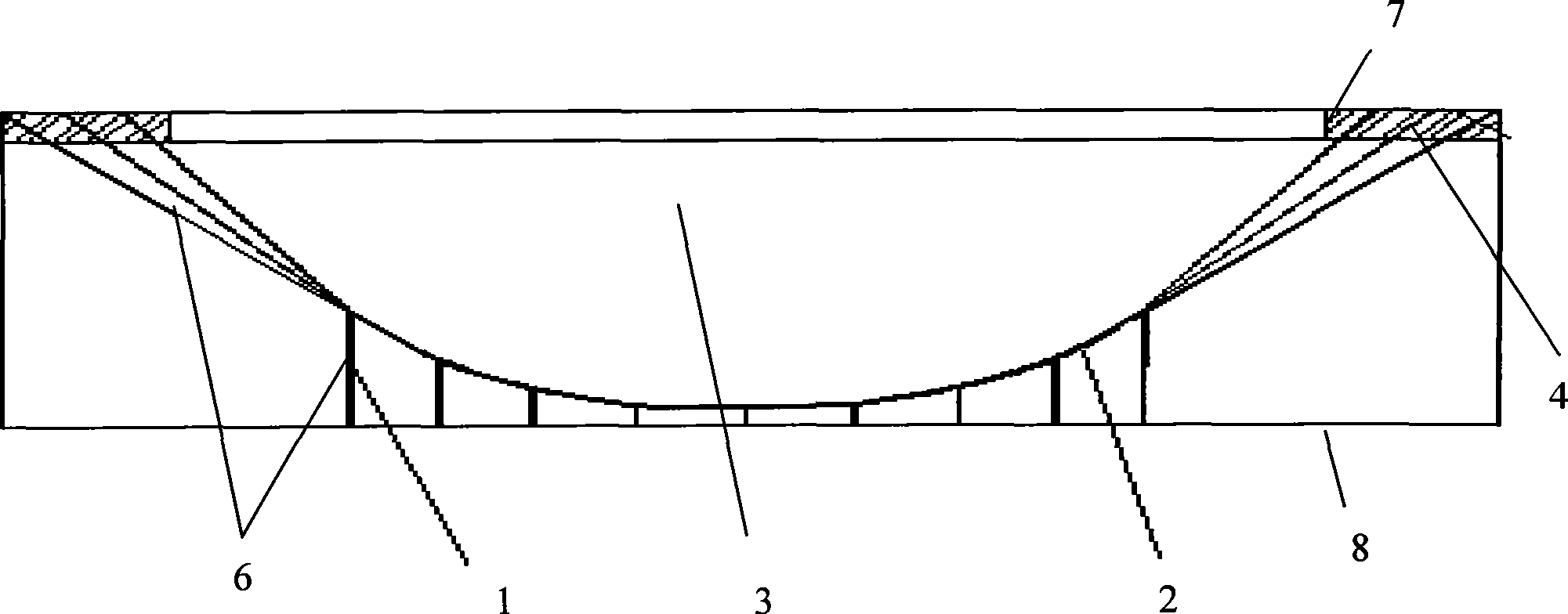

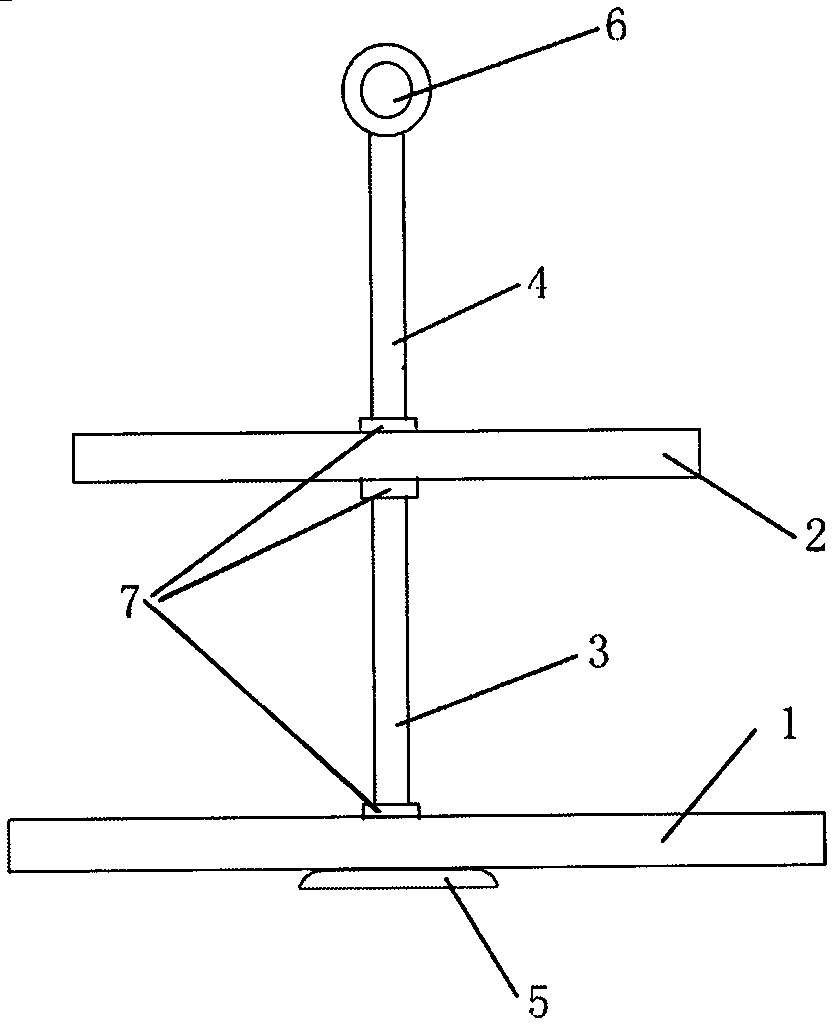

Beam strengthening method

InactiveCN101532277APlay a protective effectReduce slackBridge erection/assemblyBridge strengtheningMesh reinforcementEngineering

The invention relates to a beam strengthening method. The method comprises the following steps: firstly, chiseling a beam top anchorage groove on the top surface of a beam end, obliquely boring along the direction of two sides of a beam rib, and paving a positioning groove for fixing a prestressed steel wire buddle and a positioning tension sleeve along a beam web; mounting an anchorage plate; polishing the lateral surfaces and a bottom surface of a beam, and roughening a strengthening surface; mounting the steel wire buddle and the tension sleeve, namely arranging the positioning tension sleeve in the positioning groove of the positioning tension sleeve, threading the steel wire buddle from the anchorage plate at one end of the beam, placing the steel wire buddle into the positioning groove, then threading out the steel wire buddle from the anchorage plate at the other end of the beam, tightening the steel wire buddle and temporarily fixing the steel wire buddle by a rolling anchorage head; tensioning the steel wire buddle by using a tensioning jack or a winch at one end of the steel wire buddle, anchoring the steel wire buddle when reaching a design value, and then casting and sealing the wire buddle by concrete; implanting a pin into a beam body; after positioning and setting out a reinforcing steel bar on the beam body, binding reinforcement mats on the surface of the beam, and partially spot-welding the reinforcement mats; painting an interface agent; and plastering composite mortar. The method is active, ultra-strong and durable, can well overcome the main defects of the prior strengthening technology, and has strong effectiveness and economy.

Owner:JIANGSU TRANSPORTATION RES INST CO LTD

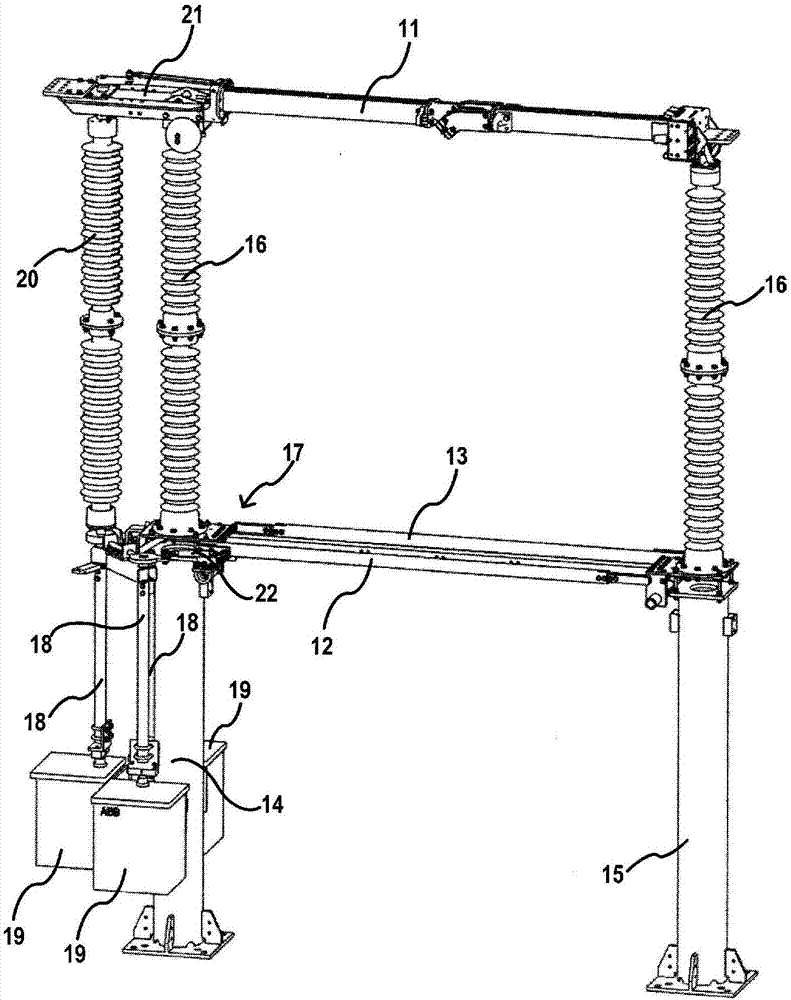

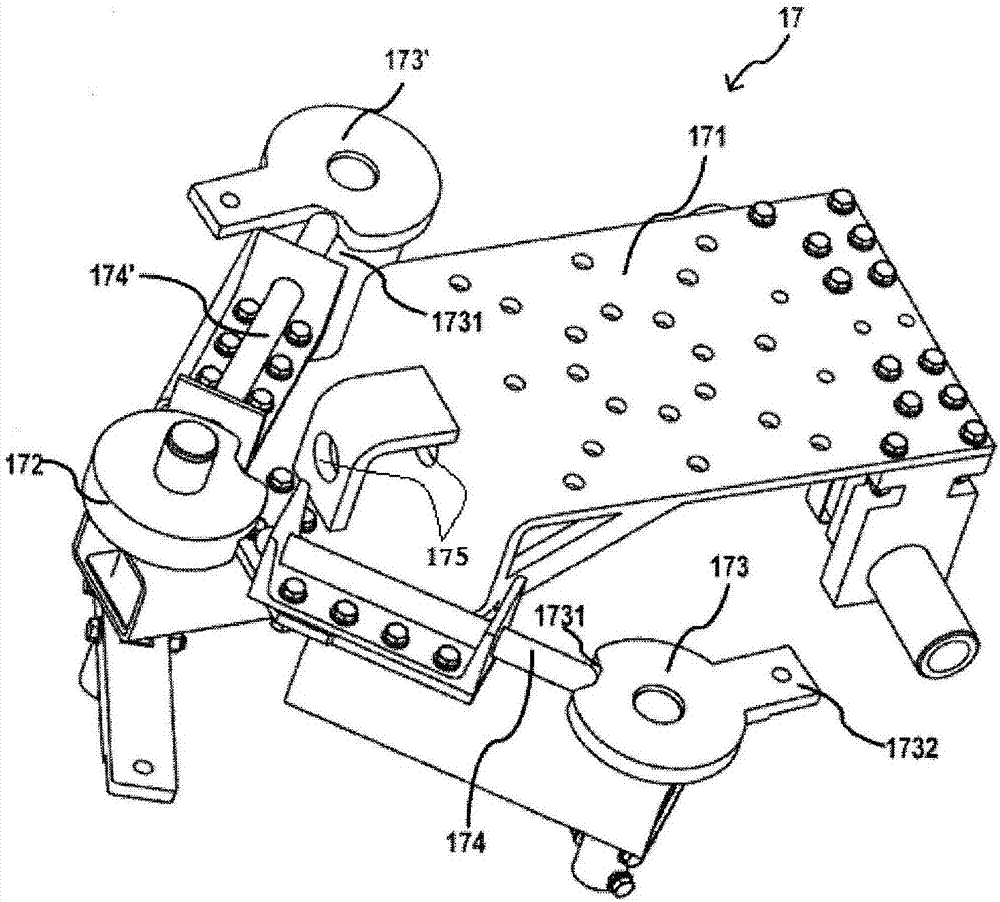

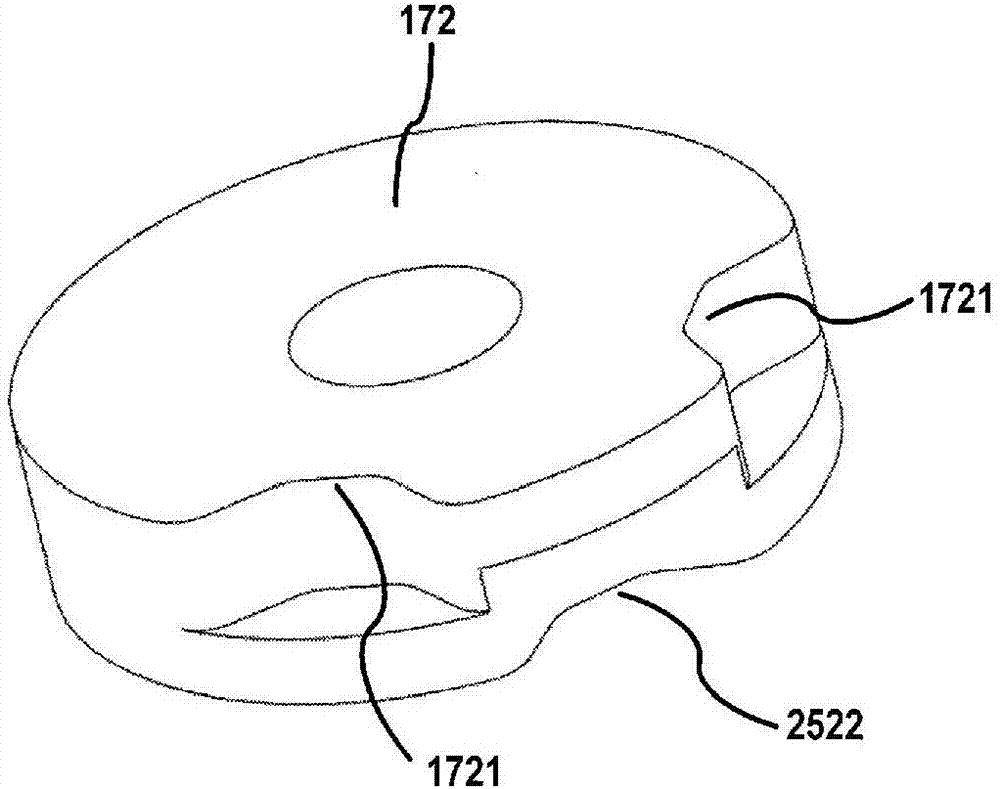

Mechanical interlock assembly for disconnector and earthing switch

ActiveCN107210148ASimple structureLow costContact driving mechanismsSwitches with movable electrical contactsInterlockDisconnector

A mechanical interlock assembly for a disconnector and an earthing switch is provided. It comprises: a main interlock disc (172) configured to actuate a movable contact of a disconnector (11), and at least one earthing switch interlock disc (173, 173') configured to actuate respective movable contact of at least one earthing switch (12, 13) respectively. The main interlock disc (172) is provided with at least one first groove (1721), and each of the at least one earthing switch interlock disc (173, 173') is provided with a third groove (1731), and it is provided with a movable interlock pin (174) between the main interlock disc (172) and each earthing switch interlock disc (173, 173') respectively. This interlock assembly can interlock the disconnector and the at least one earthing switch, and has the advantages of a simple structure, low cost and flexibility for different arrangements. A further mechanical interlock assembly is also provided to interlock another disconnector and one of the above at least one earthing switch.

Owner:HITACHI ENERGY LTD

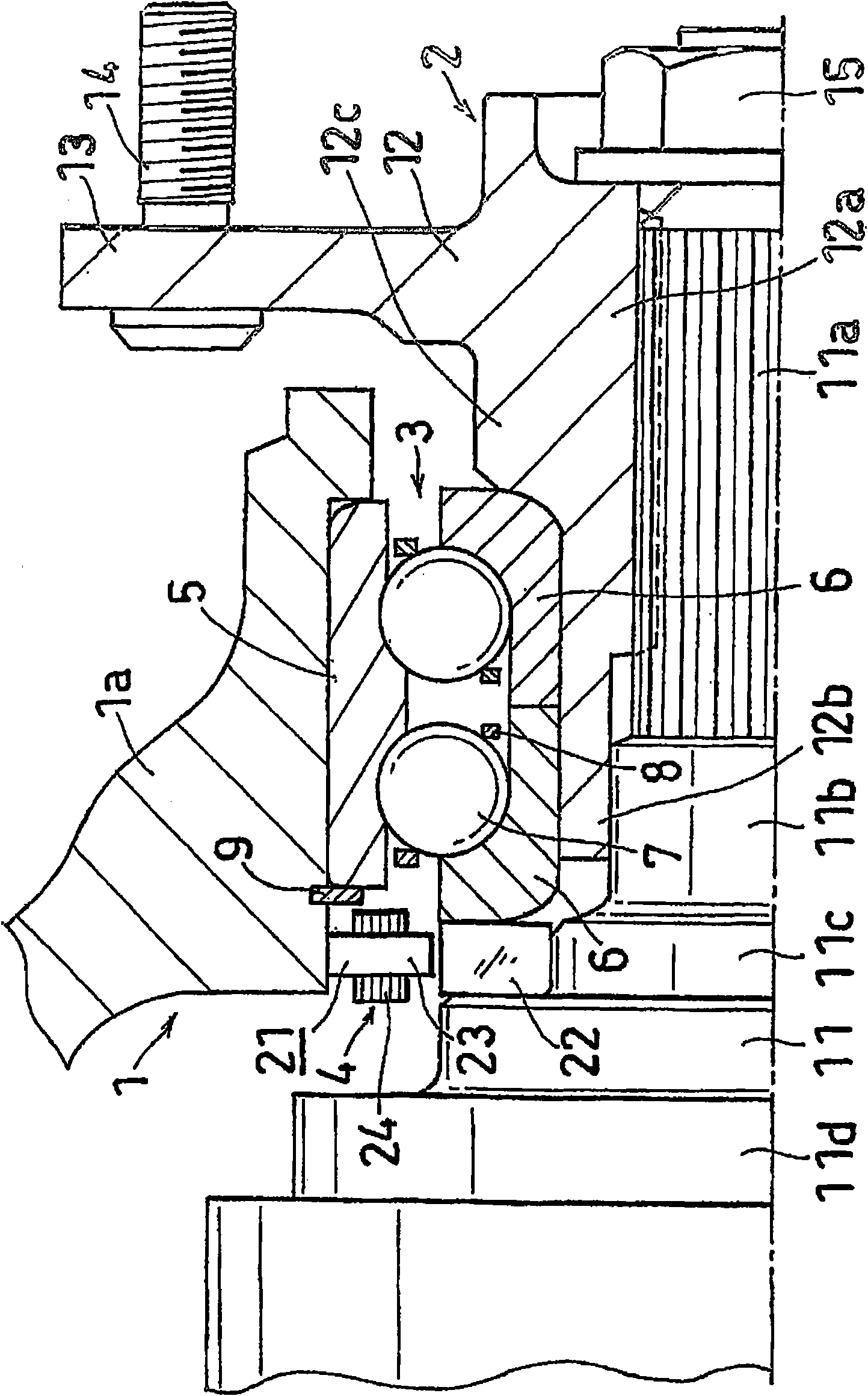

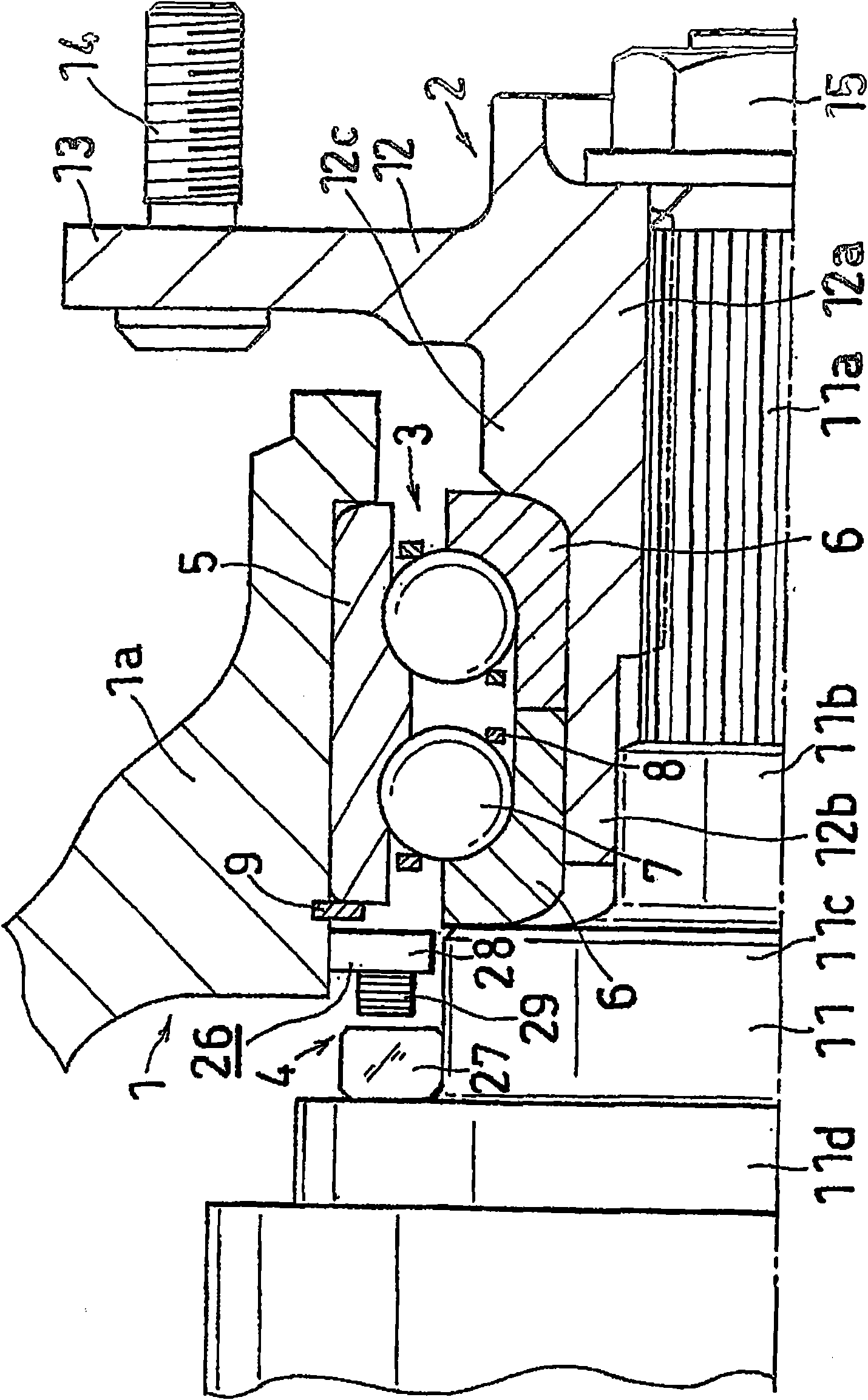

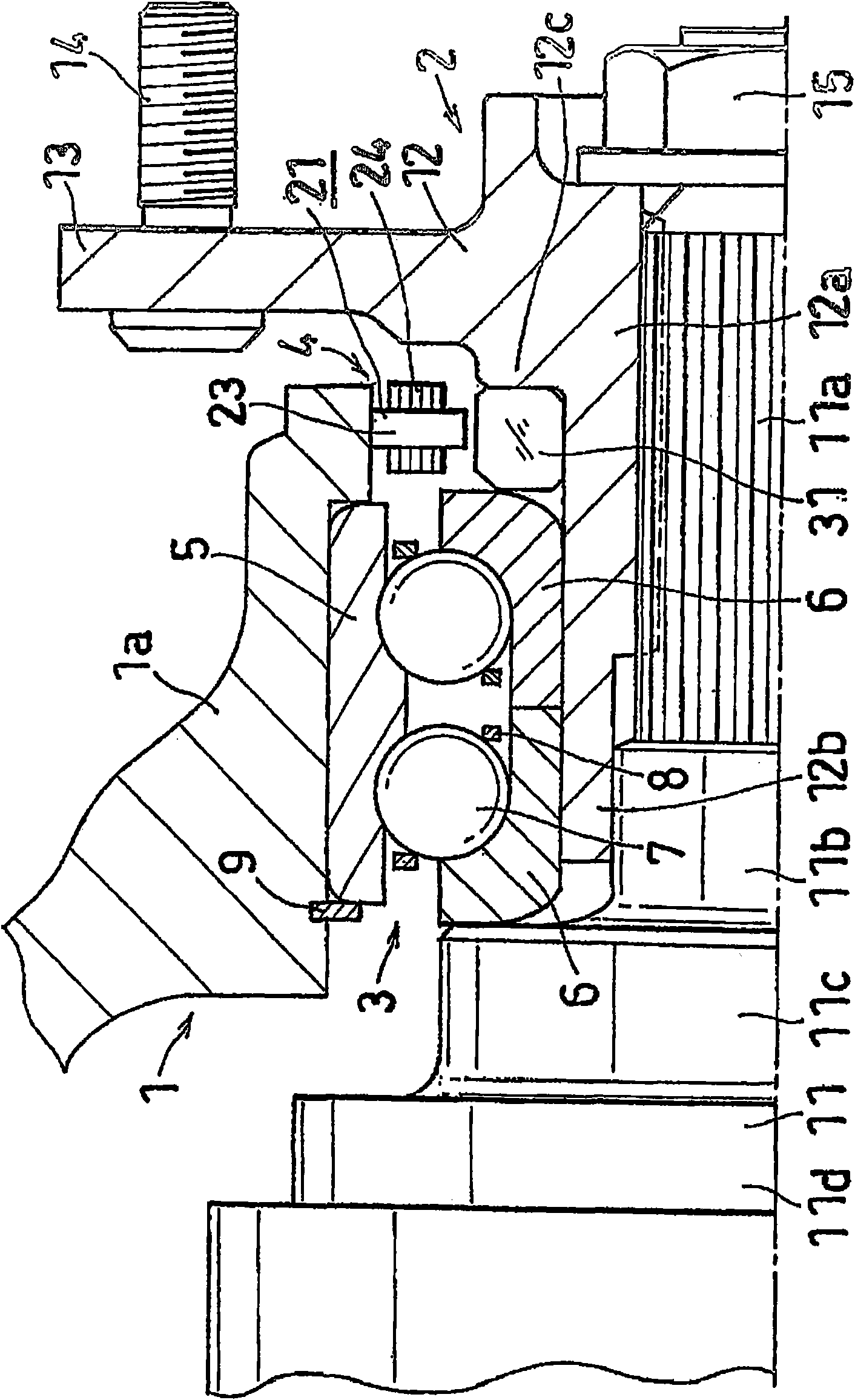

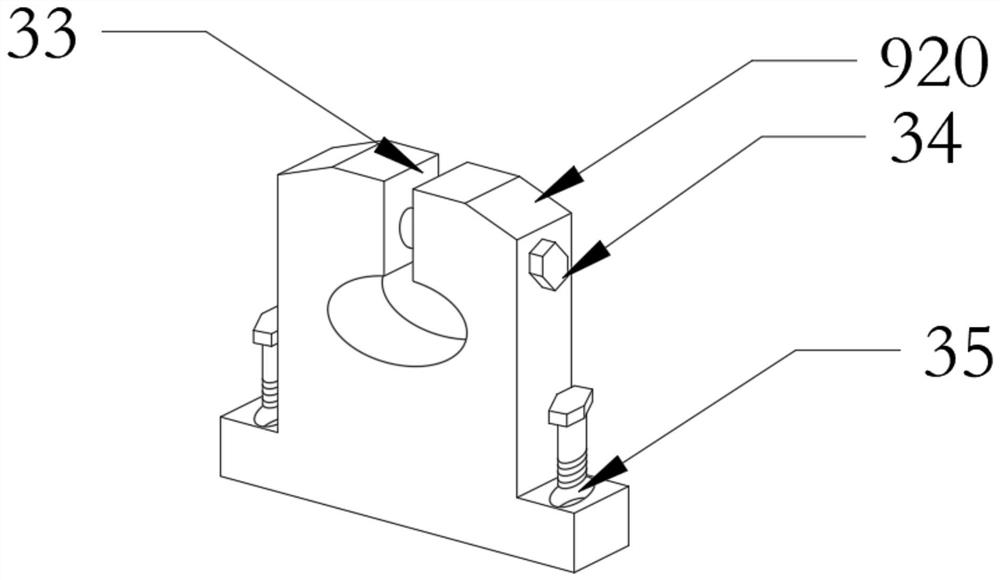

Axle-supporting device

Owner:JTEKT CORP

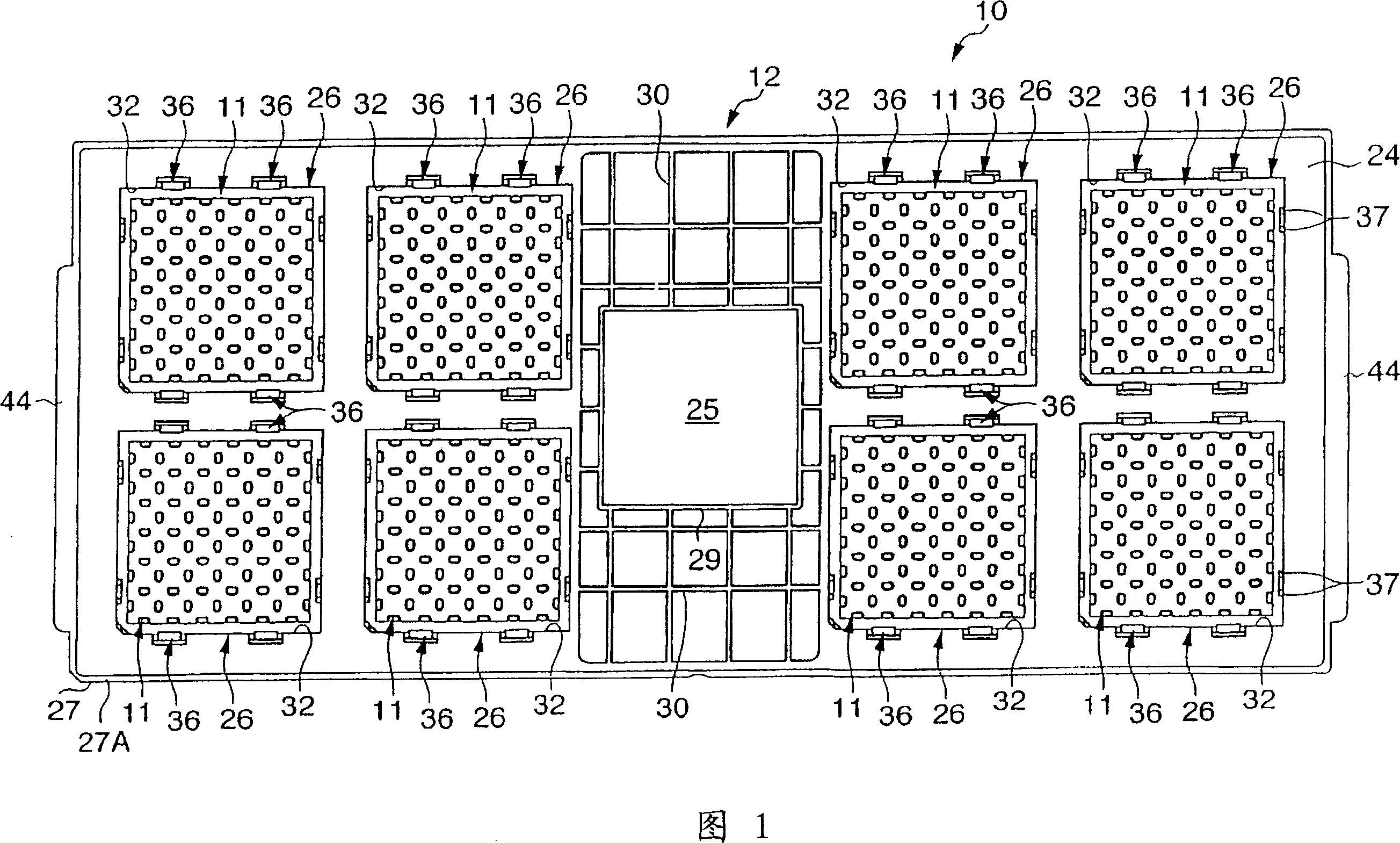

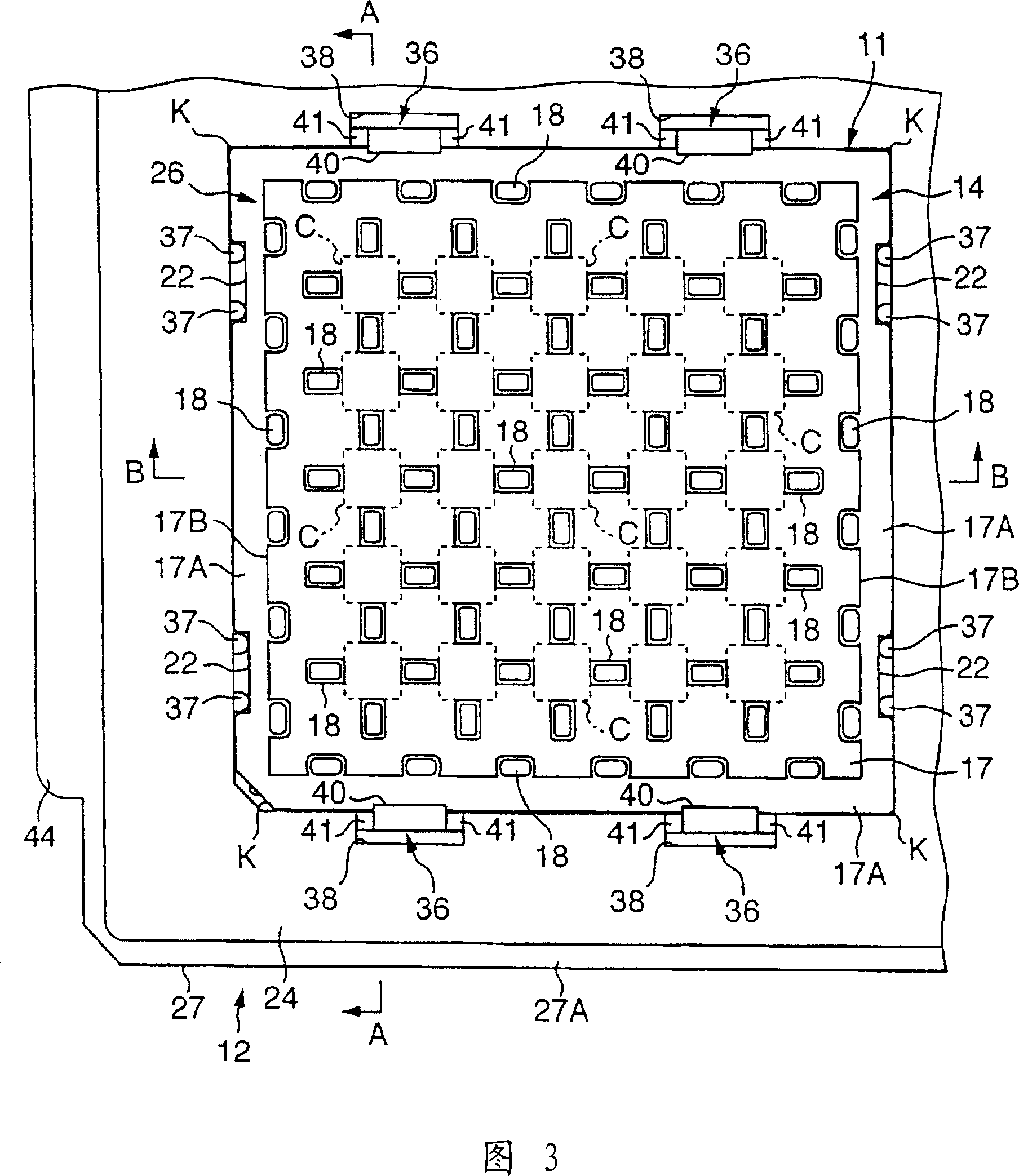

Housing for electronic components

InactiveCN1997269AAvoid position shiftStable storage conditionsSemiconductor/solid-state device detailsSolid-state devicesSurface mountingSemiconductor chip

A housing is disclosed in the invention. A housing is formed in such a way that a plurality of chip trays each holding a plurality of semiconductor chips are stored in a storage tray, wherein the chip tray is formed by vertically connecting an upper unit and a lower unit, both of which have the same structure. The semiconductor chips are held between the upper unit and the lower unit of the chip tray, thus preventing two-dimensional movement thereof. When a plurality of housings each having the aforementioned structure are vertically combined together, a plurality of semiconductor chips can be further held between the upper unit of one housing and the lower unit of another housing. This makes it possible to simultaneously transport numerous semiconductor chips, whereby the semiconductor chips are each encapsulated in a surface mount chip package.

Owner:YAMAHA CORP

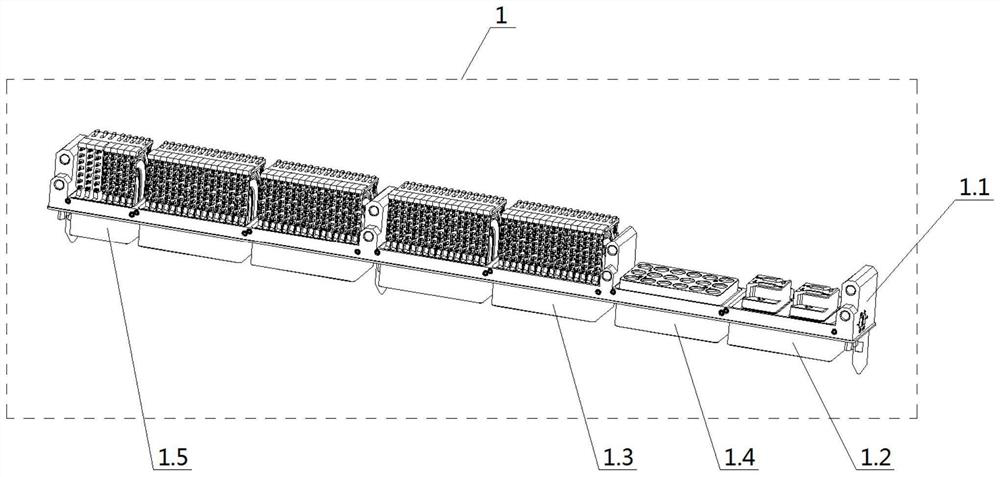

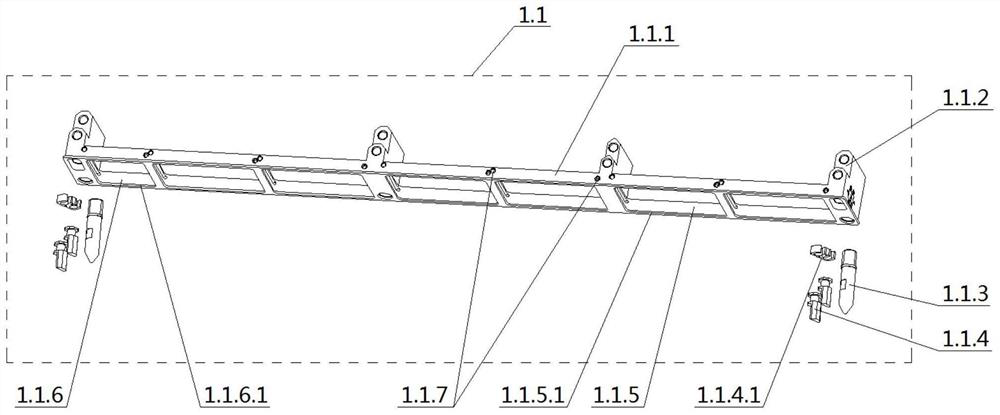

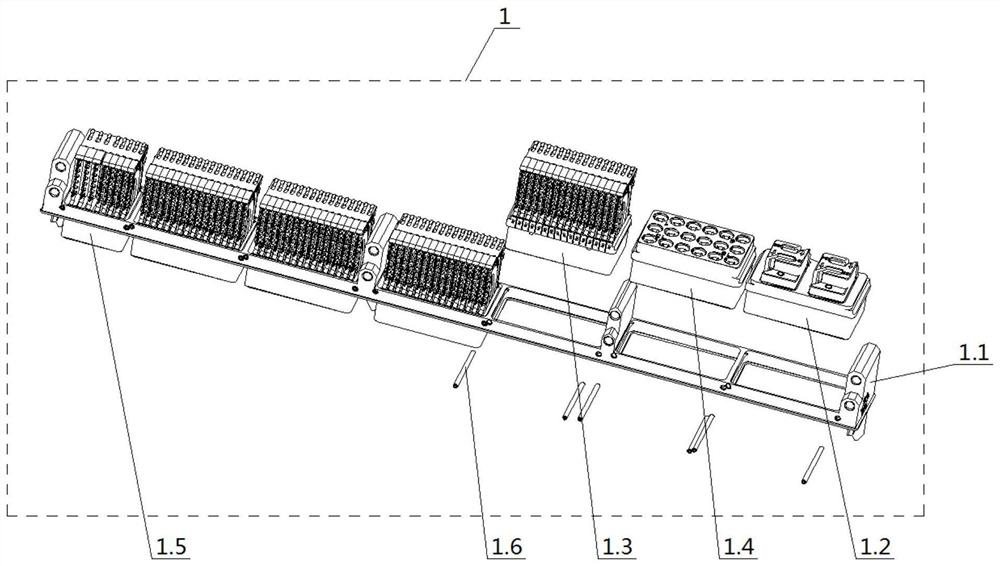

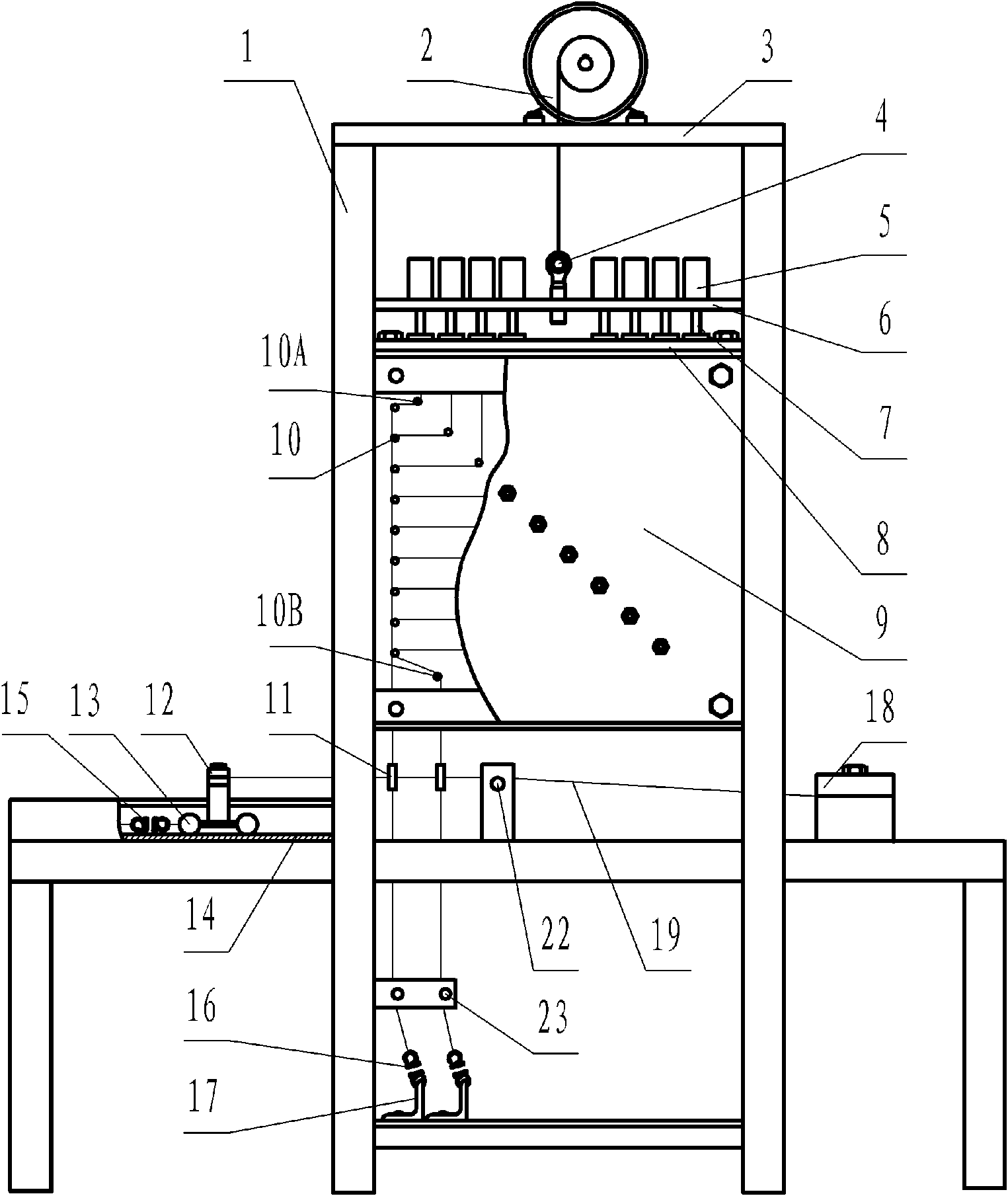

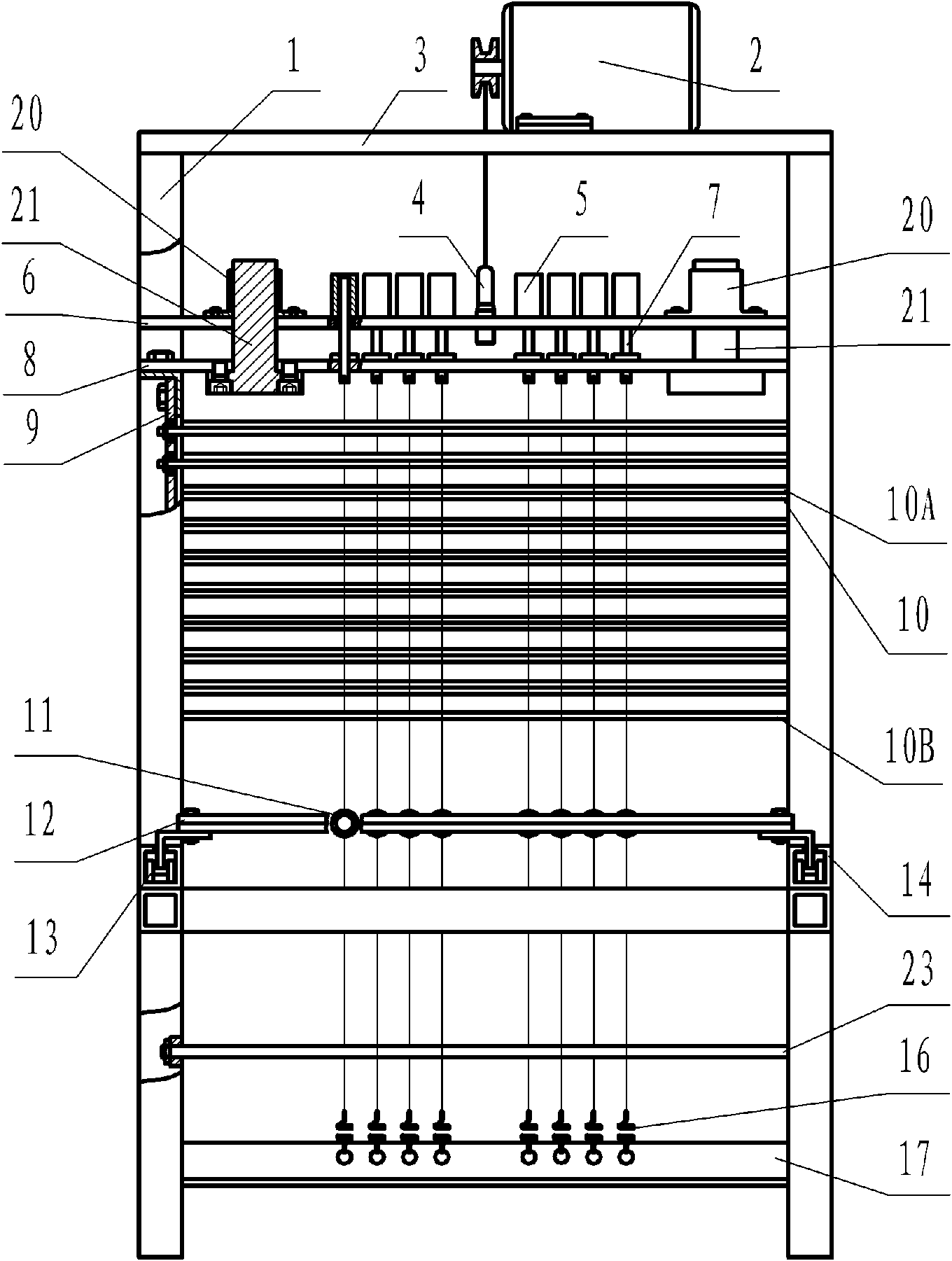

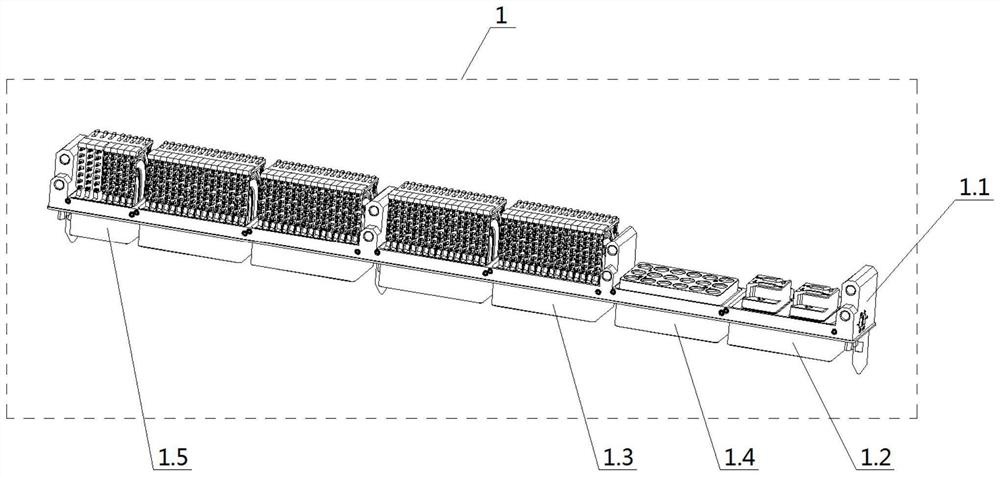

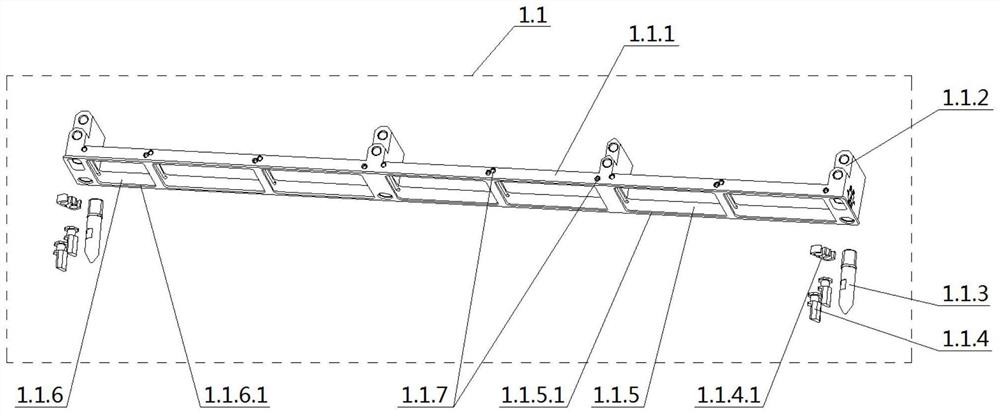

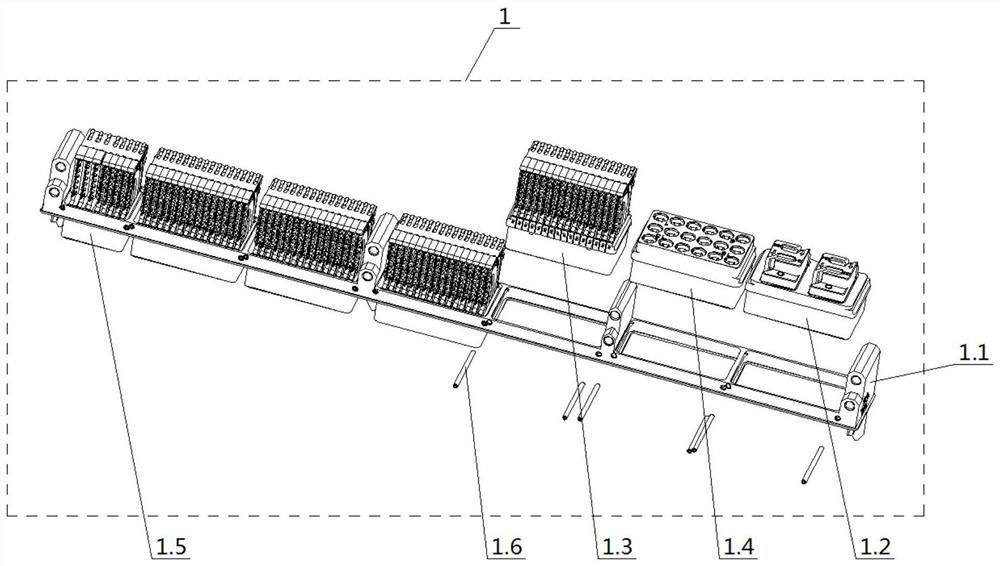

Intelligent bamboo filament braiding machine

InactiveCN101979226ALower acquisition costsInfinite varietyCane mechanical workingProcedural approachPurchase cost

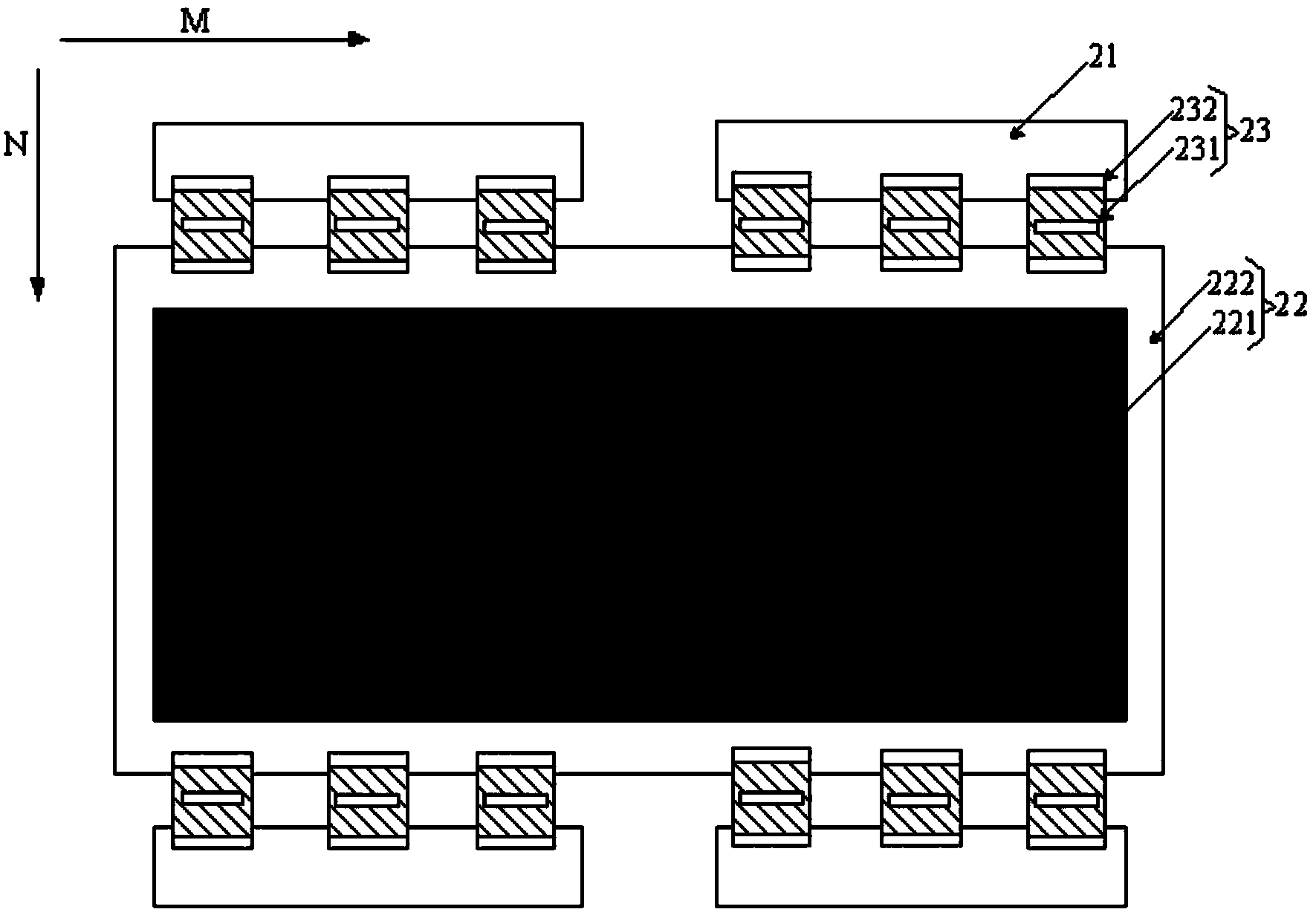

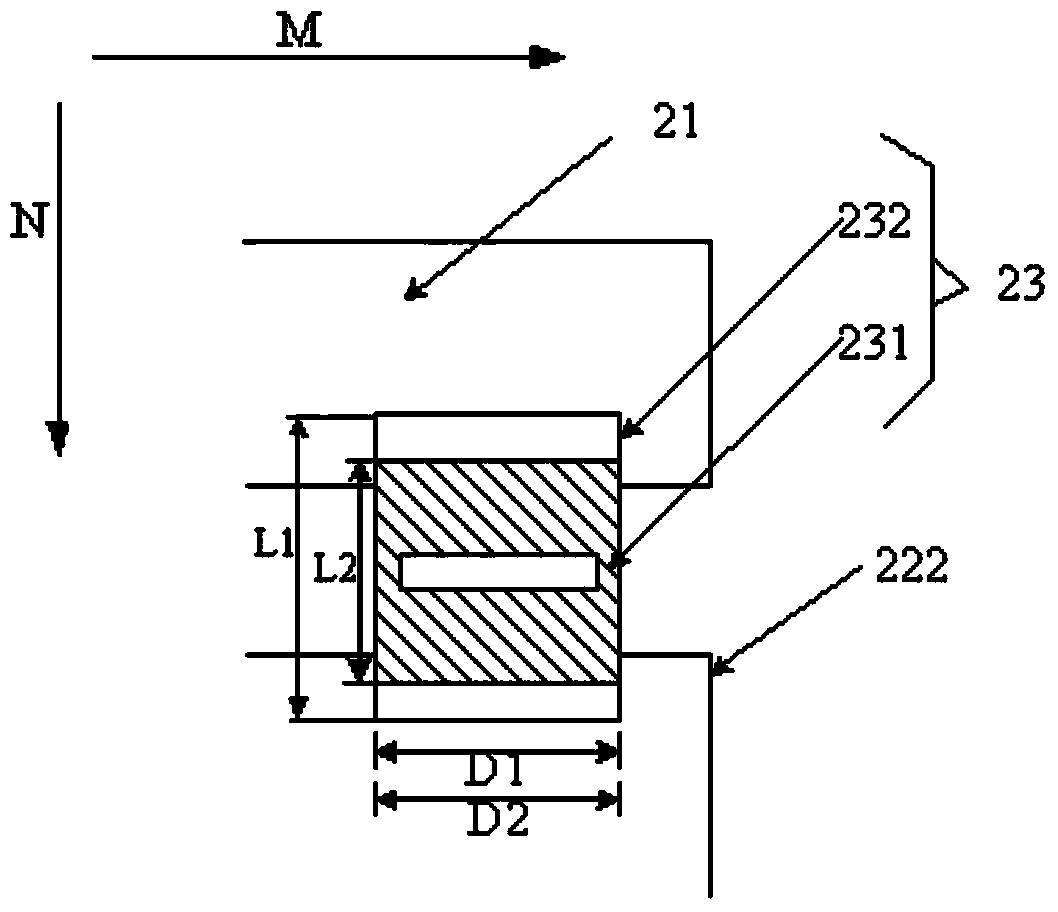

The invention discloses an intelligent bamboo filament braiding machine. The intelligent bamboo filament braiding machine comprises a frame (1), a motor (2), a transmission device and a program control device, wherein the program control device controls the energization of multi-line and multi-row electromagnets to lift or not to lift bamboo filaments in the weft direction so as to braid bamboo filament products with designed patterns. The bamboo filament braiding machine can braid the bamboo filament products with different patterns under the condition that devices do not need replacing, has low purchase cost, is easy and convenient to operate and has high braiding efficiency.

Owner:SOUTHWEST JIAOTONG UNIV

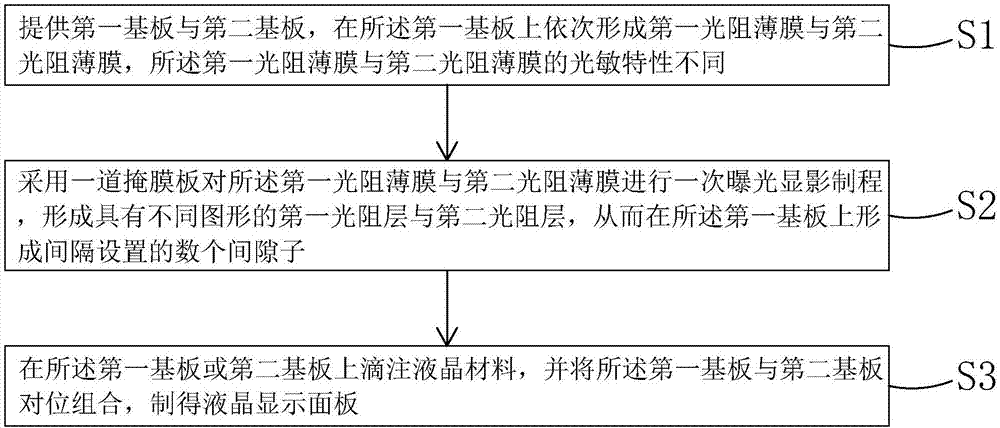

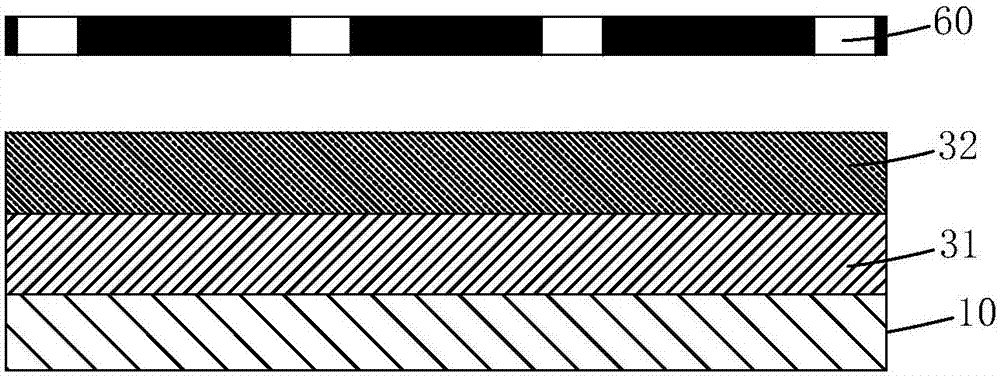

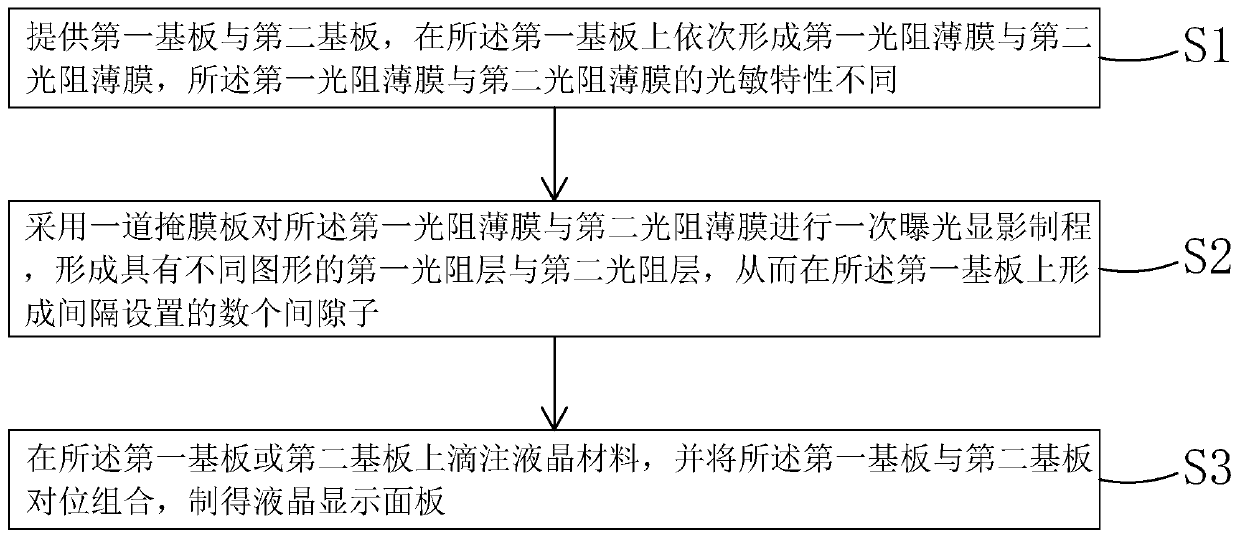

Liquid crystal display panel and manufacturing method for same

ActiveCN107402471AInclination angle θ increasesImprove arrangement spaceNon-linear opticsLiquid-crystal displaySlant angle

The invention provides a liquid crystal display panel and a manufacturing method for the same. The manufacturing method for the liquid crystal display panel is that graphical process is conducted to multi-layers of photoresistive films laminated by a common masking plate through a single-exposure development process, and laminated multi-layered photoresist layers can be achieved; photo spacers are formed between the laminated multi-layered photoresist layers; due to the diversities of light-sensitive characteristics of the multi-layered photoresist layers, multi-layered photoresist layers with different graphs can be achieved after exposure development; and the different graphs are different in aspects of at least one parameter such as upper base sizes, lower base sizes, slant angles . Slant angles (Theta) of photo spacers can be adjusted by the multi-layered photoresist layers with different graphs, so the slant angle (Theta) of each photo spacer can be effectively improved; the photo spacers of the liquid crystal display panel has the laminated multi-layered photoresist layers; the multi-layered photoresist layers has different graphs; and the slant angle (Theta) of each photo spacer can be effectively improved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

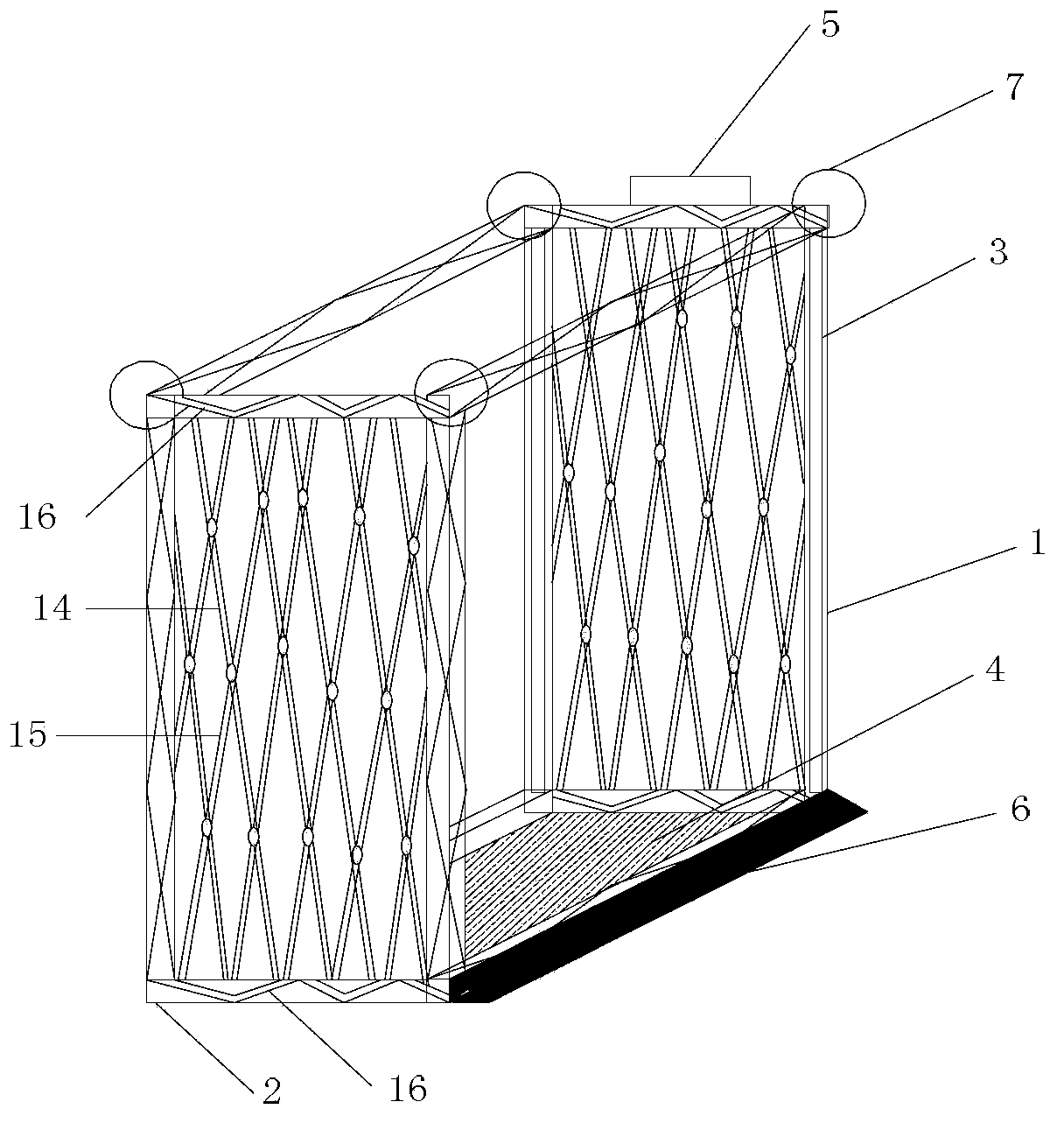

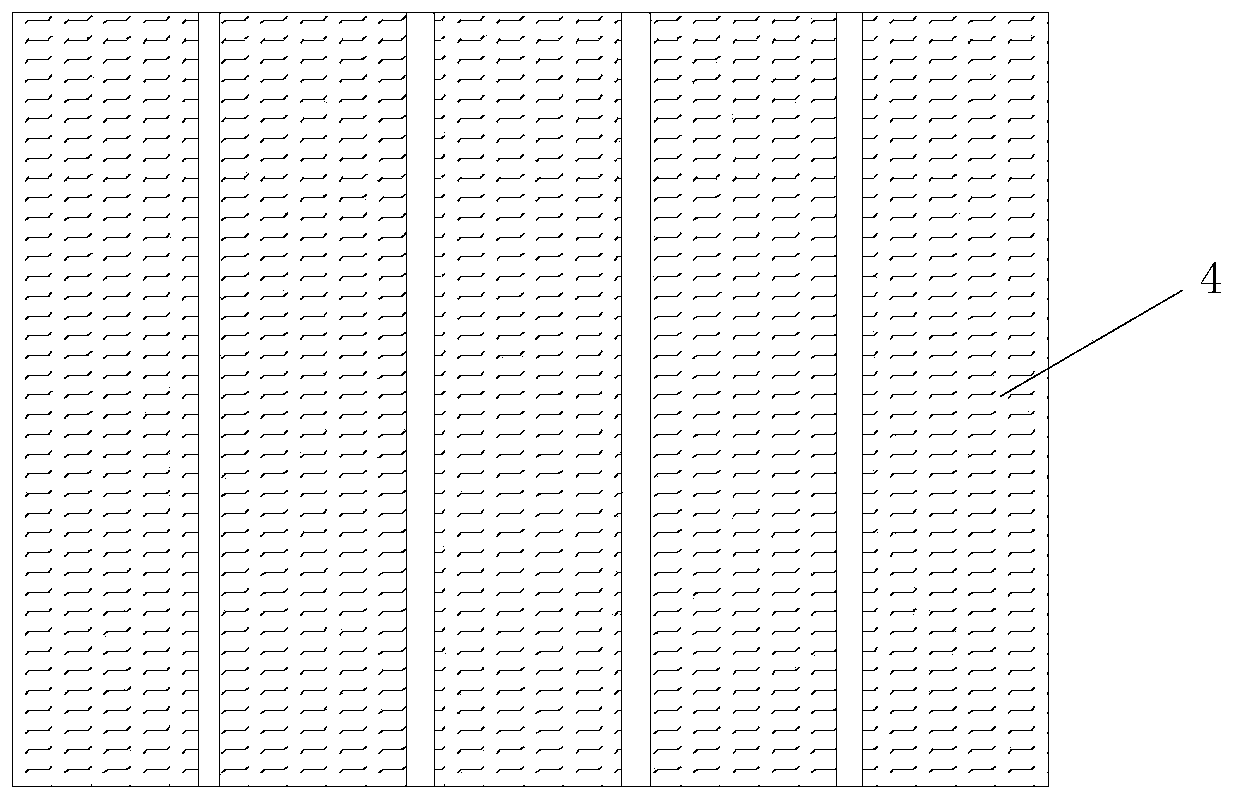

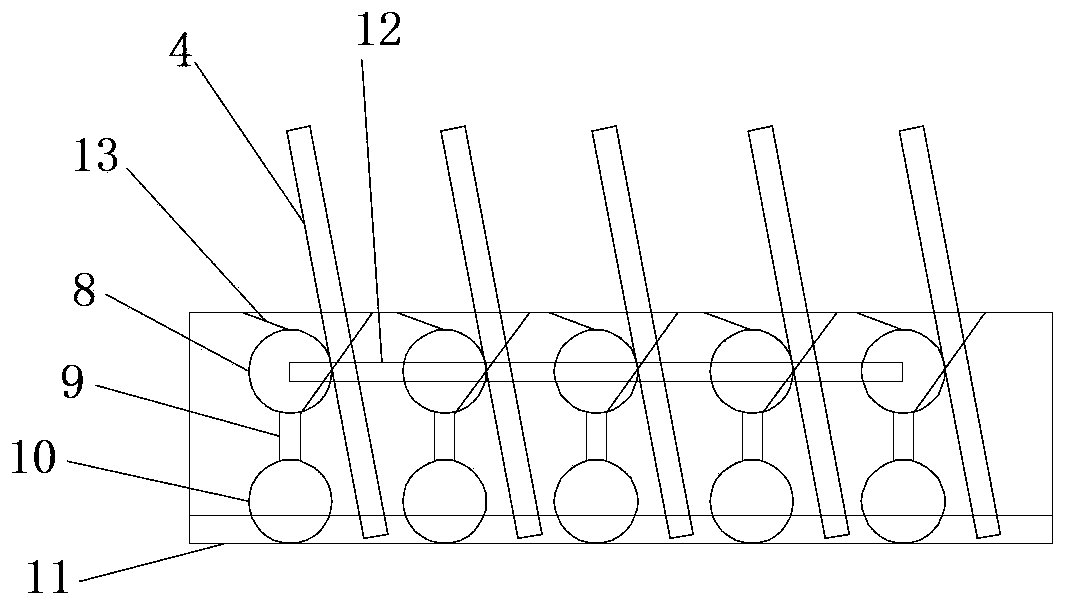

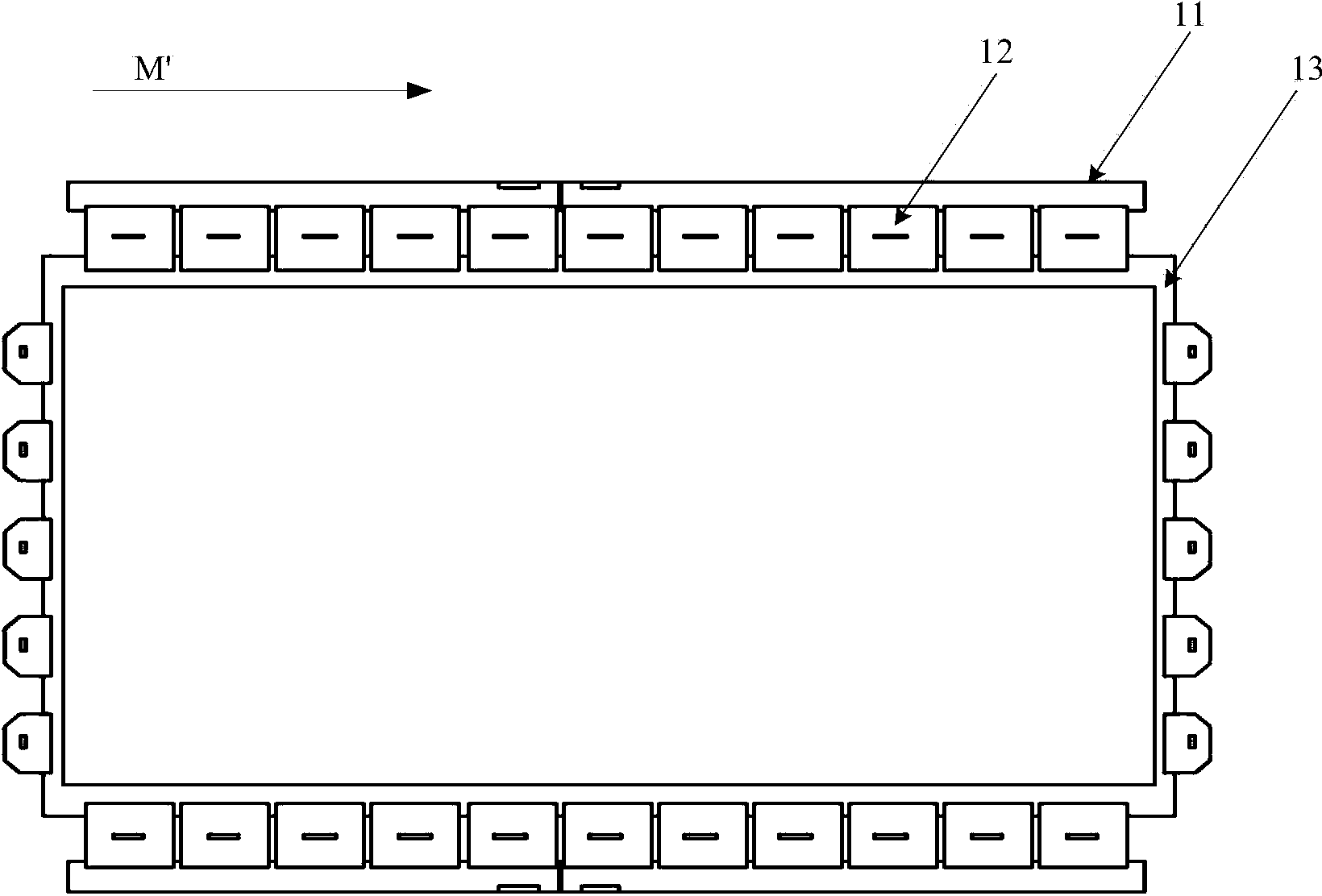

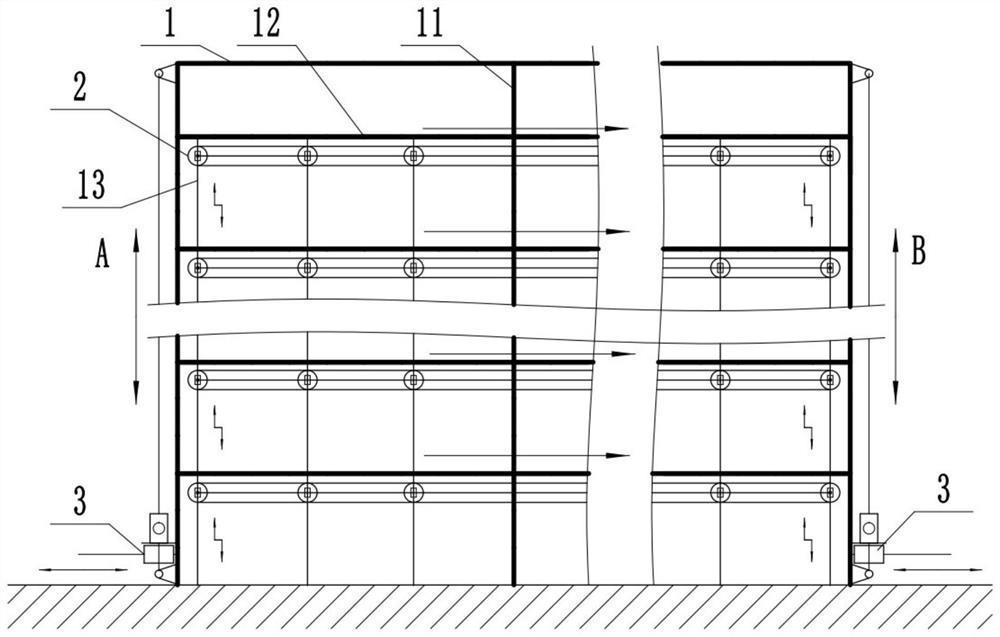

Folding car carrier structure of movable parking device

The invention discloses a folding car carrier structure of a movable parking device. The folding car carrier structure comprises a bottom steel frame and a rectangular steel frame, wherein a car carrying plate is mounted on the bottom steel frame, a group of parallel first steel bars is mounted on the rectangular steel frame, a group of parallel second steel bars intersecting with the first steel bars is mounted in the rectangular steel frame, the first steel bars are connected with the second steel bars through screws, the upper frame and the lower frame of the rectangular steel frame both are composed of a group of third steel bars, a fixed joint is mounted at the angle of the top end of the rectangular steel frame, a control box is mounted on the top end of the rectangular steel frame, driving shafts are mounted on the bottom end of the car carrying plate through rotating shafts and connected with one another through shrinkage rods, pulleys are connected to the lower ends of the driving shafts through connecting rods, and pulley guide rails are arranged on the bottom ends of the pulleys. The folding car carrier structure of the movable parking device is simple in structure, convenient to operate, and foldable, and therefore, the space usage of the car carrier is reduced and the volume of the movable parking device is reduced.

Owner:XIAN BOYU GREEN ENERGY

Liquid crystal display unit and device

InactiveCN103543542AReduce spaceSave spaceStatic indicating devicesNon-linear opticsLiquid-crystal displayLiquid crystal

The invention discloses a liquid crystal display unit and device. A plurality of connecting units are arranged between driving circuit boards and a liquid crystal display panel, every connecting unit comprises at least two tape coiling chips, and the at least two tape coiling chips are arranged in a covering mode and are all connected with the driving circuit boards and the liquid crystal display panel. Through the arrangement of the connecting units, the at least two tape coiling chips are formed on one of the connecting units in a concentrated mode, and accordingly the arrangement space in the extension direction of the driving circuit boards of the tape coiling chips can be reduced to save space, other designs such as the welding design of the tape coiling chips can be facilitated, or the addition of other devices and the like can be facilitated.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

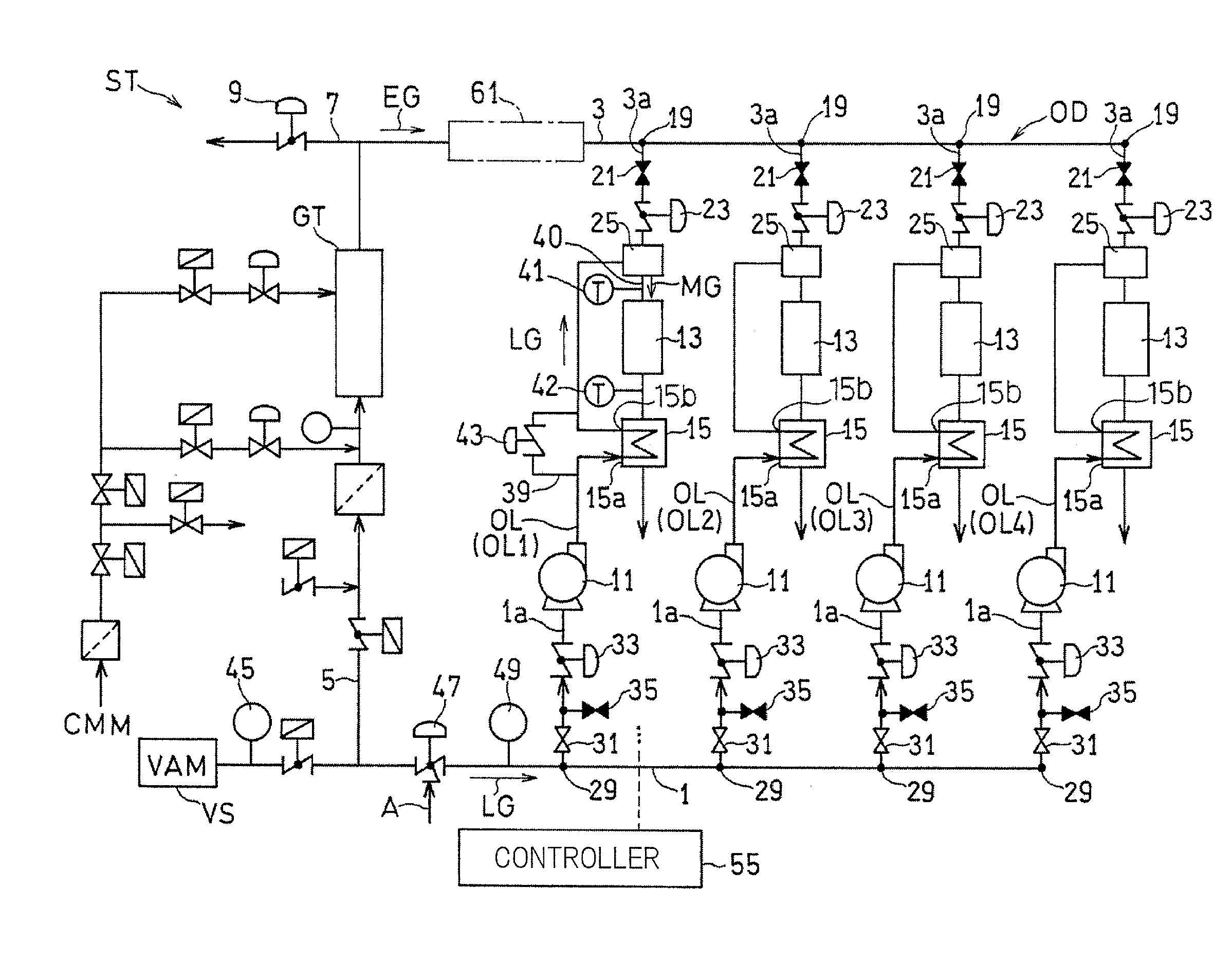

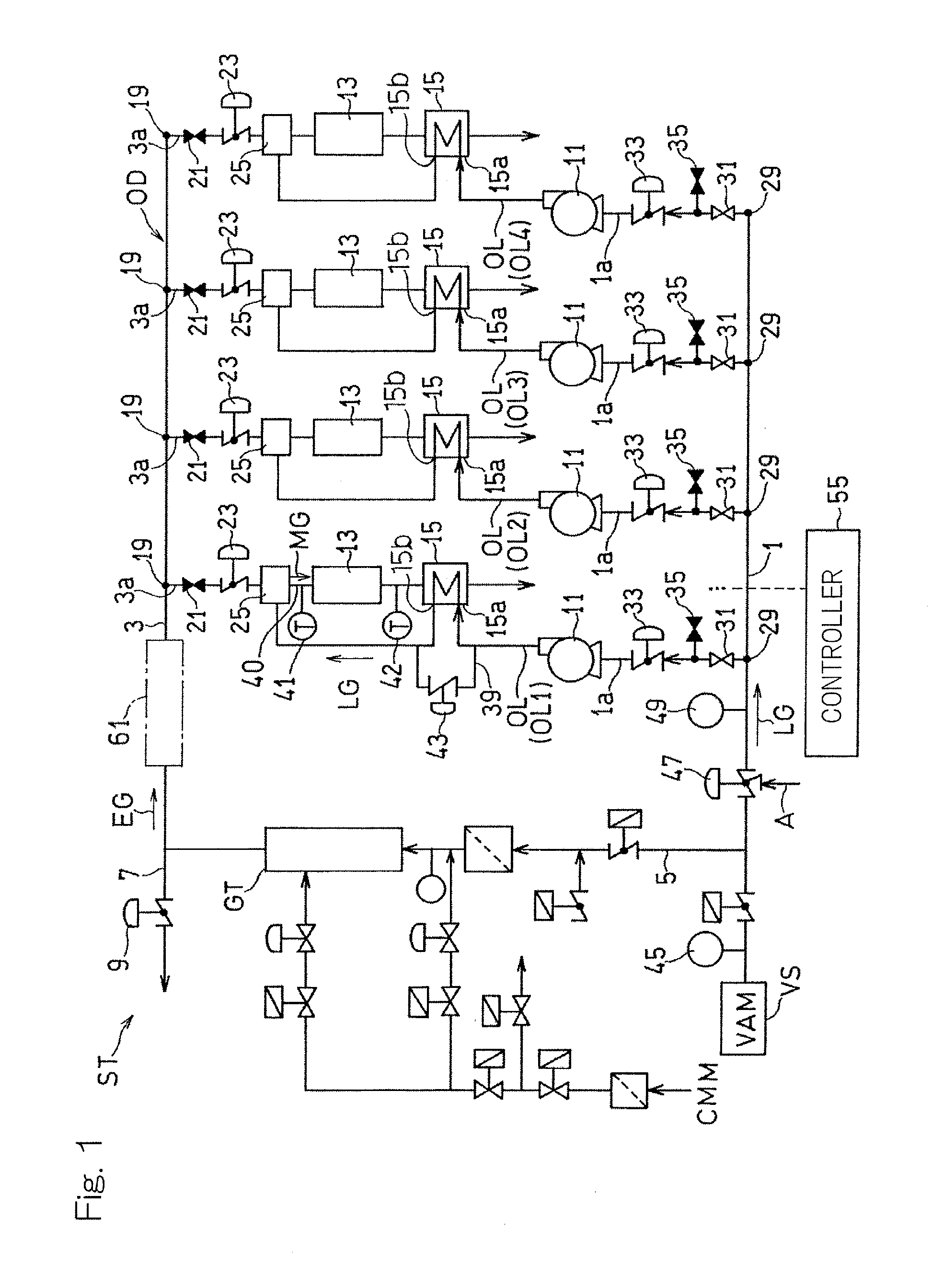

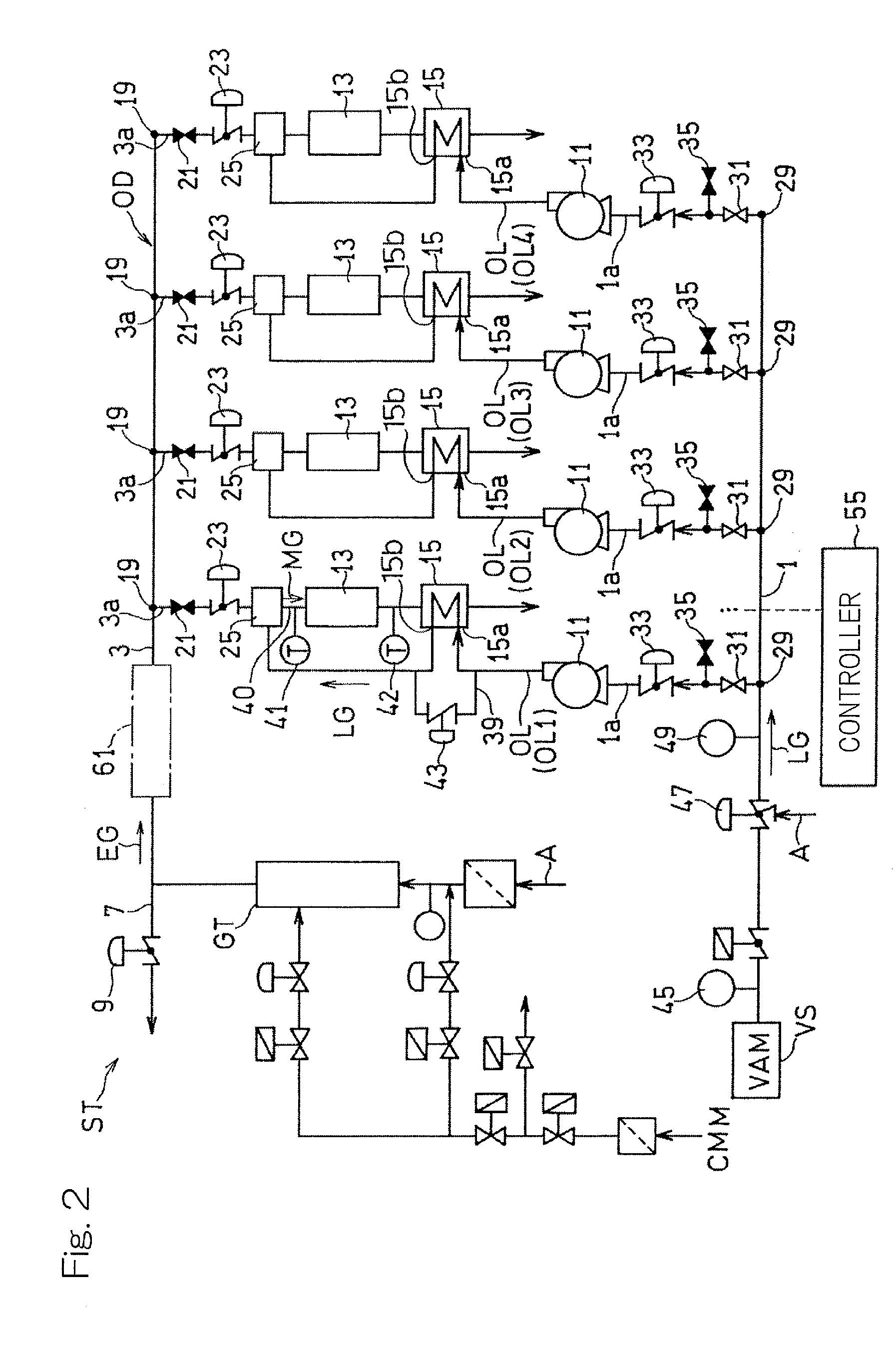

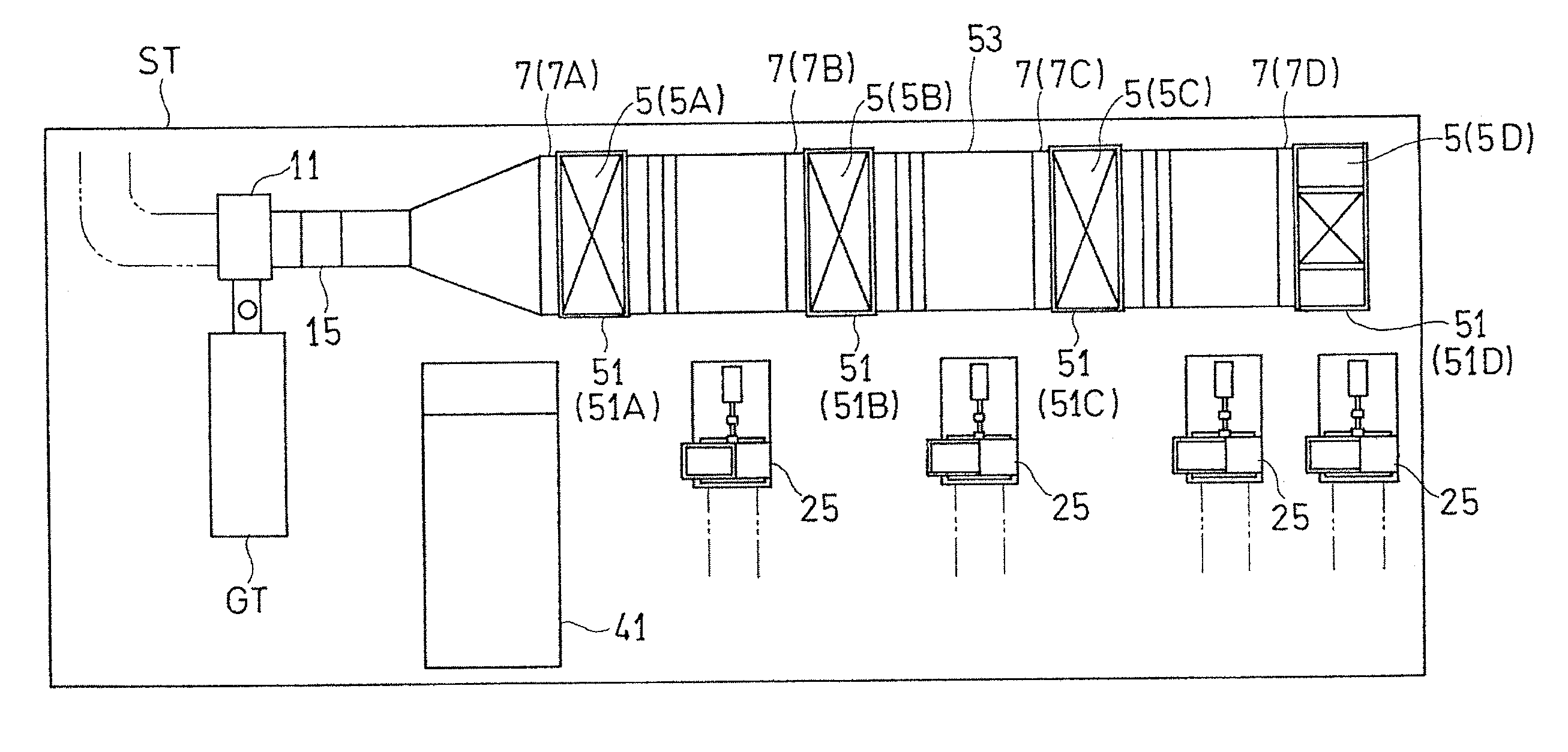

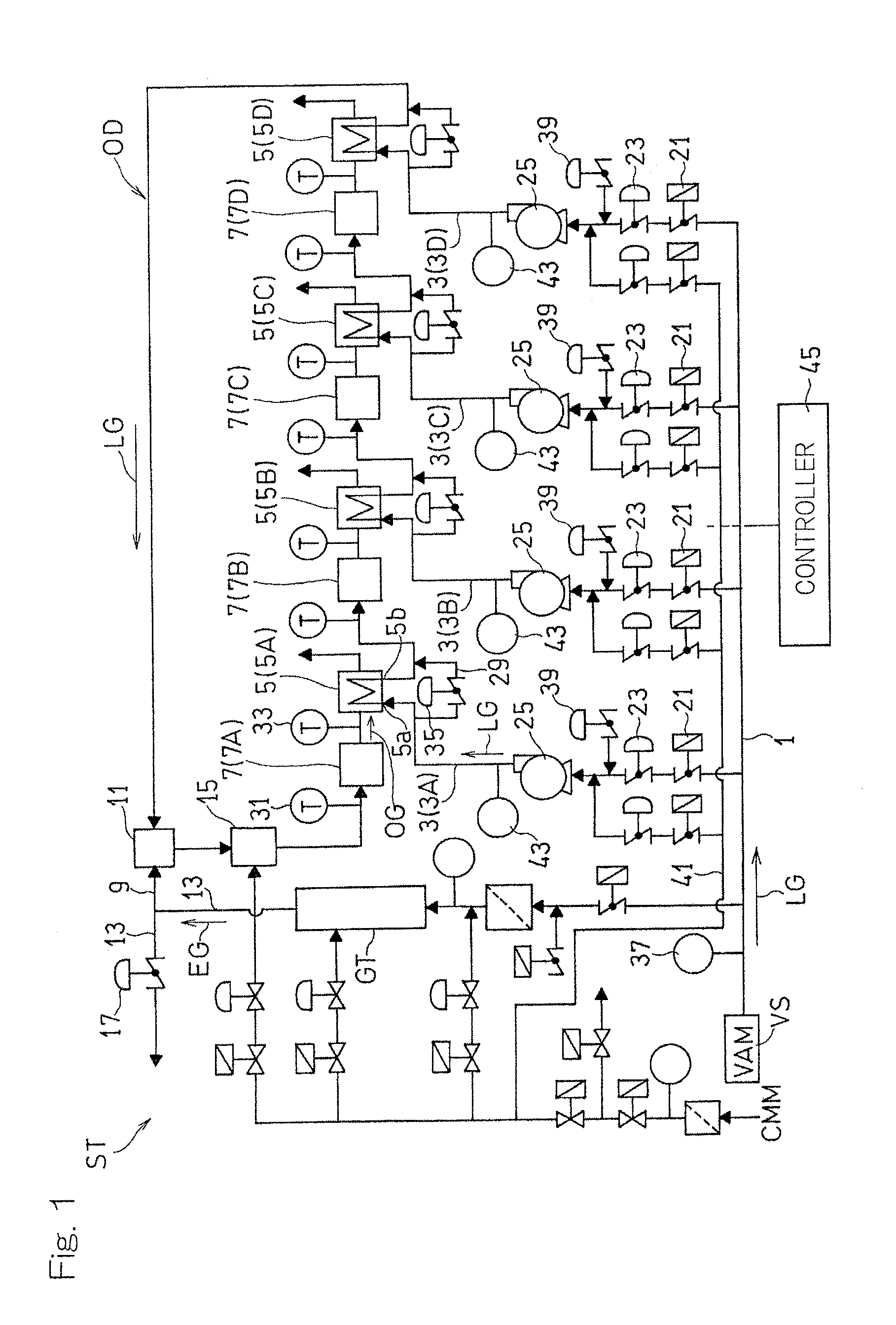

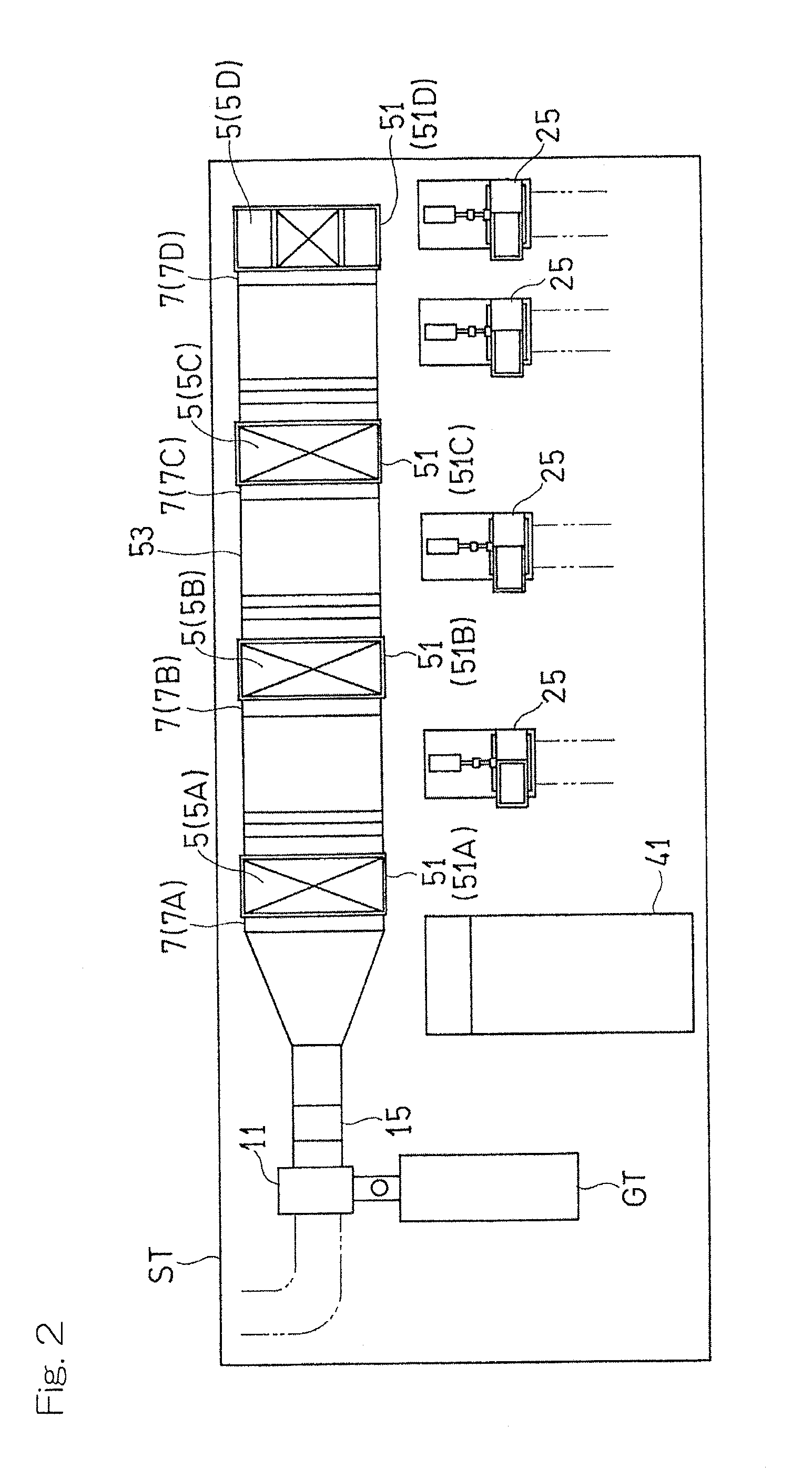

Oxidation system for treatment of low-concentration methane gas provided with multiple oxidizers

InactiveUS20150121891A1Low costImprove efficiencyContinuous combustion chamberGas treatmentCatalytic oxidationProduct gas

A low-concentration methane gas oxidation system includes a single heat source device, and an oxidation device which catalytically oxides a low-concentration methane gas by using heat from the single heat source device. The oxidation device includes a plurality of oxidation lines each including each of a plurality of branching low-concentration gas supply passages which branch, in parallel, from a supply passage which supplies the low-concentration methane gas, and each of a plurality of catalyst oxidizers provided on each of the plurality of branching low-concentration gas supply passages.

Owner:KAWASAKI HEAVY IND LTD

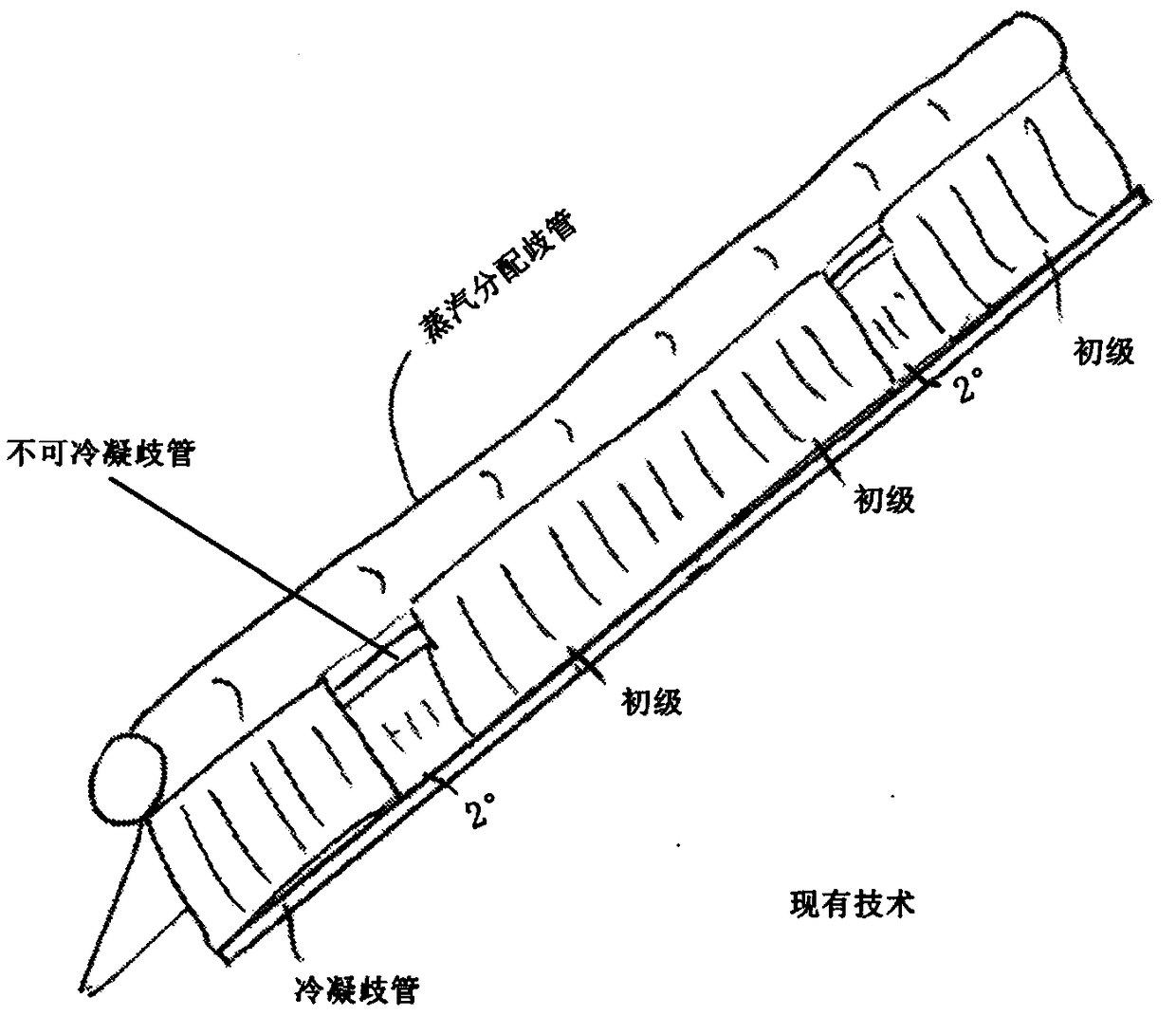

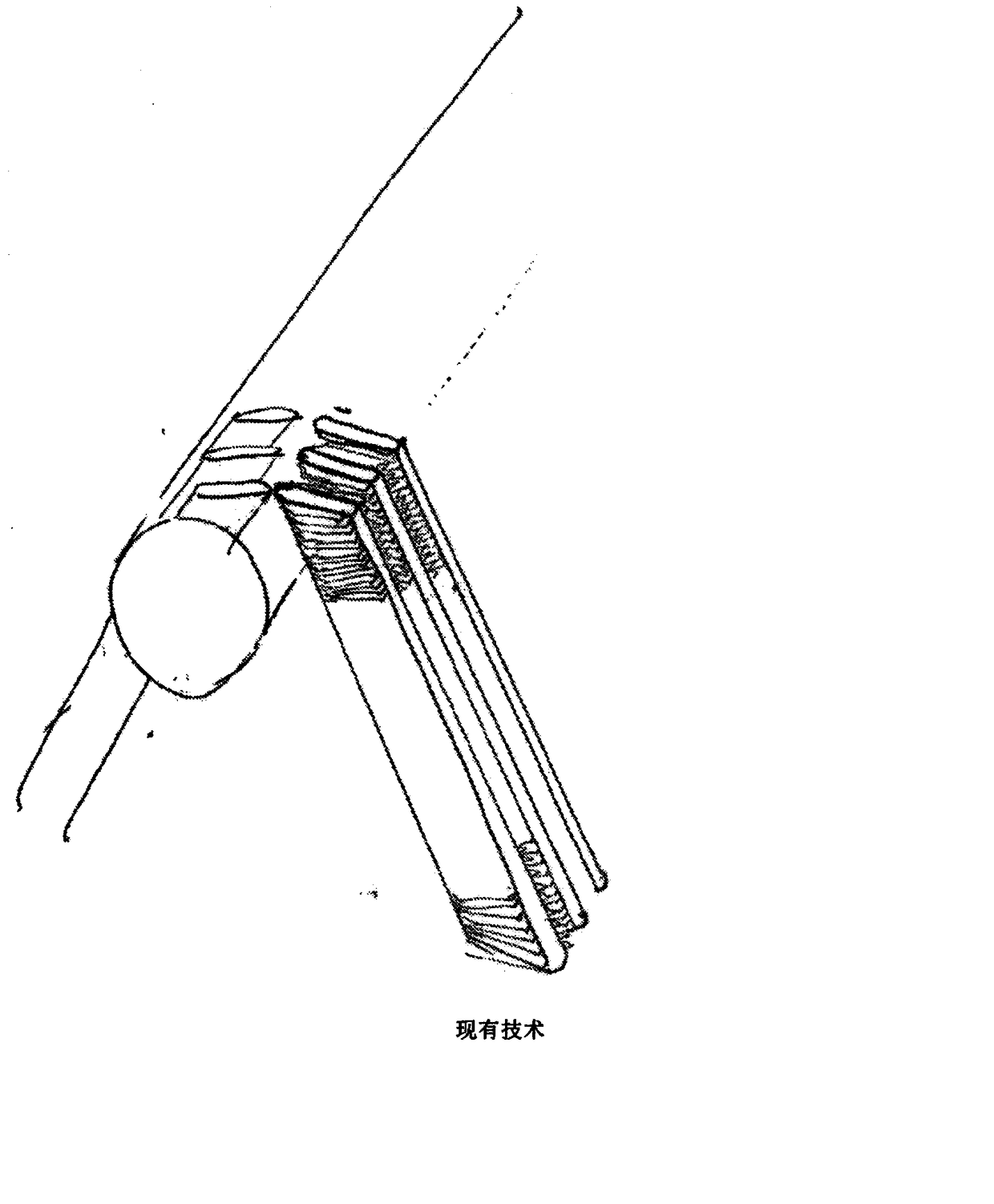

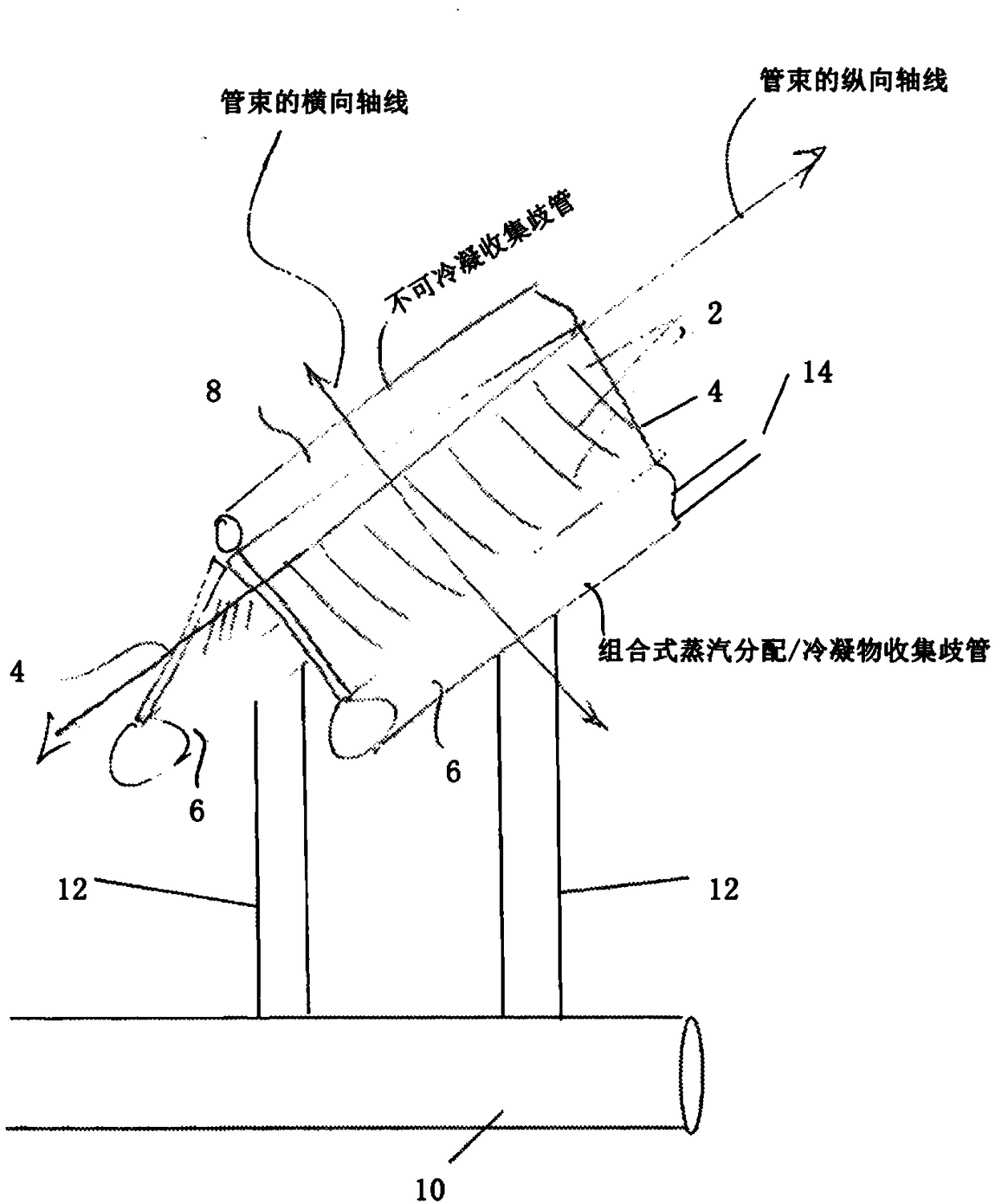

All-secondary air cooled industrial steam condenser

PendingCN109328290APrecise positioningReduce total spaceEvaporators/condensersSteam/vapor condensersThermodynamicsSteam condensation

A new design for large scale field erected industrial steam condensers in which all of the bundles are constructed as secondary bundles, in A-frame or V-Shape configuration, with tubes oriented 25-35degrees from the vertical, steam fed from the bottom and condensate is collected from the bundles from the bottom using a combination / hybrid manifold that both delivers steam to the tubes and collectscondensate from the tubes and which is constructed so that the condensate is prevented from returning down the steam delivery riser(s) and in which the cross-sectional dimensions of the tubes are 125mm wide with a cross-section height of less than 10 mm with fins that are 9.25 mm in height, arranged at 9 to 12 fins per inch.

Owner:EVAPCO

System for low-concentration-methane gas oxidation equipped with multiple oxidizers

InactiveUS20150132194A1Low costImprove efficiencyGas treatmentMethane captureMethane gasOxidizing agent

A low-concentration methane gas oxidation system includes: a single heat source device; and an oxidation device to oxidize low-concentration methane gas by using heat from the heat source device. The oxidation device includes a plurality of individual oxidation units including respective catalyst oxidizers. The individual oxidation units include: a first individual oxidation unit including a first catalyst oxidizer using heat of heat source gas from the heat source device, and a first heat exchanger to preheat low-concentration methane gas that flows into an additional catalyst oxidizer provided in a branching supply passage on downstream side, by using, as a heating medium, oxidized gas from the first catalyst oxidizer; and at least one additional individual oxidation unit including an additional catalyst oxidizer to oxidize low-concentration methane gas preheated by the first catalyst oxidizer or the additional catalyst oxidizer provided in a branching supply passage on upstream side.

Owner:KAWASAKI HEAVY IND LTD

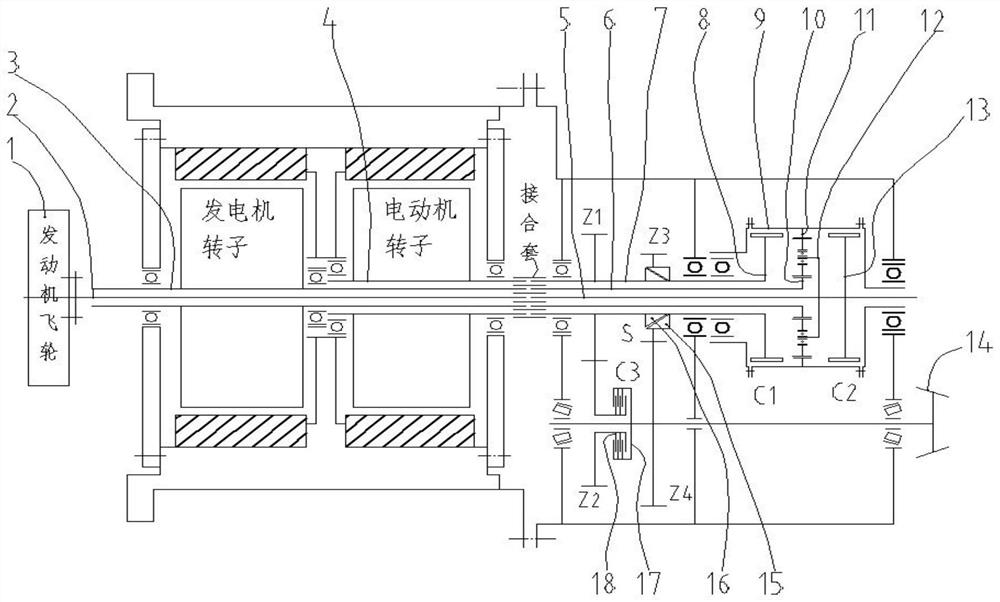

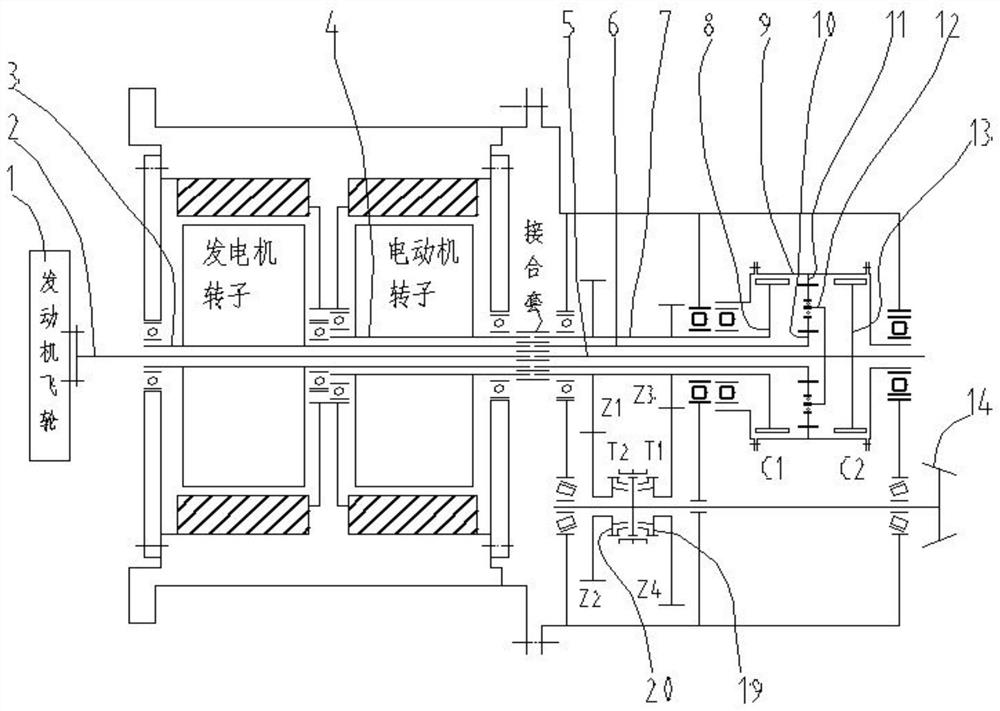

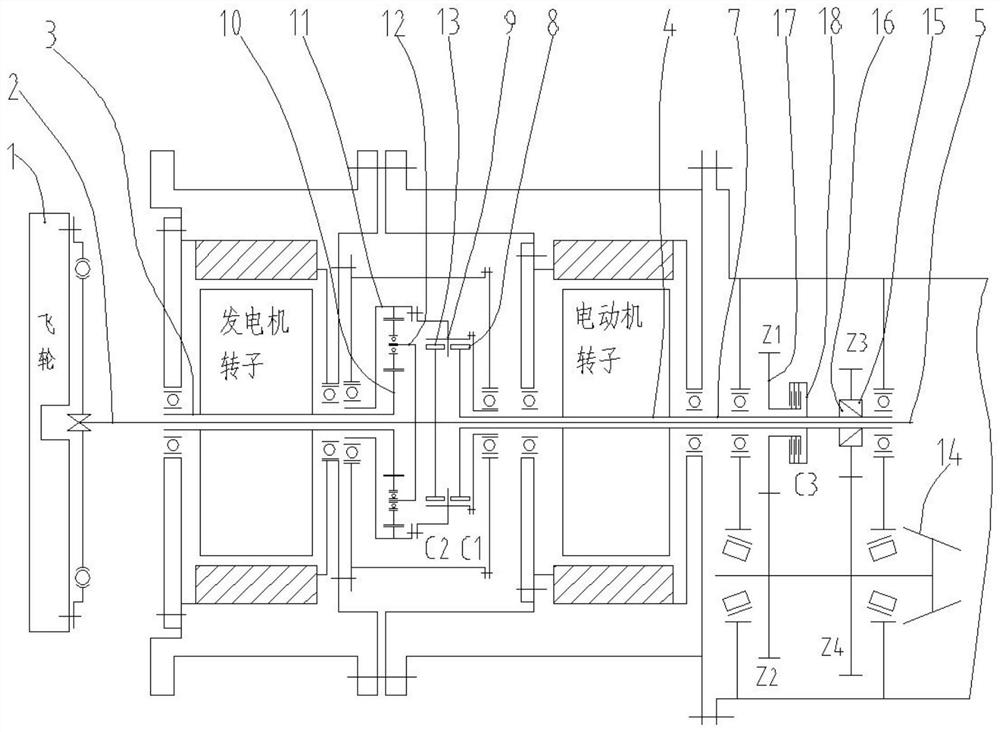

Multi-mode output intermediate-shaft-free stepless speed change transmission system

InactiveCN112937280AFulfillment requirementsSimple structureGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingGear wheelControl theory

The invention discloses a multi-mode output intermediate-shaft-free stepless speed change transmission system which is characterized in that an engine output shaft is connected with a power output shaft through a joint sleeve, and the power output shaft is simultaneously connected with a planet carrier and a driven disc of a clutch C2; a generator rotor shaft is connected with a sun wheel shaft through a joint sleeve, and the sun wheel shaft is connected with a sun wheel; a rotor shaft of the motor is connected with an input shaft of a gearbox through a joint sleeve; the input shaft of the gearbox is simultaneously connected with a gear Z1, a driving disc of an overrun clutch and a driven disc of a clutch C1; a driven disc of the overrun clutch is connected with a gear Z3; the C1 / C2 driving disc is connected with a planetary gear ring; a central transmission driving shaft is simultaneously connected with a driven disc of a clutch C3 and a gear Z4; a driving disc of the clutch C3 is connected with the gear Z2; and the gear Z1 is meshed with the gear Z2, and the gear Z3 is meshed with the gear Z4. Therefore, the function that the vehicle runs in the three CVT modes can be achieved, and the purposes of saving oil and reducing emission of the whole vehicle can be achieved.

Owner:杨振忠

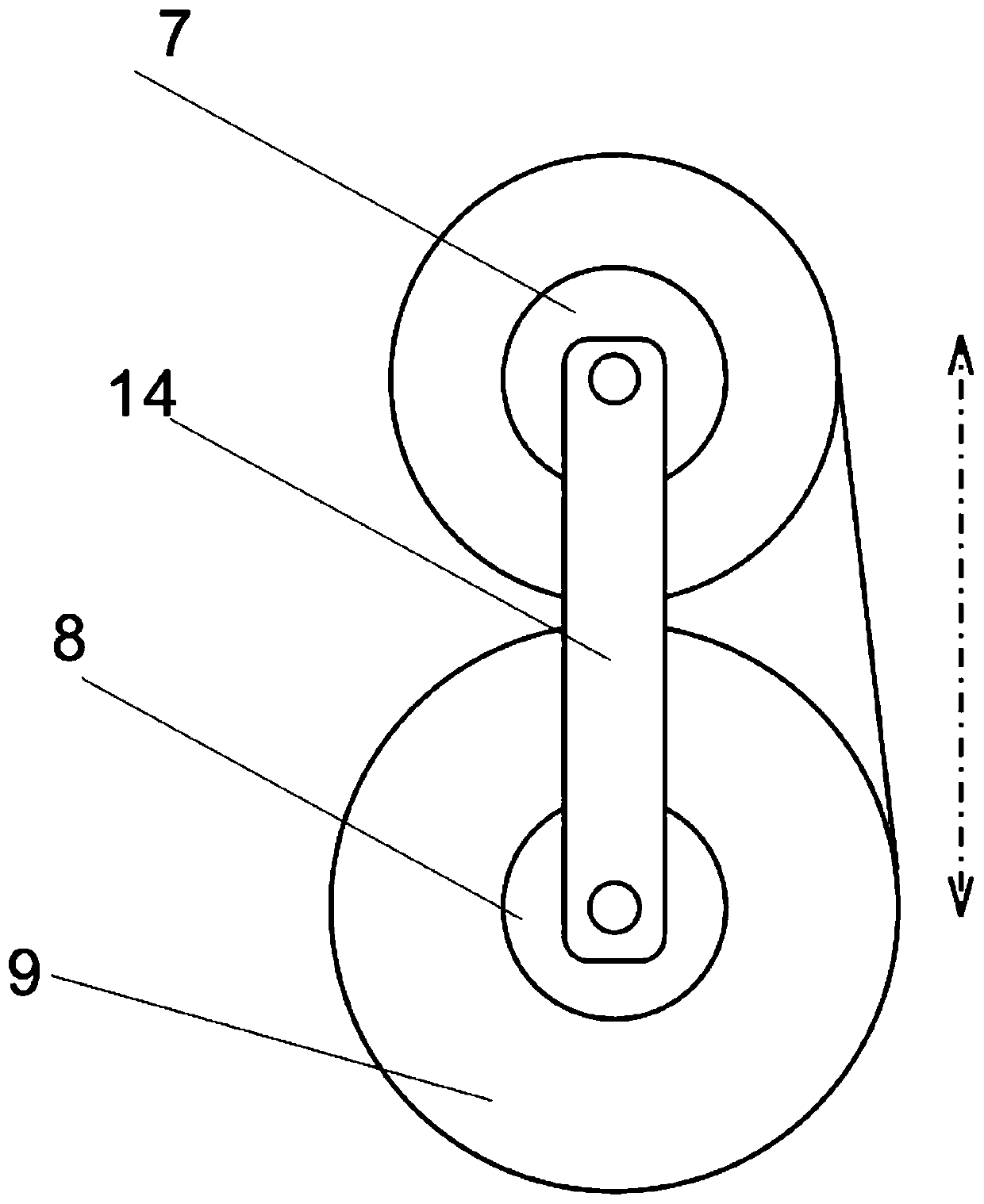

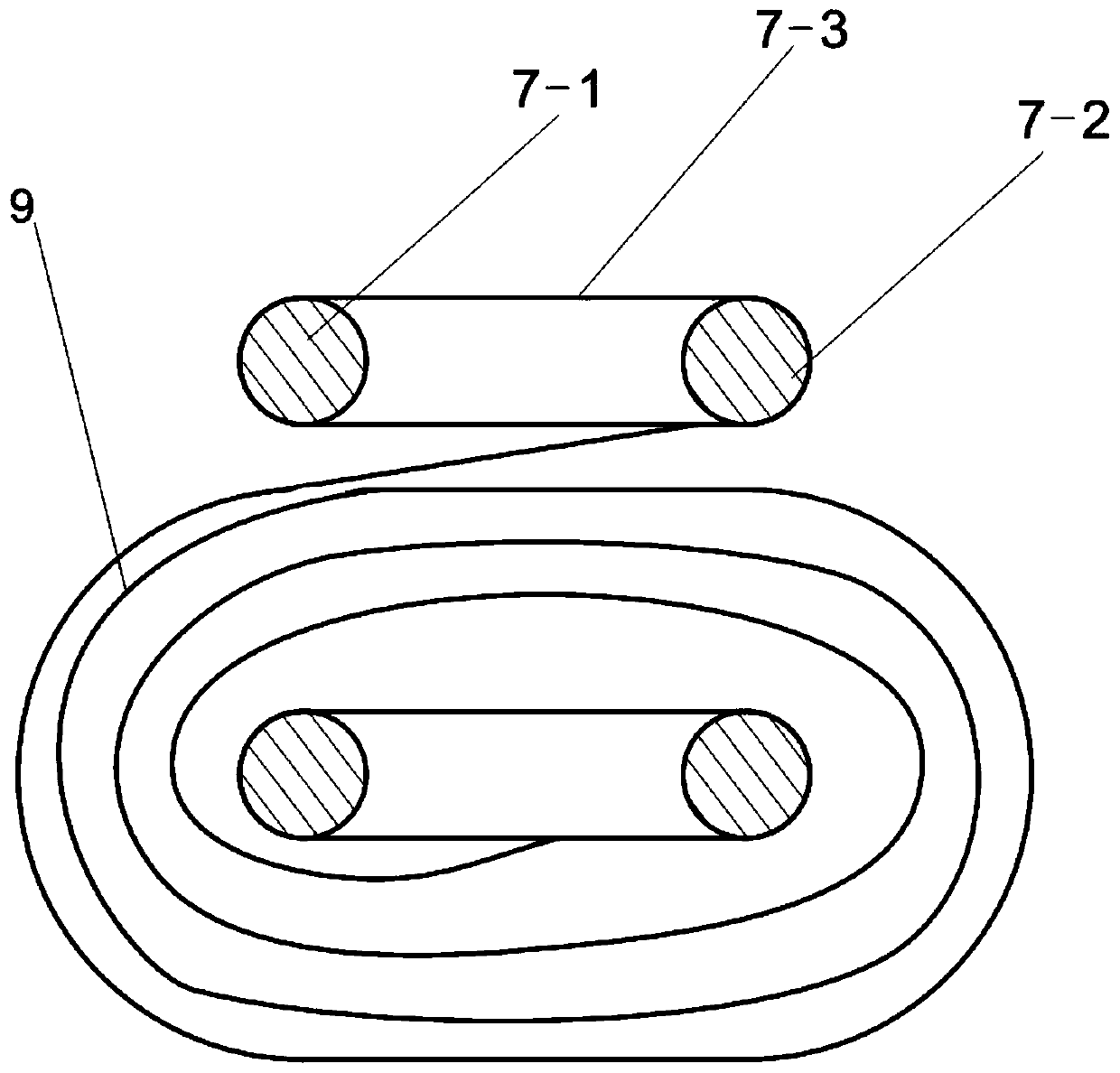

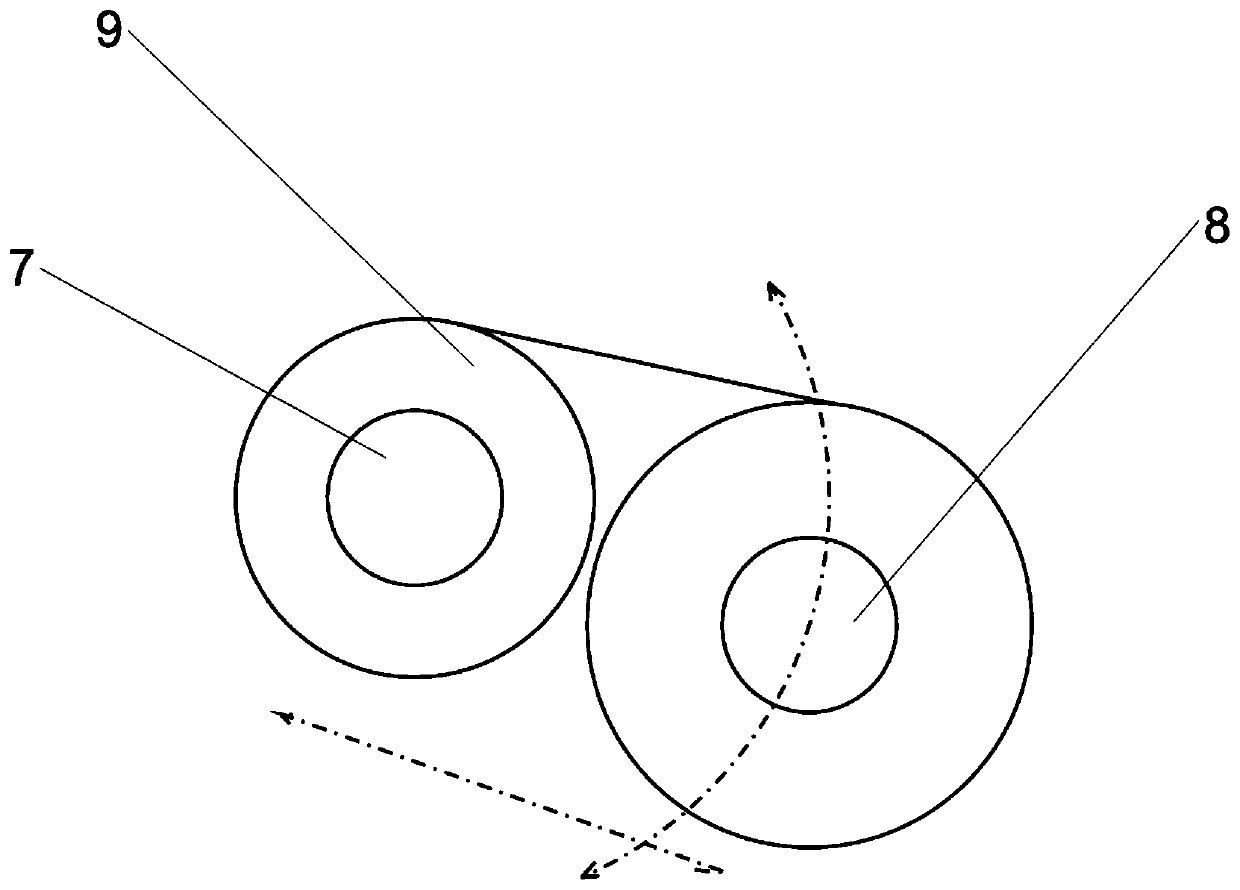

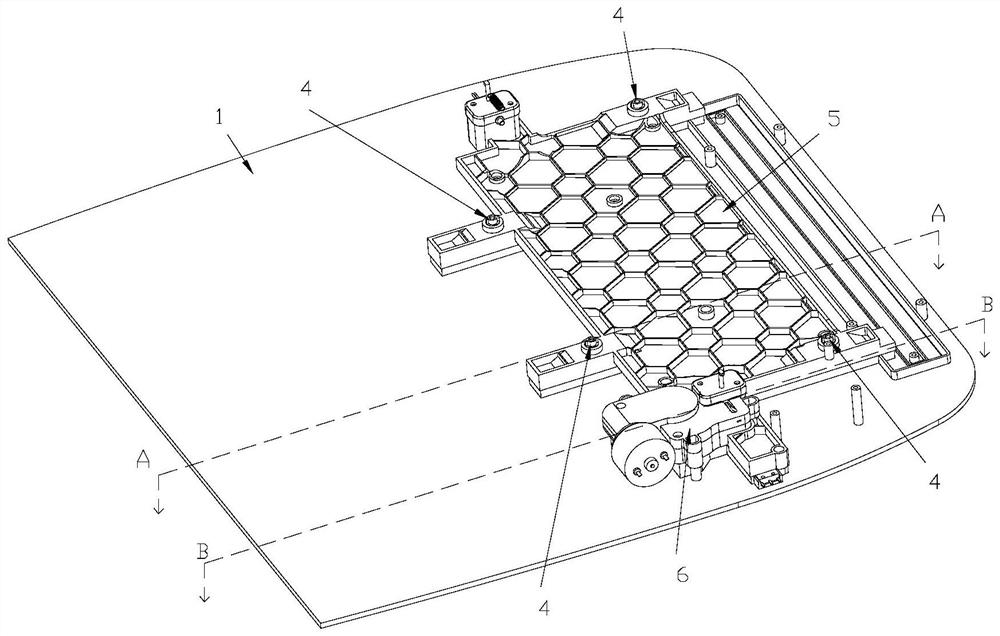

Cleaning device, cleaning machine, special garbage can and working method

PendingCN110811432AAutomatic dumpingAutomatic sweepingCarpet cleanersFloor cleanersEngineeringMachine

The invention discloses a cleaning device, a cleaning machine, a special garbage can and a working method. A robot mainly comprises two groups of reels which are arranged up and down and can move in the radial direction, and a mop strip is arranged between the reels. The robot further comprises a floor sweeping device, as well as a robot patent garbage can, a mop washing pool and a mop water squeezing device. The working method comprises the steps that a first face of the mop strip and a second face of the mop strip are used for mopping the floor, and the reels perform radial movement. The robot can automatically sweep the floor, mop the floor, dump garbage and wash the mop. During floor mopping, two sides of the mop strip can be used for mopping the floor respectively, thus during the floor mopping process, the two sides of the mop strip can be used, and therefore, the working area for floor mopping can be increased. According to the robot, the reels can perform radial movement, the reel with the increased size moves towards the reel strip with the decreased size, with the process, the total space occupied by the two reels is smaller, and thus the size of the whole robot can be effectively reduced.

Owner:蒋春燕

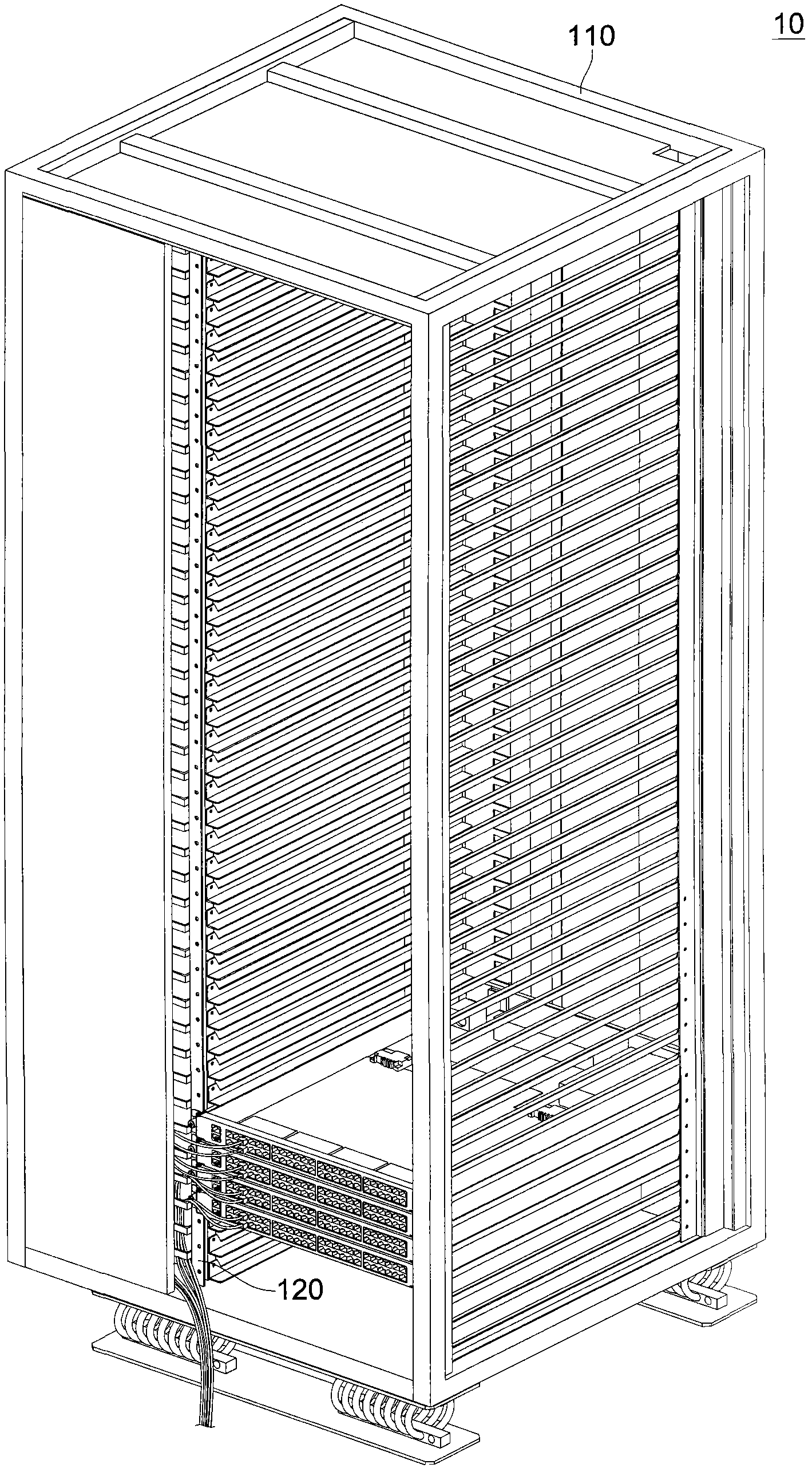

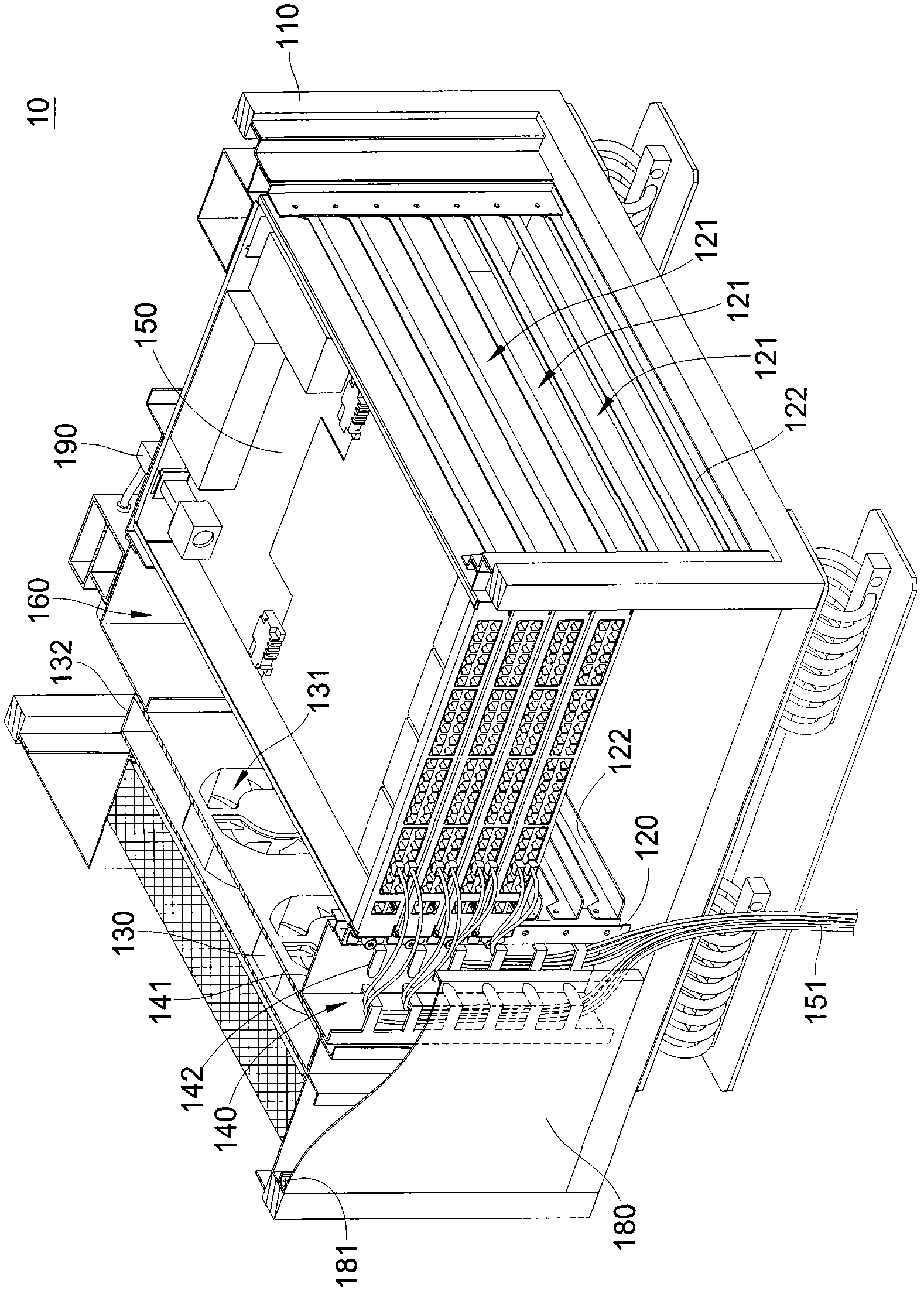

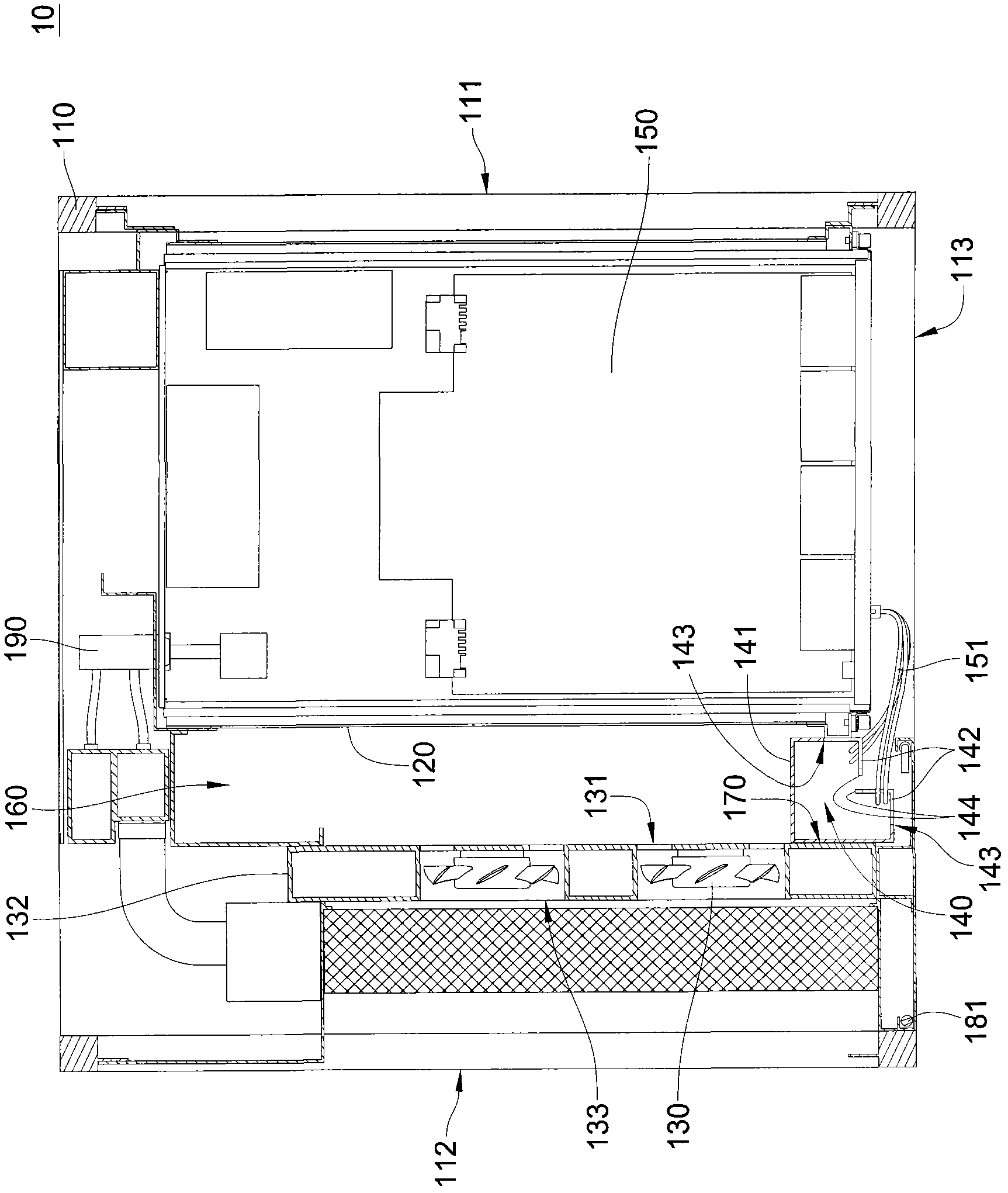

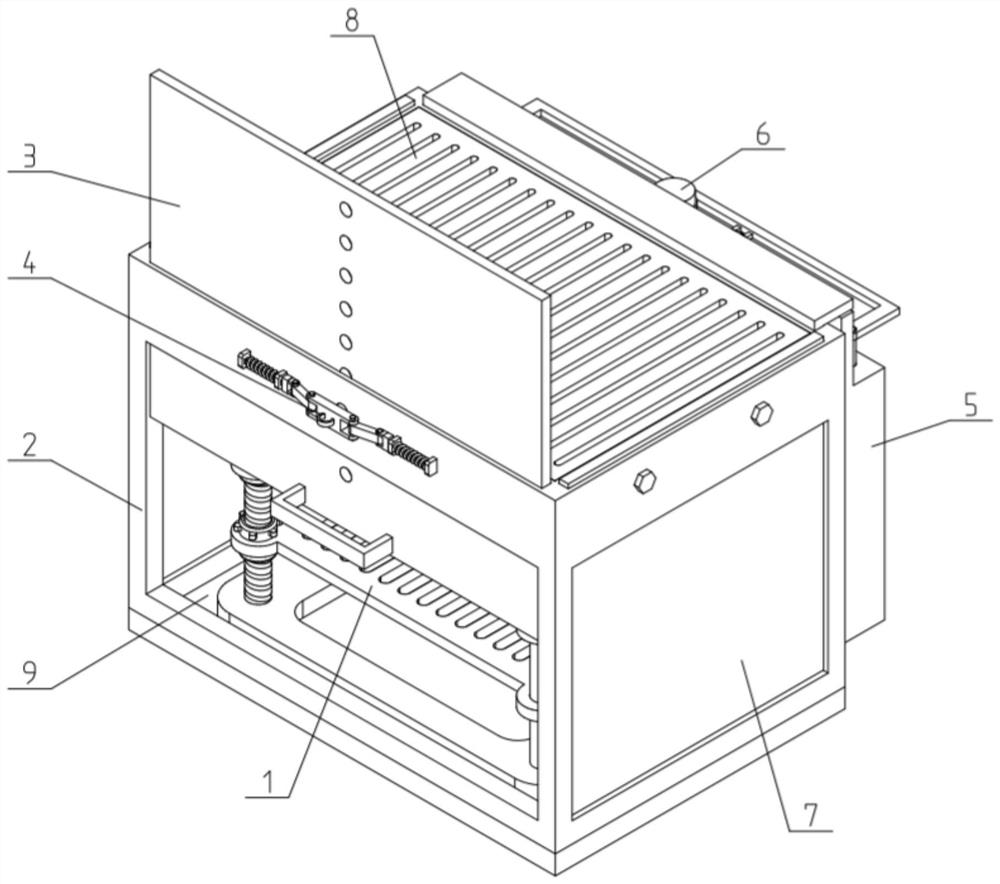

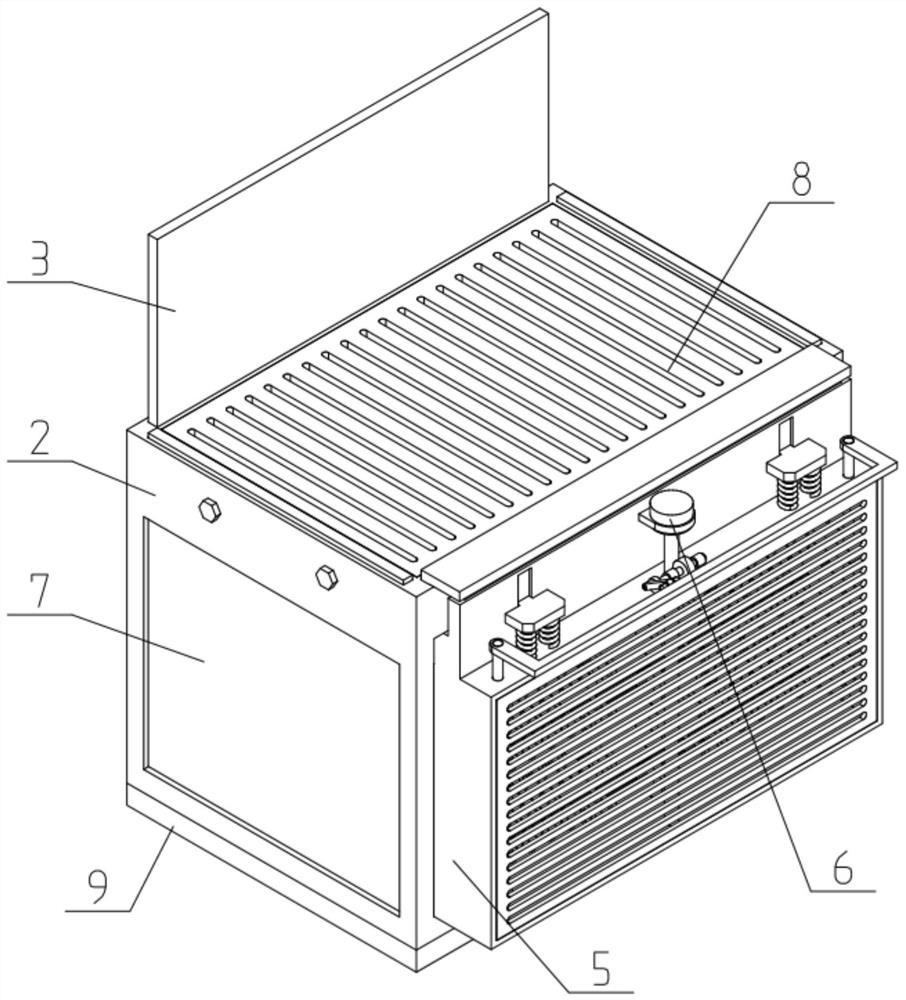

Frame structure

InactiveCN103188909ATo achieve cooling effectReduce total spaceRack/frame constructionCooling/ventilation/heating modificationsTight frameEngineering

The invention relates to a frame structure. The frame structure comprises a framework, an arithmetic device accommodating rack, at least one fan and a wire arrangement structure. The framework is provided with a first side edge, a second side edge opposite to the first side edge and a third side edge between the first side edge and the second side edge. The arithmetic device accommodating rack is arranged in the framework, and is adjacent to the first side edge and the third side edge. The arithmetic device accommodating rack is provided with a plurality of accommodating layers, and each accommodating layer is used for accommodating an arithmetic device. The fan is arranged in the framework, and is adjacent to the second side edge and the third side edge. The fan is provided with an air inlet facing to the arithmetic device accommodating rack. The wire arrangement structure is arranged in the framework, and is adjacent to the third side edge. The wire arrangement structure is accommodated between the fan and the arithmetic device accommodating rack, so that a heat dissipation space is formed between the fan and the arithmetic device accommodating rack.

Owner:INVENTEC CORP

Bonding device

ActiveCN106233442ASimple configurationAvoid shakingSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

Owner:SHINKAWA CO LTD

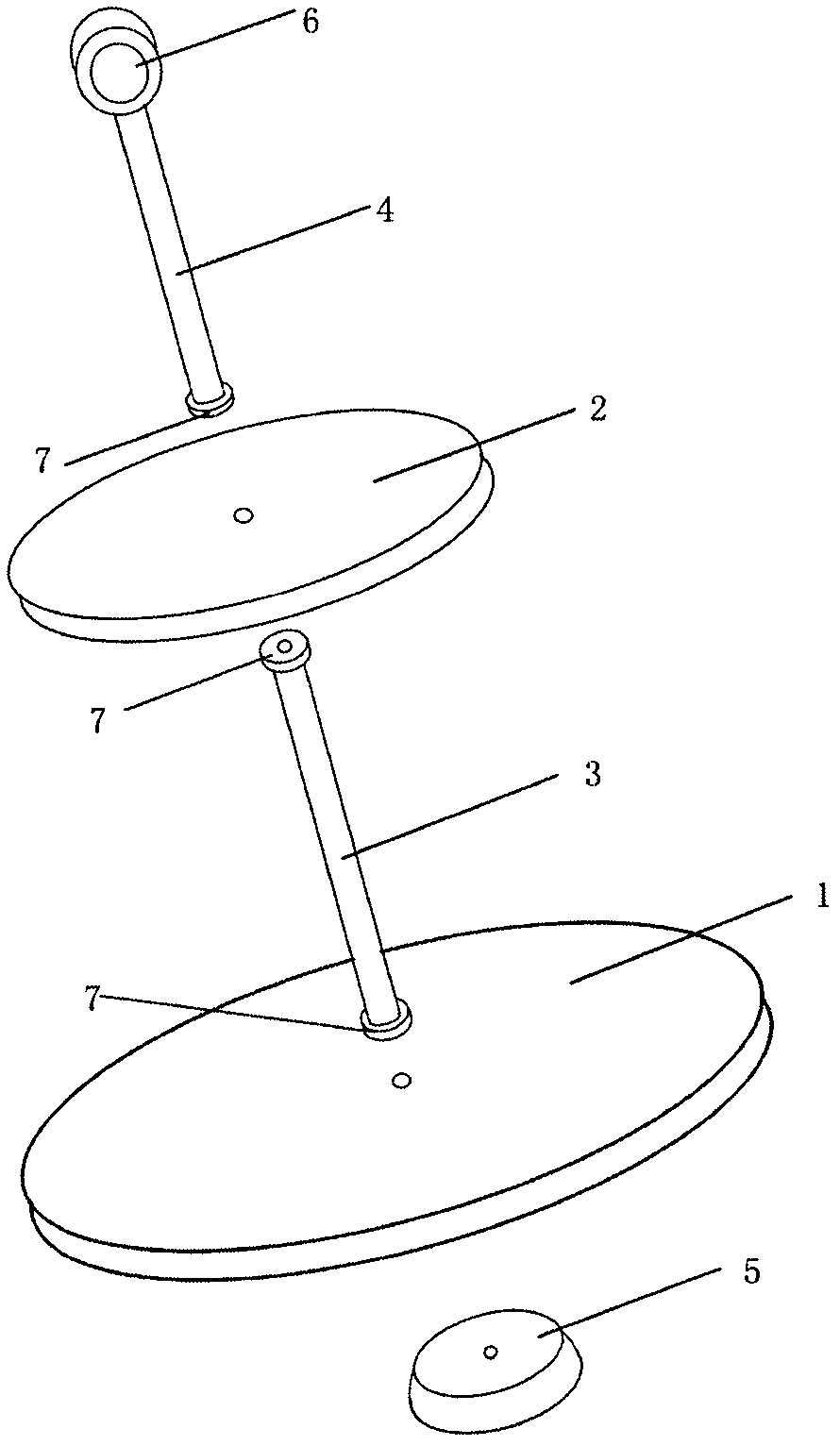

Dismountable cake tray

Owner:朱小龙

Blockchain management server cooling device

ActiveCN111642100BEasy to placeEasy to installServersClosed casingsEngineeringMechanical engineering

Owner:上海极目银河数字科技有限公司

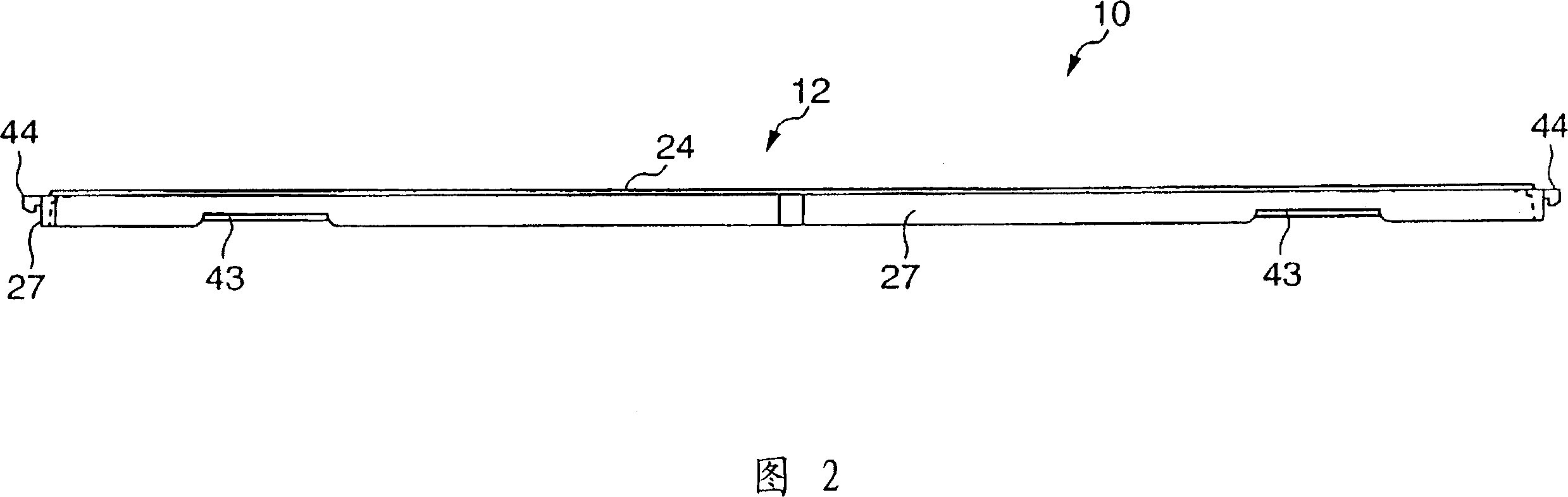

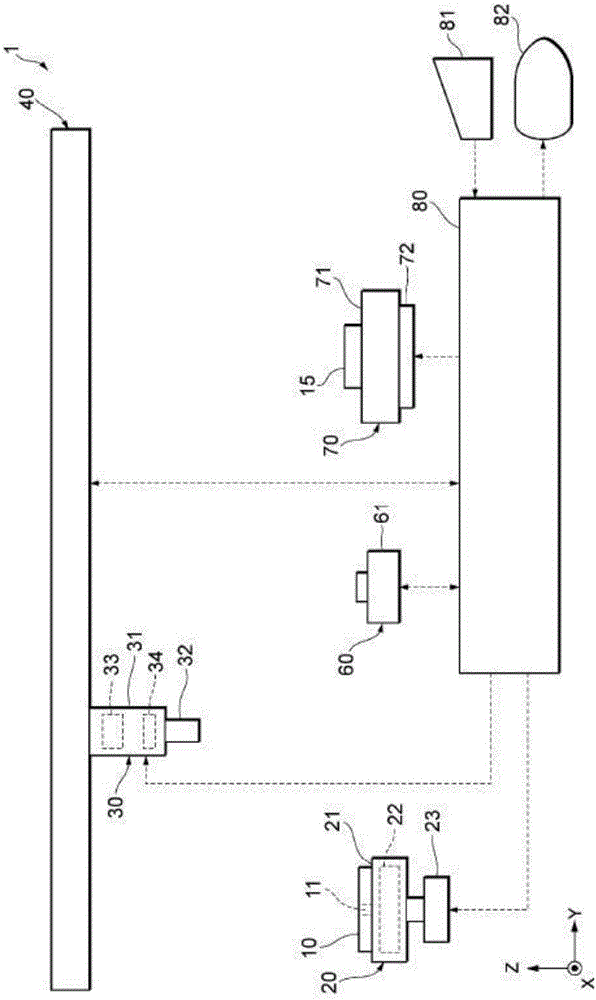

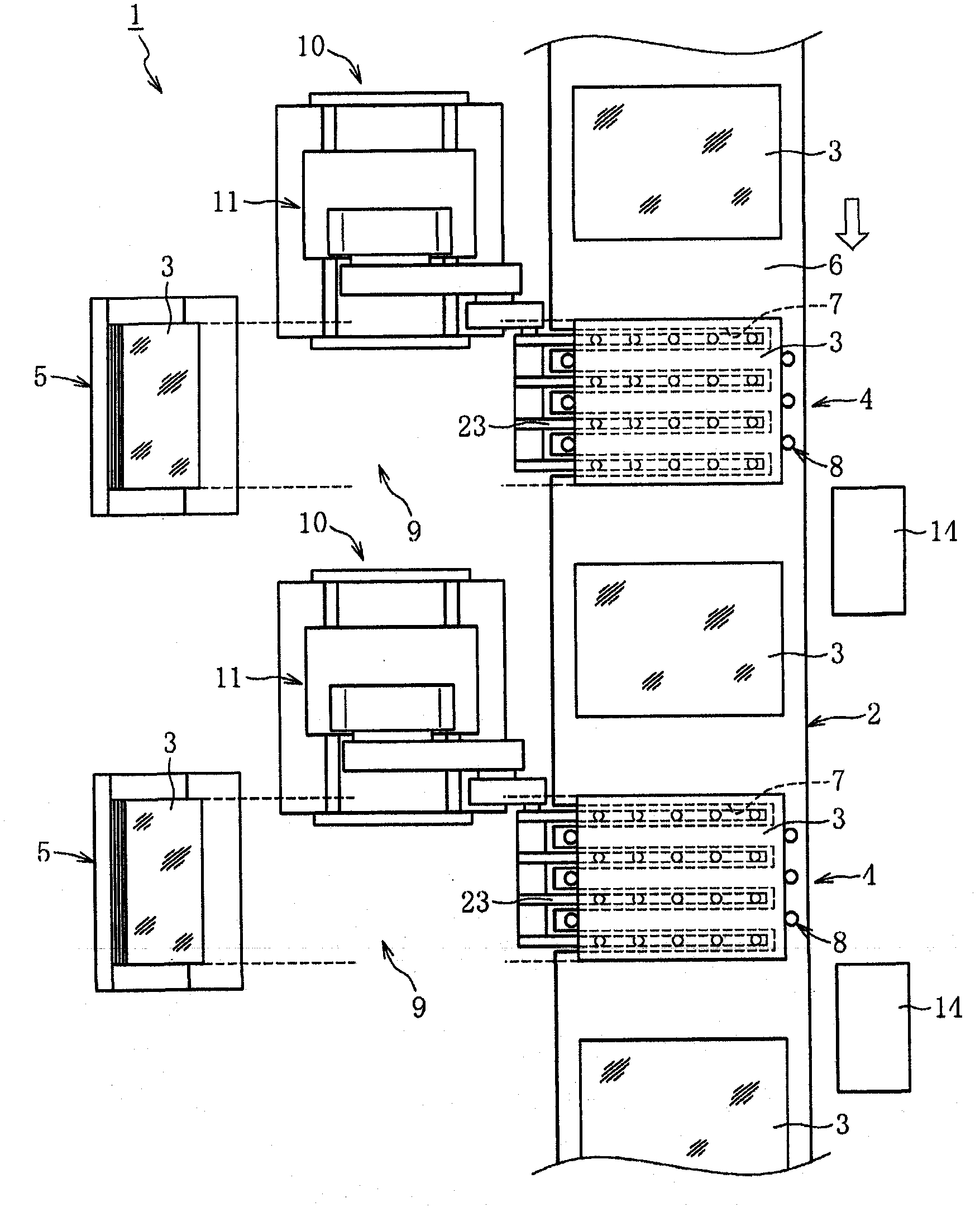

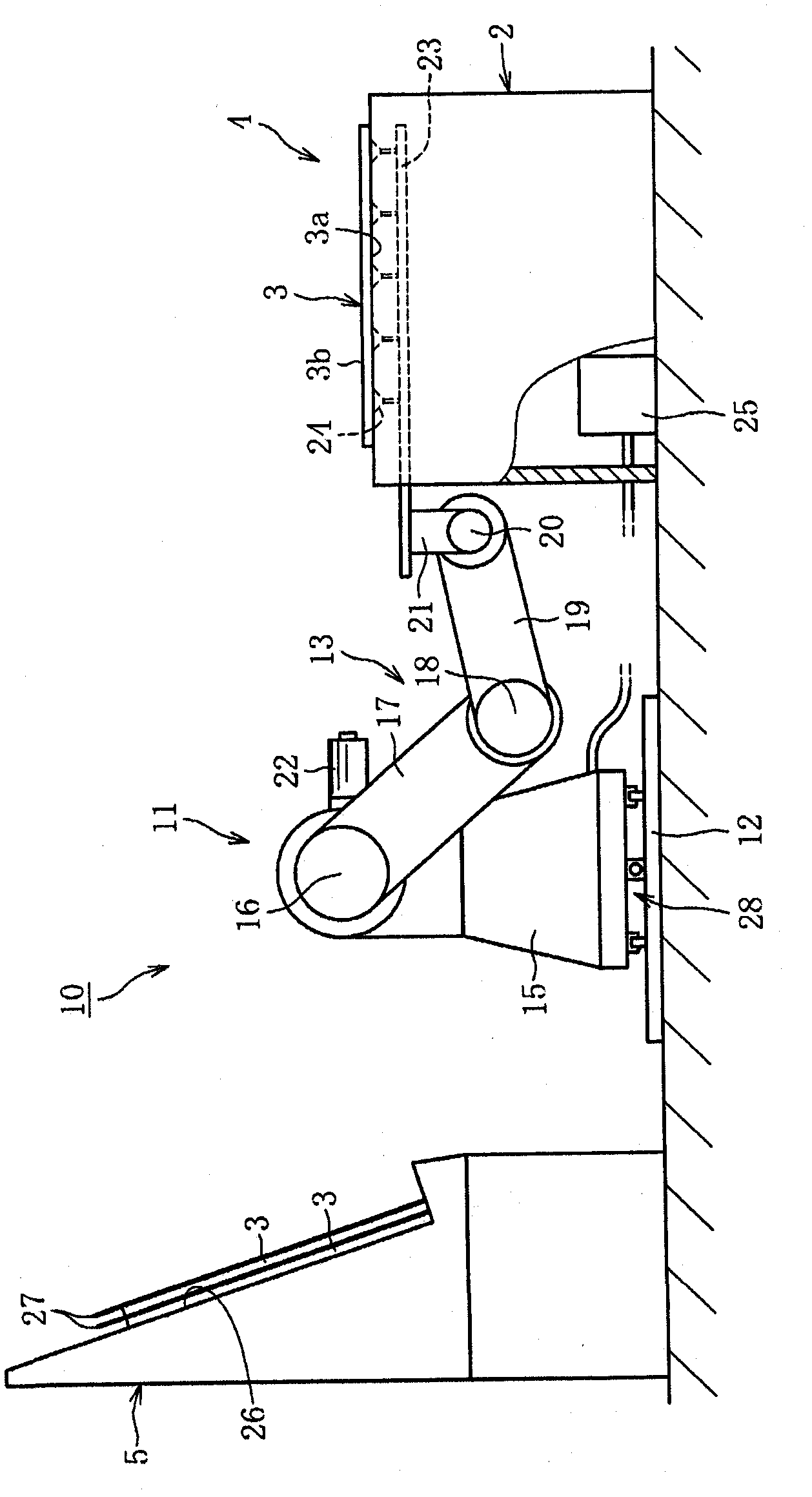

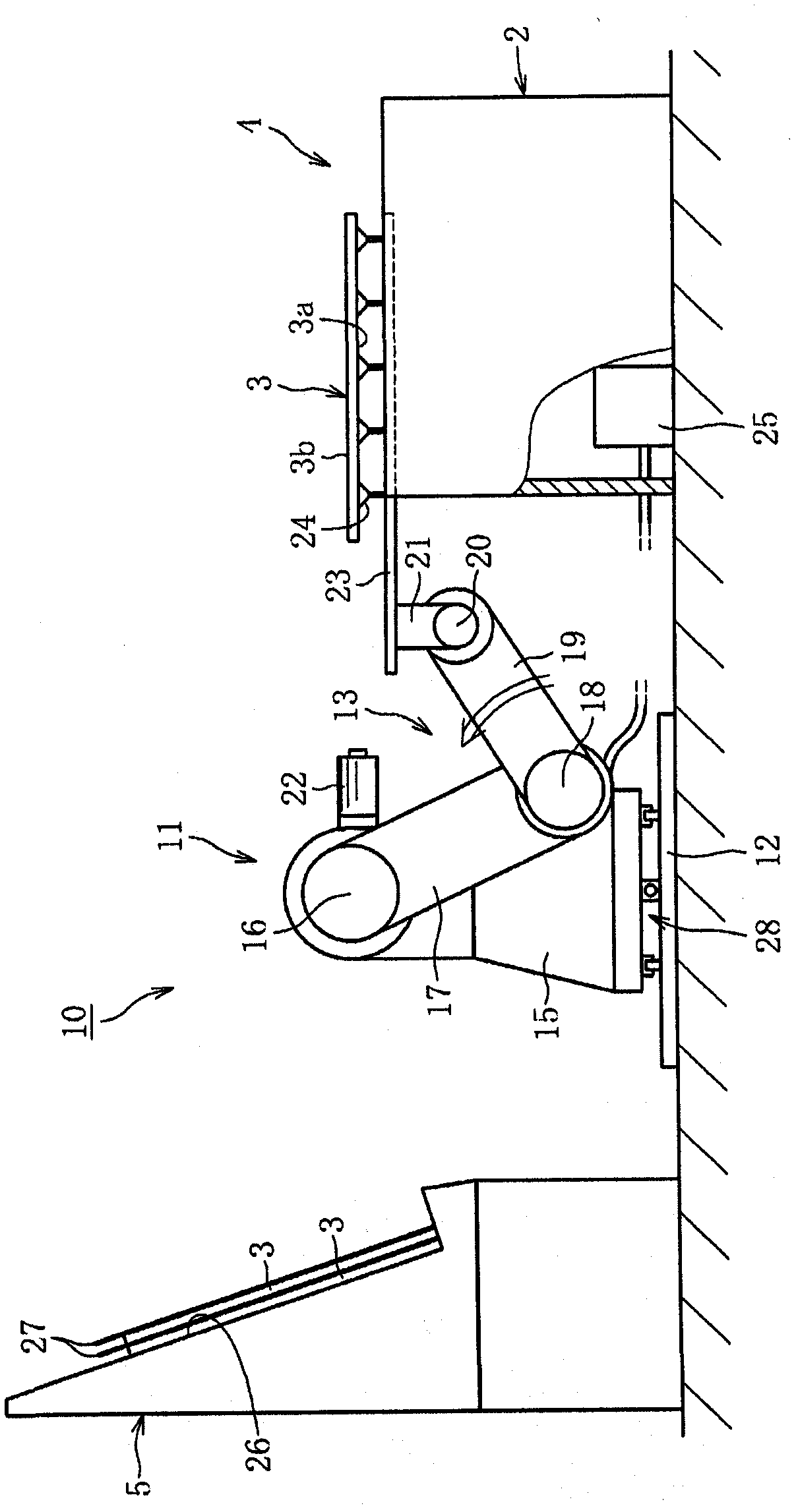

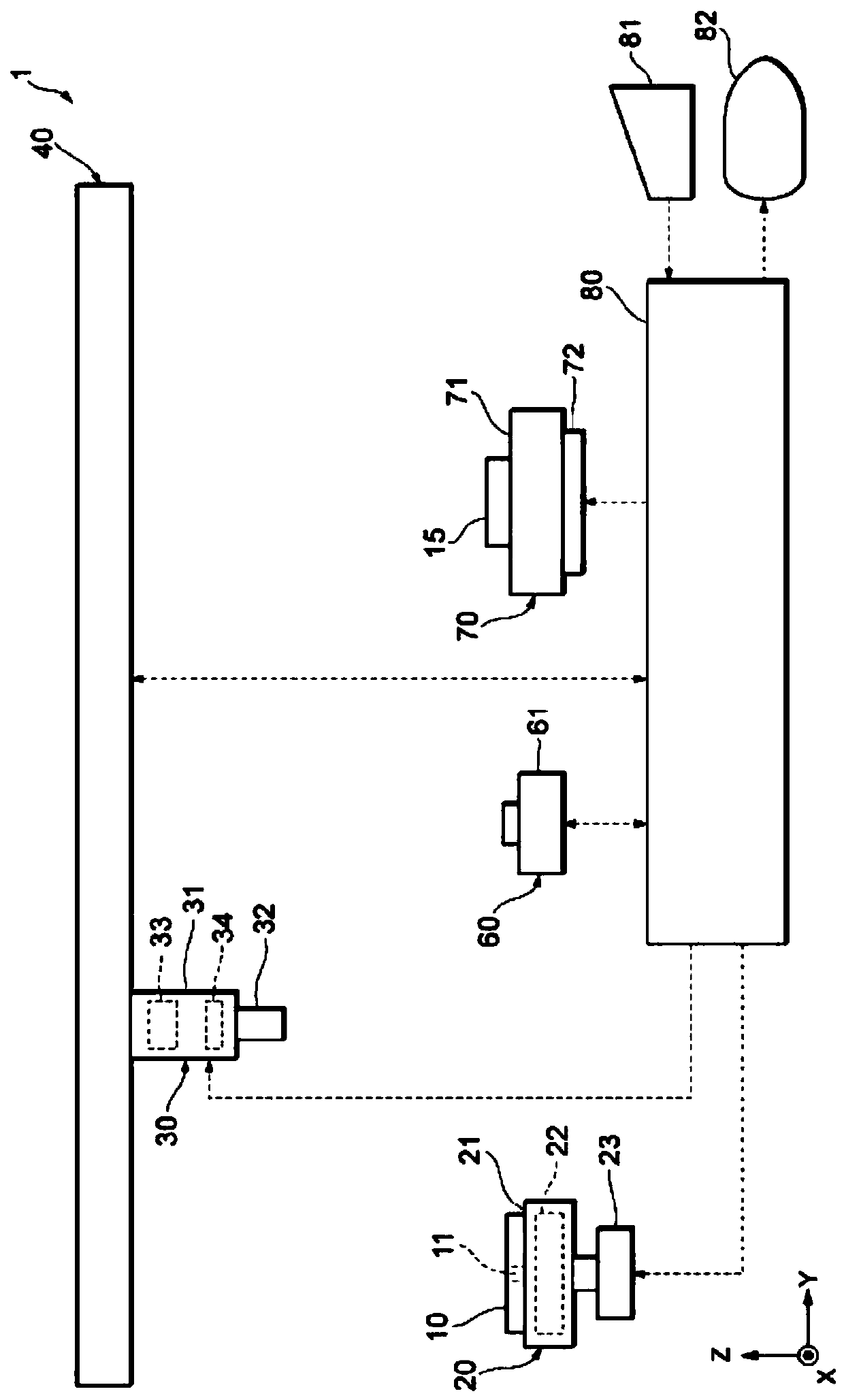

Apparatus and method for transferring board-like work

ActiveCN102105375BReduction of transfer timeReduce total spaceConveyorsSemiconductor/solid-state device manufacturingEngineeringArthrobotrys

An apparatus (10) for transferring a board-like work is provided with a multijoint robot (11), which has a series of movable arms (13) having multiple joints and a holding section (23) for holding and acquiring one surface of a board-like work (3) on the leading end of the series of movable arms (13). The multijoint robot (11) holds a supply-side lower surface (3a) of the board-like work (3) supplied to an acquiring position (4), and places an upper surface (3b) opposite to the lower surface (3a) on a placing surface (26) at a placing position. The acquiring position (4) and the placing position are arranged to face each other, and the multijoint robot (11) is arranged on a side of a facing space. The multijoint robot (11) transfers the board-like work (3) from the acquiring position (4) to the placing position over the facing space by turning, bending and stretching operations of the series of movable arms (13). A part of the transfer operation includes a reversing operation for placing the upper surface (3b) of the board-like work (3) on the placing surface (26).

Owner:NIPPON ELECTRIC GLASS CO LTD

Liquid crystal display panel and manufacturing method thereof

ActiveCN107402471BInclination angle θ increasesImprove arrangement spaceNon-linear opticsLiquid-crystal displayEngineering

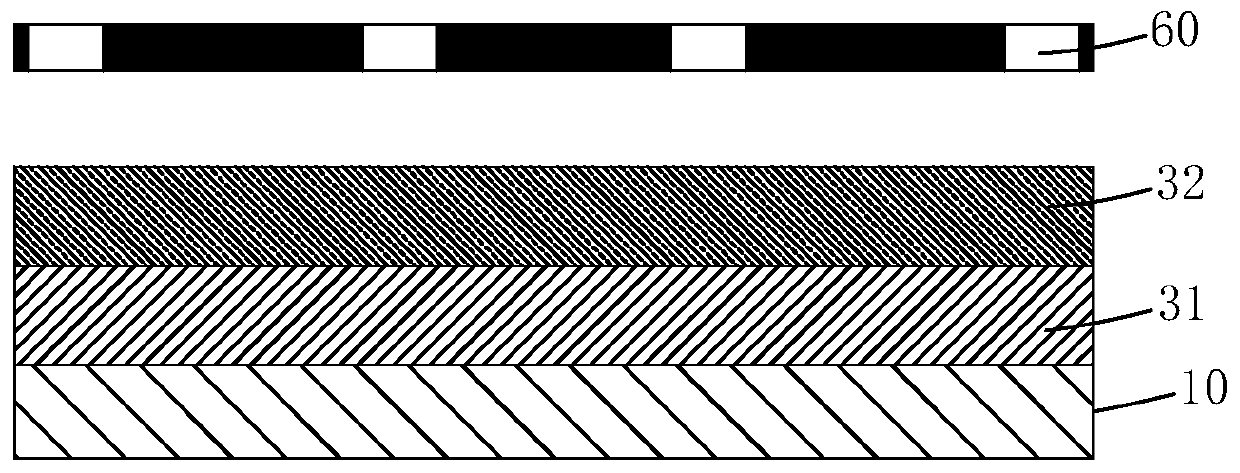

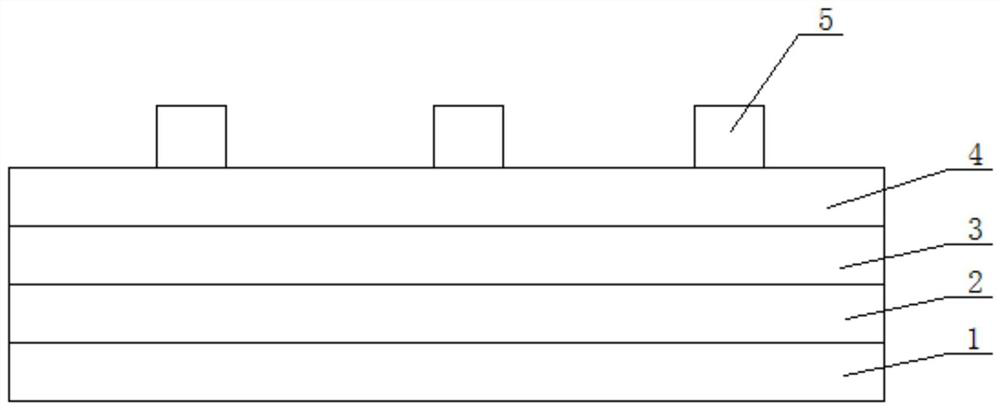

A liquid crystal display panel and a manufacturing method therefor. The manufacturing method for the liquid crystal display panel uses a common mask plate (60) to perform patterning processing on stacked multilayer photoresist thin films (31, 32) by means of a one-time exposure developing procedure in order to produce stacked multilayer photoresist layers (41, 42), gaps (40) being formed by the stacked multilayer photoresist layers (41, 42); the multilayer photoresist thin films (31, 32) have different photosensitive properties, and therefore the multilayer photoresist layers (41, 42) produced by means of the exposure developing procedure have different patterns, different patterns referring to there being a difference in at least one parameter amongst the upper base dimensions (w1), the lower base dimensions (w2), and the angle of inclination (θ1, θ2); the multilayer photoresist layers (41, 42) having different patterns are used for adjusting the angle of inclination (θ) of the gaps (40), and are able to effectively increase the angle of inclination (θ) of the gaps (40). The gaps (40) of the liquid crystal panel comprise stacked multilayer photoresist layers (41, 42) having different patterns, such that the angle of inclination (θ) of the gaps (40) can be effectively increased.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

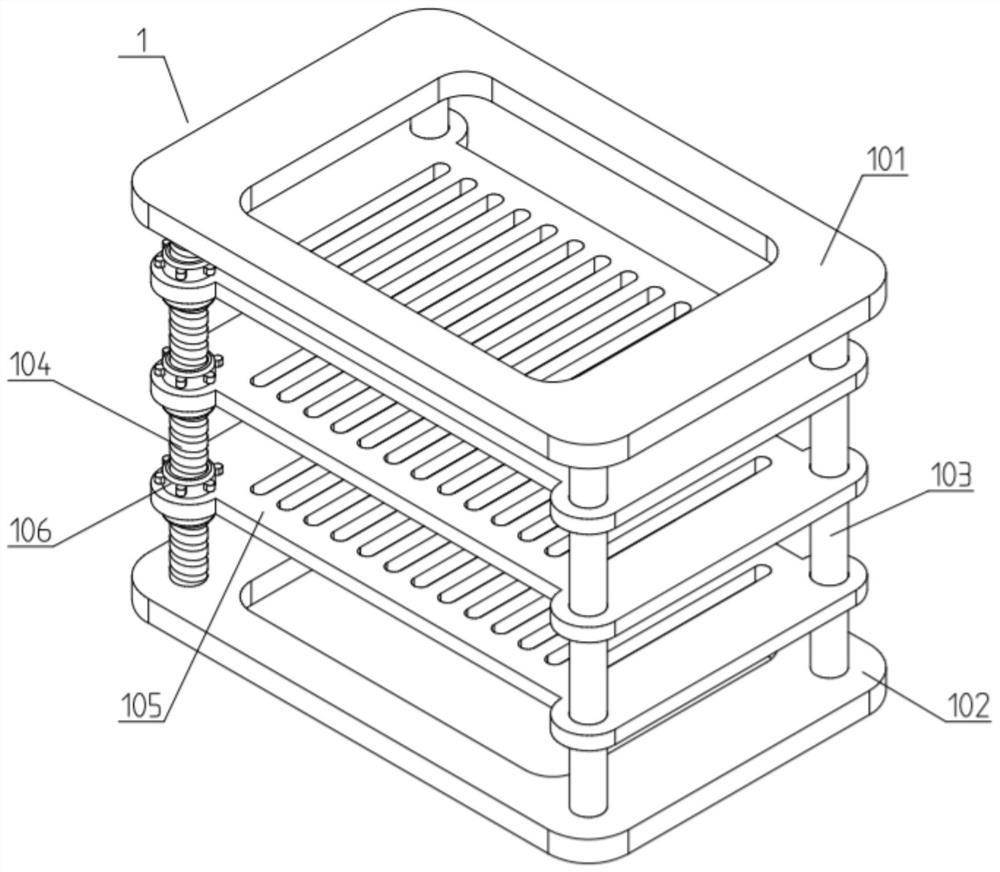

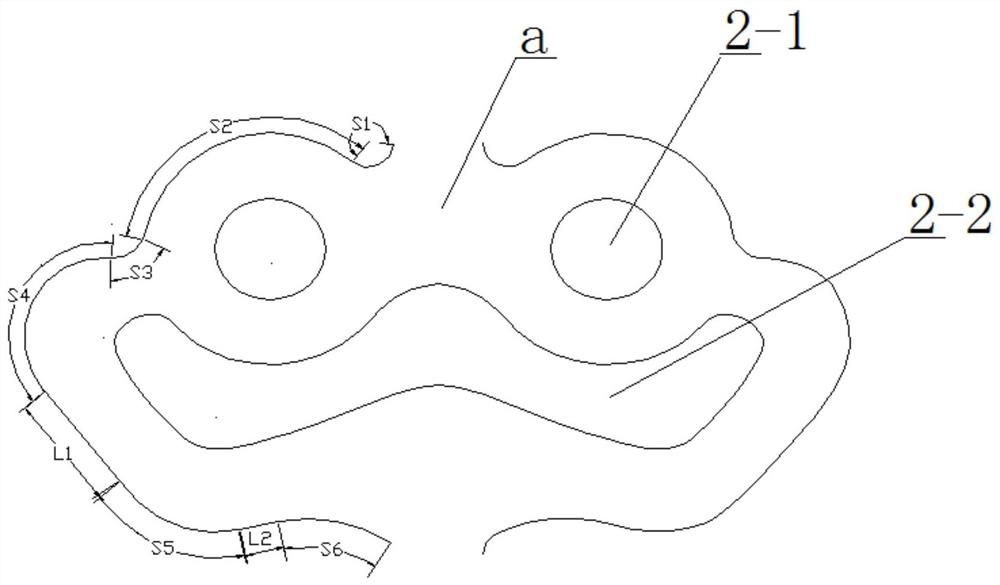

Microreactor and manufacturing method thereof

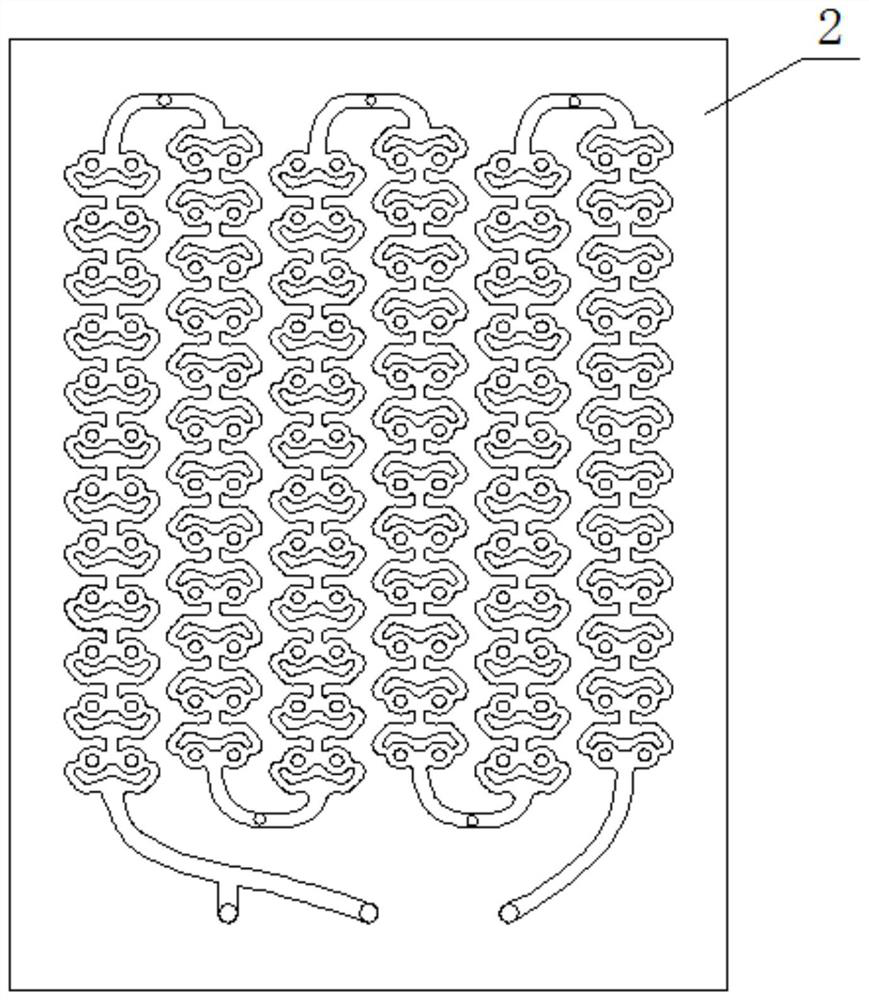

PendingCN112915941AIncrease fluid holding capacityIncrease volumeChemical/physical/physico-chemical microreactorsMicroreactorStructural engineering

The invention discloses a micro-reactor and a manufacturing method thereof. A micro-reactor body is formed in a way: a reaction channel base plate is arranged on a lower hot bath base plate, an upper hot bath base plate is arranged on the reaction channel base plate, and a cover plate is arranged on the upper hot bath base plate; the reaction channel plate is formed by processing at least one micro-reaction channel which is communicated end to end on a substrate; an inlet is formed in one end of each micro-reaction channel, an outlet is formed in the other end of each micro-reaction channel, each micro-reaction channel is formed by communicating at least one micro-reaction chamber a end to end, the micro-reaction chambers a of every two adjacent micro-reaction channels are distributed in a staggered mode, each micro-reaction chamber a is in a frog face shape, and two impact columns are arranged at the inlets in the micro-reaction chambers a; the plane where the center lines of the two impact columns are located is perpendicular to the center line of the micro-reaction channel, and an arc-shaped baffle is arranged in the micro-reaction chamber a located on the downstream portions of the two impact columns. The micro-reaction chambers of the two adjacent micro-reaction channels are distributed in a staggered manner, so that the interval space between the adjacent micro-reaction channels is reduced, the volume of the micro-reaction channels is increased, and the liquid holdup of the micro-reactor is improved.

Owner:成都叙通科技有限公司

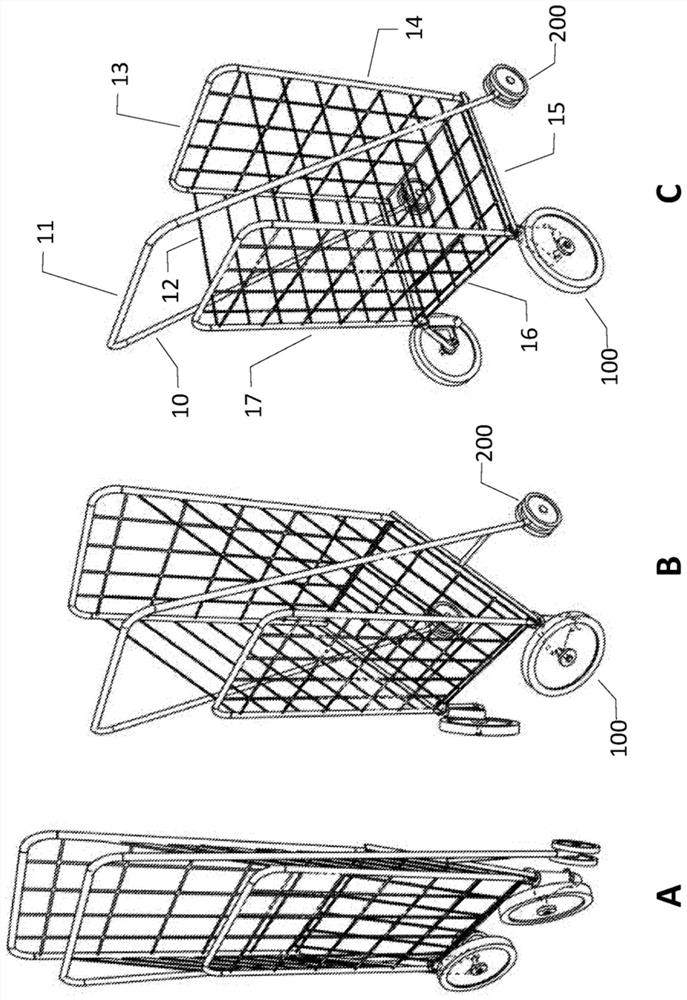

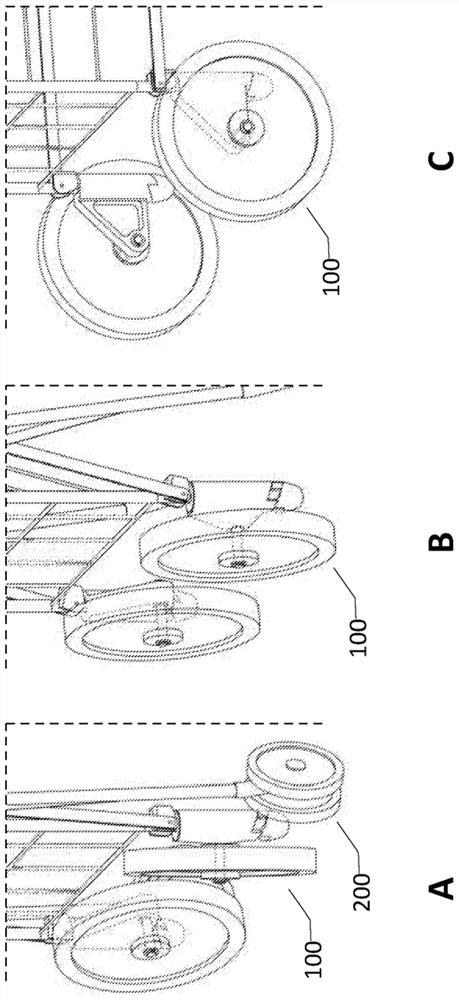

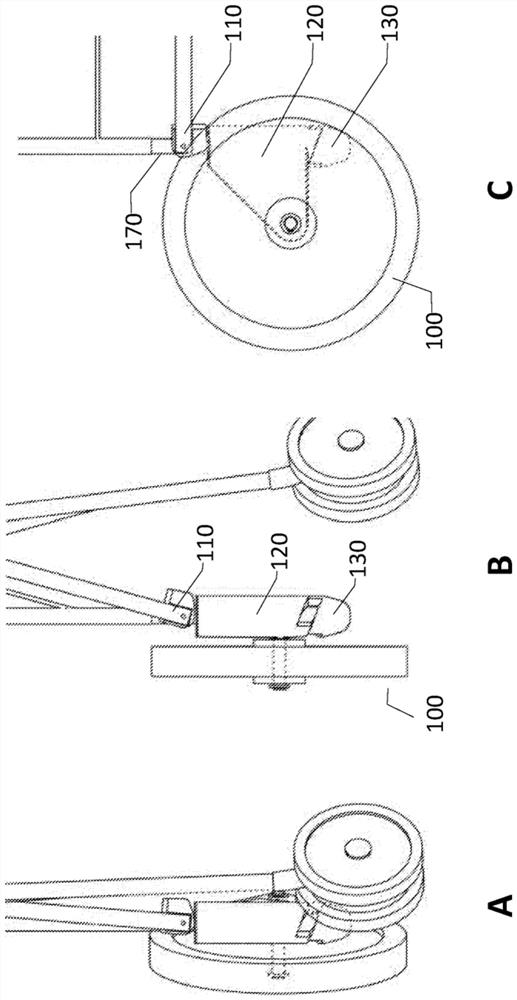

Foldable cart with deployable wheels

InactiveCN113165680ASimple structureReduce manufacturing costHand carts with multiple axesVehicle frameCart

A foldable cart includes a handle portion, a foldable frame movably connected to the handle, and one or more wheels for rolling on a surface. In an unfolded (in-use or open) condition, the foldable frame constructs a holding-space defining a receiving cavity therein for carrying items, and the action of unfolding the frame automatically deploys wheels to enable immediate use of the cart by the end-user or customer. In a folded (storage or closed) condition, the carts' frame folds to occupy a smaller space in one or more spatial dimensions, and the automatically deployed wheels turn to occupy smaller total space in one or more spatial dimensions. In the folded condition, the cart is easy to store in a small space (e.g. in a small closet, under a bed, etc.) or transport (e.g. in the trunk of an automobile, vehicle, airplane, train, ship with a courier, etc.).

Owner:D 达比修

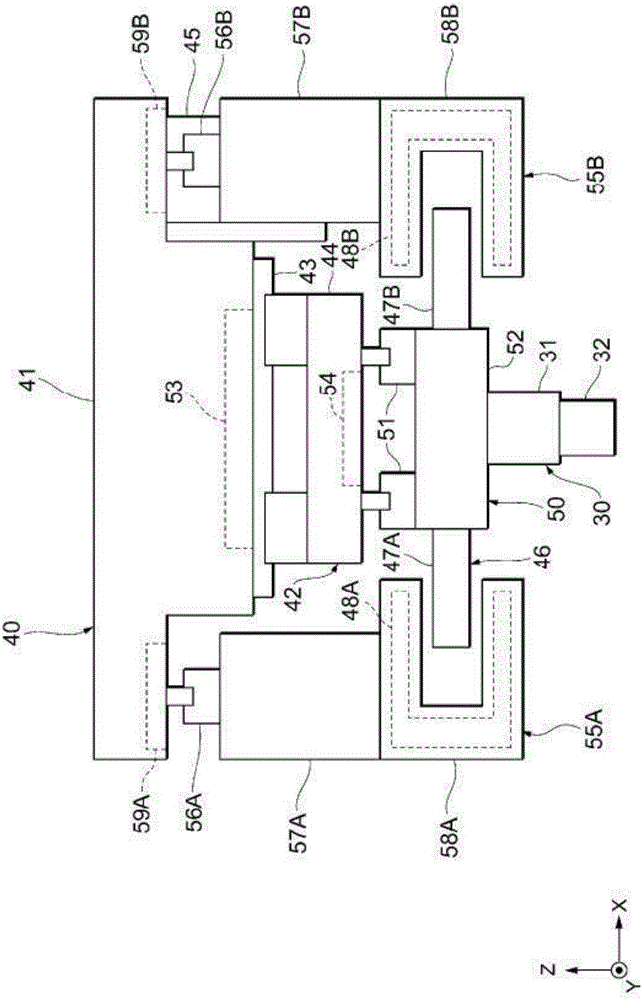

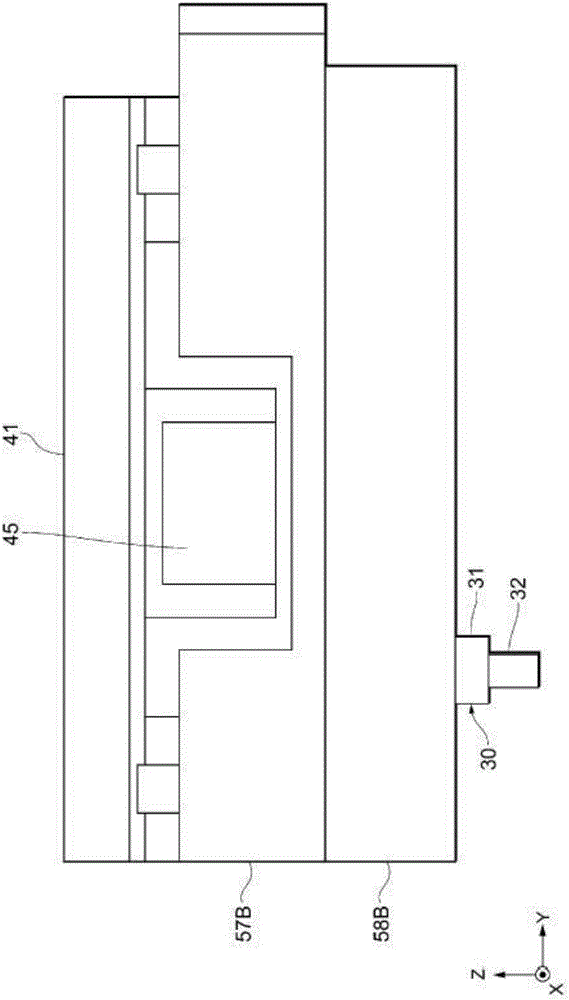

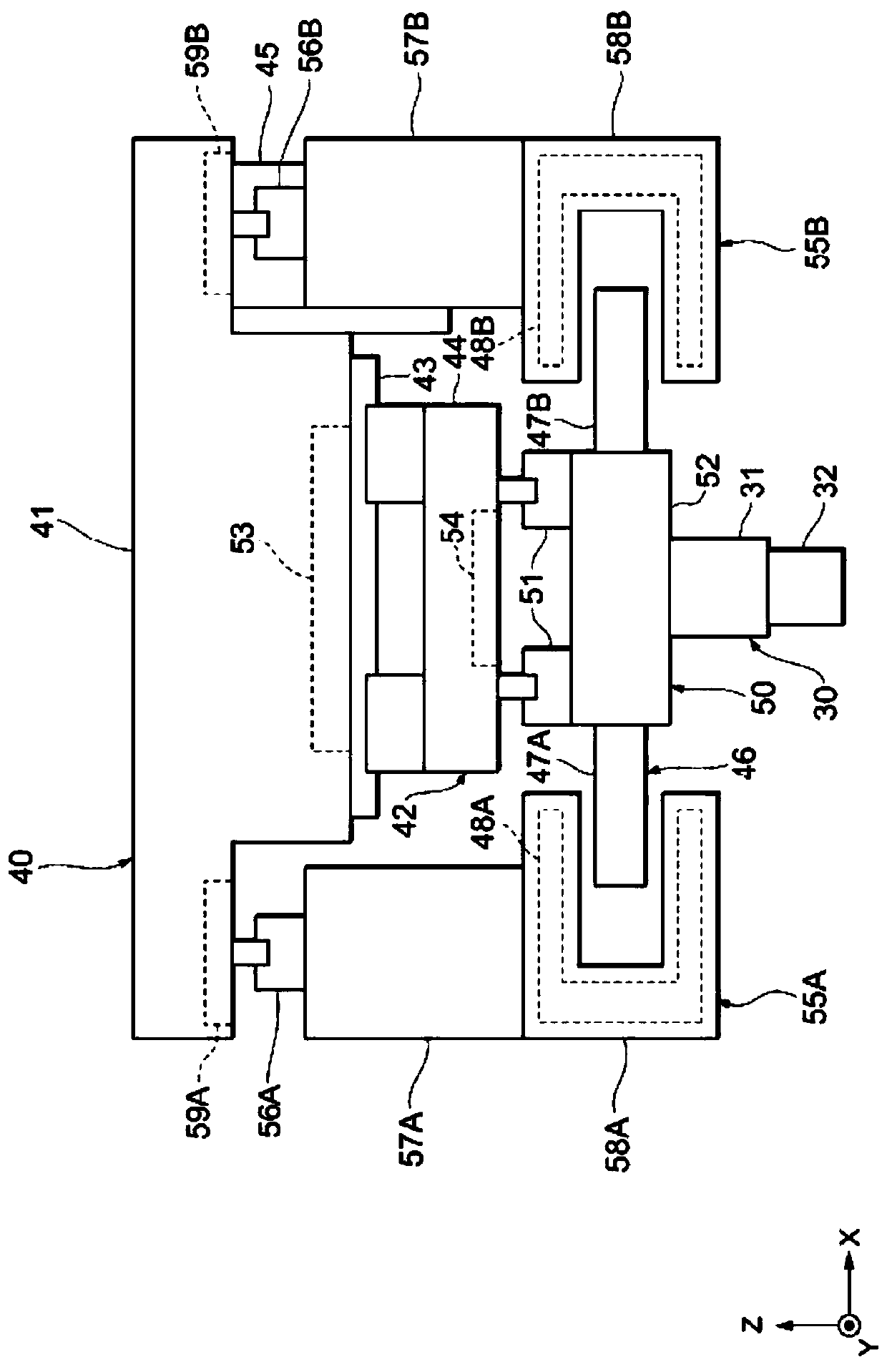

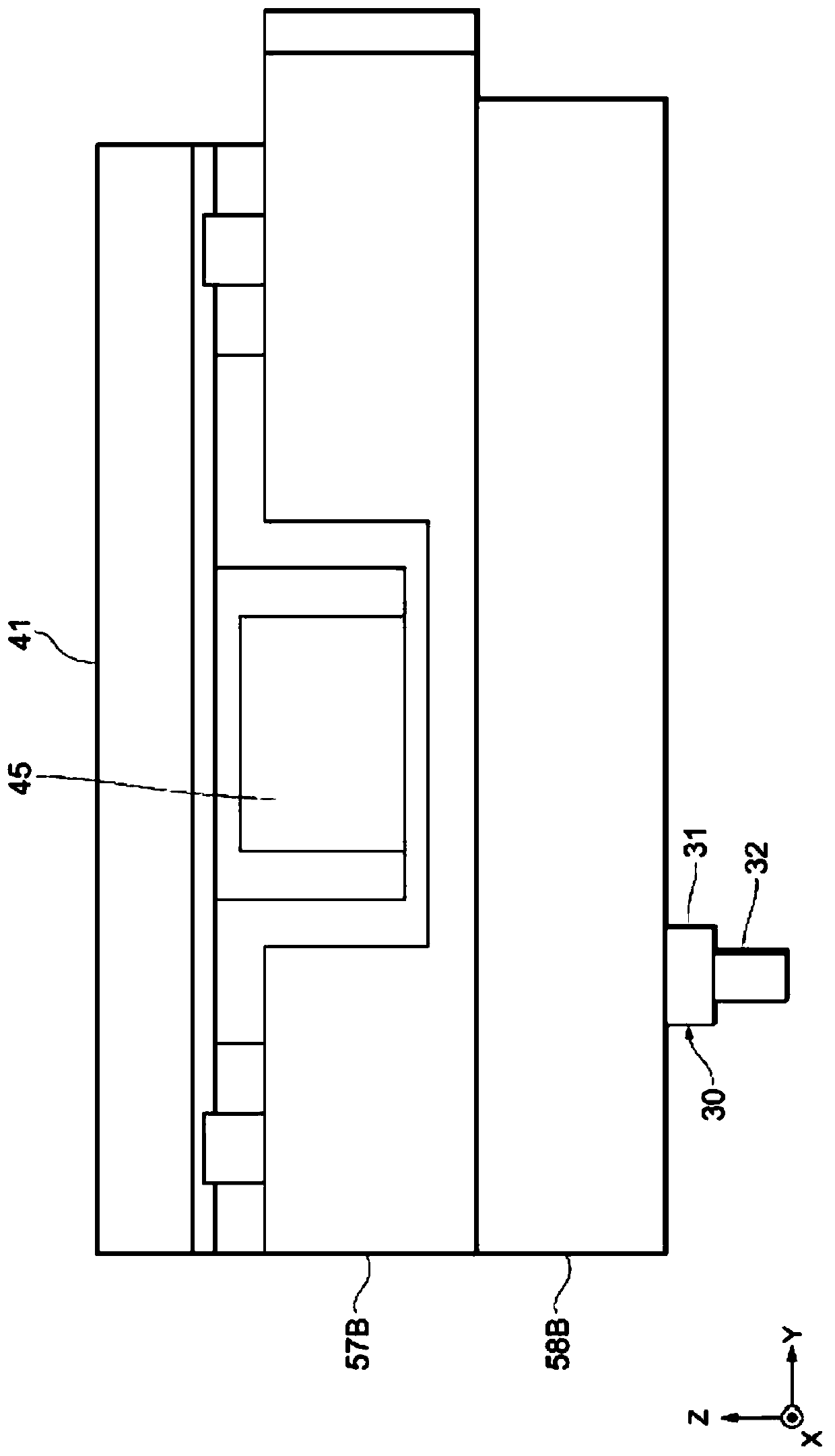

Die bonding device

ActiveCN106233442BSimple configurationAvoid shakingSolid-state devicesSemiconductor/solid-state device manufacturingGravity centerEngineering

The invention provides a crystal bonding device, comprising: a platform (52), which is arranged to move along the Y-axis direction relative to a pedestal (41); and a first reaction member (58A) and a second reaction member (58B), which are respectively opposite The pedestal is provided so as to be movable in the Y-axis direction; the first reaction member and the second reaction member are configured to move oppositely to the platform in the Y-axis direction when the platform moves in the Y-axis direction, and the first reaction member and the second reaction member The 2 reaction members are arranged on both sides in the X-axis direction with the platform at intervals, and the first reaction member and the second reaction member are arranged so that the center of gravity of the first reaction member and the second reaction member is at a position based on the center of gravity of the platform. . Thereby, there is provided a die bonding apparatus capable of suppressing an increase in space and improving the weight balance in the pedestal.

Owner:SHINKAWA CO LTD

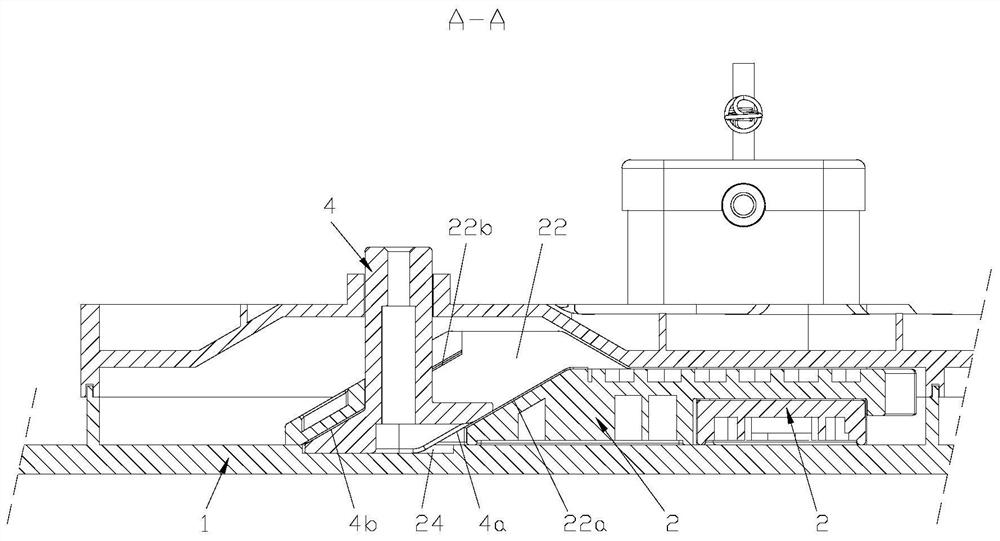

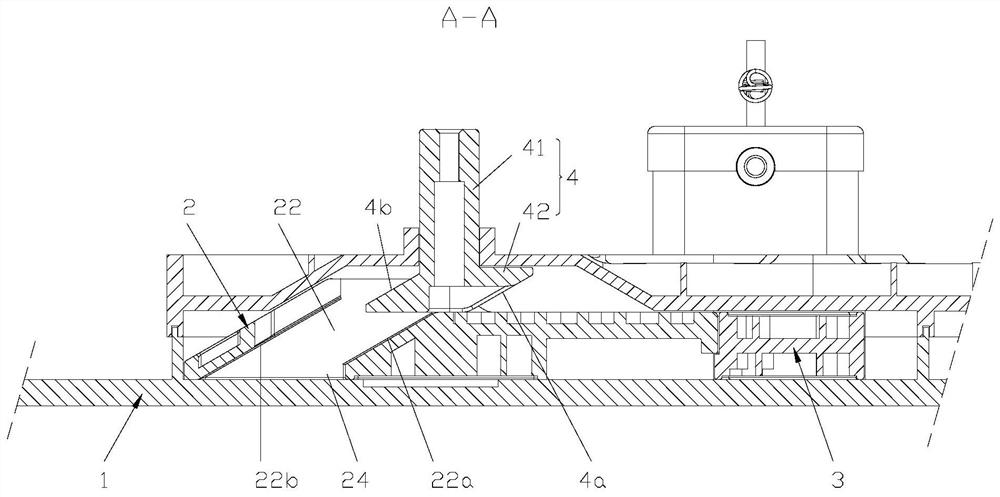

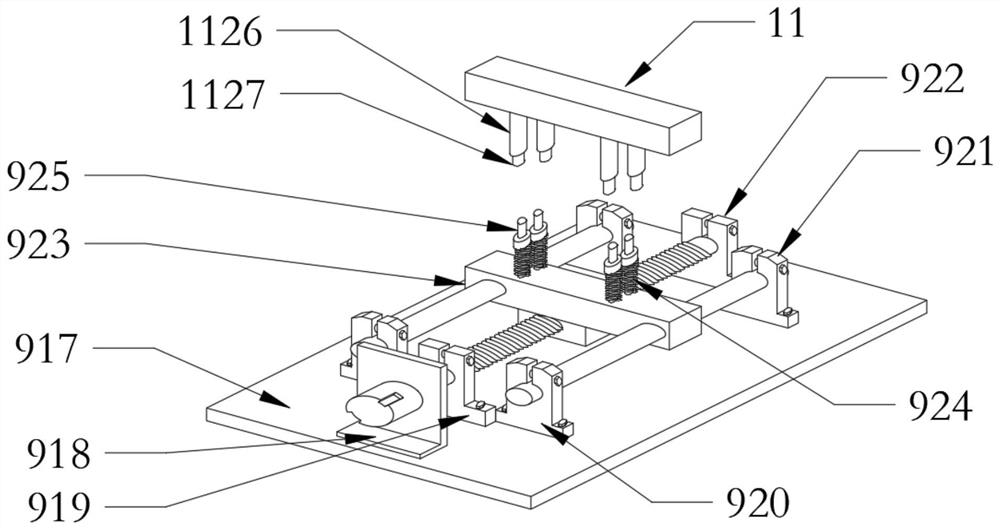

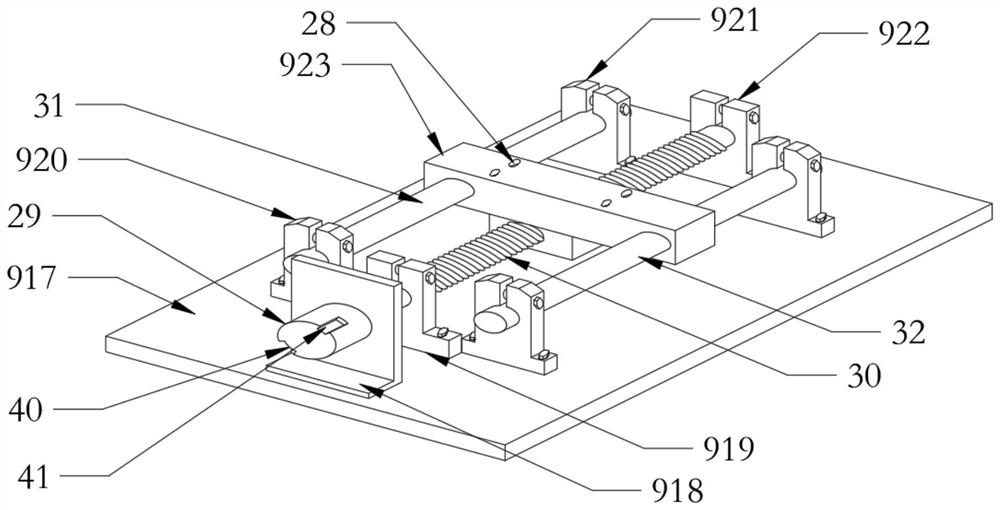

Lifting mechanism and sweeper base station

PendingCN112938816AReduce spaceIngenious structural designLifting framesEngineeringStructural engineering

The invention is suitable for the field of lifting machinery, and provides a lifting mechanism and a sweeper base station. The lifting mechanism comprises a base; a first moving part which is movably arranged on the base, wherein a first inclined plane is arranged on the side, deviating from the base, of the first moving part, the telescopic part is telescopically arranged on the side, deviating from the base, of the first moving part, the telescopic part is provided with a second inclined plane matched with the first inclined plane, and when the first moving part moves, the second inclined surface and the first inclined surface move relatively; and a fixed part which is fixed to the base and located above the first moving part, wherein a through hole is formed in the fixed part, and the telescopic part penetrates through the through hole and can move in the through hole. According to the lifting mechanism, the occupied space of the lifting mechanism in the lifting direction can be greatly reduced, the structural design is ingenious, and the size is small.

Owner:SHENZHEN TOPBAND CO LTD

PLC-based electromechanical integrated equipment locking device

PendingCN112144965AAnti-theft functionExtended service lifeKeysStructural engineeringMechanical engineering

Owner:亓秀玲

A kind of lrm photoelectric radio frequency integrated connector compatible with VPX standard

ActiveCN111969376BEliminate radial playEliminate axial playIncorrect coupling preventionTwo-part coupling devicesRadio frequencyMechanical engineering

An LRM photoelectric radio frequency integrated connector compatible with the VPX standard, including a plug and a socket; the plug includes a plug housing on which an optical fiber plug module, several high-speed plug modules, a radio frequency plug module, and a hybrid plug module are arranged ;The socket includes a socket housing, on which there are fixedly installed an optical fiber socket module, several high-speed socket modules, a radio frequency socket module, and a hybrid socket module; the plug and the socket are mated together to form an LRM photoelectric radio frequency integrated connection compatible with the VPX standard connector; the LRM photoelectric radio frequency integrated connector compatible with the VPX standard of the present invention integrates different types of connectors that meet the requirements of the VPX standard into the same connector housing, and has the advantages of small total space occupation and light weight through structural optimization design , The advantages of highly uniform connector installation and accurate relative position of the connectors ensure the reliability of signal transmission between components or systems that comply with the VPX standard, and meet the increasingly complex and sophisticated signal connection requirements between hardware components and systems that are compatible with the VPX standard .

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

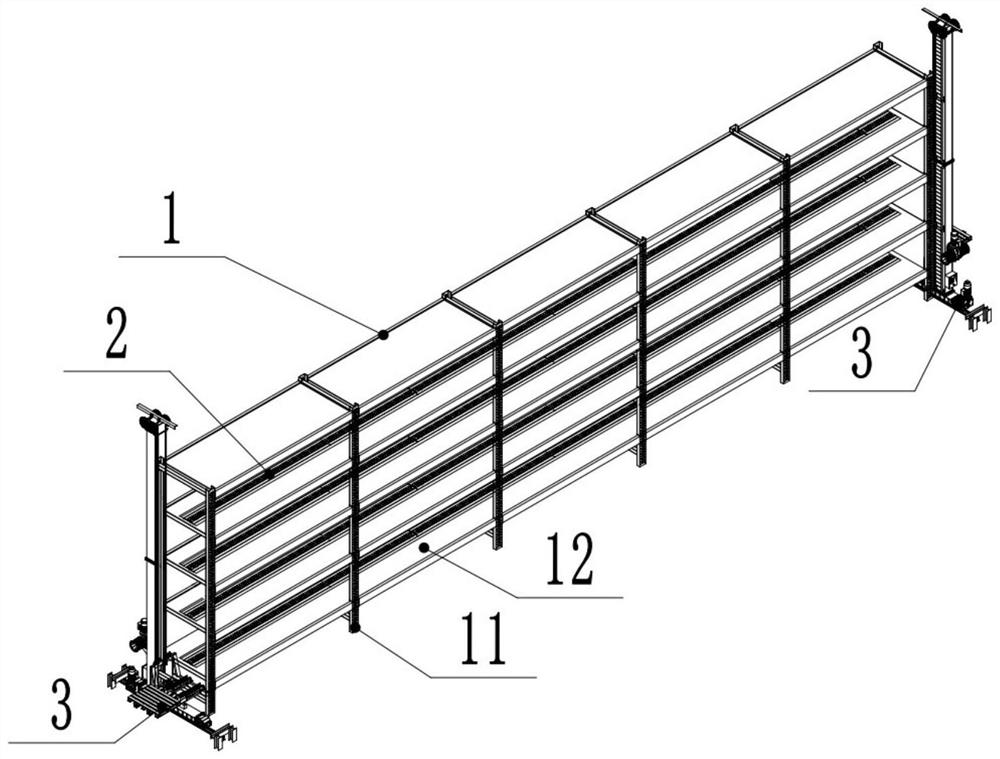

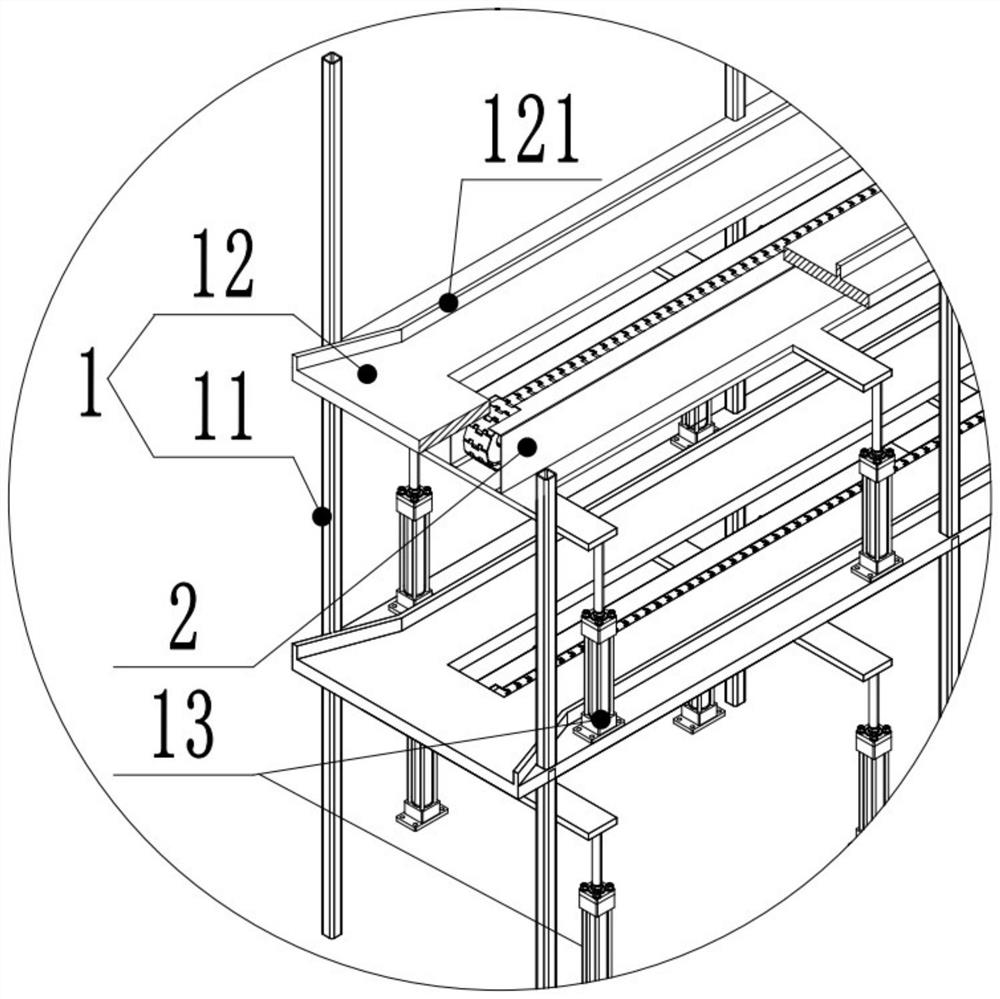

A large quantity of cargo storage and transportation equipment and transportation method

ActiveCN110789893BIncrease profitSolve the problem of code placementStorage devicesBulk cargoAgricultural engineering

The invention discloses large-scale goods storage and transportation equipment and a transportation method and belongs to the field of warehousing equipment. The large-scale goods storage and transportation equipment comprises a shelf, conveyors and stackers. The shelf comprises at least four supports vertically mounted above the ground and a plurality of laminates fixedly mounted between the supports. The laminates divide the space in the support into a plurality of parts, the laminates are parallel to the ground, a predetermined space is reserved in the middle position of each laminate, lifting assemblies are fixedly mounted below the conveyors, the moving direction of the lifting assemblies is perpendicular to the ground, the stackers are mounted at the two ends of the shelf, and the stackers are matched with the conveyors. According to the large-scale goods storage and transportation equipment and the transportation method, the stackers are mounted at the two ends of the shelf; andthe spacing in the shelf is reduced, the utilization rate of a warehouse is increased, and the speed of warehouse-in and warehouse-out of the goods is increased by arranging the conveyors in the shelf.

Owner:JINLING INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com