Electric continuous zooming mechanism with high-stability image surface

A zoom mechanism, high stability technology, applied in the direction of installation, optics, instruments, etc., can solve the problems of poor image quality, processing precision limit design software, poor image plane stability, etc., to improve imaging quality, novel structure, and improve precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

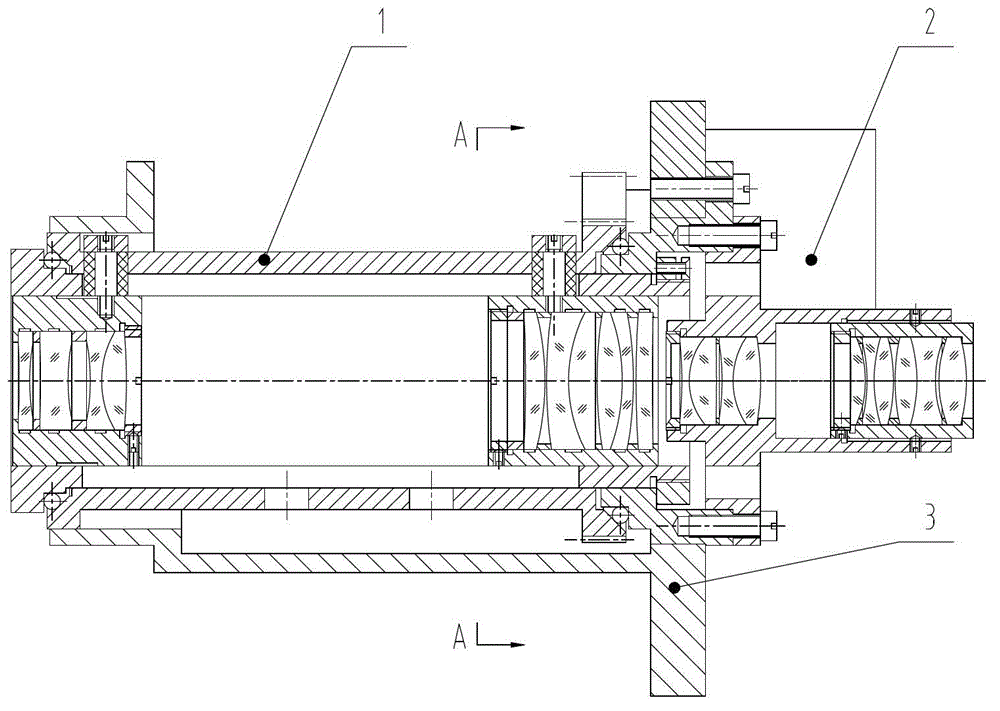

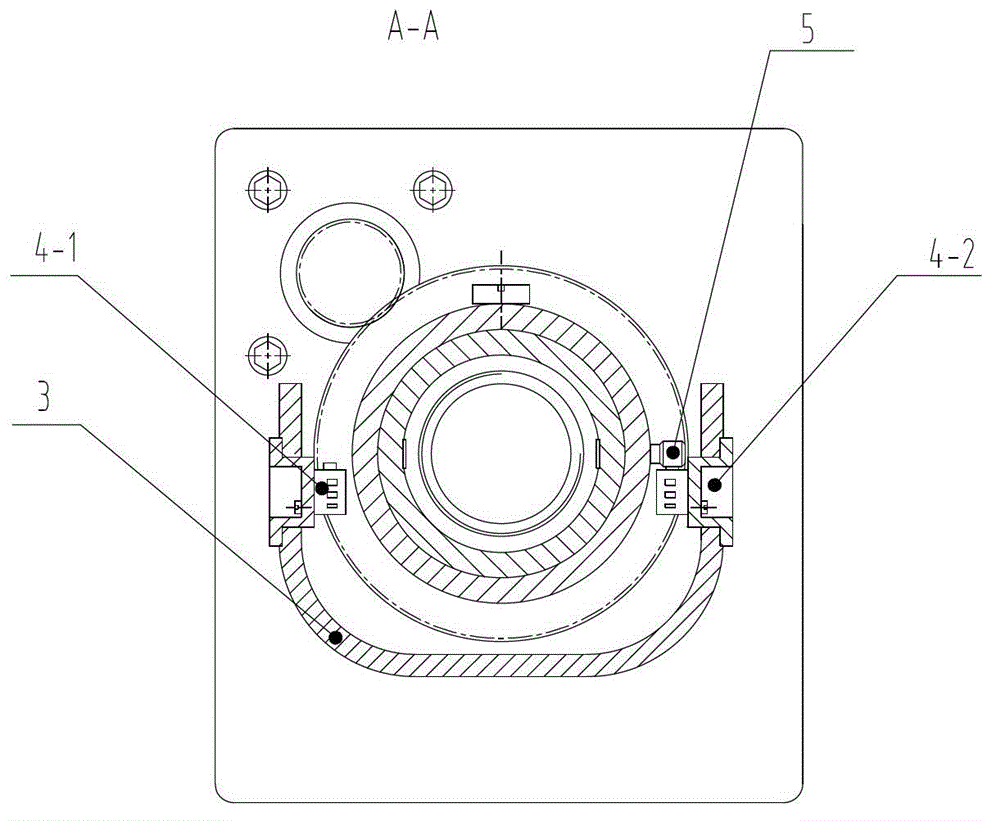

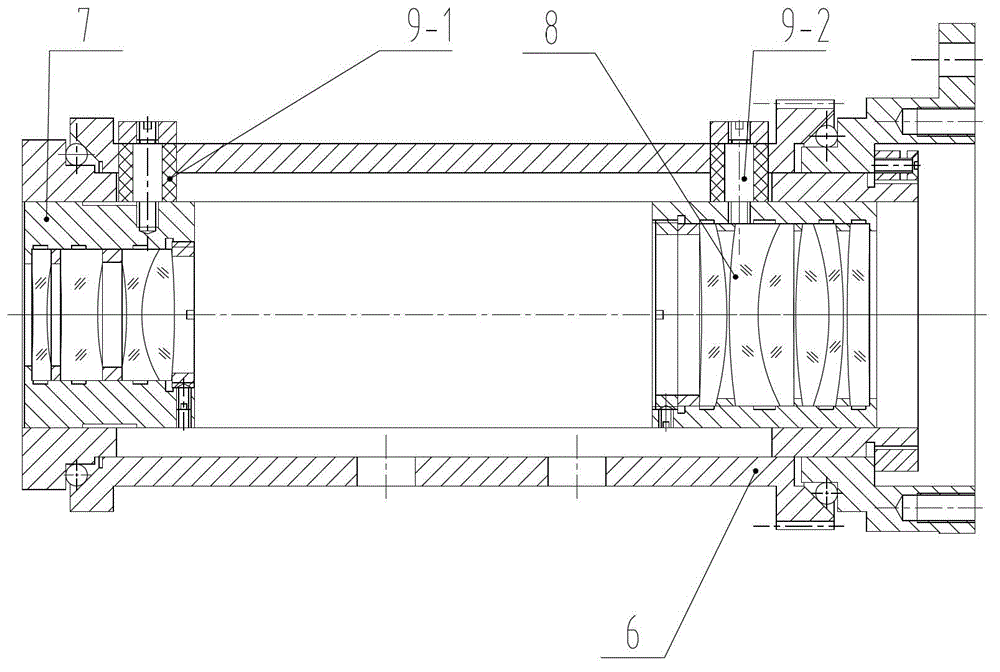

[0024]Referring to Fig. 1 embodiment, zoom lens group 1, motor group 2, the first limit switch 4-1, the second limit switch 4-2 are respectively fixed on the casing 3, outside the zoom in zoom lens group 1 A threaded hole is set in the middle of the barrel on the barrel 14, and a contact 5 capable of contacting the first limit switch 4-1 and the second limit switch 4-2 is set in the threaded hole, and the first limit switch 4-1 It is set at one end of the casing 3, and the second limit switch 4-2 is set at the other end of the casing 3, and the installation positions of the first limit switch 4-1 and the second limit switch 4-2 are relative to the zoom outer cylinder 14 shaft symmetry. The zoom outer cylinder 14 is sleeved on the zoom inner cylinder 13, the zoom inner cylinder 13 is fixed on the casing 3 through the bearing seat 15, the opening pressure ring 16 compresses the axial direction of the zoom inner cylinder 13 on the bearing seat 15, and passes through The key 17 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com