Intelligent bamboo filament braiding machine

A weaving machine and bamboo silk technology, applied in mechanical equipment, sugarcane machining, etc., to achieve the effects of high weaving efficiency, reduced purchase cost, and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

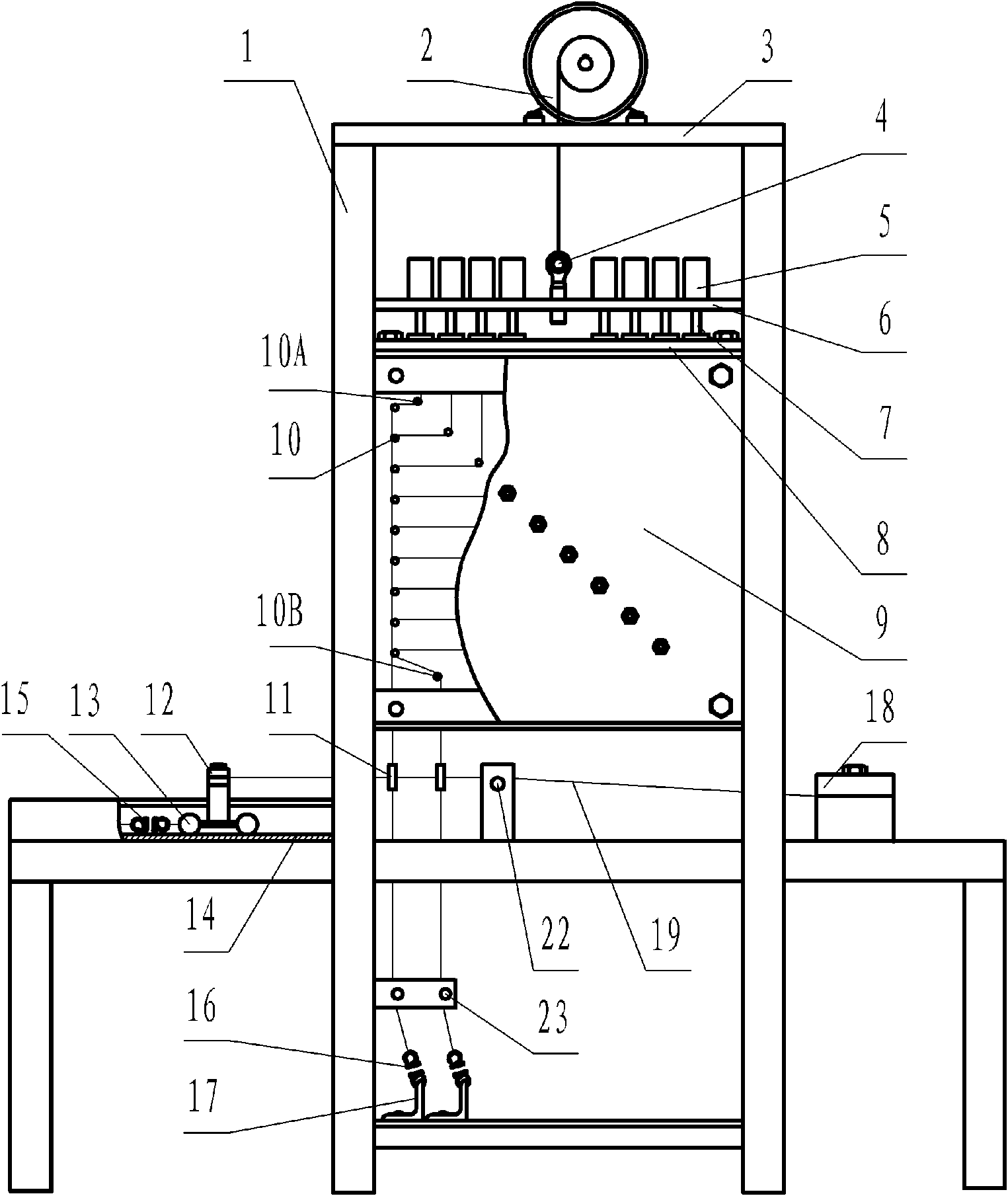

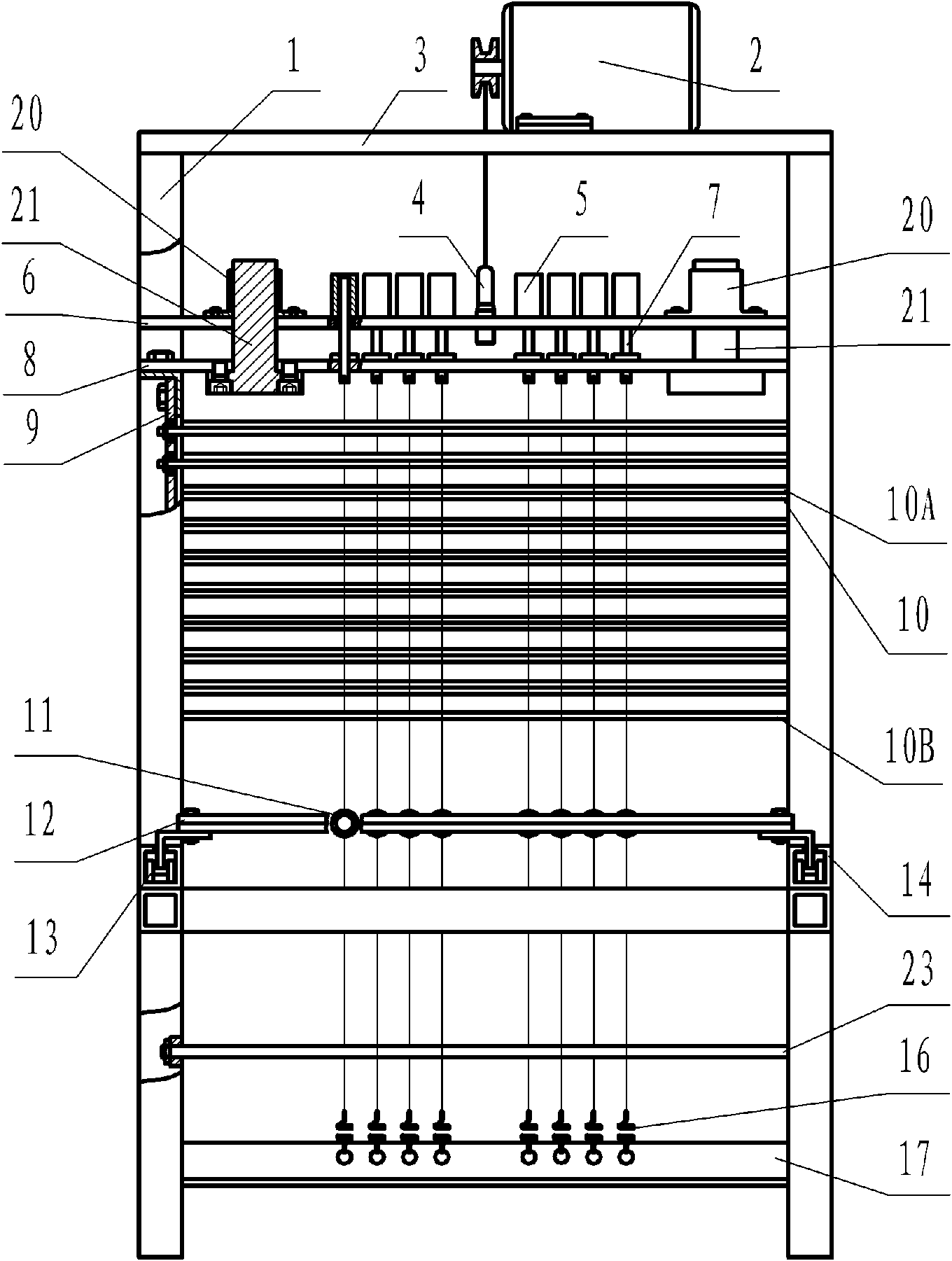

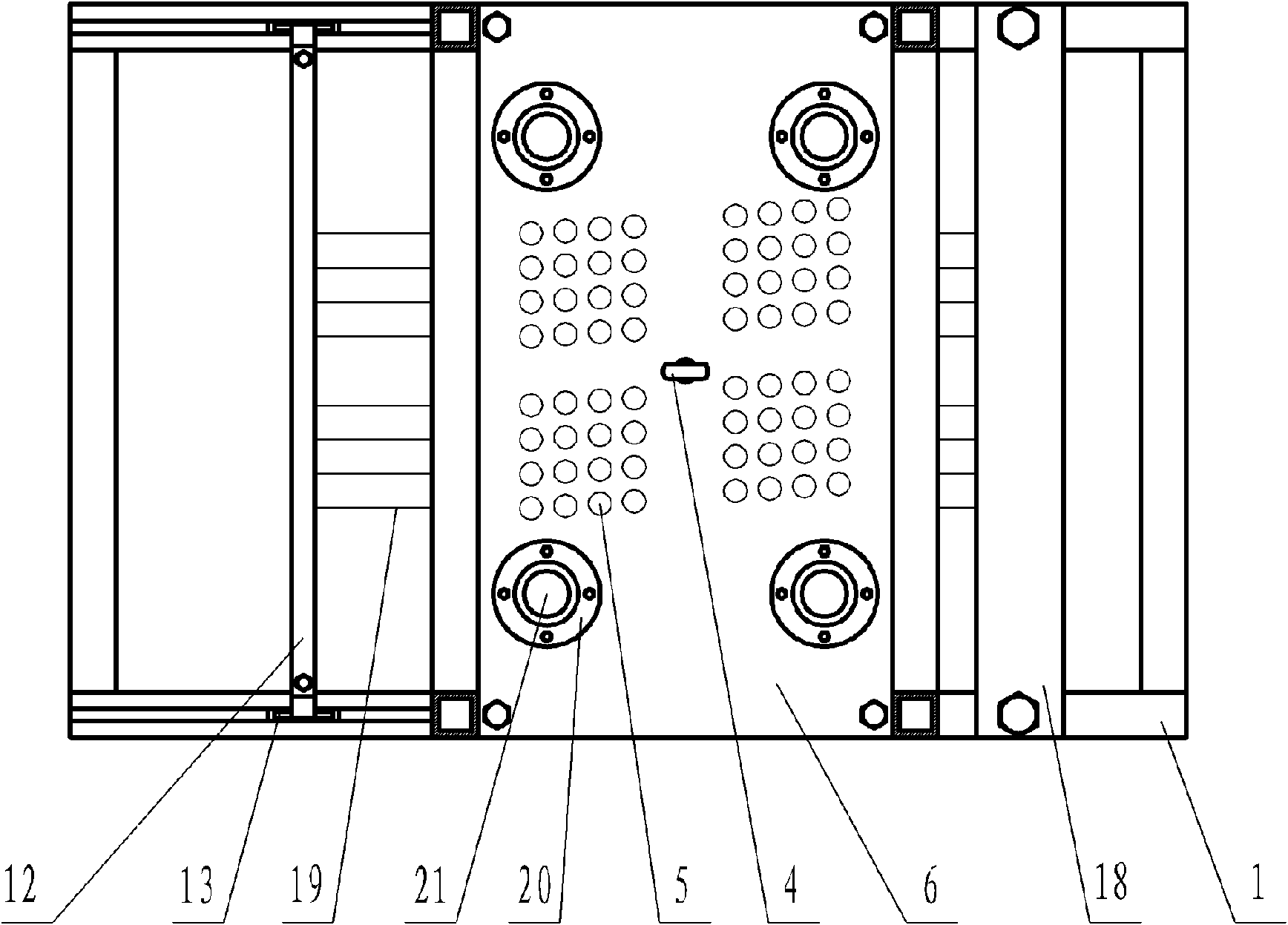

[0023] A specific embodiment of the present invention is an intelligent bamboo silk weaving machine, which includes a frame 1, a motor 2, a transmission device and a program control device. in:

[0024] figure 1 , figure 2 As shown, the motor 2 is installed on the upper cover plate 3 of the frame 1, the motor 2 is connected to the electromagnet mounting plate 6 under the transmission device 4, and the vertical linear bearing 20 on the electromagnet mounting plate 6 fits On the vertical shaft 21 on the slide bar mounting plate 8, the slide bar mounting plate 8 is located directly below the electromagnet mounting plate 6 and is fixed on the frame 1. On the electromagnet mounting plate 6, a plurality of inner cavities are also installed. Electromagnet 5, electromagnet slide bar 7 is worn in the slide bar hole on the slide bar mounting plate 8, and the top of electromagnet slide bar 7 is inserted in the inner cavity of electromagnet 5, and the middle and lower part of electroma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com