Bonding device

A crystal bonding device and center-of-gravity position technology, which is applied in the manufacture of electrical components, electric solid devices, semiconductor/solid-state devices, etc., can solve problems such as center of gravity offset between platforms and reaction components, poor balance of pedestal weight, and increased space in the driving direction. , to reduce deflection, improve weight balance, and prevent shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

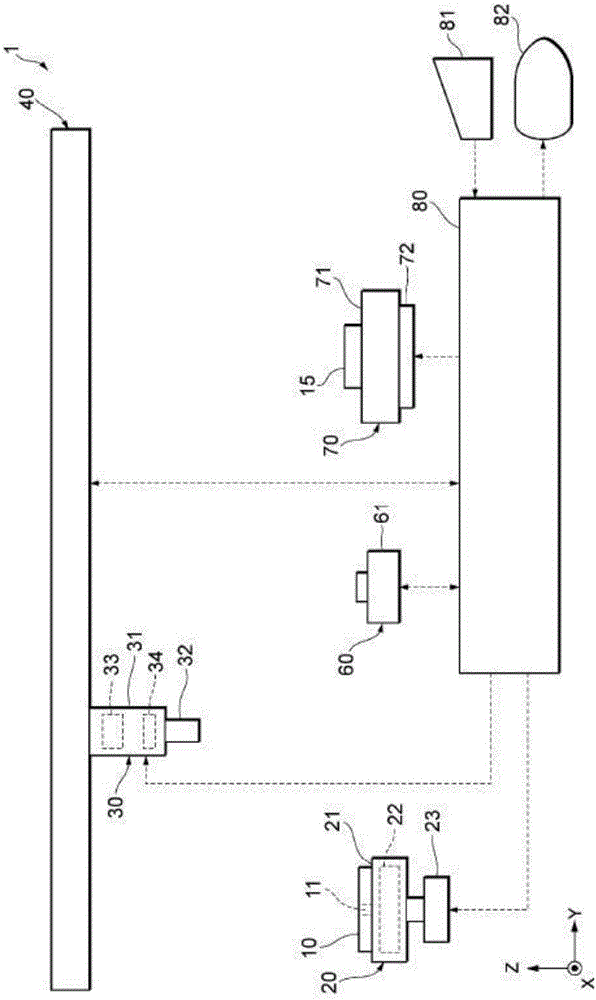

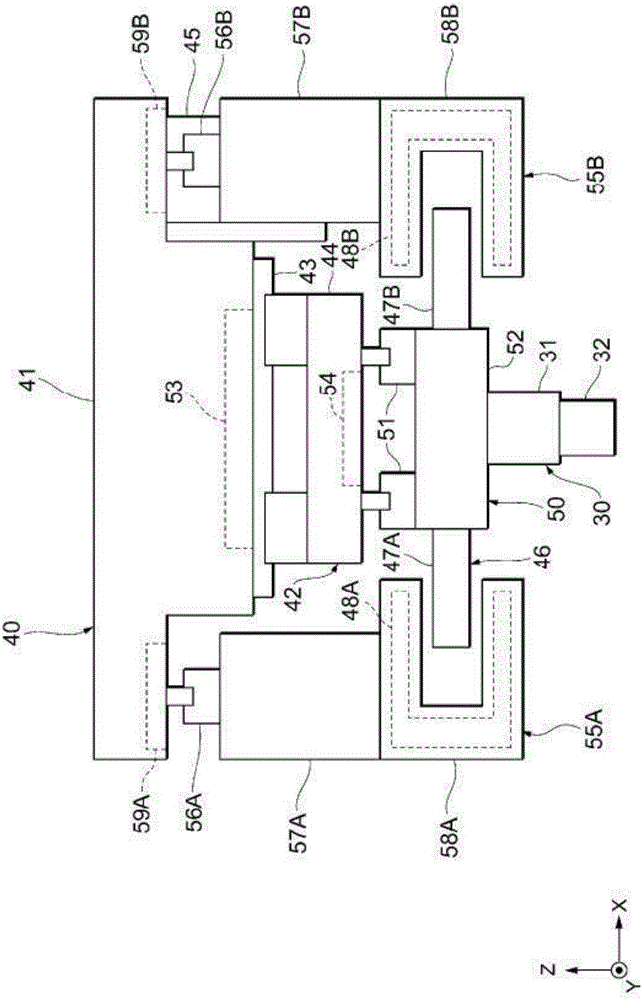

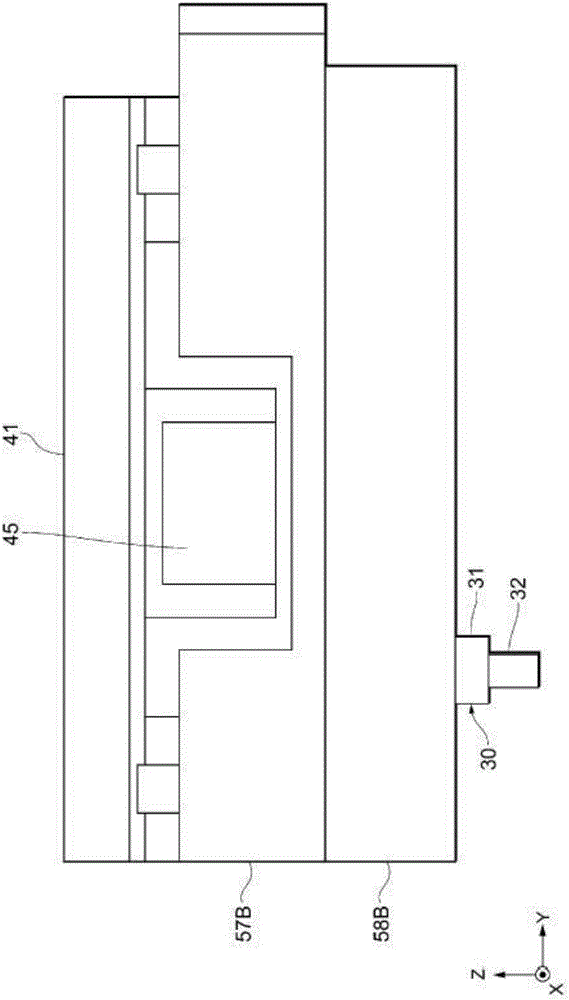

[0030] Embodiments of the present invention will be described below. In the following description of the drawings, the same or similar parts are denoted by the same or similar symbols. However, the drawings are schematic drawings. Therefore, specific dimensions and the like should be determined in consideration of the following description. Furthermore, of course, there are also parts where the relationship or ratio of mutual dimensions differs among the drawings. Furthermore, the technical scope of the invention of the present application should not be limited to the above-described embodiments and should not be interpreted. In addition, in the following description, the upper side of the drawings is referred to as "upper", the lower side is referred to as "lower", the left side is referred to as "left", and the right side is referred to as "right". The direction along and parallel to the X-axis shown in the figure is called the X-axis direction, the direction along the Y-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com