Cleaning device, cleaning machine, special garbage can and working method

A technology of cleaning device and cleaning machine, applied in the direction of cleaning machinery, cleaning equipment, applications, etc., can solve the problems of no cleaning machine, cleaning machine stuck, large machine volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

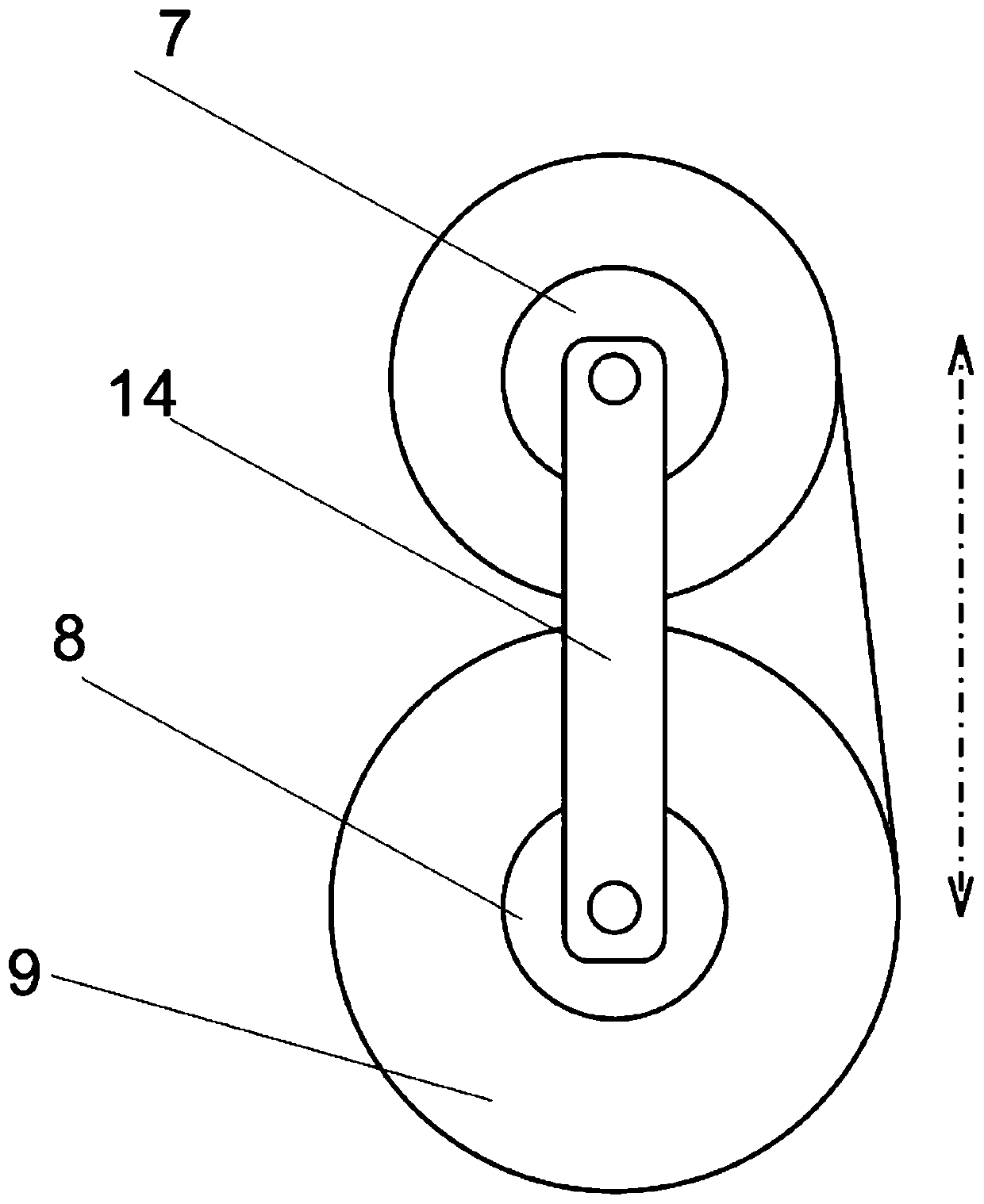

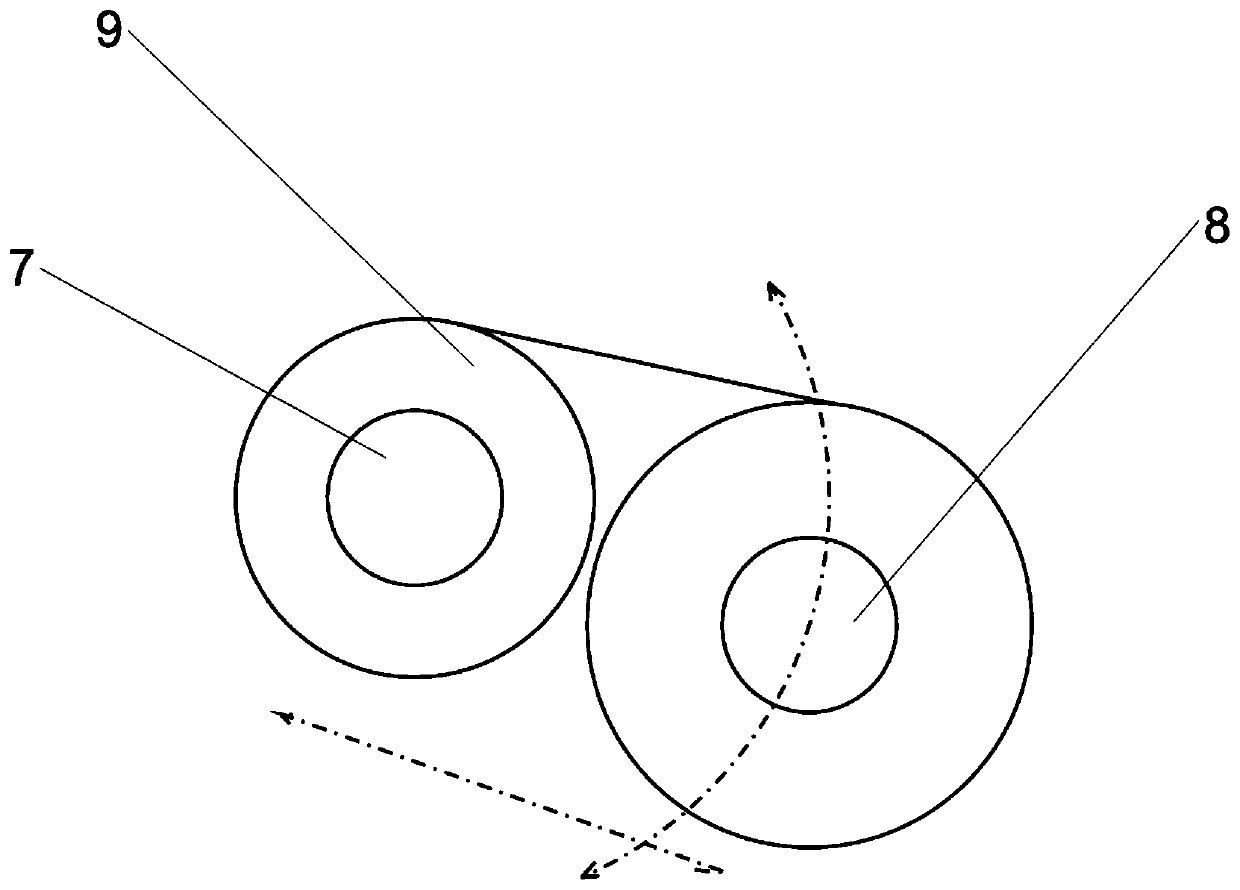

[0034] refer to Figure 1-11 : cleaning machine of the present invention, comprises casing, walking device, control device and mopping device, and mopping device comprises at least two reels, is wound on the mop strip 9 between the reels, and mop strip 9 two ends are respectively connected on two on the scroll.

[0035] Examples of Cleaning Devices: Reference figure 1 , the reel is movable and installed, specifically: the reel can move radially. Specifically: the reel can move vertically, horizontally, obliquely, horizontally, or around a circular arc relative to the casing 15 .

[0036] The sweeping device includes a sweeping roller brush and a garbage box.

[0037] The special dustbin for the cleaning machine includes a dustbin and a mop cleaning device.

[0038] The reel is enclosed in the casing; the reel is a bar-shaped round shaft.

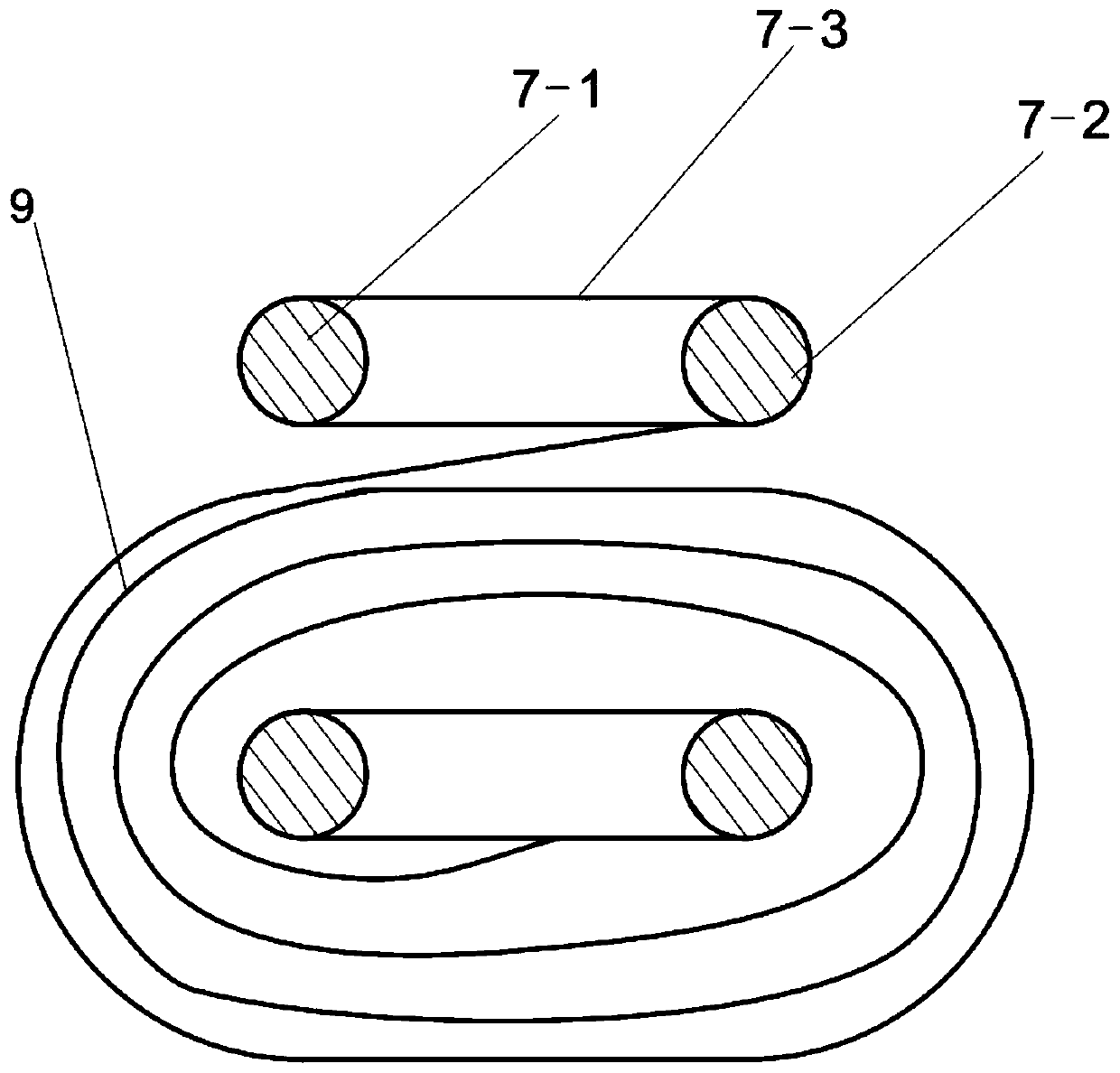

[0039] The second embodiment of the structure of the cleaning device. refer to figure 2 , the reel is composed of more than one rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com